Dual extruders or MMU

Sorry if this has been discussed previously

I looking at using some expensive filaments (NylonX or carbonyte plus straight nylon) so clearly the amount of waste in a wipe tower is a concern. So I understand the new MMU can use fill for the waste, so does it reduce the waste tower by much ( I know depends on the design) and second, might a dual extruder be a better solution, if that is possible?

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: Dual extruders or MMU

You'll get a lot of opinions about dual extruders vs. single extruder for multimaterial prints. They have their plusses and minuses, and the only thing really definitive thing you can say is that the dual extruder approach has been around for a long time and still has problems, while the single extruder approach is a lot newer.

Advantages of multiple extruders:

Disadvantages of multiple extruders:

Advantages of single extruders:

Disadvantages of single extruders:

Personally I prefer the single extruder approach. The couple of people I know who have multiple extruder printers eventually gave up on doing multi-color prints and just use them in single extruder mode, but I keep using my Palette+ despite the frustrations.

However, your mileage may vary. It sounds like the cost of the purge might be important to you, and it isn't important to me (PLA is cheap).

Re: Dual extruders or MMU

Thanks Peter - very comprehensive.

I guess I will wait to see how the new Prusa MMU works in regard to a smaller purge tower as it purges to infill.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: Dual extruders or MMU

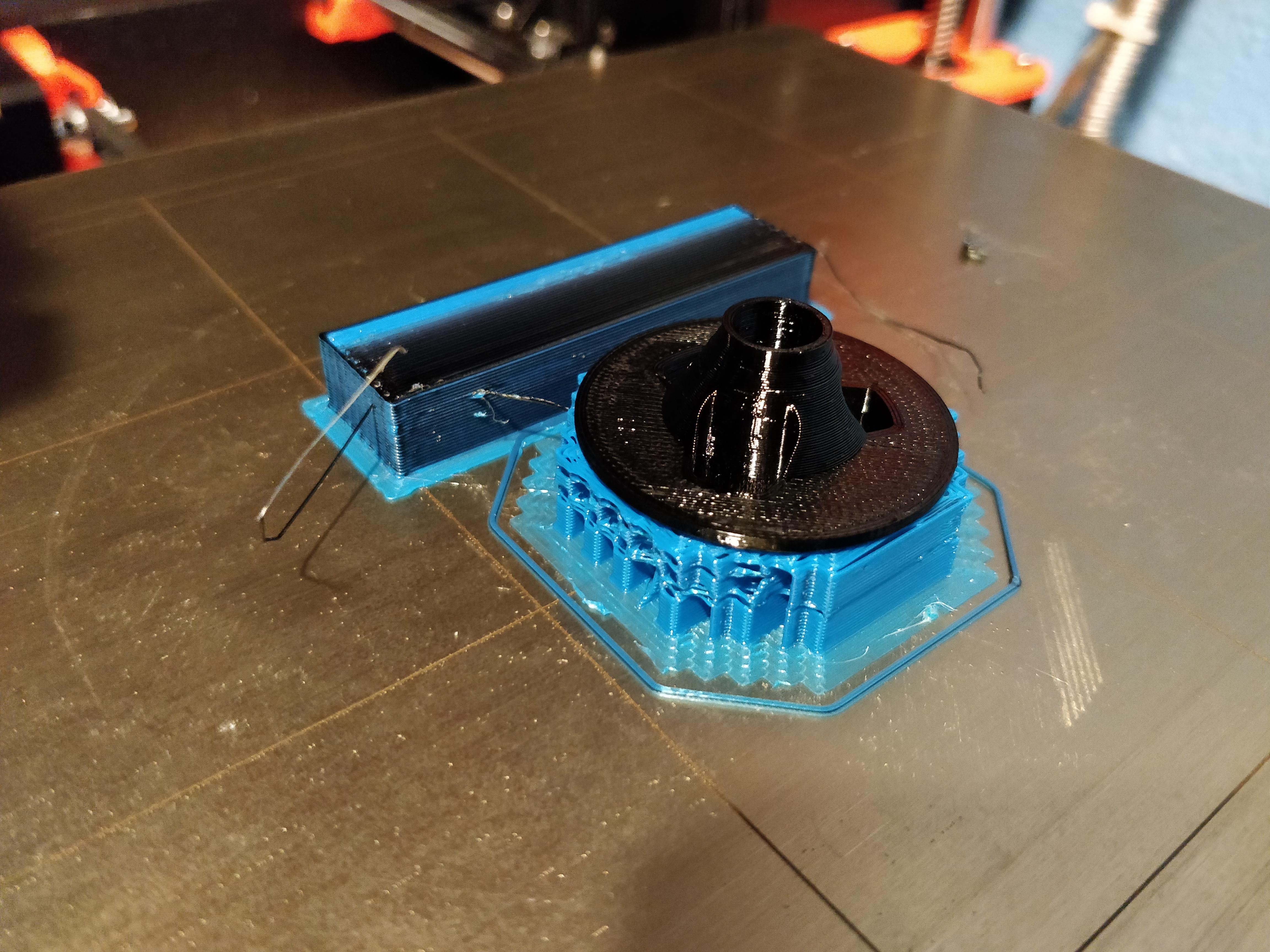

As someone who has been trying to get a custom dual-nozzle set up working for the last 6 months while waiting for the MMU to show up.. Yeah - you might as well see how you get with the MMU.

There are some clever devices for moving nozzles out of the way, but they are a real pain. I had the same reasoning - faster and less material waste.

So far, it's unreliable and drools, mixing colors or leaving holes where PVA later washes out.

It's really great for banging out something huge, or likely better than nothing for stuff you can't just print and remove supports, but I'm not yet sold.

The MMU has been a 3 day headache, but we're making progress.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Dual extruders or MMU

The MMU has been a 3 day headache, but we're making progress.

😆

From my experience, the headache lasts 1-2 weeks and then it's pretty good. I can't point to any one thing that I'm doing differently now than when I started, but my MMU has been getting steadily more reliable as I get more experience.

Re: Dual extruders or MMU

Peter: Thanks - that's what I'm hoping for. Believe you me, after this Chimera+/CR-10 build... I've certainly learned some patience.

I wish I knew someone with an Ultimaker so I could get a comparison.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Dual extruders or MMU

This is the single reason I'm looking at dual extruders:

Easier to print with different plastic types, especially plastics that print at different temperatures.

Thanks Peter for the good analysis. You've put it all in perspective.

I'm a practical printer/maker. I don't need the MMU2 . I don't have a need for multi colours, but I do have a need for printing different types of material.

Agree, the MK3 is not the machine for dual extruders (too small).

I love my MK3, had it for nearly 7 months and hardly a complaint and no failure (except wearable parts like the nozzle). Does the job!

Guess I have to go look else where for what I need.

Re: Dual extruders or MMU

It's not a total loss, using the changer. It IS slower, and it does waste material.

The temperature difference part I haven't noticed as much - I have had some minor layer adhesion issues which may be due to incomplete purging, but I'm not ready to blame that yet - some parts come out great.

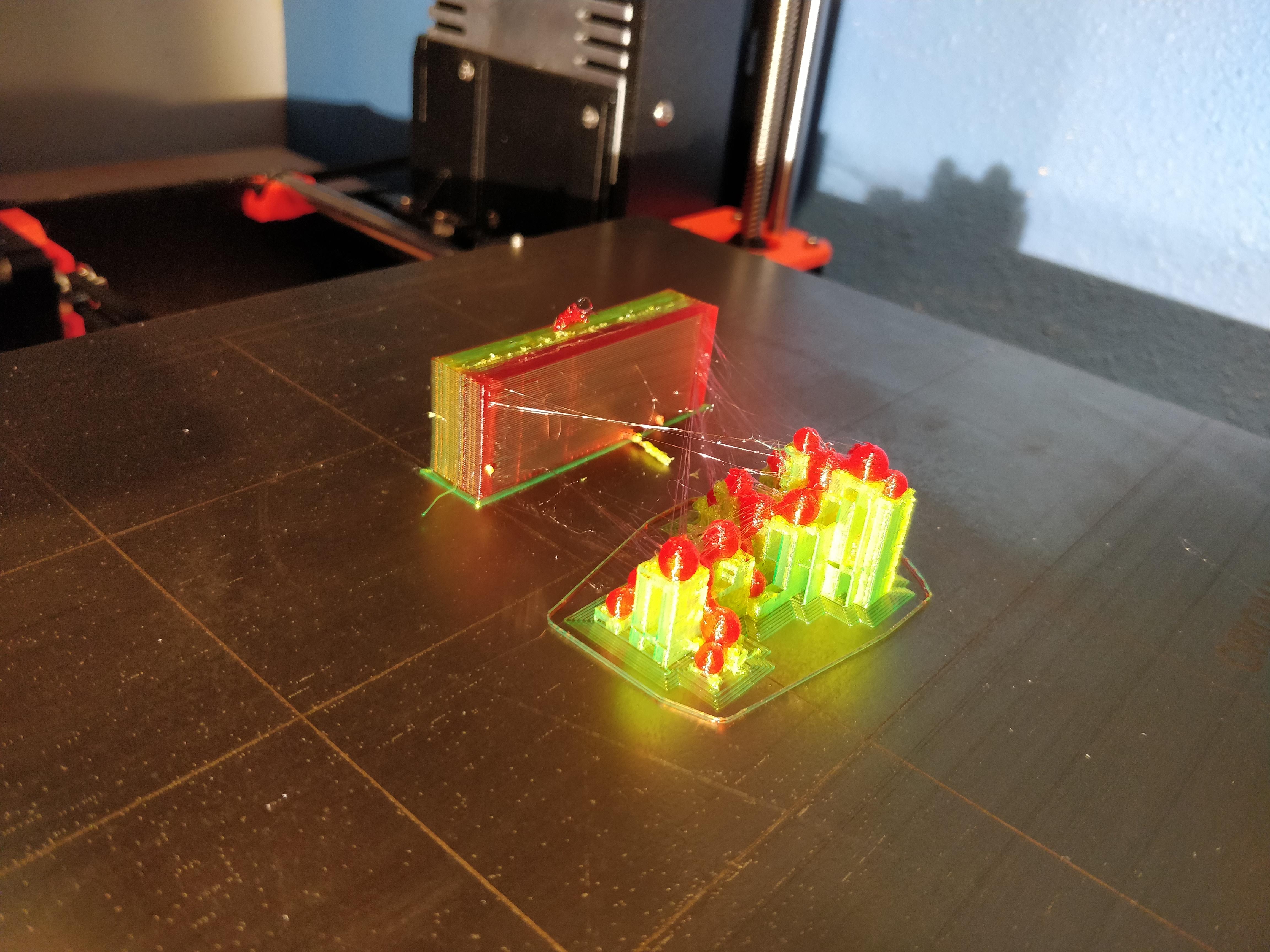

I have both styles of machine, and if you haven't used a dual nozzle yet, imagine you joy when your perfect part is filled with holes where the second head dribbled material down that was later dissolved away...

Getting the first extrusion looking good often takes a prime tower of its own, and that can fail....

There's no real silver bullet here - lifting the heads (a la UM), or an active nozzle cap would make it great. I feel the real answer is two independent heads. I've got about 8 months under my belt and I can say both approaches have massive issues.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Dual extruders or MMU

I've used multi-extruder printers for many years, with pretty good results. Some thoughts:

- The MMU2, when it works, provides much cleaner results. With multiple extruders, the "other" extruder drools plastic, plus stringing, leaving bits of the wrong color wiped around. It's very hard to get clean prints with multiple extruders for this reason.

- The best solution to the 'drooling' problem is to use a 'wipe shell' around the object, which tends to wipe off the other nozzle's drool so that it hits the object less. It's not perfect, and it uses a lot of extra filament, a bit like the wipe tower.

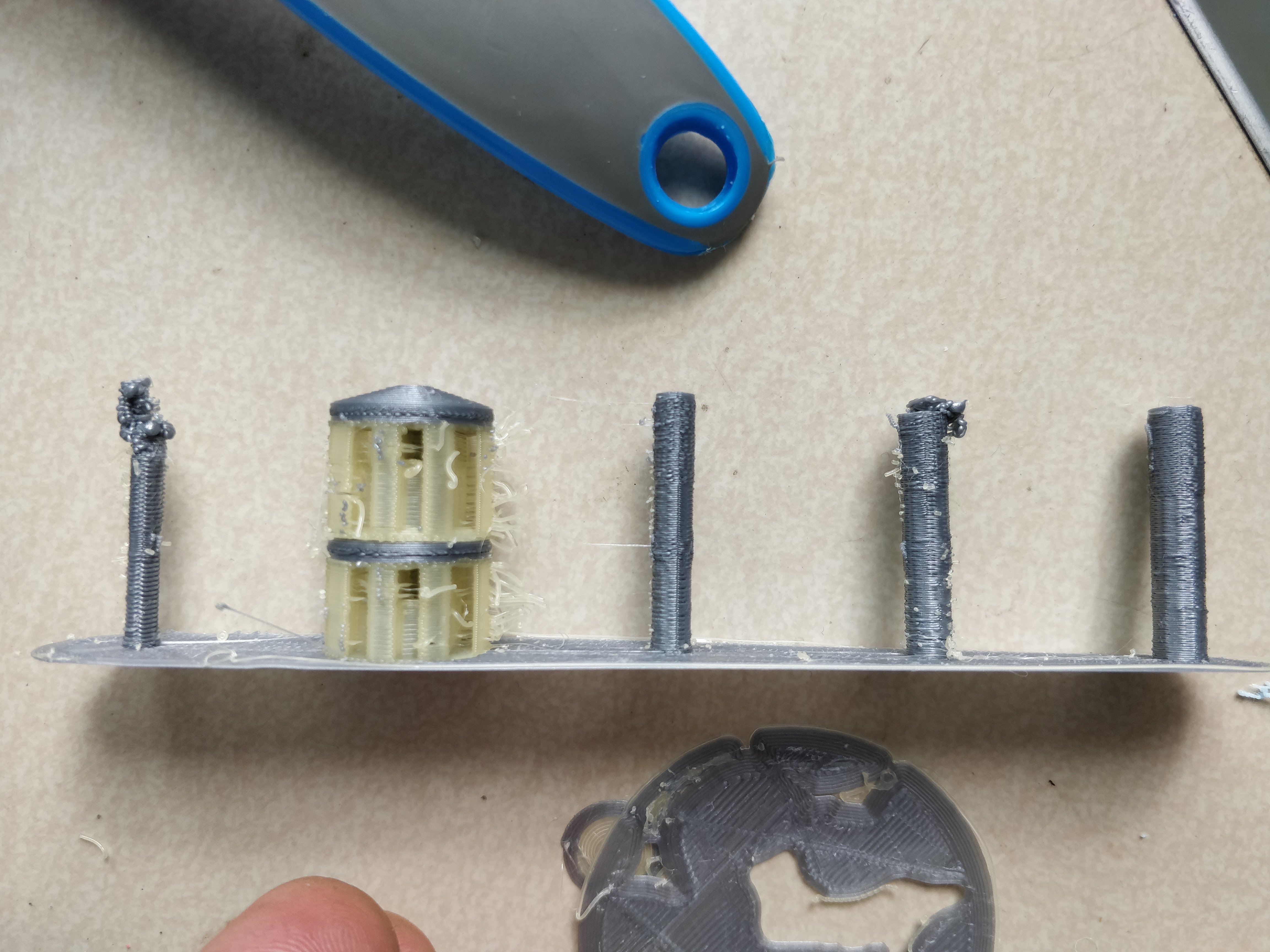

- Multiple extruders are much, much faster than exchanging filament in one extruder, because of the unloading/reloading multiple times per layer time saved.

- And you can extrude two different materials at two different temperatures easily. That's possible with one extruder, I think, but you'd have to work out varying temperature during filament changes, which I certainly haven't tried with the MMU2 yet.

- It's nice to have two extruders so that when one jams the other is working. Or if you have two different materials loaded you can print with either one, one at a time, which can be convenient compared to unloading/reloading a single extruder.

- Two extruders cost more than one. And five extruders (with 5 motors, etc.) to match the MMU2 would be both expensive and unwieldy. More extruders reduces print area, because the area that all the extruders can reach is smaller than one extruder, by the width/depth of the extruders.

- One nifty trick with multiple extruders (in Sailfish firmware) is that you can slice an object and print it with both extruders at the same time, allowing you to crank out twice as many of a narrow object (e.g. 33mm wide or less on my dual extruder printers) which is pretty specialized, but comes in handy when cranking out 3d printed give-aways at Maker Faires or school demo's and such.

Overall, I think the MMU2 will be great, once they get unloading/reloading reliable. It's slower, but produces superior results.

Re: Dual extruders or MMU

Are any printers using dual X axis? So that the other print head can move independent on the X axis, out of the way to stop drooling and scraping as well as being offset on demand so much you can print two large objects at the same time.

Re: Dual extruders or MMU

Mirar: https://www.lpfrg.com/en/benefits-of-independent-dual-extruders/

Not the first one I've seen, but the first thing I found on Google this morning. 🙂 I'm convinced this is the Right way to do dual extrusion, and everything else is a hack. You can get alignment issues this way, I bet. But I'd settle for that to get CLEAN prints.

Nicely put all the way around, I agree with you on all of it. I've never tried Sailfish (though I wondered about doing just that - printing two objects - but I like two independently translating extruders in concept)

- The MMU2, when it works, provides much cleaner results. With multiple extruders, the "other" extruder drools plastic, plus stringing, leaving bits of the wrong color wiped around. It's very hard to get clean prints with multiple extruders for this reason.

Totally. Totally. I have issues where PVA leaves holes in parts after being washed away.

- The best solution to the 'drooling' problem is to use a 'wipe shell' around the object, which tends to wipe off the other nozzle's drool so that it hits the object less. It's not perfect, and it uses a lot of extra filament, a bit like the wipe tower.

It might be the best solution, but it's not good enough. The Ultimaker guys have it right: Just get it tuned so it doesn't drool. I had NOTHING but issues and then after not touching it for a month (working on MMU) I fired it back up and everything is beautiful. I also found shells to fail occasionally, or one layer won't stick and it'll pull the line through the part.

- Multiple extruders are much, much faster than exchanging filament in one extruder, because of the unloading/reloading multiple times per layer time saved.

Mostly true - but if you use temperature to keep it from drooling, it does add some time during the swings. CURA is reasonable at handling it, but it can add time. Another spot independent heads would be great, you can preheat more without oozing.

- And you can extrude two different materials at two different temperatures easily. That's possible with one extruder, I think, but you'd have to work out varying temperature during filament changes, which I certainly haven't tried with the MMU2 yet.

It's not a problem. I print PLA and TPU and PET-g in the same print reasonably often. My biggest issue, I think, is underpurging - I'll get bad layer adhesion I can't track down, then I add more purge between material types and it fixes it. I don't THINK it's temperature but I'll admit I haven't looked into it carefully, I'm too distracted by things like the printer running at 1/3 speed most of the time.

- Two extruders cost more than one. And five extruders (with 5 motors, etc.) to match the MMU2 would be both expensive and unwieldy.

Certainly it gets worse as you need more colors. Having separate motors leaves you a firmware away from color mixing, for what it's worth.

Overall, I think the MMU2 will be great, once they get unloading/reloading reliable. It's slower, but produces superior results.

I agree with you!!! It's why it is so frustrating that issues aren't being fixed while there's so many people sharing issues and demonstrating functional low/no cost fixes. I'm trying not to be a negative Nelly here but like a month in and I'm starting to question the odds this is going to get better when most of the improvement come from independent developers.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: Dual extruders or MMU

Mirar: https://www.lpfrg.com/en/benefits-of-independent-dual-extruders/

Not the first one I've seen, but the first thing I found on Google this morning. 🙂 I'm convinced this is the Right way to do dual extrusion, and everything else is a hack. You can get alignment issues this way, I bet. But I'd settle for that to get CLEAN prints.

I really think it would be the way forward with dual material, to have dual carriages on the same X-axis. It doesn't even seem to be hard to do; flip the belt so it loops horizontal, add another belt and another extruder carriage...

I really want to do this now.

It could even have more than two. I could imagine three or four carriages on the same axis, but more than two starts to get hairy for orienting the motors and bearings.

...and nothing stops you from having one MMU2.0 per extruder. Other than that Slic3r PE needs a major clean up so there's a difference again between extruder and filament.