Re: Successful MMU2 prints

Since this is such a popular print 😎

did you run that print through octoprint or use an independent camera time lapse?

Issue: had the red filament Snap at the spool holder one time which messed up the MMU 2 times, requiring a fix on unload and then on load for the next layer. Delay was about 1/2 hour on fix.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Successful MMU2 prints

Octoprint, pi cam, octolapse plugin

Least you recovered the print.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Successful MMU2 prints

was keeping an eye remotely through the camera and i noticed the nozzle had not moved in some time figured the MMU threw an error.

went down and saw the Red filament snapped at the spool and the machine sucked the remained until the FINDA prob tripped with no filament error. so it tripped a load error. then there was another issue with the red filament about 2 layers later that tripped an unload error as the FINDA saw string.

I suspect that section of the filament from hatchbox on the spool was not 100% mixed properly and the properties were different then the rest of the spool. after that section of filament ran and was cut out the rest of the print ran for another 9 hours with no issues.

i've seen hatchbox have sections were the filament acts like it is contaminated suddenly it is very brittle or gets very stringy.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Successful MMU2 prints

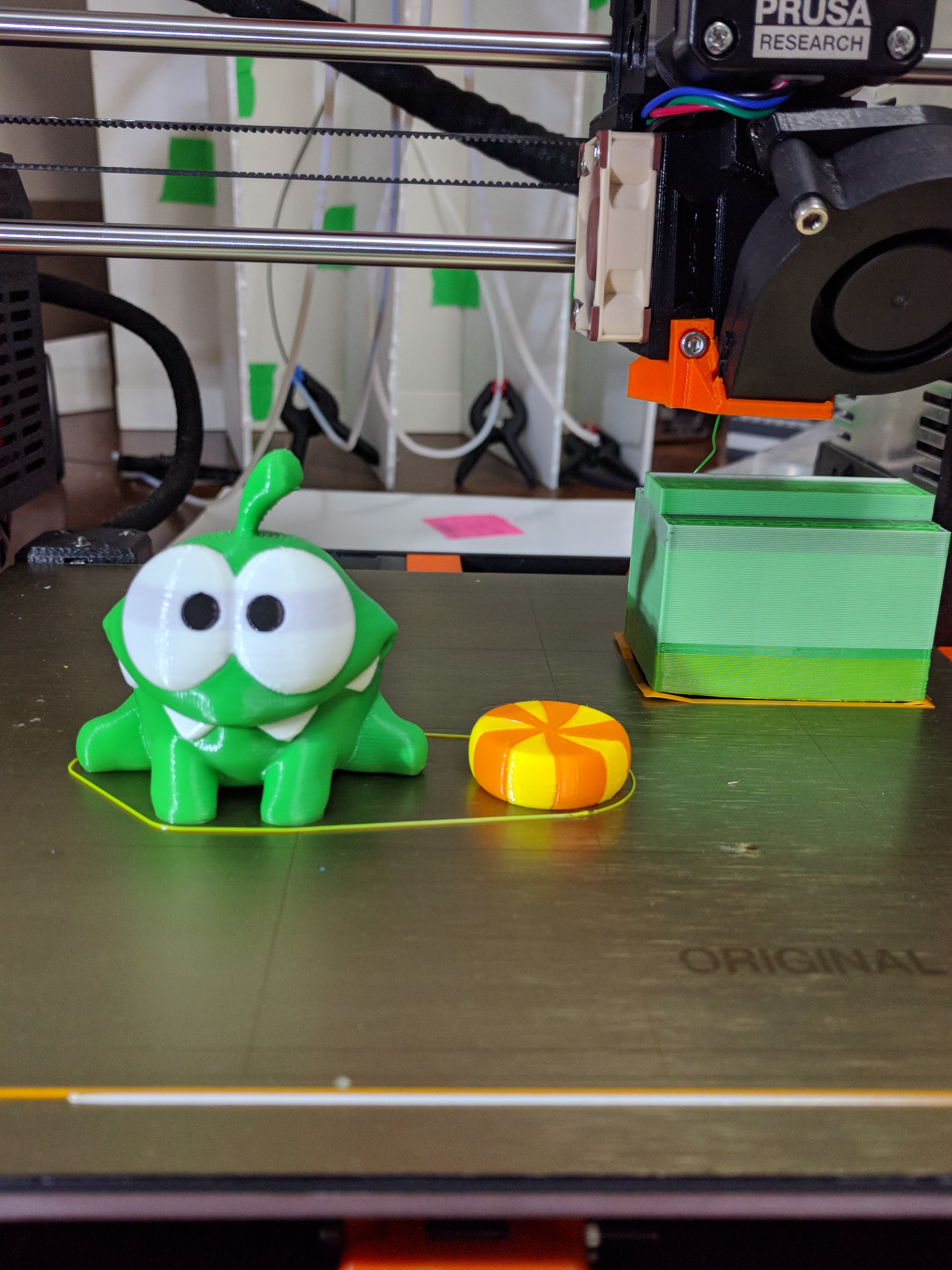

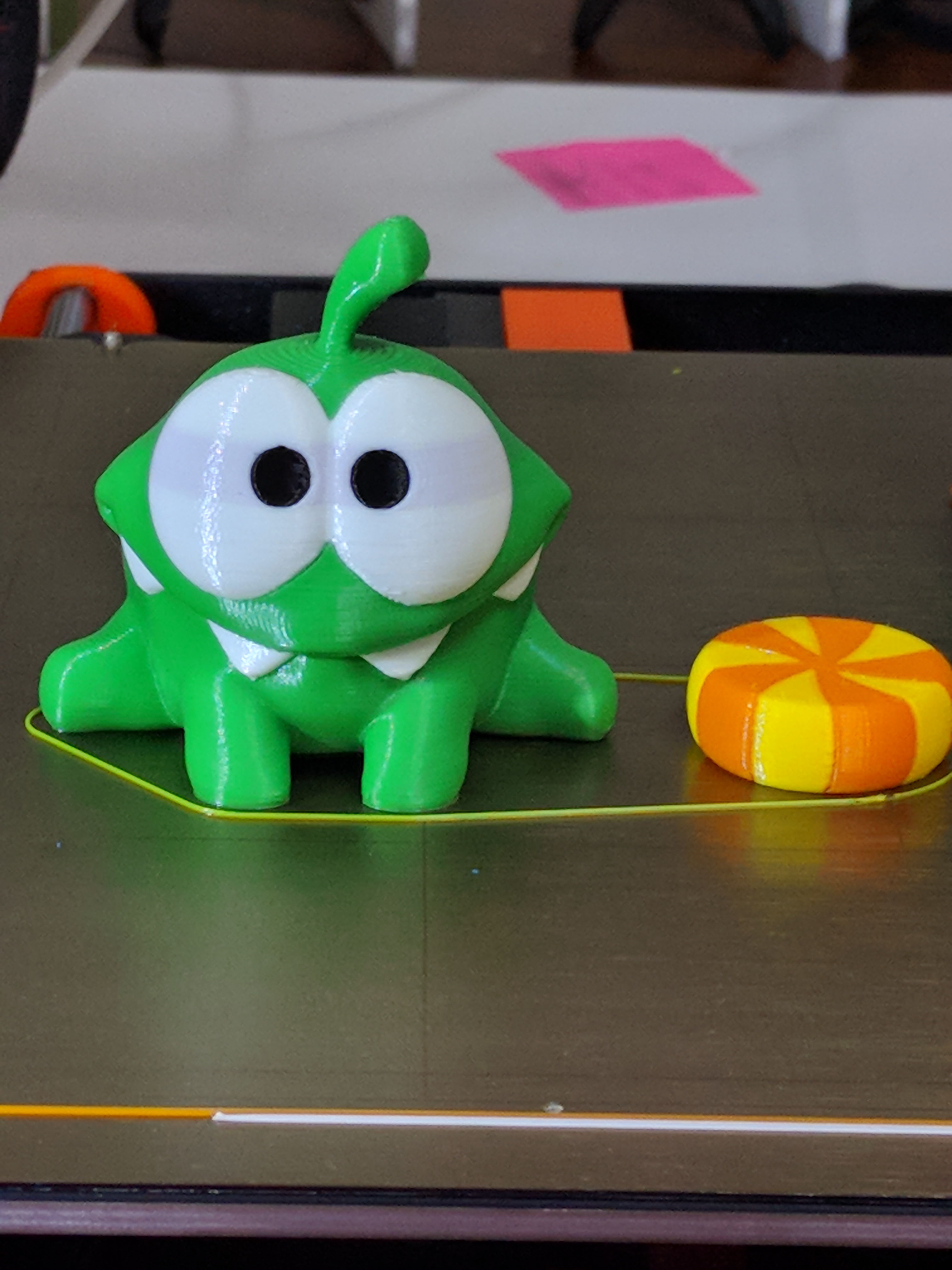

This is my weekend work:

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Successful MMU2 prints

@nikolai.r

Awesome. Is that Archimedean chords top fill pattern?

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Successful MMU2 prints

@nikolai.r

Awesome. Is that Archimedean chords top fill pattern?

Not really. Just load the amf file in Slic3r, adjust the filament temp and give it a go.

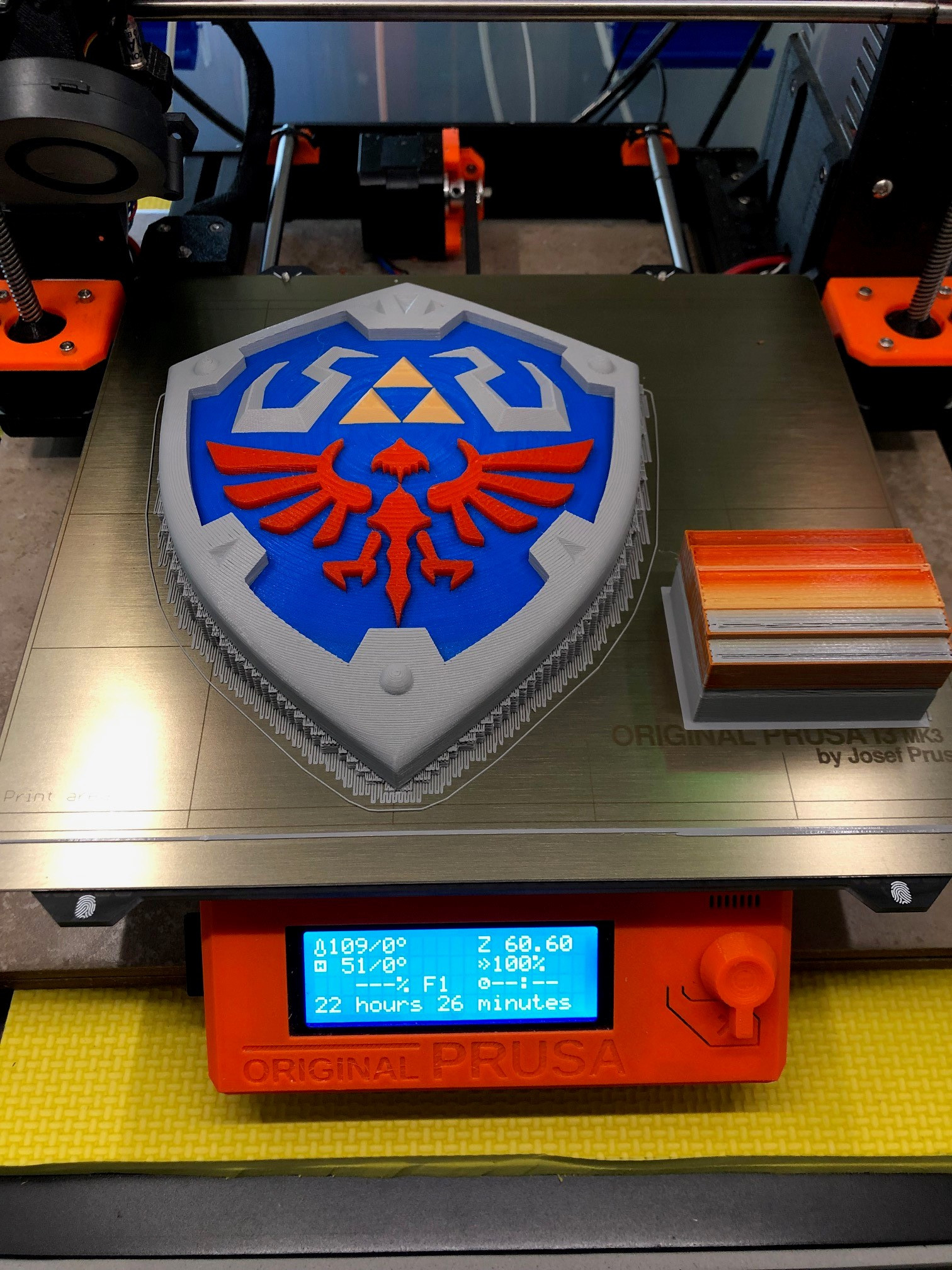

https://www.thingiverse.com/thing:2677486

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Successful MMU2 prints

i was gonna print the shield for my daughter...but I wana use water soluble. how well did the underside clean up?

I have a Prusa,therefore I research.

Re: Successful MMU2 prints

i was gonna print the shield for my daughter...but I wana use water soluble. how well did the underside clean up?

Not so easy but doable. I don't see a back of it because it's handing on the wall, so it doesn't make sense to me to use PVA. (too expensive)

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Successful MMU2 prints

i just tried my first ever use of BVOH.

My print completed 100% no load/unload errors ran for 6 hours.

however i'm not happy with BVOH at all. it basically contaminates the nozzle and effects the next material put through it.

it makes PLA brittle as the materials ability to bond is effected by the BVOH still in the nozzle even after wipe purge.

you have to really agitate it in water to start to remove it as well.

totally not what i was expecting from soluble material and you are better off using traditional Supports from the same material or redesigning the part to compensate for overhangs.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Successful MMU2 prints

Thanks for the update. I read already BVOH is not the best material. Try PVA instead.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Successful MMU2 prints

i read on PVA and the results people had are usually worse then BVOH

there was some threads about it in the MMU discussion area and many people abandoned PVA for BVOH.

both materials don't really fuse well even to itself. you have to print slow, there is cross contamination of the material into the next material.

very slow printing requiring modification of supports.

the cross contaminated areas have additional issues when you use water to dissolve the BVOH or PVA the cross contaminated areas then become additionally porous from the dissolving and become even more brittle.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Successful MMU2 prints

hm... doesn't sound promising.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Successful MMU2 prints

no it doesn't i threw out the soluble test i ran. i tried some load tests and watched it just fall apart in all the cross contaminated areas.

one reason i wanted the MMU was for the soluble material i figured it would make better parts without complex supports but i can see it will not live up to my needs.

basically you can make prettier models with less clean up but they will be structurally weak and break very easily compared to standard support and possibly lots of clean up.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Successful MMU2 prints

i just tried my first ever use of BVOH.

My print completed 100% no load/unload errors ran for 6 hours.

however i'm not happy with BVOH at all. it basically contaminates the nozzle and effects the next material put through it.

it makes PLA brittle as the materials ability to bond is effected by the BVOH still in the nozzle even after wipe purge.

you have to really agitate it in water to start to remove it as well.

totally not what i was expecting from soluble material and you are better off using traditional Supports from the same material or redesigning the part to compensate for overhangs.

You have to increase the BVOH purging values like it is stated in their mmu2 manual on page 23. Unload 120, Load 100. I print a lot with PLA and BVOH and the interface layer are looking phantastic. BVOH is WAY easier to remove than PVA.

Re: Successful MMU2 prints

"BVOH is WAY easier to remove than PVA."

that's nice to know. for "fine" prints. its a bear. but I should print thicker at first anyhow

I have a Prusa,therefore I research.

Re: Successful MMU2 prints

i just tried my first ever use of BVOH.

My print completed 100% no load/unload errors ran for 6 hours.

however i'm not happy with BVOH at all. it basically contaminates the nozzle and effects the next material put through it.

it makes PLA brittle as the materials ability to bond is effected by the BVOH still in the nozzle even after wipe purge.

you have to really agitate it in water to start to remove it as well.

totally not what i was expecting from soluble material and you are better off using traditional Supports from the same material or redesigning the part to compensate for overhangs.

You have to increase the BVOH purging values like it is stated in their mmu2 manual on page 23. Unload 120, Load 100. I print a lot with PLA and BVOH and the interface layer are looking phantastic. BVOH is WAY easier to remove than PVA.

thanks will try it and run the test again

“One does not simply use a picture as signature on Prusa forumsâ€