Re: Work in progress MMU2 Inland PLA profile

I have seen some of your settings on other posts. Is there a screen shot some where I can copy them down? I would love to give them a try.

Unfortunately not. I use modified MMU firmware and highly customised load/unload and all that is within KISS 🙁 My suggestions for Slic3r are simply based on what the MMU firmware does and (rather surprisingly) settings from MMU1.

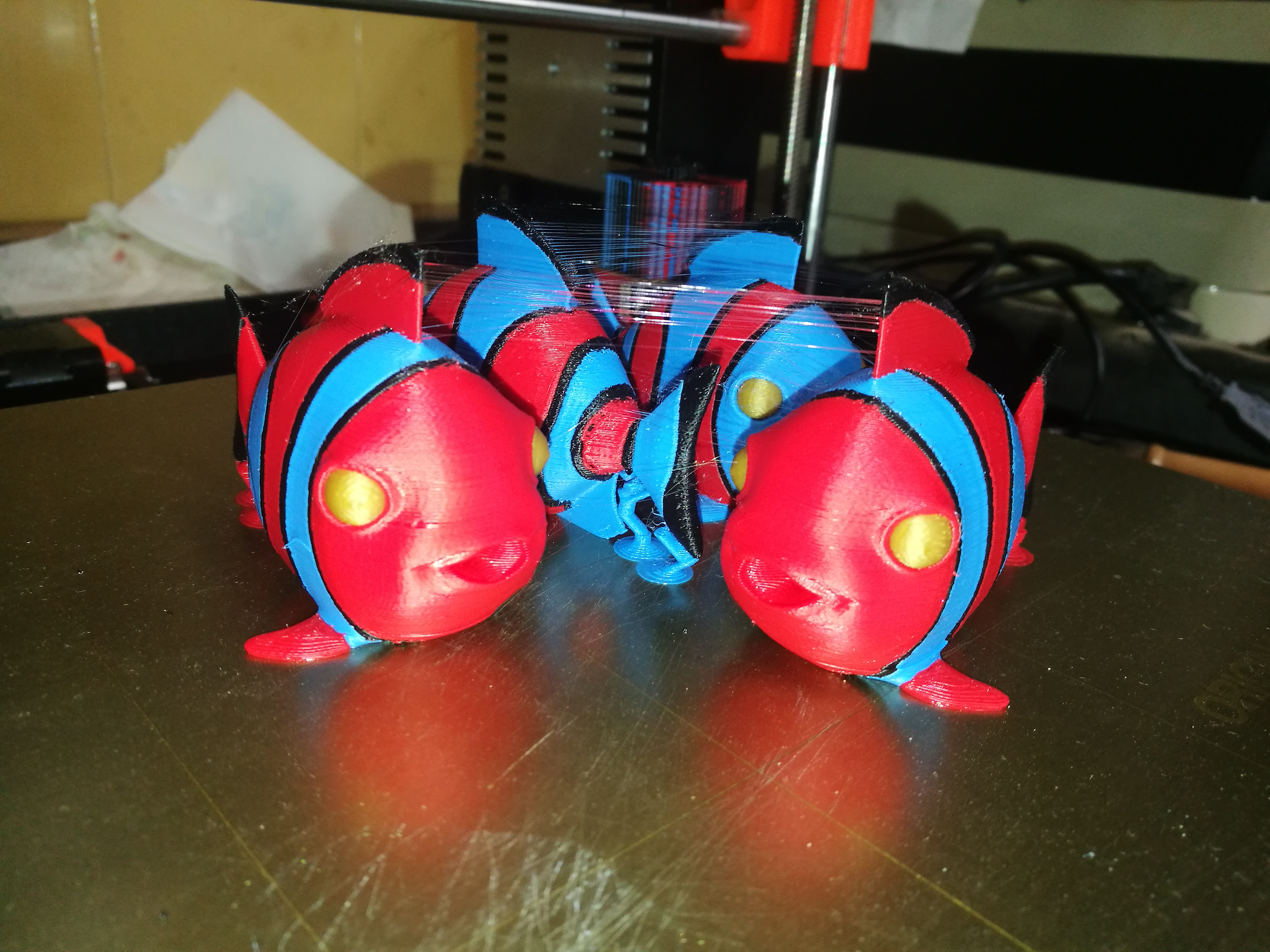

Anyway, I printed some 4C clown fish; there was a layer shift at about Z=2 which was entirely my fault (speed too high and insufficient Z-lift):

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Work in progress MMU2 Inland PLA profile

No worries, I have gleaned some settings from different locations and I am starting to get good results. I will post them up later today.

Re: Work in progress MMU2 Inland PLA profile

Here are the settings I am currently using for PLA printing at 205. I am using a couple of different kinds, Inland, Matterhackers, Prusa, at this point they are all working the same. I had to line one of my extruder gears up a little better and sort them all smallest to largest, but things are looking much better.

Re: Work in progress MMU2 Inland PLA profile

chris.r16

I cant see your pics.... What ramming settings did you settle on?

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Work in progress MMU2 Inland PLA profile

Here are the settings I am currently using for PLA printing at 205. I am using a couple of different kinds, Inland, Matterhackers, Prusa, at this point they are all working the same. I had to line one of my extruder gears up a little better and sort them all smallest to largest, but things are looking much better.

https://lh3.googleusercontent.com

Those lh3.googleusercontent.com links don't work for me either. Try imgur? Or work on the permission settings for your google content?

Re: Work in progress MMU2 Inland PLA profile

Sorry about that, it should be fixed now.

Re: Work in progress MMU2 Inland PLA profile

Those lh3.googleusercontent.com links don't work for me either. Try imgur? Or work on the permission settings for your google content?

It is always better to attach your images directly to your post. That way they are always there for all to see.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Work in progress MMU2 Inland PLA profile

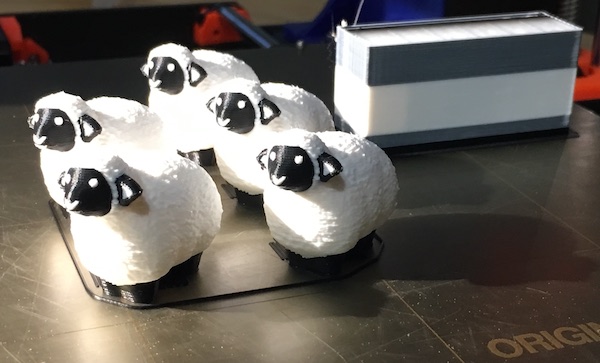

Five perfect baby sheep (50%). Standard Inland PLA, black and white, fresh rolls.

205C (first) 200C (layer 2+), drop temp to 195 before RAM, generic PLA ram/load/unload settings.

Trying other colors this weekend, as well as a few rolls of Inland PLA+

Re: Work in progress MMU2 Inland PLA profile

Purge settings on the black were too low, but at least it completed no layer skips.

Chris Warkocki's profile from facebook.......best success so far

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Work in progress MMU2 Inland PLA profile

Five perfect baby sheep (50%). Standard Inland PLA, black and white, fresh rolls.

205C (first) 200C (layer 2+), drop temp to 195 before RAM, generic PLA ram/load/unload settings.

IMG_2052 2.JPG

Trying other colors this weekend, as well as a few rolls of Inland PLA+

IMG_2050.JPG

junkie 😀

I have a Prusa,therefore I research.

Re: Work in progress MMU2 Inland PLA profile

junkie 😀

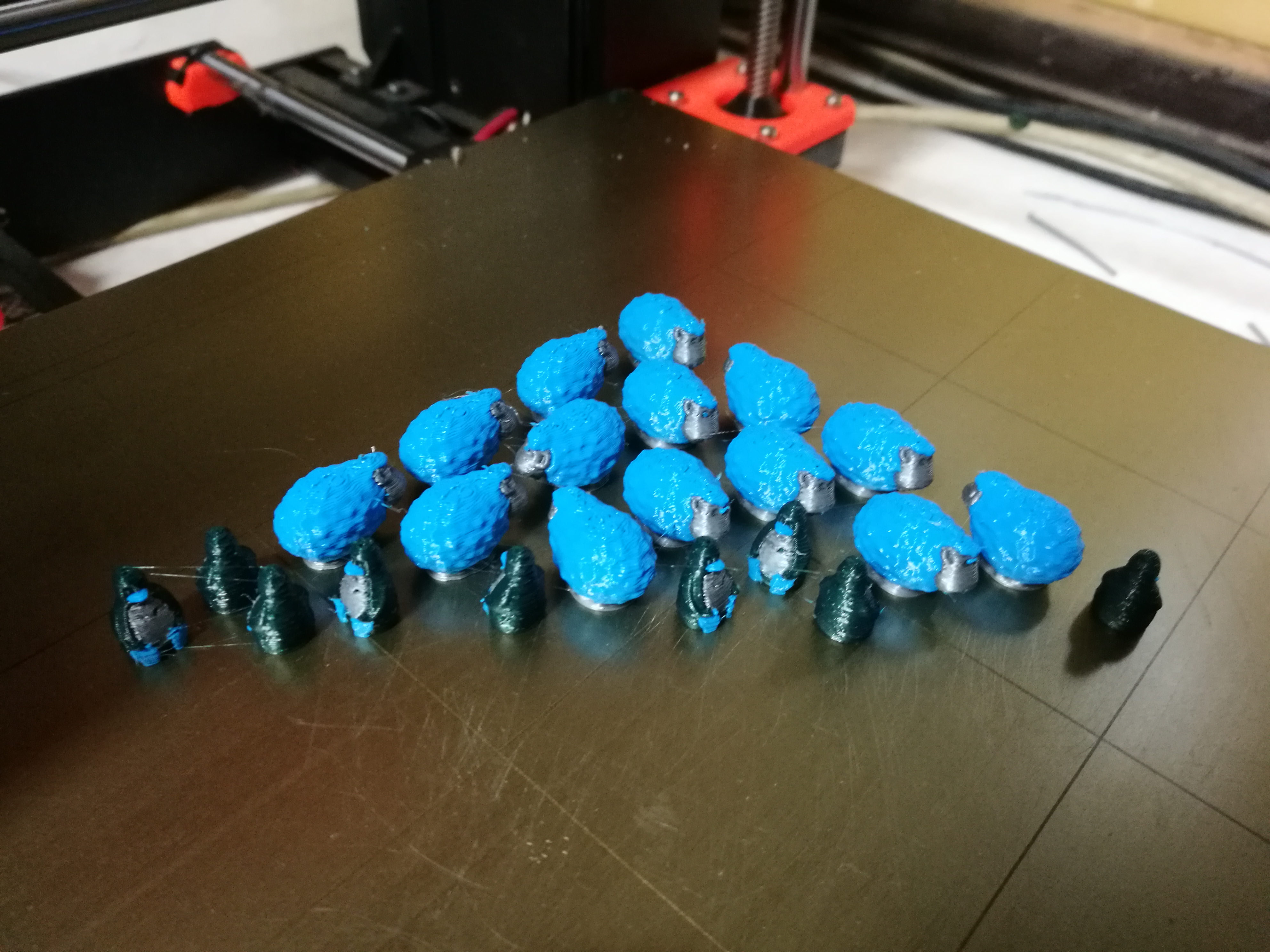

During beta-testing, we were challenged to print some sheep and penguins. But the size of them was not specified:

🙂

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Work in progress MMU2 Inland PLA profile

For others looking for Inland PLA settings, I am currently having luck with:

- 205 first layer, 200C other layers

- Generic PLA load/unload except 4 second ram, and 140 mm/s starting unload speed.

- post-processed with the new "no wait" that basically cuts power completely to the nozzle and then rams

(cool_ram.py -nw -i input.gcode)

Re: Work in progress MMU2 Inland PLA profile

@PJR

Your herd of successful sheep is far more impressive compared to mine.

@Paul.m27

Since PJR is able to lower temps b4 ramming in his slicing software and your script accomplishes the same I hope its added to Slic3r.

As for as Inland PLA MMU settings.....

Chris Warkocki's profile produces far better tips then what I was able to come with.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Work in progress MMU2 Inland PLA profile

I'm digging into Chris Warkocki's profile. Diffing "MMU2 Pretty PLA V1.2" and comparing it to a (I think) stock Prusa Generic PLA profile, the changes I see that seem MMU2 load/unload/tip-shape related:

- 2 cooling moves (instead of 1)

- loading start/loading 19/21 (vs 3/14)

- unload_start 110 (vs 100)

- retract_before_wipe 5% (0%)

Changes that seem more generic mk3 related (but might have an affect(?)):

- first layer width 0.45 (vs 0.42)

- infill accel 1200 (vs 1250)

- infill speed 120 (vs 200)

- machine_max_accel 5000,8000 (vs 8000,8000)

- machine_max_jerk_e 2,1.5 (vs 1.5,1.5)

- overhangs 1 (vs 0)

- retract_before_travel 2 (1)

- retract_speed 30 (35)

- seam_position aligned (nearest)

- solid_infill_speed 120 (200)

There was also a change to the start_gcode, but that looked like just a time optimization.

That seems pretty close to the Generic PLA. 2 cooling moves, slightly faster unload, much faster load, retract before wipe.

The faster load is the one I find most intriguing. I have not played with that yet.

Re: Work in progress MMU2 Inland PLA profile

The faster load is the one I find most intriguing. I have not played with that yet.

That's the one I came up with a while back and it's posted here (somewhere). It is designed to match the MMU firmware load speed. I think it needs to be 19.25mm/s for a slightly better match.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Work in progress MMU2 Inland PLA profile

The faster load is the one I find most intriguing. I have not played with that yet.

That's the one I came up with a while back and it's posted here (somewhere). It is designed to match the MMU firmware load speed. I think it needs to be 19.25mm/s for a slightly better match.

Peter

I dont really spend that much time on facebook, but I heard good things about Chris Warkocki's profile. Anyway I just wanted to mention that Chris gives you (PJR) credit:

https://www.facebook.com/groups/prusacommunity/permalink/857964411210959/

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Work in progress MMU2 Inland PLA profile

Anyway I just wanted to mention that Chris gives you (PJR) credit

That's nice; thanks for that. Chris is a great guy and we have had some decent chats during beta-testing. He tinkers with hardware and I do the same with the firmware, so it's a good combination 🙂

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Work in progress MMU2 Inland PLA profile

I have seen some of your settings on other posts. Is there a screen shot some where I can copy them down? I would love to give them a try.

Unfortunately not. I use modified MMU firmware and highly customised load/unload and all that is within KISS 🙁 My suggestions for Slic3r are simply based on what the MMU firmware does and (rather surprisingly) settings from MMU1.

Anyway, I printed some 4C clown fish; there was a layer shift at about Z=2 which was entirely my fault (speed too high and insufficient Z-lift):

Peter

Finally. The 1's with layer 1 skip are especially painful.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: Work in progress MMU2 Inland PLA profile

So far I am finding that 5 degrees in either direction and increasing ramming time has made a lot of difference for me.

Hatchbox Black - I lowered temp

Solutech Glow in the Dark I raised temp and increased ram time to 4

Inland purple+ and pink+ - used Chris's Pretty profile

Prusa Sliver - using Prusa profile

Maker Geeks yellow - Generic PLA profile with temp at 230

Re: Work in progress MMU2 Inland PLA profile

This script is not working correctly for me. It is not picking up all the temp changes and therefore restoring the wrong temp. I think it is because it only looks for temp changes while "idle" and the filament temp changes in the Gcode are happening during the "busy" state.

snippet from my processed Gcode:

G1 E-14.0000 F1200

G1 E-4.0000 F600

G1 E-2.0000 F360

M104 S215

G1 Y148.680

G1 X170.750 E10.0000 F692

M73 Q0 S191

G1 X227.543 E-10.0000 F346

M73 P0 R190

G1 E-50.0000 F2000

G1 Y148.760 F2400

G4 S0

M104 S200 ; restore temperature

T1

M220 S100

G4 S0

; CP TOOLCHANGE LOAD

For others looking for Inland PLA settings, I am currently having luck with:

- 205 first layer, 200C other layers

- Generic PLA load/unload except 4 second ram, and 140 mm/s starting unload speed.

- post-processed with the new "no wait" that basically cuts power completely to the nozzle and then rams

(cool_ram.py -nw -i input.gcode)