RE:

I get the UV issue but there has to be another cause for PLA brittlness. I never leave my filament in the printer after printing. It always goes back in a sealable bag with a drying agent then in the box it came in then into a cabinet. Maybe repeated stress on the filiment while printing temperature. I have only had one partial spool do this to me and it was stored correctly. When loading the filiment from that partial filament roll it was fine but after a hour or so there was a brittle section. It was down towards the bottom of the spool where the filament coils were the smallest.

I removed it and put it in the drier for a few hours and it was fine after that.

RE: Filament breaking in unused tools. Common?

if putting it in the dryer [1] solves the problem, this suggests more "tempering" than "moisture issue"; UV cannot be an issue inside the ptfe Bowden tubes as ptfe blocks UV almost 100%...

[1] my brain read dryer a lot as "clothes dryer" - imagine putting your filament in one of those 🙂

RE: Filament breaking in unused tools. Common?

Uh… no…

If a spool is breaking, cooking it in a low temp oven will not fully solve it. One theory I recall was if you cook it to just under its glass point it rearranges the molecule chain, but in practice it did not fully fix an entire spool. I know because I and my staff have tried over and over. If moisture was the problem then how come PVA,PVB, nylon and abs all of which suck way more moisture than pla doesn’t go brittle when left in daylight? Only pla behaves this way.

Moisture does affect it, but not the way uv does. Moisture muddles the glass point so that as the filament moves you’ll get uneven extrusion or uneven fusion. More impactful though is what moisture can do to the outer diameter of the filament making it go out of tolerance by expanding and clogging the thermal tube.

Best solutions for breaking pla is to always keep the spools in darkeness, sealed in an air tight bag with fresh desiccant. Or..

The real solution is to stop using pla! You may think pla is good material for real production of functional objects, but it’s not! It’s for toys, models, burn out molds, and things you won’t have to depend on. Cheerios.

RE:

Thank you for the explanations. After use, place the filament directly in a cool, dry and light-protected container. I prefer to use the original packaging (has always worked well). I always place nylon in a dehydrator for a few hours before printing so that I achieve a more homogeneous surface when printing.

(printing without drying)

(printing after drying filament)

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Filament breaking in unused tools. Common?

Having had a MMU2S on my MK3S and having a 5TXL I have never had this occur. I’ve had some Red and Blue Atomic PLA loaded waiting for me to start my big Starliner print so I’ll check it out tonight.

how come PVA,PVB, nylon and abs all of which suck way more moisture than pla doesn’t go brittle when left in daylight? Only pla behaves this way.

Moisture affects different polymers in different ways. PVA goes to mush, nylon strings to uselessness, ABS strings and stinks. Use a dryer, ovens are a poor substitute.

Best solutions for breaking pla is to always keep the spools in darkeness, sealed in an air tight bag with fresh desiccant.

... and dry it every time. Agreed.

The real solution is to stop using pla!

PLA is just another polymer with it's own characteristics; used accordingly is is perfectly serviceable. I don't print toys or models, some moulds, yes, but some of my prints include safety critical marine parts and PLA remains an option when stiffness is the main criterion and the part can be properly maintained.

Cheerio,

RE: Filament breaking in unused tools. Common?

I’ve had it snap during print on a freshly opened overture pla. I bought it like a year ago but just recently opened to do some test prints. It definitely seems like xl isn’t forgiving to brittle pla. I’ve had a few issues now where it stops extruding both pla and tpu. I think heat creep in enclosure with door closed for the pla. Still diagnosing tpu issue. I’ve had two tpu prints quit extruding over 50 percent in. I might need to up temp a few deg for the tpu issue. The snapping filament is annoying but I’m going to retry after some drying

RE: Filament breaking in unused tools. Common?

PLA is just another polymer with it's own characteristics; used accordingly is is perfectly serviceable. I don't print toys or models, some moulds, yes, but some of my prints include safety critical marine parts and PLA remains an option when stiffness is the main criterion and the part can be properly maintained.

You argue that moisture is responsible for pla brittleness, yet you also say that you use it for “critical marine parts”.

Really?

cheerios to you.

RE:

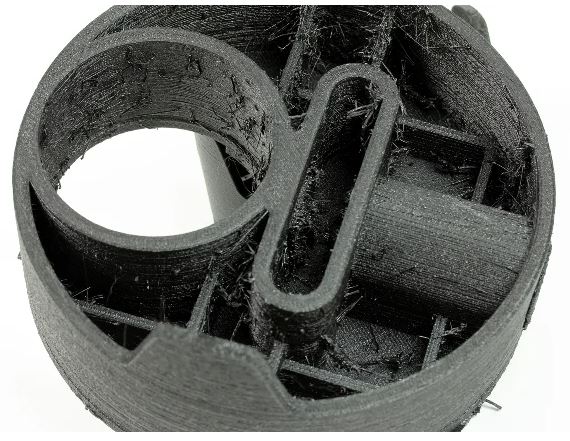

Interesting... This just happened to me. Yesterday I ran several multicolor prints (PLA x 5). This morning I start up and the filament in one PTFE has broken into about 20 pieces. I couldn't figure out a way to remove the shattered filament from the PTFE (pushing with a spare piece of filament didn't work.) I had to replace the PTFE (luckily I have a supply on hand). It was the oldest spool of those mounted on the XL but stored in the same space as my others (humidity kept below 30%).

RE: Filament breaking in unused tools. Common?

That's exactly what happened to mine. I'm sure the tension that the S curve the filament is in when parked is part of the reason. To remove the broken bits I had to remove the PTFE from the tool and filament sensor, unclip from the carriers and then with the PTFE as straight as possible use some other filament to slow push the broken bits out. That worked thankfully.

Interesting... This just happened to me. Yesterday I ran several multicolor prints (PLA x 5). This morning I start up and the filament in one PTFE has broken into about 20 pieces. I couldn't figure out a way to remove the shattered filament from the PTFE (pushing with a spare piece of filament didn't work.) I had to replace the PTFE (luckily I have a supply on hand). It was the oldest spool of those mounted on the XL but stored in the same space as my others (humidity kept below 30%).

RE: Filament breaking in unused tools. Common?

moisture is responsible for pla brittleness, yet you also say that you use it for “critical marine parts”.

Yes, safety critical, I also said: "and the part can be properly maintained."

Sailors have always known that it's paint that keeps boats afloat and grease that keeps machinery running.

I generally advise a three year maximum use span but used parts have remained strong.

I also use PLA for prototyping (repacement) parts before reprinting in more suitable materials: since I enquired after one prototype never returned from testing and I discovered it had done a couple of thousand sea miles local engineers have become used to prototypes marked like this:

Cheerio,

RE: Filament breaking in unused tools. Common?

I sure hope these are not for the US Navy!

So now you’re saying you use pla for test parts and some other material for the working part. As I recall you argued with me that PLA was better than PETG for in situ material.

Looking back at your previous posts I don’t see anything that indicates that you actually have an XL let alone a multiple tool XL. How about a picture of your XL?

RE: Filament breaking in unused tools. Common?

In another forum there were discussions on why pla goes brittle and one of the participants was a Chemical Eng. I recall him posting that he felt that the basic PLA formulation had similarities to uncurred resin. He had guessed that uv light interacted with the material causing the brittleness.

For our podcast we actually tested it, putting a coil in sunlight, a coil in a pail of water and another coil in the dark. Only the coil in sunlight got brittle. Moisture does impact pla as well, but moisture is not the cause of the brittleness. BTW the coil that was in water for a day printed fine.

For all of my machines I add a line of gcode at the end which retracts the material out of the extruder. This makes it real easy to always remove the spool and stash it after printing.

I sure hope these are not for the US Navy!

They make their own.

I recall you argued with me that PLA was better than PETG for in situ material.

Don't deliberaely misinterpret: Yes, for some things PLA is much better - even for underwater parts, but not for all - it's surprisingly effective in acoustic transponders for example but terrible in travelling rigging; horses for courses.

And I'm not playing the 'My XL is cuter than your XL' game.

Cheerio,

RE: Filament breaking in unused tools. Common?

Frankly Diem, I don’t believe you actually have an XL and your posts are very trollish.

cheerio

RE: Filament breaking in unused tools. Common?

Yeah quoting my own post, but I pulled my Red and Blue Atomic PLA that had been sitting in position 4 & 5 for a couple of weeks. No sign of brittleness or breakage.

Having had a MMU2S on my MK3S and having a 5TXL I have never had this occur. I’ve had some Red and Blue Atomic PLA loaded waiting for me to start my big Starliner print so I’ll check it out tonight.

RE: Filament breaking in unused tools. Common?

be not afraid

RE: Filament breaking in unused tools. Common?

I've been having a hell of a time with ESUN filament in the XL.

the filament kept snapping off inside the tubes and tricking the filament sensor into thinking it was still loading.

esun seems to be VERY brittle and the movements of the XL snap it easy. I took out my Hatchbox PLA and it has not been brittle or snapping off in the XL.

some filaments seem to be brittle by nature.

i reordered new hatchbox PLA to continue my projects.

Esun Brown PLA is the worst offender, no matter how dry it snaps.

“One does not simply use a picture as signature on Prusa forumsâ€

RE:

if one googles "does ptfe block uv", the first result is: "PTFE has particularly good UV resistance because of its very strong carbon- fluorine (C-F) bond [almost 30% higher than the carbon-hydrogen (C-H) bond], which is the common side bond that surrounds the carbon (C-C) backbone in a helix and protects it."

so I'm going to say that the PLA inside the Bowden tube is MORE protected than just by sitting in the dark corner 😉

summayr: lol 🙂

You're misreading that. Having good UV resistance means the material does not break down due to photochemical reactions caused by UV. It does *not* mean that the material perfectly *blocks* UV from passing through. So you are making a false assumption in your logic.

It is true that Teflon/PTFE, like many materials, reflects a lot of incident UV light, but it still allows a significant portion through. One study I found showed a 10% transmission rate at a constant thickness of 2mm, which is way thicker than our PTFE feeder tubes. That dropoff was also nonlinear, so a tube that was 1mm thick would let through more than just 20%.

The only way to really prevent UV levels in a room would be UV-blocking coatings or tinting film on the windows, and no use of fluorescent light bulbs.

Brand new to 3D printing and my 5-tool XL is my first 3D Printer!Check out my Multi-Tool fork of PrusaSlicer to mix and match nozzle sizes.

RE: Filament breaking in unused tools. Common?

fair enough, but still blocks a fair bit, and short of full or even indirect sunshine... I'm sure most people are not printing on their sunny outdoor decks right? lol

however, to re-emphasize a prior point, printer is in a room with a north facing window (cannot view sun, curtained, usually window closed to keep temp constant while printing) , as far away from the window as possible, so there is basically zero daylight reaching the printer as a rule, thus little to no uv at all. It could reflect from the walls potentially without curtains, but if I turn off the room light, it's pretty dark (enough so that my baby monitor for the printer has to go into night vision)