Curwa: build plate?

Hello,

I watched the video of the SL1 on the blog post. To use the CurWa (it really needs a better name, particularly for those who speak Polish 🙂 ), do you just move the build plate with print as a whole from the SL1 to the Curer/washer? Does this make it almost a use and forget? And if so, does the curer/washer come with a second build plate?

Any word on pricing/lifetime of the consumables (e.g. fep film)?

The main reason for me not to consider SLA was in the issues with washing/curing/post processing. However, filling a machine with isopropanol is not a big ask, and moving the build plate from one machine to another also is not difficult...

I was more or less decided on a mk3 in January, but this made me reconsider. Any idea about the environmental requirements for operating and those for storing the printer and the curer/washer? I realized I could put devices on a closed balcony (has adequate ventilation, but lack of isolation makes it rather exposed to the elements (mainly temperature).

Thanks!

Re: Curwa: build plate?

Background:

I own an AnyCubic Photon which, spec-wise, is fairly similar to the SL1. I've been trying to convince myself to go all in with the SL1.

For a wash station, I've been using a $45 magnetic stirrer and 2 cross-shaped stir bars ($13). I keep my 2 washes in similar, air-tight Rubbermaid containers (~$15) and designed "grills" that raise the floor high enough for the stir bar to spin unobstructed. I built a UV curing station with a $20 nail drying lamp, ~$10 worth of filament, and $11 in flexible mirrors.

With this configuration, for just over $110, no second build plate is required and I can run a print through a wash and another through the cure process at the same time.

The Point:

The biggest problem I see with placing a build plate directly into the wash station is lost resin. I scrape a lot of resin off of a build plate before I remove the prints from it. This resin would otherwise reduce the life of the IPA in the wash and moving from the wash back to the printer would require clean/dry time to prevent contaminating the resin in the printer.

I certainly hope the process doesn't require the build plate move from the printer to the "CurWa".

Regarding using the printer on a balcony, I'd recommend against it as the sunlight will cause problems with curing prematurely. When the bottles are closed, there is no smell and most resin states to store it in a "cool, dark place". I print in a window-less room in my basement and have a small filter attached the printer, there is a minor odor and I need to determine how to improve the filtration. It looks like the SL1 will have a decent filtration system. These chemicals are classified as hazardous and should be disposed of properly.

The Mk3 and the SL1 are very different, your decision should be based on your intended usage. I use my Mk3 for everything but thing I need to be multi-material (I use my Mk2s w/ MMU) or small, intricate items like game minis (Photon is used here).

Edits: In trying to answer all of your questions, I made several edits.

Re: Curwa: build plate?

Thanks for you insights!

My purpose is not business related, so I have more freedom in choice between sla/ffm. It is mainy for boardgame related stuff, so ideally quite detailed miniatures. While I think the SLA-quality may be more interesting for me, I feel/felt the issues with chemicals may be such that I could settle for an ffm and just have less detailed objects - but of course I'm not sure how happy I would be with that output. It also would be my first 3D printer, so I'm not sure if SLA is a good choice for a first printer. Of course, whenever I see something new in the SLA field, it pulls me back to it.

My main issue is that I live on a small apartment with limited outside venting capacity. As such, any printer I get either has to be in living space or on the closed balcony; in the living space I cannot have a dedicated vent to duct air outside. When I meant that I could put it on the balcony, you should know that it is a non-isolated closed area (but I can open windows); anything I put there would be inside some cabinet or so to shield it from sunlight as it is a south-southeast facing balcony. It does get hot in summer and cold in winter... Come to think of it, in one room I have a window facing a different side and I could put a printer in front of that one (the sla printer requires less desktop space compared to an fdm printer).

It is interesting to read about your DIY solutions for curing/washing, as this is one of the aspects that scares me the most from the SLA printing. Another aspect is perhaps less transparent usage costs (e.g. how often to you need to change the reservoir, ...). So you basically use a rubbermaid container in which you put a grill that allows you to put the printed item above the stirrer-tablet and then put the whole thing on a magnetic stirrer?

Re: Curwa: build plate?

It is interesting to read about your DIY solutions for curing/washing, as this is one of the aspects that scares me the most from the SLA printing. Another aspect is perhaps less transparent usage costs (e.g. how often to you need to change the reservoir, ...). So you basically use a rubbermaid container in which you put a grill that allows you to put the printed item above the stirrer-tablet and then put the whole thing on a magnetic stirrer?

I always wear gloves and a mask when working with resin, the chemicals aren't that bad with the proper protection.

After each printing session, I drain the reservoir back into the resin bottle, filtering through a paint screen and funnel.

I use 2 washes, the first gets pretty dirty and the second clears away anything missed in the first wash.

Another concern is that by leaving the printed object on the build plate, you'd also be leaving support material. I find that if I leave the supports on during the wash, my prints don't get as clean.

The stirrer is a great improvement over just letting the item sit. I was leaving the prints a static bowl of 99% IPA for 1 hour per wash. The stirrer brings that down to 15 minutes per wash with a better over-all cleaning. Another 15 minutes in this box cures it.

The CurWa sounds convenient but potentially wasteful.

If this is your first foray into 3D printing, I can't recommend the Mk3 enough. For minis, I'd suggest picking up a .25mm nozzle. VirtuallyJason on Thingiverse has been doing some very impressive models with that setup.

Re: Curwa: build plate?

I use 2 washes, the first gets pretty dirty and the second clears away anything missed in the first wash.

Another concern is that by leaving the printed object on the build plate, you'd also be leaving support material. I find that if I leave the supports on during the wash, my prints don't get as clean.

Good point about the supports...

If this is your first foray into 3D printing, I can't recommend the Mk3 enough. For minis, I'd suggest picking up a .25mm nozzle. VirtuallyJason on Thingiverse has been doing some very impressive models with that setup.

I think you can understand my dilemma... I feel I would be better off with an SLA printer (I would love the detail it offers), but am not sure I have the space/desire to handle the chemicals and the knowledge to use it properly (though I think it may be easier as there can be no clogging or so). But is there more apart from washing and curing? An fdm printer seems a better start, but would mean objects with less detail (which I most likely not make all over again if I ever get another printer later). However, regarding the chemicals: with the fdm printer I most likely will have to consider some air filtering as well, as it would have to be in living space. Difficult... 🙂

Re: Curwa: build plate?

With SLA, there is no further required post-processing once washed and cured. Painting is highly encouraged as excessive UV exposure can degrade the printed item, this is no different than with FDM material though.

If you print with PLA or PETG on an FDM printer, there is no significant smell and filtration (for odors) is not necessary. ABS on the other hand produces a foul odor that I'm convinced is unhealthy.

Re: Curwa: build plate?

With SLA, there is no further required post-processing once washed and cured. Painting is highly encouraged as excessive UV exposure can degrade the printed item, this is no different than with FDM material though.

If you print with PLA or PETG on an FDM printer, there is no significant smell and filtration (for odors) is not necessary. ABS on the other hand produces a foul odor that I'm convinced is unhealthy.

I read some things on ultra fine particles which made me think that it is better to be overly safe. 🙂 I've found online that spraying resin prints with a clear acrylic paint helps (although I don't think my prints will have excessive UV exposure - and spray painting is a problem on an apartment).

My choice will have to be between sla, which allows for more fine detail, or fdm, which allows for different materials. Either could be interesting in the context of boardgames, so there is something to be said for either of them.

Seeing the SL1 launch and sample prints made me look again at the SLA/DLP type printer (detail is just amazing), but given the space issues (lack of dedicated workspace), I probably should stick with my plan of a mk3.... (also as it is a first 3d printer)

Re: Curwa: build plate?

Seeing the SL1 launch and sample prints made me look again at the SLA/DLP type printer (detail is just amazing), but given the space issues (lack of dedicated workspace), I probably should stick with my plan of a mk3.... (also as it is a first 3d printer)

I think this is definitely the right idea. For a hobbyist, it makes sense to start with FDM before tackling a resin printer. FDM has many advantages over resin; really the one thing resin has going for it is the fine detail.

Re: Curwa: build plate?

FDM has many advantages over resin; really the one thing resin has going for it is the fine detail.

Yeah... but it is a nice thing... 😀

But for my purpose, what it lacks in detail I think I could compensate with material choice. So back to plan A: mk3.

Re: Curwa: build plate?

For miniatures the Photon is a great printer. Frankly it is so cheap that the decision becomes a no-brainer. Never mind the chemicals, some resins can be cleaned with soap water. Just get disposable gloves and protective glasses and don't fool around.

If you hate it I'm sure you can get most of the money back on ebay, there's not much risk involved for anyone buying a used one.

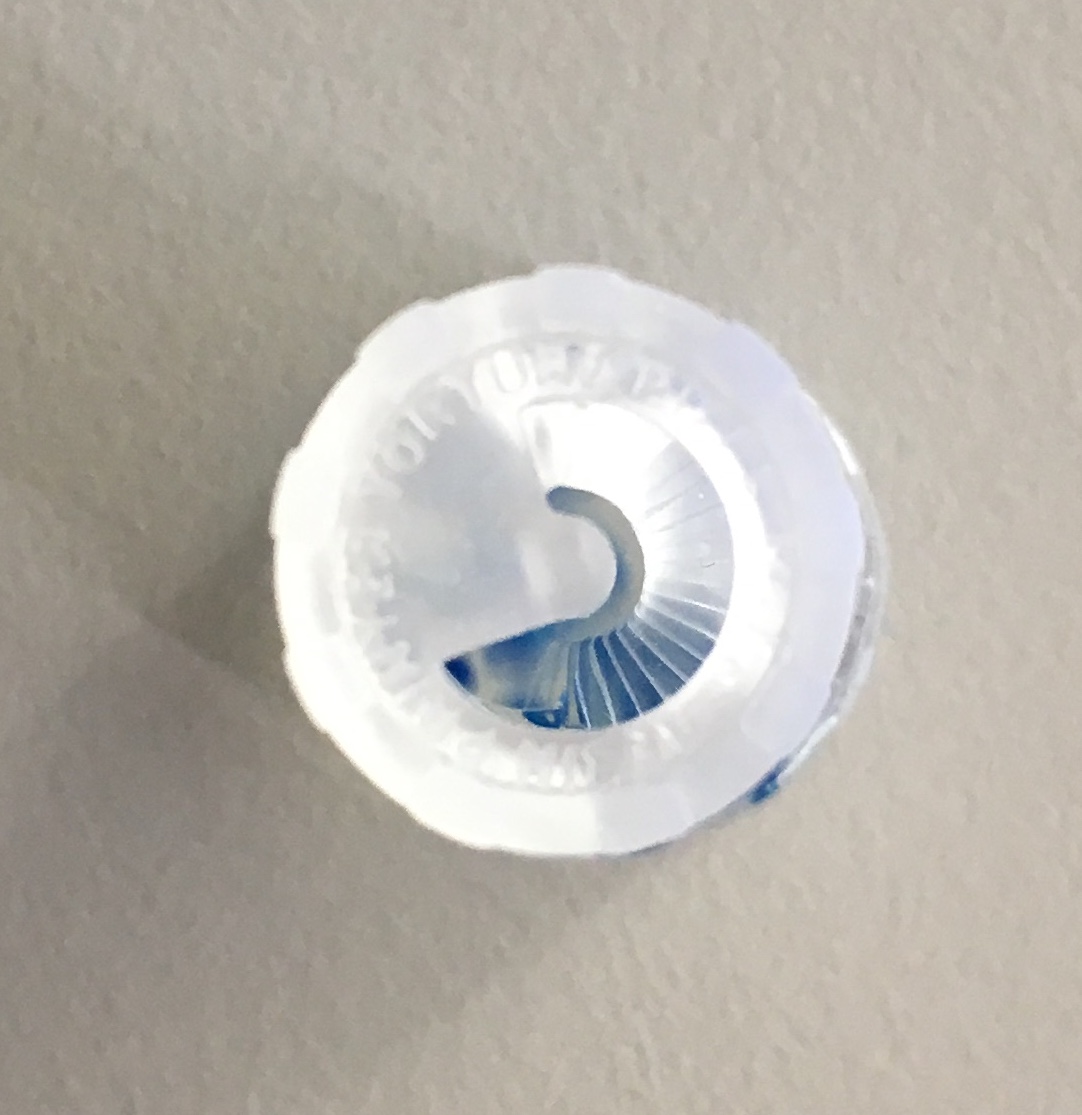

I mean, look at the images. You can't read the text on the photo (crappy phone), but it's crisp in real life. Height is 22mm, default print settings, no supports, no postpro except wash&cure. The helix inside is about 0.5mm thick, no way this is printable on FFM. You can see every individual pixel under the microscope. And what is rarely mentioned: It doesn't increase the print time if you fill the build plate, only thing that matters is the height of the highest object (->whole sets of miniatures in your case).

Not saying an FFM printer is not great (love and use them all the time), but for your specific purpose SLA is better in my opinion (and cheaper).