Re: Work in progress MMU2 Inland PLA profile

This script is not working correctly for me. It is not picking up all the temp changes and therefore restoring the wrong temp. I think it is because it only looks for temp changes while "idle" and the filament temp changes in the Gcode are happening during the "busy" state.

Can you attach your gcode file and the command line you used to run? I'll debug. I haven't had an issue, but my 'soak testing' consists of running my test structure and sheep. BTW, is your code sliced from Prusa Slic3r? For anything else, ymmv.

Re: Work in progress MMU2 Inland PLA profile

it won't let me attach the file

This is my command line and result:

cool_ram.py -nw -i 3C_Lizard_1_0.2mm_PLA_MK3MMU2.gcode

Traceback (most recent call last):

File "C:\Users\ckron\Documents\cool_ram.py", line 86, in <module>

for line in infile:

File "C:\Program Files (x86)\Python37-32\lib\encodings\cp1252.py", line 23, in decode

return codecs.charmap_decode(input,self.errors,decoding_table)[0]

UnicodeDecodeError: 'charmap' codec can't decode byte 0x8d in position 6657: character maps to <undefined>

Re: Work in progress MMU2 Inland PLA profile

Have you been using filament that all uses the same temp?

Re: Work in progress MMU2 Inland PLA profile

I think I managed to attach the file by renaming it as a jpg

Re: Work in progress MMU2 Inland PLA profile

now I don't see it

I uploaded them to Google Drive and here is a link:

https://drive.google.com/drive/folders/1rYM4fP6rIXiQCpm8TPO6ugZGLZYMG0-C?usp=sharing

Yes, I am using Prusa Slic3r

Re: Work in progress MMU2 Inland PLA profile

Have you been using filament that all uses the same temp?

Yes, I think that is the issue. You are getting a temp change during the tool change, and my script doesn't handle that case. I'll work on a fix, see if I can get your file to work.

BTW, I have no idea why you got the "UnicodeDecodeError: 'charmap' codec can't decode byte 0x8d in position 6657". I run the same file on my mac and have no issue. I can test it on an Ubuntu linux box as well, but I never run python on Windows.

Re: Work in progress MMU2 Inland PLA profile

Thank you for taking a look at it!!!

FYI, that temp change during the tool change is not a good spot for it. It changes the temp to the next filament right after the tool head arrives at the wipe block. A real problem when going from a 200 degree filament to a 235 degree filament.

I am testing a hand edited gcode file where I changed those to 180 and put the temp change where T(0-4) appears...so right before it switches filament. I think that makes it pretty much how you intended

We will see how that goes

I just added that file to the shared folder

Re: Work in progress MMU2 Inland PLA profile

Have you been using filament that all uses the same temp?

Yes, I think that is the issue. You are getting a temp change during the tool change, and my script doesn't handle that case. I'll work on a fix, see if I can get your file to work.

BTW, I have no idea why you got the "UnicodeDecodeError: 'charmap' codec can't decode byte 0x8d in position 6657". I run the same file on my mac and have no issue. I can test it on an Ubuntu linux box as well, but I never run python on Windows.

It was actually much simpler than that. The Slic3r code for normal temperature changes uses the line:

"M104 S205 ; set extruder temp"

The temperature change during the tool change just uses:

"M104 S215"

No space, no comment. It turns out my regex pattern had a space after the temperature, which matched the space before the semicolon, but didn't match if there was no space.

Fixed, pushed to github if you want to test it.

Re: Work in progress MMU2 Inland PLA profile

OK, that picked up all the temp changes. However, it cut off the end of the file

I uploaded it to the shared folder

Re: Work in progress MMU2 Inland PLA profile

OK, that picked up all the temp changes. However, it cut off the end of the file

I uploaded it to the shared folder

Chris, let's take this discussion to the dedicated thread for my script, so we stop driving the inland PLA profile post off-topic.

I'll look at it and follow up here:

Re: Work in progress MMU2 Inland PLA profile

no worries.... just making it seem as though everyone loves inland.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Work in progress MMU2 Inland PLA profile

no worries.... just making it seem as though everyone loves inland.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

RE: Work in progress MMU2 Inland PLA profile

Just checking to see if there is an updated "great" profile for Inland PLA. I'm having great results on the Black, Blue, & Green but Orange seems to string in the tip more than any of them. I see the last update to this is like 9.5 months ago so thought I'd check for any updates...

RE: Work in progress MMU2 Inland PLA profile

Hello, has anyone done any optimization for Inland PLA+ filament?

I’ve had trouble printing with the MMU and I’m thinking the default settings might not be optimal for this filament.

thx,

Larry

RE: Work in progress MMU2 Inland PLA profile

I guess I'm an odd ball, but the standard Prusament profile works just fine for me with Inland's PLA and PLA+.

In my experience Inland is one of those brands (Amazon/Overture is another I've used) that is on the rough and stiff side. This exacerbates any friction issues you might have in the filament path. Also getting the idler door on the extruder tuned just right makes a big difference too.

RE: Work in progress MMU2 Inland PLA profile

I am using Inland PLA+ without any changes to the advanced tab settings in Prusa slicer, I get ok tips. Not a lot of strings but it's there. It's thick strings. I am getting unloading problems because the filament inside the MMU2S is getting grinded at. Only when unloading. Loading is all fine. Why would it grind up the filament if loading is fine?

RE: Work in progress MMU2 Inland PLA profile

I guess I'm an odd ball, but the standard Prusament profile works just fine for me with Inland's PLA and PLA+.

In my experience Inland is one of those brands (Amazon/Overture is another I've used) that is on the rough and stiff side. This exacerbates any friction issues you might have in the filament path. Also getting the idler door on the extruder tuned just right makes a big difference too.

So after getting a food dehydrator for my filament I have found that my stiff/rough issues with both Inland and Amazon/Overture had to do with age and/or moisture. After running filaments through the dehydrator that I had given up using with the MMU, they are all perfectly happy again.

I've been printing exclusively with Inland PLA and PLA+ for almost 3 months now and it hasn't given me a lick of trouble either as a single or multi-tool print. Just default Prusament PLA settings.

RE: Work in progress MMU2 Inland PLA profile

I am using Inland PLA+ without any changes to the advanced tab settings in Prusa slicer, I get ok tips. Not a lot of strings but it's there. It's thick strings. I am getting unloading problems because the filament inside the MMU2S is getting grinded at. Only when unloading. Loading is all fine. Why would it grind up the filament if loading is fine?

The most likely/usual cause is that the tips are on the larger side and aren't allowing the filament to move freely back up the filament path. If this is the case, it's probably that your hotend PTFE is not seated correctly.

The other option is that something in the filament path is binding up during retraction, but isn't an issue during load. Typically I've seen then when there is too much play in the PTFE tubes between the MMU and buffer/spools and they move around during the unload process. The fix for this is making your tubes as straight as possible with any curves being as gentle as possible. Trimming the tubes to remove any excess is also helpful as is using a couple of PTFE holders (something like https://www.thingiverse.com/thing:3690086 (haven't used that one, just the first that came up)).

Given your mention of stringing I think the later case might be your issue as the string forms before it would run into issues due to a fat tip.

RE: Work in progress MMU2 Inland PLA profile

@gnat

Can you post some info about your food Dehydrator? It might help fix my consistency issues. I use Inland Pla as well.

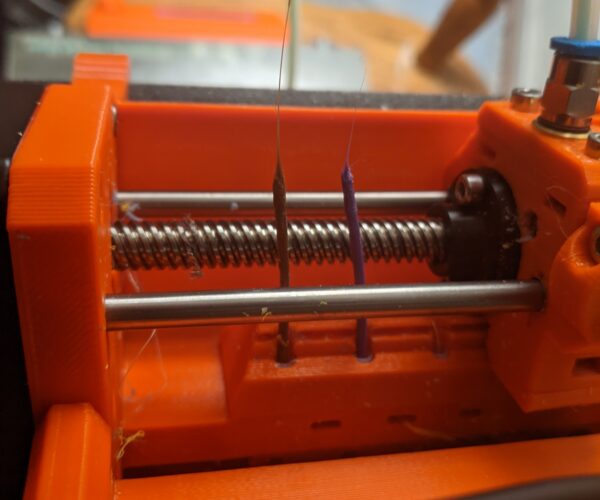

The print hasn't finished yet but I can see the brown and purple filaments failed a few times. The hand book says I should check if the IR sensor is calibrated and it has been. The handbook also says the nozzle is clogged. However if this is true, I believe the other colors would fail at the same layer as well. I have concluded that the filament is getting stuck around the bondtech gears. I want to try using the food hydrator to dry the filaments and see what happens.

There isn't a big difference in the tips for the 3 filaments that worked and the 2 that didn't

The profile I use is above

RE: Work in progress MMU2 Inland PLA profile

@raizetto

It's a Cosori, but I don't have the model handy. It has digital controls and stackable trays. Just cut the centers out of the trays and you can get 2 1kg spools in at once. I set it to 120f for both PLA and PETG and turn it on for 24 hours at a time, though 4-8 hours seems to be all that is really needed.