RE: Z axis trouble but only when printing

During the installation of the camera, I took the opportunity to disassemble the main cable and inspect it thoroughly. Nothing suspicious was noticed. I made sure to followed all the steps meticulously. Everything has been reassembled now, and just this morning, I performed three tests without encountering the problem again.

I'll be crossing my fingers that it doesn't return, but more importantly - I no longer need to frequently change the G-Code whenever Prusa modifies its configuration in Prusaslicer.

RE: Z axis trouble but only when printing

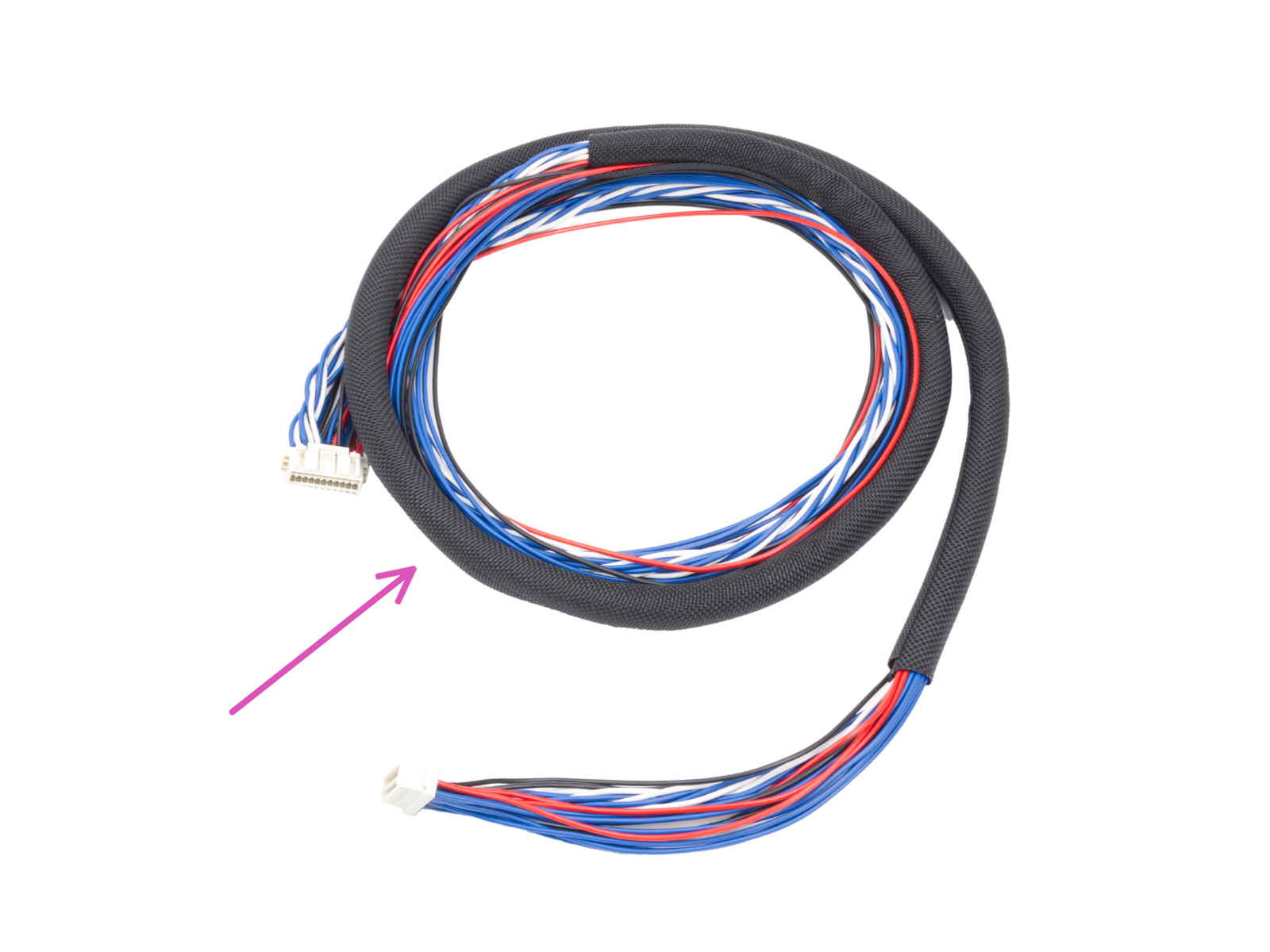

main cable

Do you mean the "Main FE cable" from the assembly manual?

Great to hear that your print was successful!

RE: Z axis trouble but only when printing

RE: Z axis trouble but only when printing

Oh man.. thanks, my brain was already sleeping, sorry.

RE: Z axis trouble but only when printing

So after much experimentation, I've determined that the back right of my Core One upgrade is not usable if it has to be probed. The printer will not pass a probe sequence if it has to probe the back right corner. If I place a small print in the center where the back right doesn't have to be probed, the print will succeed. If for any reason the printer has to probe the back right, MBL fails and the print won't start.

RE: Z axis trouble but only when printing

Just to be sure: back right = NOT where the print bed cables are?

If yes: probably the filament sensor/cable/ptfe tube being in the way of the Y-bearing-bracket.

If no: probably the print fan duct hitting the print bed cable cover.

RE: Z axis trouble but only when printing

There is no contact with the gantry arm, print head cable, or print bed cable at any point in the range of motion.

New Development

Stacking two buildplates allowed the 49 point probing sequence to complete without error. If i remove one of the build plates, the probing fails each and everytime int he back right corner. Can we get some data from others on this? Generate a print file that fails consistently, stack two build plates and run the file again and let us know if the probing completes.

RE: Z axis trouble but only when printing

Update: Lowering the nozzle ~1mm using the thumb screws also allows the probing sequence to complete without issue.

RE: Z axis trouble but only when printing

@discojon, this sounds very much like the "heatbed cable cover touches the Nextruder fan shroud" issue. I understood you to say in the other thread that there is no contact -- but could you please double-check? Nextruder in the back/left position.

RE: Z axis trouble but only when printing

Just to add to this: the "nozzle loadcell" is basically the whole nextruder frame, so if you apply pressure anywhere on the print head, it'll think the nozzle has hit something.

So if stacking print sheets helps, there's definitely "something hitting something" going on with just one sheet.

RE: Z axis trouble but only when printing

Can you show me a photo of what exactly you are referring to? I don't see any contact anywhere but I may be missing it.

RE: Z axis trouble but only when printing

I build a Prusa Core kit and I have a problem with the Z axis: ther is a high difference bettween the front and the réarmement Z axis : 3 mm. So when I want to Print, the wipping Print!ng head is ok but when the calibration plate begin, the error message appear and the printing cycle stop : impossible to levelling. Today, Ihave no solution. Is it possible to help me? Thank you and best regards.

RE: Z axis trouble but only when printing

I build a Prusa Core kit and I have a problem with the Z axis: ther is a high difference bettween the front and the réarmement Z axis : 3 mm. So when I want to Print, the wipping Print!ng head is ok but when the calibration plate begin, the error message appear and the printing cycle stop : impossible to levelling. Today, Ihave no solution. Is it possible to help me? Thank you and best regards.

Vertical calibration is first achieved by the printer lowering the bed to the very bottom and continuing - so that the motors skip - in an attempt to ensure all 3 are at the very bottom. Then the bed is lifted in sync (all 3 motors are driven in unison) until it senses it touching the nozzle.

If, for whatever reason, the bed bottoming out isn't level, you will have a tilted bed - always - and bed probing will accommodate and adjust the height during printing so that it appears level in relation to the nozzle at all times.

You need to determine why the bottoming out process results in a tilted bed. Check that all the motor mount screws are tight to the bottom plate as it is these that the bed mount bottom out on to.

As you are out by 3mm I would lower the bed to the bottom, turn off the motors, and then manually turn the threaded rods to ensure that all 3 are at the very bottom. Then do the z axis calibration from scratch. It could be that you are so out that not all the motors bottom out (although unlikely).

Then raise the bed so that is is close to the nozzle and, again with motors turned off, manually move the gantry around and eyeball the nozzle distance from the bed. If you do see a difference you have something misaligned somewhere.

Finally, loosen your nozzle thumb screws, push the nozzle fully up, lower it 1mm and tighten the thumb screws.

RE: Z axis trouble but only when printing

Perfect solution! Without this custom g-code: homing errors till crash message. With it: quick start and solid print! MK4s to Core One Kit in my case.

Thanks for sharing. I hope Prusa delivers quick a new firmware…

RE: Z axis trouble but only when printing

Same issue , the code solved it. 👍

RE:

Like many here. I have been working through problems with my pre-built Core ONE and it still doesn't work reliably as I have come to expect from a a Prusa product.

The first thing I discovered is that my X and Y stepper pulleys were not screwed on properly (neither pulley had a grub screw aligned with the flat part of the stepper motor shaft.) Fixing that made the x/y homing process much more reliable (though it still does fail -- I think we're calling this "corner humping"?).

I started looking for forum posts about Z-axis issues today and found this thread. Inserting the two "ADDED BY ME" lines proposed in this thread solved my z-axis problems, at least for one print. So I am another user experiencing the problem where the nozzle heater appears to interfere with the operation of the load cell.

RE: Z axis trouble but only when printing

The gcode fixed the issue for me also and I did find a spot on the cable that looks sus. Support is sending a new cable and ill test continuity when I receive the new one huge thanks to the guy that posted the gcode im greatful to be able to print while waiting for the permanent fix

RE: Z axis trouble but only when printing

I completed the MK4S to CORE ONE conversion with 6.3.3 firmware and had a few successful prints with PETG. I switched to TPU and then got into a homing crash loop with the build plate nowhere near the nozzle. What I did notice was there was a slight play which I corrected by slightly loosening that side by like a 1/4 turn. Afterwards, the homing issue went away (for now). Have no idea if this was the "fix" I needed. Will wait and see.

RE: Z axis trouble but only when printing

Yup, it was only a fluke. Adding the gcode patch worked for me. Starting to make sense that it's a grounding problem which was perhaps solved (mechanically) when support shipped out new love board main cables and (for some) the problem went away.

RE: Z axis trouble but only when printing

I also have the same problem as you. Have you solved the problem?

I build a Prusa Core kit and I have a problem with the Z axis: ther is a high difference bettween the front and the réarmement Z axis : 3 mm. So when I want to Print, the wipping Print!ng head is ok but when the calibration plate begin, the error message appear and the printing cycle stop : impossible to levelling. Today, Ihave no solution. Is it possible to help me? Thank you and best regards.