Loading MMU - Rounding Filament Tips

I’m thrilled with the MMU3. Numerous prints with multiple brands of PLA & PETG have yielded a 100% success rate in filament changes.

However, I do have problems loading into the MMU. The tips catch just before the rollers. This can happen one any one of the five positions.

If I carefully round the tip with an emery board I can get it loaded. But sometimes it still takes several stabs.

Anyone know of a fix for this to make it less temperamental?

Alternatively, is there a tool that I can make to do the rounding easier and faster?

RE: Loading MMU - Rounding Filament Tips

I’m starting a get a complex. It’s not often that any post goes 5 days without a reply lol

I guess that either no one else experiences this problem or no one has found a solution.

RE: Loading MMU - Rounding Filament Tips

I am not so often in this Forum so I did not read this before. When it catches next time, open the MMU and look where it catches exactly. So you can try to find the cause.

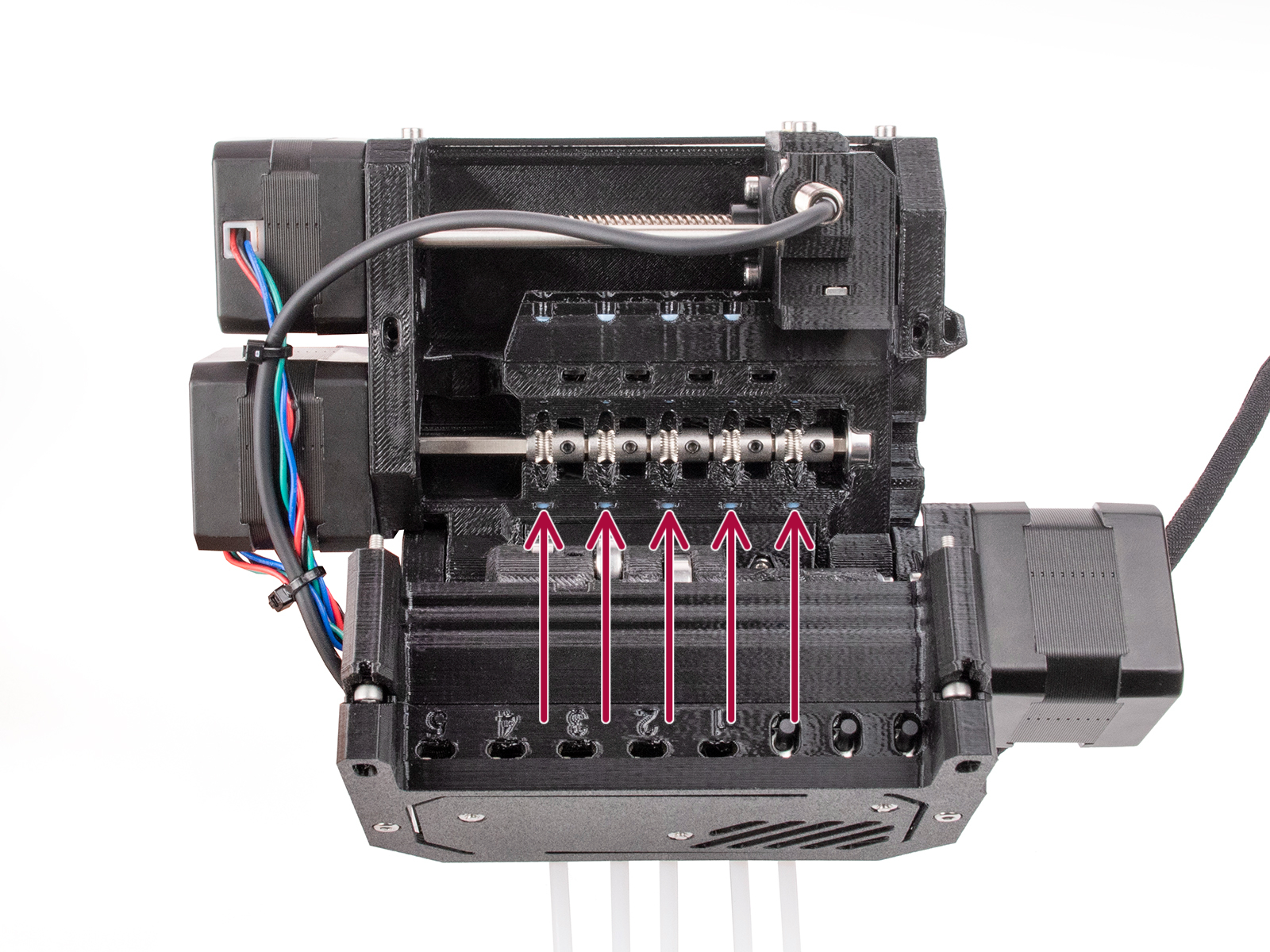

I also had such a problem in the beginning. This happened because I did not insert the PTFE-tubes all to the end and the filament catched between the PTFE and the inlet. Look at the inlets, you have to see the PTFE-tubes from the inside as shown in this picture:

Printing PLA and PETG at the same time? See the Guide for MultiMaterialSupports ----- Ejecting Buffer cassettes is not satisfying? May the Fork be with you!

RE: Loading MMU - Rounding Filament Tips

Thanks @Saphir. I’ll check that.

By the way, I got your Fork to print and it’s working well. Thanks for sharing your design.

RE: Loading MMU - Rounding Filament Tips

For whatever it's worth, this had been a concern of mine when I first built the MMU3 -- it looked as though having to ever-so-carefully shape the ends of filament would be very time consuming (and irritating).

In practice, what's worked for me is to cut the end at an angle, leaving a very long and sharp tip. Between that, and making sure the filament end is straight, I ususally don't have a problem with loading (and when I do it's often because of a curve in the filament end that needs to be straightened out).

RE: Loading MMU - Rounding Filament Tips

Good answers guys. I had a hard time pushing in the tubes fully during assembly. My solution was to use a silicone sheet for a better grip. I also find it best when I cut the filament end on an angle and straighten a few inches of filament before inserting.

RE: Loading MMU - Rounding Filament Tips

All of my PTFE tubes are fully inserted as verified by the witness slots.

The photo shows position 1 (with red filament) and position 2. The filament is stuck at this point. You can see that the opening of #2 is deformed with the top drooping down into the filament pathway. This is hard to see without magnification though the closeup photo shows it clearly.

Rather than trimming the obstruction I elected to heat the end of a scribe and heat-form the pathway to smooth it out. That worked well and now the filament glides in easily. Obviously one has to be careful not to get the scribe too hot and make a total mess out of it.

I needed to get a print started so I only fixed position #1. I’ll finish the other 4 tomorrow.

Thanks to all for your help.