Brainstorming on MMU2 filament handling

My MMU2 just arrived today, and I have not opened the package yet. Mostly because I am dreading the flicking snake tongues of filaments I will be dealing with.

I see a bunch of great ideas for various methods of managing the filament retraction problem, but I was thinking about something even simpler than all the rest.

I dont have a drawing or cad print, just a thought rattling between my ears, and it goes like this:

How about a carriage that can support 5 or 6 spools. It would be a roller style that the rims of the spools sit on.

The difference is that one of the rollers would be connected via a clutchs to a motor shaft so that there would be a constant force to rewind the filament slack back onto the spools.

The motor clutches would need to be set so as to not pull excessively hard against the MMU2, but still be fast & strong enough to eliminate slack.

One main shaft from the motor would drive individual clutch driven rollers on all 5 spools.

It could be made compact enough to fit in a dry box above the MK3.

Call it the KISS filament rack, "Keep It Simple Stupid"

Any thoughts?

Re: Brainstorming on MMU2 filament handling

Yes !

try this:

no motor or clutch involved just simple mechnics.

I use 5 of them in a holder i designed to fit my Ikea enclosure

Re: Brainstorming on MMU2 filament handling

Yes !

try this:

no motor or clutch involved just simple mechnics.

I use 5 of them in a holder i designed to fit my Ikea enclosure

I saw that one and I like it! If I cant find a easier solution, that is probably what I will go with.

That design is what prompted my post.

My one concern with the spring rewind is, if it has enough spring capacity to keep the filament wound without having to reset the spring occasionally.

My thoughts on a single motor running 5 clutchs allow for a slightly more compact area for 5 spools (maybe more)

If the spools just sit on rollers, they should be easier to change out than ones on a central shaft.

With a clutch on the drive roller, when installed, the fresh spool will auto tension with the rest, without needing any other intervention.

Again, just thinking out loud. My MMU2, sitting in its black wrapper, within arms reach, taunting me to open it and start building, but I want a plan in place before I start 🙂

Wayne

Re: Brainstorming on MMU2 filament handling

This my setup and not one jam or snagging only cost me £7.00

Re: Brainstorming on MMU2 filament handling

Hi,

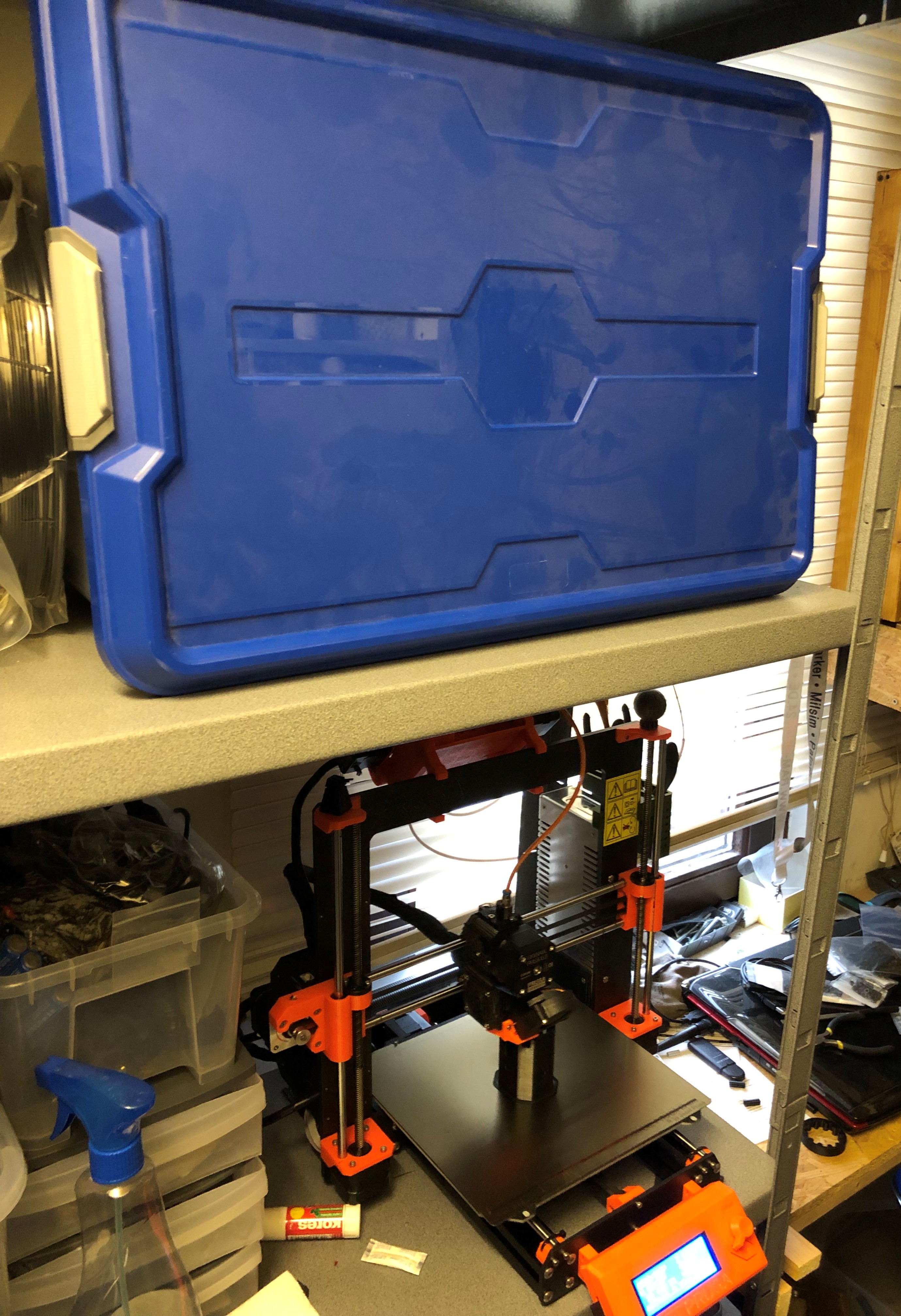

I use a drybox with Tush2 (the bearings from the MMU2 kit fits, fitted on a bar and can slide) mounted on the side so I can open the box, the lid is faced front. My box is above my MK3/MMU.

Problem: When changing Filament it get pushed into the box and slides off the wheel and oft getting stuck.

On the drybox I got around 15cm ptfe tubing with a small tube mounted on the tip. The opening towards the MMU is a bit bigger so that the PTFE tubing can slide in or out. So now when changing Filament the PTFE tubes just split apart to let the filament slide out of the MMU. When Done printing and I don't need the exposed filament i manually roll it back on the roll so it is no longet exposed.

this work very well and I haven't had a MMU stop since then.

Re: Brainstorming on MMU2 filament handling

can make some pics if you wish.

Re: Brainstorming on MMU2 filament handling

I guess the goal in my head, is to keep things simple, neat and organized along with keeping the spools in dry containment.

Whatever combination of tools and toys that gets me there without spending a fortune will do.

Last week I picked up this old Lottery Kiosk on ebay for $11

I will put the printer in the top on a sliding shelf and the spools below.

I will need a filament retraction method that will be tolerant of the spools being below the printer.

Depending on spare time, money and ambition, I will seal it up with temperature & humidity control.

Having the spools in a single removable dry box with self winding module would be great to avoid having to seal the entire rack.

Re: Brainstorming on MMU2 filament handling

My setup, works fine.

Re: Brainstorming on MMU2 filament handling

My setup, works fine.

I see you have inverted or modified the mounting bracket for the MMU2?

I am looking over the rack I bought and it may be more practical to put the spools over the printer, but the angle of MMU2 mounting is not optimized for that.

I found this, and it may do the job to get a better angle. http://www.thingiverse.com/thing:3129292

Re: Brainstorming on MMU2 filament handling

I see you have inverted or modified the mounting bracket for the MMU2?

I am looking over the rack I bought and it may be more practical to put the spools over the printer, but the angle of MMU2 mounting is not optimized for that.

I found this, and it may do the job to get a better angle. http://www.thingiverse.com/thing:3129292

I tested this as well, but the Version I use has the Advantage to mount the MMU 10mm back so the angles are better and I can use the whole print volume. I use the 10°/10mm Version.

Thingy: https://www.thingiverse.com/thing:3286954

Key in an enclosure is the underslug Control Panel: https://www.thingiverse.com/thing:3211711

Re: Brainstorming on MMU2 filament handling

I've been wanting to make a tip-forward MMU mount for a long time. Anyone tried it?

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Brainstorming on MMU2 filament handling

Wouldn't that add vibration to the printer? With it centered on top is one thing, but to stick it out so far I would think it would be better to mount it from above than to do this.