Filament getting stuck in PTFE tube after every print or change of filament

I have strange problem, the filament gets stuck inside the PTFE tube after every print or during every change of filament during multi-filament printing using MMU2S. I have Prusa MK3S MMU2S.

before installing MMU2S the printer was running perfect. i wonder if something is worng with calibration of Tube Length?

i noticed that when print ends or when MMU wants to change filament, while ejecting the filament gets stuck. after lots of trials and examinations, i noticed that the end part of the filament always becomes much thicker (creates a small blob at the end which comes out of the print head) than the diameter of the PTFE tube, this causes the filament to get stuck in tube, and the MMU2 keeps trying to pull the filament out, consequently grinding the filament inside the MMU2 module.

is there any solution for this ? since few months i am banging my head to solve this issue.

RE: Filament getting stuck in PTFE tube after every print or change of filament

I've been struggling with the MMU2S for about 3 weeks, reading every article I can find on this website and others, watching youtube videos, and nothing solved the problem where the 'bulb' ends of the filament were getting stuck in the PTFE tube between the MMU and the extruder. I tried everything that made any sense, to no avail.

As of about an hour ago, I think I finally got my MMU2S working correctly.

TL;DR - I swapped the PTFE tube between the MMU2S unit and the extruder with this:

https://www.amazon.com/gp/product/B073RFQQ3Z/ref=ppx_yo_dt_b_asin_title_o00_s01?ie=UTF8&psc=1

If the link is broken, here is the headline:

"PTFE Teflon tubing 25ft- 2mm ID X 4mm OD for 1.75 Filament Bowden 3D Printer -Allen Tech PTFE Teflon Tube"

The key difference is the inside diameter of the tube. I measured the inside diameter of the tube supplied with the MMU2S to be about 1.8 mm.

The tube I bought, above, has inside diameter 2.0 mm. Man, what a difference that makes!

My printer is currently about 75% done with this test print:

https://www.thingiverse.com/thing:3727620

I can't say with certainty that replacing the PTFE tube will make the MMU2S work perfectly, but I can say that before the change, I had to intervene to help the MMU2S push or pull those filament end bulbs every 2 to 4 filament changes, which is simply infuriating.

After swapping the tube, four out of five of my filaments immediately worked perfectly as the MMU changed filaments. I was having trouble with one filament almost every time though. I double-checked the tightness of the two spring screws on top of the MMU. They were flush with the plastic. I tightened the screws about 1/3 of a turn and now all five filaments have successfully undergone about 100 changes without any intervention at all. This is mind-blowing! I might actually have a useful MMU after all.

For those having the same problems, I have the MK3S kit, purchased January 2020. I got that working to my satisfaction. I thought the MMU2S would be a little more challenging, but had no idea how much time I would spend trying to get it to work. I'm currently running the stock MK3S. I made these alterations with the MMU2S:

A) Changed the mounting brackets.

https://www.thingiverse.com/thing:3384946

I switched to these brackets for the following reasons:

- The PTFE tube between the MMU and the extruder was curved so much that I wanted to reduce the friction to see if it would help. I think it helped a little bit, but with the new tube I'm not sure it's necessary.

- I tested what would happen if I raised the extruder to the maximum Z level, them moved the extruder across the X axis. The tube crosses itself, then has to twist as the extruder passes the MMU outlet. I'm not sure how well the filament will move through the tube when the extruder is this high. Looking at it now, I may design new horizontal brackets that situate the MMU unit to the rear about 3 inches/7 cm. This would prevent the tube from crossing itself with the extruder at maximum Z, and I don't think the tube length has to change. I'm a little concerned that the MK3S frame might distort just enough from the extra torque of the MMU pushing down at that distance away from the frame that it might cause noticeable stress, maybe with the Z axis bearings/alignment, but it doesn't seem likely that it will be a problem.

B) The other change probably doesn't make any difference, but for full disclosure:

I replaced the original filament "buffer" supplied with the MMU2S with:

https://www.prusaprinters.org/prints/4951-mmu2-filament-buffer

I made this change because having to manually assist the filament through the MMU very frequently while bending over my worktable to squeeze my fingers into the cutouts of the buffer to grasp the filament was really making me angry. That said, this change was not as simple as I expected. The wheels recommended by the spool holder (from here: https://www.thingiverse.com/thing:3529934 are too narrow (about 12.7 mm) to fit within the holders without the filament sometimes wedging between the wheel and the frame. I had to widen the wheels to 13.7 mm to get it to work fairly reliably. 14mm was too wide to rotate without friction. Also, I thought I'd be able to print the frame without supports, but at the top end, those thin supports were wiggling around as the extruder deposited more filament. I ended up stopping the print and super-gluing a plastic square (from a z-axis test print) across the tops. I screwed all five frames to a wooden board to hold them steady. It works as long as the filament isn't twisted when inserted into the PTFE tubes to the MMU. If they are twisted, the filament won't stay aligned with the wheel and can still get stuck between the wheel and the frame, or tangled with other filament of adjacent frames if they are close together.

Now that the MMU seems to be working, the original filament buffer would be OK. Just amazingly bulky and awkward.

RE: Filament getting stuck in PTFE tube after every print or change of filament

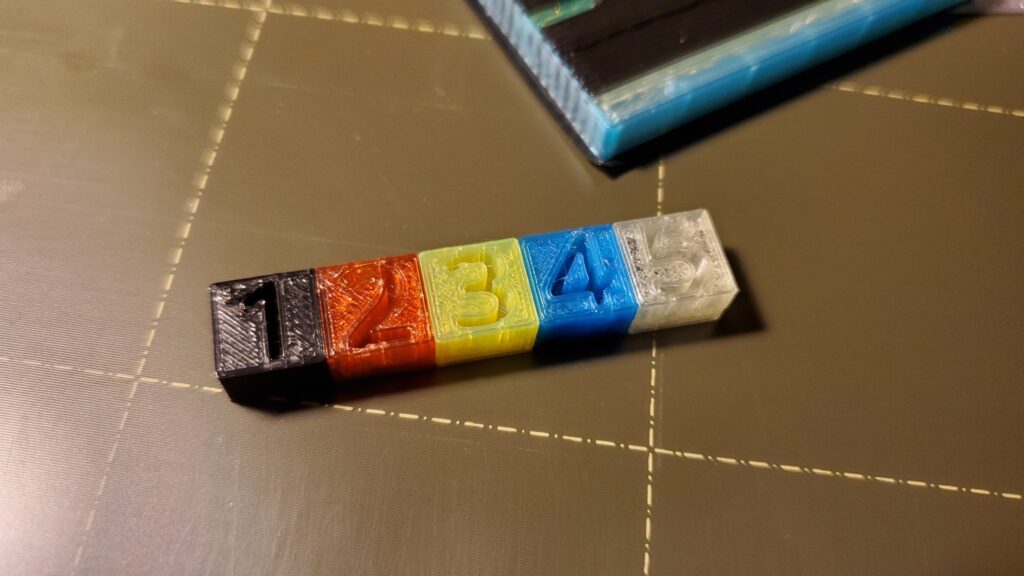

Per my previous post, here is my first success with the MMU2S. After the first few layers, tightening the spring loaded screws on the MMU a tiny bit was enough for all five filaments to insert and retract perfectly, with no more fiddling.

RE: Filament getting stuck in PTFE tube after every print or change of filament

Witajcie.

Miałem ten sam problem. Jest rozwiązany !!!.

Też winiłem siebie przez kilka tygodni, a problem był banalny i spowodowany przez .... nie wiem kogo.

Gdy już byłem bliski załamania i wyrzucenia MMU2S do kosza, natkęło mnie, by pomierzyć srednice rurek.

Rurki zamienne w sklepie PRUSA mają średnicę wewnętrzną 2 mm.

W moim zestawie miały 1,85 mm.

Po kilku mailach otrzymałem właściwe i problem znikął !!!.

Tak więc:

Rurka w hotendzie ma być 1,85 mm, wówczas zgrubienie na filamencie jest niewielkie i przechodzi dalej.

Rurka łącząca MK3S z MMU2S musi mieć srednicę wewnętrzną 2 mm (u mnie było 1,85 mm)

Rurki łączące MMU2S z buforem też mają mieć wewnątrz 2 mm ( u mnie było 1,85 mm).

Po wymianie wszystko działa wyśmienicie. 🙂

Okazuje się ,że mój problem nie był odosobniony.

Piszcie do suportu PRUSA, też powinni wymienić na właściwe.

Pozdrawiam.

Krzysztof

RE: Filament getting stuck in PTFE tube after every print or change of filament

@k-nowak-serby

Krzysztof,

I am happy to hear that 2mm inside diameter tubing fixed your MMU2S too!

[translate.google.com - Cieszę się, że rura o średnicy 2 mm naprawiła również twój MMU2S!]

-Carl

RE: Filament getting stuck in PTFE tube after every print or change of filament

Another sample showing the MMU2S working:

This print took about 48 hours. The filament is 'silk' style PLA, which is more brittle than regular PLA, and the extruder temperature was 220 C.

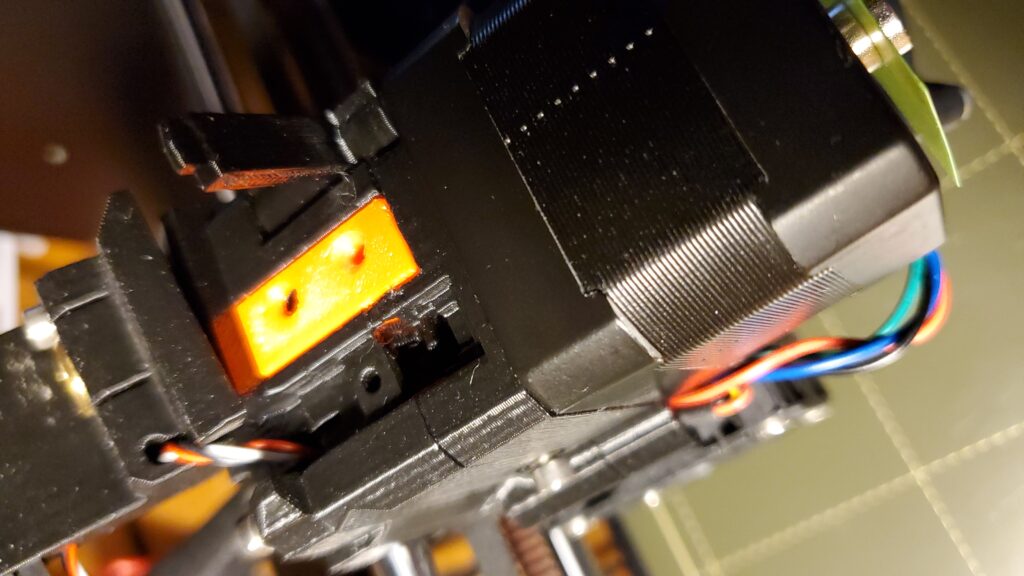

By the way, I had to put a countersink on the orange color part shown in the picture below, because sometimes the blue filament would get caught on the orange part: I had to slide the top part of the extruder all the way to the right side so that the IR sensor triggers when filament enters the extruder, but this made the hole in the orange part off-center when looking down into the extruder. Also, make sure the QSM-M5 fitting is tightened with the wrench.

RE: Filament getting stuck in PTFE tube after every print or change of filament

I see your wipe tower was substantial. Maybe you could try the Retractable Purge Mechanism on Thingiverse