Poll - using of soluble material with MMU2

Hi all,

For me, the biggest disappointment with the MMU2 is the inability of using solubles, as this was the reason I ordered it.

I simply couldn't get it to make the filament-tip in the required shape, not even in any shape reliably. Consistency is my problem - if it was forming the same shape again and again I could at least start tuning...

If I use the same materials in different colours the MMU2 runs fine, no complaint there, but that ain't really what the name is standing for... Maybe a rename is in order? MCU2 instead of MMU? MultiColourUnit instead of MultiMaterialUnit? 😉

So I was wondering if there are any users out there that are able to use the MMU2 with solubles with success.

And maybe you could chime in to let us know your secret magic ingredient?

Cheers,

Daniel

Re: Poll - using of soluble material with MMU2

Using PVA on mine.

Did a temp tower to dial in the appropriate temp and other than that used basic PVA settings. Works well.

PLAFlex is a bit trickier, I need to dial in the cooling on that still.

Re: Poll - using of soluble material with MMU2

pva worked for me with stock PVOH settings

I have a Prusa,therefore I research.

Re: Poll - using of soluble material with MMU2

I am also disappointed, still trying to print a small test file ( https://www.thingiverse.com/thing:3339380 ) with PVA/PLA. I use PrimaSelect PVA+ from Prusa and the Stock BVOH/PLA settings but with 15 mm/s support speed so that the PVA lays down properly.

2 problems occur again and again:

1. Due to fast printing speeds on the wipe tower (you cannot change it through Slic3er) PVA does not lay down properly.

2. The PVA-tip has a thing string which prevents it from a proper reload occasionaly (every 2nd-4th layer).

pva worked for me with stock PVOH settings

@toaf and @martin.a22 Can you please show a picture of it or can you try to print the test file? Not that I do not trust you but it would make me happy again finally if I see that it can work... 🙂

Re: Poll - using of soluble material with MMU2

I just printed the color benchy upside down a few weeks ago. take it for what it is. but it put pva everywhere. cleaned up just fine tho

I have a Prusa,therefore I research.

Re: Poll - using of soluble material with MMU2

found a picture of the first one I printed. it lost a layer because my purge block wasn't setup for such a small pva part it printed right before the missed layer.

shocked I had a picture

I have a Prusa,therefore I research.

Re: Poll - using of soluble material with MMU2

I have the same issue with BVOH and I'm disappointed, too. The shape of the filament-tip is kind of random and I am never able to perform more than ~50 tool changes with BVOH; PLA-only prints work perfect for me. I tried to tweak the BVOH settings for weeks, even with the help from the chat, but I was never successful. Therefore, I am also very interested, if anyone was able to print a 20h+ print with BVHO.

As a workaround, I tried the filament Polysupport ( https://polymaker.com/product/polysupport/ ). It's a break-away support and works nice: It prints with stock PLA settings (just increase the temperature to 230) reliable and you can break the support very easily by hand in no time. The downside is, that it only sticks to PLA and won't work for models, where water soluble support is mandatory (for example a ball in a cage).

Re: Poll - using of soluble material with MMU2

my machine works with BVOH no problem. however i do not like the results when using the material.

this is a fault in the material not the MMU2.

BVOH acts like a oil contaminate unless you want to have an obscenely long purge for each tool change requiring BVOH.

The reason is any contamination of PLA from BVOH introduces brittleness and weakness into the PLA.

BVOH is fine for a pretty print where you do not really care about structural strength or loads otherwise i find the stuff expensive, prone to failure due to the materials EXTREMELY lose bonding to itself at any temperature, and the clean up can be just as bad as dealing with normal solid supports (even with hours of high tempature drying to get as much water out as possible) depending on design. it is more a novelty as a filament then actually useful.

now there is a firmware issue with the filament changes causing the speed of the machine to change from 100% to slower numbers, this is causes some issues between different materials and they have yet to fix it.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Poll - using of soluble material with MMU2

I am also disappointed, still trying to print a small test file ( https://www.thingiverse.com/thing:3339380 ) with PVA/PLA. I use PrimaSelect PVA+ from Prusa and the Stock BVOH/PLA settings but with 15 mm/s support speed so that the PVA lays down properly.

2 problems occur again and again:

1. Due to fast printing speeds on the wipe tower (you cannot change it through Slic3er) PVA does not lay down properly.

2. The PVA-tip has a thing string which prevents it from a proper reload occasionaly (every 2nd-4th layer).

pva worked for me with stock PVOH settings

@toaf and @martin.a22 Can you please show a picture of it or can you try to print the test file? Not that I do not trust you but it would make me happy again finally if I see that it can work... 🙂

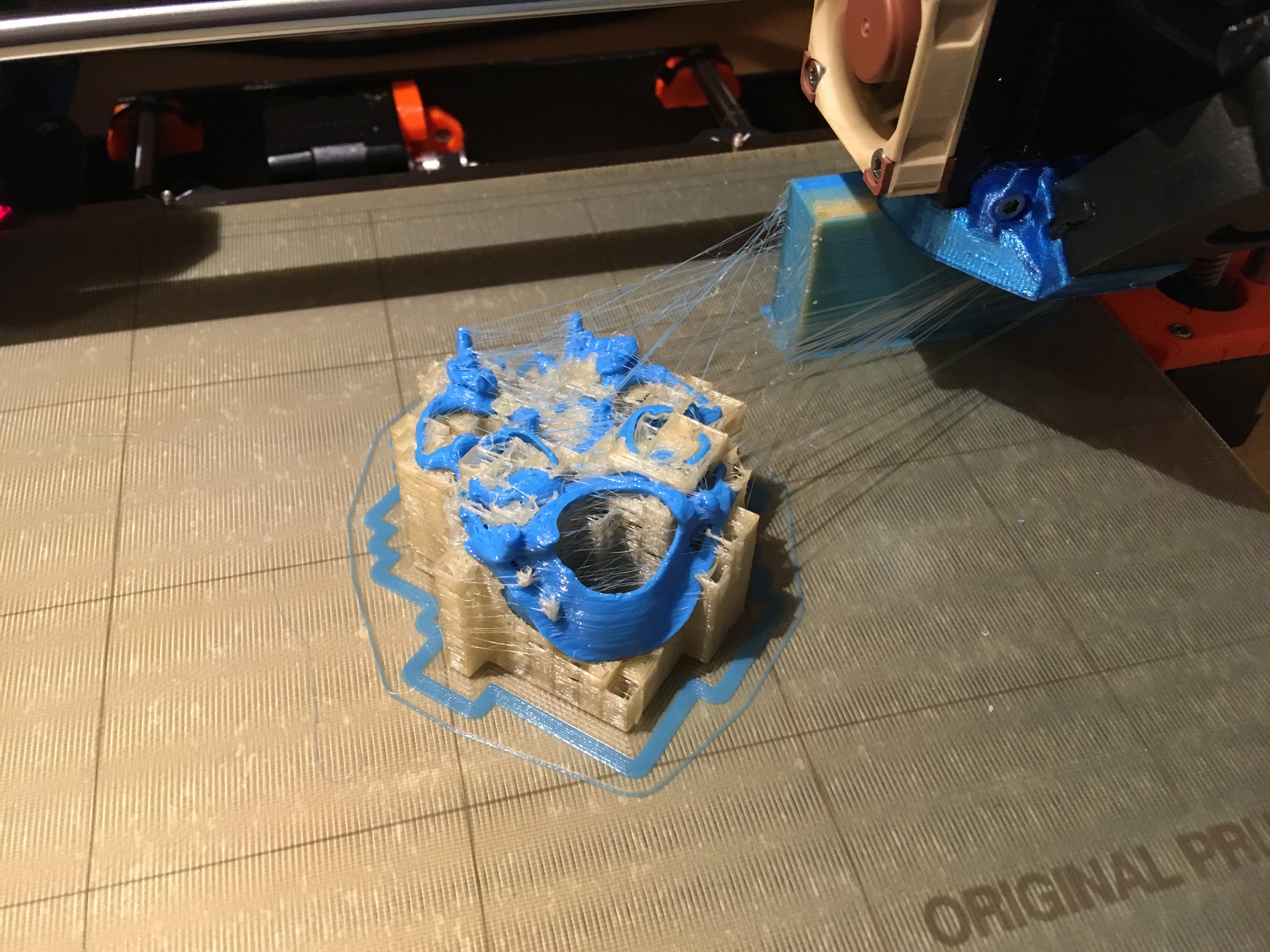

Printer is busy at the moment, but here's an early test. This is PLAflex and PVA. The failure near the top was from the PLAflex, not the PVA. I still need to dial in cooling for the PLAflex. While there's stringing on the fast moves between wipe tower there isn't much stringing during retraction back to the MMU, I presume do to appropriate cooling movements.

Re: Poll - using of soluble material with MMU2

pva and flex.. you are far more brave then me

I have a Prusa,therefore I research.

Re: Poll - using of soluble material with MMU2

Well that looks promising! To prove that your pictures helped at least in motivation leading to further tuning I also have a picture - best moring surprise ever :D.

I used BVOH-settings for PVA (PrimaSELECT) and I used the leftover of the Prusa PLA I had from years ago, also on stock settings (Prusa PLA). I changed the support speed to 15 mm/s and also the loading speed at start to 19 mm/s. Besides that I tuned the MMU unit so that there are is less resistance as possible considering the filament path.

However, I guess due to PVA-bleeding more than temperature, the layers on the vertical toruses could be torn apart extremely easy when I tried to solube the support.

I will no try a bigger interlocking mesh so bleeding is less of a problem considering material strength and that the tool changes are comparable to your two extraordinary results.

Re: Poll - using of soluble material with MMU2

turning up the purge numbers would help also.

I went higher just to print it the 2nd time.

I have a Prusa,therefore I research.

Re: Poll - using of soluble material with MMU2

pva and flex.. you are far more brave then me

Getting close. Just need a few more tweaks on the PLAflex. My TPU and ABS print worked nicely. 😀

Re: Poll - using of soluble material with MMU2

I feel the pain of that. I did get real lucky loading my flex. pushed it right thru first time. im sure that will never happen again.

I have a Prusa,therefore I research.

Re: Poll - using of soluble material with MMU2

and I thought upside down benchy was a challenge 😀

ok you must print an upside down rubber benchy

I have a Prusa,therefore I research.

Re: Poll - using of soluble material with MMU2

I feel the pain of that. I did get real lucky loading my flex. pushed it right thru first time. im sure that will never happen again.

Gentle on the idler tension screws. 😀