Layer Heights

Hi

Apart from using the variable layer height in Prusa Slicer, is there a way to control the vertical resolution to obtain the exact vertical dimension? For example if I need a thickness of 2mm while using a 0.4mm layer height with first layer at 0.2mm I end up with a component 2.2mm thick.

Thanks

layer height

I think layer height is the only way.

Hi

Apart from using the variable layer height in Prusa Slicer, is there a way to control the vertical resolution to obtain the exact vertical dimension? For example if I need a thickness of 2mm while using a 0.4mm layer height with first layer at 0.2mm I end up with a component 2.2mm thick.

Thanks

--------------------

Chuck H

3D Printer Review Blog

you could also use a height range modifier to change the layer height used in its range to a smaller layer thickness, one that will give you a precise multiple of the height you need.

Its usually easier though to just use the Variable Layer Height tool to just make a few thinner which does the same thing.

Layer Heights

Thanks for the reply Neophyl

What is a height range modifier?

It frustrates me that this appears to be a failing of the slicer software. I am pretty sure that this could be done with the addition of some modified coding. Come on Joseph sort this out.

Come on Joseph sort this out.

He did, it's called the Variable Layer Height tool, it must be enabled in Printer Settings.

Use that, or calculate your layer heights for an integer result, or use a bit of sandpaper.

Cheerio,

RE: Read the article

Hi

Obviously you have not read the article fully. If you have no positive input, please , I respectfully ask you to be silent.

What is a height range modifier?

It frustrates me that this appears to be a failing of the slicer software. I am pretty sure that this could be done with the addition of some modified coding. Come on Joseph sort this out.

A height range modifier allows you to change the printing parameters within that range. You should really read the manual and knowledge base articles on Prusa Slicer to get the basics down as its obvious you have not. The section in specific for modifiers is located here https://help.prusa3d.com/en/article/modifiers_1767 One of the parameters you can change is printed layer height.

For your stated example of a 2mm high model and a normal 0.4mm layer height you can define the height range modifier to cover 1.8-2mm and then set the layer height in that range to be 0.2. That would give you 0.2 (first layer)+0.4+0.4+0.4+0.4+0.2, which my math says is 2mm. Its just quicker/easier to do with the variable layer height tool though.

Digitization is lossy

[...] It frustrates me that this appears to be a failing of the slicer software. I am pretty sure that this could be done with the addition of some modified coding. Come on Joseph sort this out.

Keep in mind that we are still in the relatively early days of 3D printing, and Prusa has done a lot to build PrusaSlicer on the basics of Slic3r. In this case, you've specified parameters to use, including layer heights. The slicer is essentially digitizing a physical object (the STL) in the same way a digital camera digitizes an image of a physical object. You set a resolution and the software does the best it can with the parameters you set. If you set a finer resolution (layer height) the resulting digitized result is more accurate. Instead of CPU and disk space, we pay for that accuracy with longer print times.

If PrusaSlicer were to automatically "fix" this problem by inserting one different layer, there are valid objections that the software is ignoring the settings that you specifically specified.

Variable layer heights (VLH) are the compromise. You can tell the software to approximate layer heights to more accurately model the original object (STL). Variable layer heights can both increase layer heights where less resolution is needed (e.g., stacked vertical walls) and decrease them where more is needed (e.g., curved surfaces).

Keep in mind, VLH are still NOT guaranteed to exactly match your object's exact dimensions. It's much the same challenge architects face when designing buildings to be built with blocks or other prefab materials. Vary from using even multiples of components and you're looking at expensive and tedious custom work. VLH will get close (or closer), but again only within the parameters you set.

The ideal fix is to model your physical object to be 3D printed. If precision within 0.2mm is required, if possible, model heights that are even multiples of typical (e.g., 0.2mm) heights. The same goes for extrusion widths. (FYI - Cura is working on the extrusion width issue with their Arachne engine.)

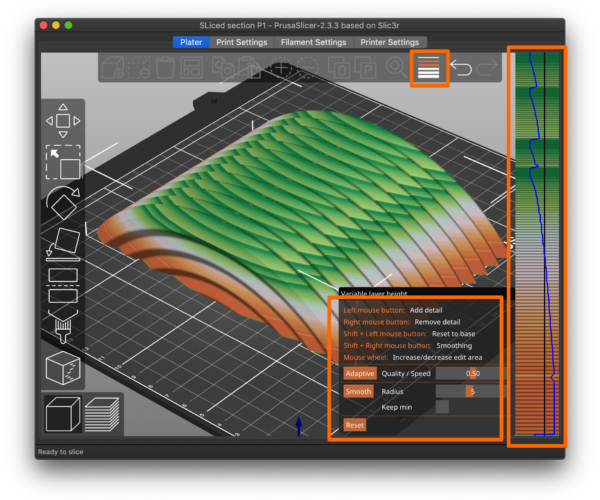

Definitely check out variable layer heights. Here's a shot showing the interface:

Select your part, click on the "hamburger" stacked lines button at the top, and then you can use the parameters in the box to control resolution and smoothing between transitions. The results are in the colored box at the right. You can manually override heights using the mouse as described in the settings box. It's a little clunky, but easy to use once you get the hang of it.

You can turn on VLH and use the mouse to manually select lower (and more accurate) layer heights near the top without affecting the rest of your print if you prefer.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…