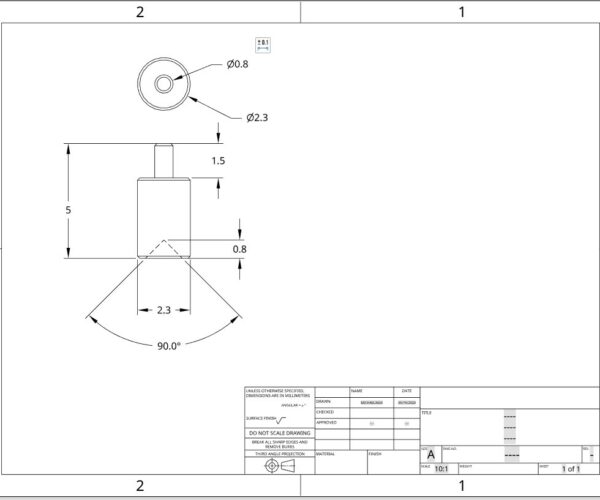

RE: Does this part seem printable on the SL1?

This part is easy to print with any printer. But resin prints are brittle and break easily.

RE: Does this part seem printable on the SL1?

I assume that you mean that it would be printable by any SLA or MSLA printer? I didn't have any luck with an FDM printer on this part.

In my limited research thus far, it appears that "tough" resin, such as Prusa sells, translates to brittle and that durable resins may be a bit more accommodating to stress and less prone to breakage. Does anyone have a suggestion for a good resin to use for this sort of duty?

RE: Does this part seem printable on the SL1?

It should work on an FDM printer with 0.25 or 0.2mm nozzle too.

RE: Does this part seem printable on the SL1?

It should work on an FDM printer with 0.25 or 0.2mm nozzle too.

Thanks - 0.2/0.25mm nozzles weren't an option on my old FDM printer with it's closed slicer but would be on the Prusa Mk3s that just arrived. I'll buy some nozzles and give those parts a shot with that.

RE: Does this part seem printable on the SL1?

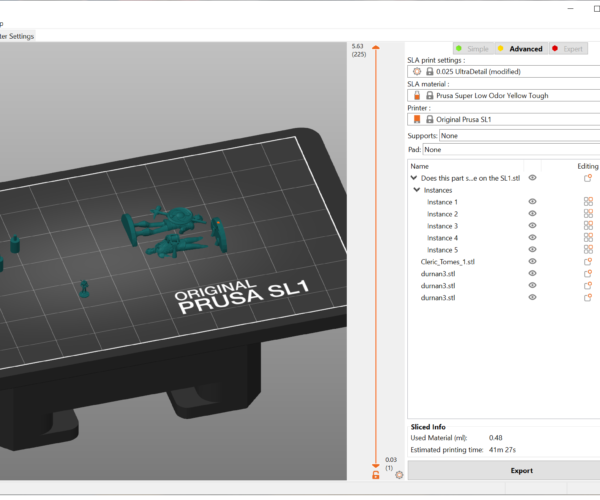

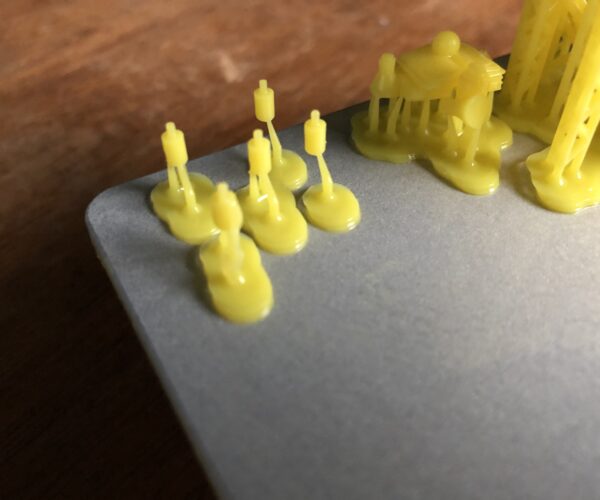

Decided to CAD your part and test it at the highest resolution on my SL1. A mate wants me to test the resolution of miniatures on the SL1, so thought I would kill two birds with one stone, so to speak.

When I say highest resolution, I mean at the highest print setting that comes by default with Prusaslicer, which is 0.025mm. The SL1 is rated all the way down to 0.01mm, but you’d have to define those settings yourself.

Here I printed six of your part, along with miniatures shrunk down to the height of your part. The man standing in the middle is the same man I’ve sliced in half and laid horizontally, all ~5mm high. The editor in this forum has cut the left side off this picture. There are another five of your part in the left side of this screenshot, which aren't visible.

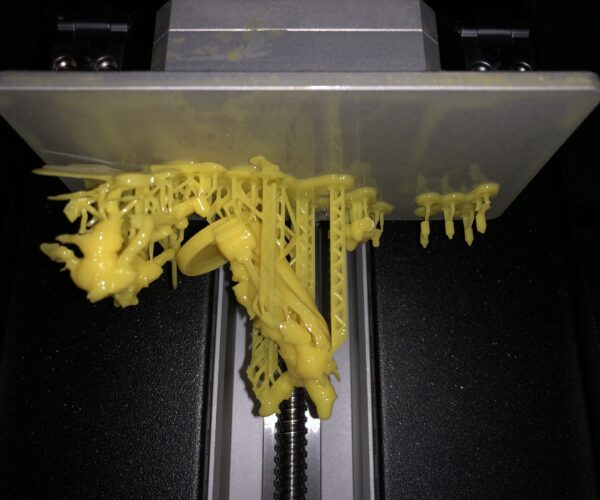

Unfortunately, none of your parts were visible on the print bed, even before washing. Strangely, the standing miniature survived. Looking at your design again, I think it likely that the cone on the base didn’t leave enough material for the rest of the object? It didn’t even print once!

In any case, the detail on these first layers appears overwhelmed by the resin left behind. Also, the chamfers on your part I modelled at only 0.025 high which is the layer height, so your print won’t show any detail.

There is so much resin left on this build plate after washing that I think viscosity is a problem. This print was done at 120C. Running this print at higher temperatures would have helped the resin drip off these parts.

Still, all is not lost. I think the next thing to try would be to print supports, because supports adhere to the print bed and to your print, and would lift your print out of the resin typically left on the build plate itself. The drawback is the print will take much longer. This print took an hour because the layer height was so small, but so was the overall height. Adding supports would double this amount of time, as print time is directly proportional to height of the tallest print and inversely proportional to layer height.

RE: Does this part seem printable on the SL1?

@mbarr

Thanks for trying to print the parts - I do appreciate it even if the results were not promising. As you say adding supports may be helpful. 3D printing often seems to lead to lessons in research and I'm resigning myself to a future of trial and error.

RE: Does this part seem printable on the SL1?

Decided to give this a go again, but this time with supports You can see them here in the right side of this screenshot. Two have one support, two have two supports and two have three supports;

Before looking at the next photo, I draw your attention to the warning symbols next to Warrior_Cleric. NetFabb was unable to fix them, but I printed anyway;

Success! The test objects printed with supports, whether they had one, two or three supports.

I appear to have a problem with adhering to the print bed on the near side of the print bed. I suspect I know what the problem is, but that’s going to have to wait on further testing.

The Warrior_Cleric printed, even though it showed warnings;

Still, a good result, methinks;

RE: Does this part seem printable on the SL1?

That does look pretty good and it looks like the SL-1 would probably work for the sorts of things I want to make. Thanks for spending the time on this. Can I compensate you for time and material?

Mike

RE: Does this part seem printable on the SL1?

Thanks for the offer Mike, but no need. This is my new 'big boys toy' and I'm pushing the envelope with it to see what it can do. What I really want it for is to form metal. My first test leaves me confident I'll get there, but its going to take time and effort to get it right. Have already demonstrated that I can bend 2mm thick B304 stainless steel with prints from the SL1!

I still think you will be able to print your parts directly on the build plate. That is something I want to chase down to improve the quality of my own prints.

Incidentally, the hollow cone is visible on the bottom of your printed parts.

RE: Does this part seem printable on the SL1?

OK, I understand about "big boys toys" and the exploring that goes with them. At least half the fun is learning how to get a job done satisfactorily, or at least the reasons why it can't be done. FWIW, you've firmed up my decision to buy an SL-1.

RE: Does this part seem printable on the SL1?

You should consider using Siraya tech functional resins such as tough - "Blu", flexible - "Tenacious" or recent tappable - "Build". Also you can mix them to suit your needs.

So far it seems like they are offering best quality resins for money.

RE: Does this part seem printable on the SL1?

Thanks - Siraya Tech was already on my short list so it's good to see that it is well liked.