Temperature in the enclosure

Hi,

I have a Prusa MK3S+ and for my printing I mainly use PETG and ASA, time to time PC Blend (only small object).

With theses filaments, the temp of the hotend and heatbed are pretty high. I guess the ambiant temp in the enclosure is probably pretty high too.

So my questions are:

- What is the ambiante temperature inside the enclosure during long printing?

- Is there any impact on the printed parts of the printer itself ?

Thanks in advance.

Regards

RE: Temperature in the enclosure

1) I guess that would depend on the ambient temperature in the room.

2) Maybe!

RE: Temperature in the enclosure

Hello, after reading your post, I think you have experience with printing in ASA and PC blend. I'll tell you that I recently bought the enclosure for the mk3s plus printer and I would like to know if you need to make any changes to the original printer such as nozzles and ptfl tube to print asa and pc blend???. What printing profile do you use with pc blend for small prints and what steel sheet do you use on the bed? Thank you very much for your attention.

Hi,

I have a Prusa MK3S+ and for my printing I mainly use PETG and ASA, time to time PC Blend (only small object).

With theses filaments, the temp of the hotend and heatbed are pretty high. I guess the ambiant temp in the enclosure is probably pretty high too.

So my questions are:

- What is the ambiante temperature inside the enclosure during long printing?

- Is there any impact on the printed parts of the printer itself ?

Thanks in advance.

Regards

RE: Temperature in the enclosure

Hi,

Anyway, about the setting and profile, I do it simple and Prusa solution is simple. I have :

- an original prusa machine, nozzzle 0.4mm, no modifications.

- original Prusaslicer with default settings

- Original filaments from Prusa (Prusament type).

So I am using the default setting of prusaslicer. For ASA and PCBlend, I activate the Draft shield option. I tried with smooth and textured sheet (with glue).

For small parts, usually, no problem or minor problem. For larger parts, problems are coming.

I hope with an enclosure, larger parts wll be easier.

Note : For the company I am working for, I've already ordered the originale prusa enclosure and I am waiting for the shipping. But the shipping is little bit delayed and because I will take a new job in another company, I will never have the chance to try it. 😖

RE:

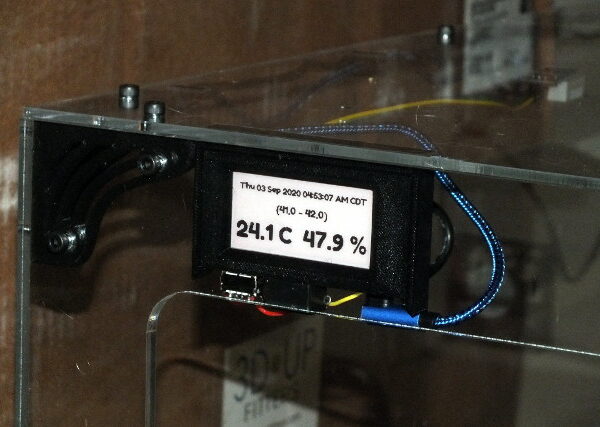

When I added the enclosure to the printer a couple of years ago (3d Upfitters), I tried searching for the best enclosure temperatures for various filaments.

The numbers that appeared out there on the Interwebs varied quite a bit, but seemed to be in the range of low 30s (C) for PLA and 50-60-ish (C) for ABS.

My idea was to use a simple monitor and controller (Raspberry Pi Zero) to switch the fan on and off to maintain a consistent temperature, using the heat from the printer to warm the enclosure, and the fan (supplied with the enclosure, intended to run continuously) to cool it.

I had a temperature/humidity sensor in the junk box, so that's what I used, so I ended up with a display of both temperature and humidity in the enclosure.

My initial tests (set up on the spare bedroom floor) first using a heat gun and then with the printer sitting in it set to preheat, showed that yes, it would heat the enclosure to around 30C (for PLA) and although it takes a while, the fan would turn on, and yes, the fan would cycle off and on to hold the temperature in the 30-31 range.

I found, however, that in the real world, when doing a run of prints, the amount of control using the printer as the heater and the fan to pull in cooler room air, was not enough to hold things at the desired temperature nearly as closely as I wanted.

I found that during a run of PLA prints, the enclosure would indeed heat to around 30C (I settled on control points of 29C and 30C) but after printing for a while it was obvious that the fan was not powerful enough to draw in enough cooler room air to get the temperature down to that 29C off control point. For a room temperature in the mid 20s (C) the temperature in the enclosure settled in the low to mid 30s.

For ABS prints I settled on control points of 40C and 41C, far below the so-called recommended 50-60-ish range, but quite a bit warmer than room temperature.

I always preheat the machine 15 minutes or so and let it stabilize when doing an ABS print. I found that this (preheating and stabilizing) is one of the key details for producing good and consistent ABS prints on the I3.

I found, however, that after a preheat session at ABS temperature for 15-20 minutes, the enclosure temperature would only get to the mid-high 30s, and would approach 40C only after an hour or so of ABS printing, still far below what appeared to be recommended.

It became obvious that in order to get a true temperature-controlled enclosure, I would need to both increase the airflow for cooldown, using a more powerful fan, plus add some kind of an additional heat source (I thought of maybe a low speed hair dryer into the front of the enclosure) to get the enclosure up to where I wanted for ABS prints.

The obvious issue with both (larger fan and forced warm air) is that they would both increase the degree of turbulent airflow within the enclosure, something that is not wanted.

The bottom line is that yes, the enclosure itself was effective in producing more consistent quality ABS prints so I left things alone, settling for temperatures in the low to mid 30s for PLA prints, mid to high 30s for ABS prints, and in between for PETg prints.

RE: Temperature in the enclosure

Thanks for all those information.

Regards

RE: Temperature in the enclosure

I built an insulated enclosure for my MK3 many years ago. The inside is lined with drywall, 1-inch foam insulation, then wood on the exterior. The temp gets up to 55c inside on longer prints. I had to reprint all of the printer parts in PC blend except for the electronics box because they started to droop.

I also purchased a pre-fab enclosure from Printed Solid. It is not insulated but there is only one clear panel and the rest is metal coated plastic. In that one, the temp gets to around 45c at the max. But I am starting to see drooping on the factory PETG parts especially the heat bed wiring cover and some other parts near the bed.

I know the manual says to not exceed the enclosure temp of 42c but that seems very low and I wonder if they will now recommend certain parts be printed in ASA or PC blend or even the new polyamide filament. I'm in the US and will not be installing the fire suppression unit, but I also wonder at which temperature that device is activated - maybe their 42c rule has some bearing on the fire suppression.

RE: Temperature in the enclosure

It's my impression that the big thing about an enclosure is more about the isolation from turbulent (or even laminar) flow of room air and holding the temperature somewhat consistent, than maintaining a particular value of temperature.

RE: Temperature in the enclosure

thank you very much for your information