What are all the parameters that control tip thickness?

It seems like no matter what I do, every 1-20 filament swaps gives me a tip that's too thick and gets stuck in the PTFE tube!

First, I'm using the MMU2.0 on a MK2.5. I read in another topic that the heatbreak on the MK3 has as different diameter, so maybe that's contributing to my woes?

Other than that, I've adjusted the temperature between 190-210C, I've changed the ramming time between 2.5-3.5s, and I've changed the number of cooling moves from 1-3. All of them inevitably resulted in thick tips.

Does anyone have any other suggestions on what I could tweak?

Re: What are all the parameters that control tip thickness?

is the filament backing out fast enough during ramming and backup?

I am 100% default prusa pla settings. (using inland pla)

I can say I am 100% defaults for everything.

I have a Prusa,therefore I research.

Re: What are all the parameters that control tip thickness?

It seems like no matter what I do, every 1-20 filament swaps gives me a tip that's too thick and gets stuck in the PTFE tube!

First, I'm using the MMU2.0 on a MK2.5. I read in another topic that the heatbreak on the MK3 has as different diameter, so maybe that's contributing to my woes?

Other than that, I've adjusted the temperature between 190-210C, I've changed the ramming time between 2.5-3.5s, and I've changed the number of cooling moves from 1-3. All of them inevitably resulted in thick tips.

Does anyone have any other suggestions on what I could tweak?

Mine is MK2.5 + MMU 2.0 also and having the same issue on filament tips. Please look for my post Filament tip problem. This coming Monday my MK3/Multimaterial heatbreak will arrive and I’m going to see if the culprit is the heat break. I suspect the issue with our MK2.5+MMU2.0 is the heat break that’s why no matter we adjust the parameters it still having the same issue. MK2.5 uses the original MK2 heat break while MK3 uses different ones. MK3 inner diameter is wider than MK2 heat break.

I will update on my post the result once I manage to replace my heatbreak.

Re: What are all the parameters that control tip thickness?

I spoke to Prusa support, and they said that the heatbreak didn't make a difference, and to increase the cooling moves by 2-3.

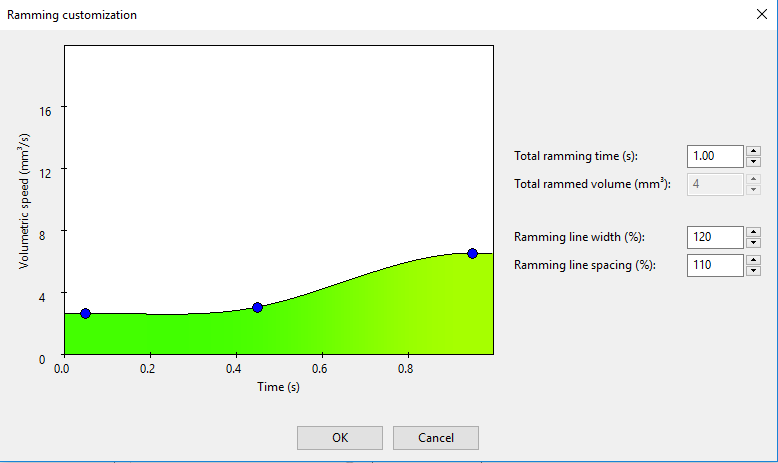

Increasing cooling moves to 4 helped, but ultimately, what sealed the deal was decreasing ramming to 1s and increasing the volumetric speed at 1s to ~6mm^3/s.

This is 464 tool changes, zero user interventions, one layer skip:

Re: What are all the parameters that control tip thickness?

doesn't the one skipped layer just make a sad panda? a shame they wont just allow us to turn on the filament sensor.

I have a Prusa,therefore I research.

Re: What are all the parameters that control tip thickness?

This is 464 tool changes, zero user interventions, one layer skip:

That's a lot of support there.I usually only place support up to the chin.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: What are all the parameters that control tip thickness?

Yeah, it was a suboptimal print for a number of reasons, incuding the Cheshire's cat nasty teeth - but it's nice to know that the MMU2.0 can work with the MK2.5 after all!

Re: What are all the parameters that control tip thickness?

Hi Albert,

At the moment I'm like "too nice to be true..." 😉

Before I start testing on my own towards your figures - how's the situation with the hairs?

I rarely had (not saying never thought!) an issue with too thick tips, it was mostly hairs that were pulled out of the tips. They then either jammed the selector or the new filament going down the tube...

Looking forward to your experiences! 🙂

Cheers,

Daniel

Re: What are all the parameters that control tip thickness?

When I did the settings for Colorfabb XT I just experimented with everything, trying 5 (I have 5 XT filaments) at a time in different directions for maybe 50 different settings until I was satisfied. I still don't understand what they do completely.

Is that PLA? Want to share a screenshot of the settings?

Re: What are all the parameters that control tip thickness?

I think Prusa gave us the tools but not the way how they work.

An official guide /tutorial explaining different slicer setting for filament tip formation is needed.

Yes, different filament behave differently, it is difficult to give detailed . But please at least give us principles and directions to work on.

People are just testing and doing experiment randomly at the moment.

Re: What are all the parameters that control tip thickness?

I know I am. But then again, I also feel quite successful with iterative randomness. 😀

Re: What are all the parameters that control tip thickness?

I spoke to Prusa support, and they said that the heatbreak didn't make a difference, and to increase the cooling moves by 2-3.

Increasing cooling moves to 4 helped, but ultimately, what sealed the deal was decreasing ramming to 1s and increasing the volumetric speed at 1s to ~6mm^3/s.

This is 464 tool changes, zero user interventions, one layer skip:

WhatsApp Image 2018-12-06 at 7.03.27 PM.jpeg

Can you please share a screenshot of your config for the ramming?

Re: What are all the parameters that control tip thickness?

So, my saga took a bit of a turn:

I had a heatbreak jam that required disassembly to clear, and after that, I kept getting jam after jam. I spoke to Prusa support again, and a different rep told me that the heatbreak did indeed matter. I did get five successful prints with the MK2 heatbreak, so I'm sure it is possible to get it to work - but I needed 5 cooling moves, 190C printing temp, and very little ramming.

For those asking, here are my ramming settings when I was still using the MK2 Heatbreak, but I could no longer get it to work after my jamming issue:

However, when I switched to the MK3 heatbreak, the default profile started working. I'm still 0 for 3 on the MK3 heatbreak, but the problems have nothing to do with tip shape - they've been flawless.

Re: What are all the parameters that control tip thickness?

Did you have the menu 1 or just the mk2s? I know I had a different heartbreak from MMU1 so wondering if that is also another factor I have to figure out.

Re: What are all the parameters that control tip thickness?

Just the MK2S - I never had the MMU1.0, so I only had the MK2S heatbreak.

Re: What are all the parameters that control tip thickness?

Mine also. After replacing my original MK2S heat break to MK3, all my problems were gone and running flawless. Before I installed the MK3 heat break, I compared it with my old one. Those jamming filament tips can go through the hole of MK3 heat break.

Here is my why-why analysis:

Why MMU jamming & layer skipping? --> Filament can't be inserted back to the extruder.

Why filament can't be inserted back to the extruder --> Extruder can't accommodate the enlarged filament tip.

Why extruder can't accommodate the enlarged filament tip. --> Heat break hole of the extruder is small

Why the heat break hole of the extruder is small --> Wrong heat break

Why wrong heat break --> MK3 heat break not included in MK2.5+MMU2.0 upgrade kit.

Why MK3 heat break not included in MK2.5 upgrade kit --> probably PR missed out during design of MK2.5+MMU2.0.

Re: What are all the parameters that control tip thickness?

I had similar success after I changed to the mk3 heat break

I still needed to tweak a few things but the filament no longer got stuck during unload

Re: What are all the parameters that control tip thickness?

I spoke to Prusa support, and they said that the heatbreak didn't make a difference, and to increase the cooling moves by 2-3.

Increasing cooling moves to 4 helped, but ultimately, what sealed the deal was decreasing ramming to 1s and increasing the volumetric speed at 1s to ~6mm^3/s.

This is 464 tool changes, zero user interventions, one layer skip:

WhatsApp Image 2018-12-06 at 7.03.27 PM.jpeg

Man, I think your settings will save my life 😀

Seems to be working!

RE: What are all the parameters that control tip thickness?

Hello,

I upgraded from the MK2S to MK2.5S and then MMU2S. I was getting tips that were too fat/thick and constantly grinding gears at the extruder. I tried all sorts of cooling move variations, volumetric speed changes, etc to no avail. I tried replacing the PTFE tube in the extruder, confirming it was the narrower 1.85mm one, but it'd get stretched out over time to 2mm. The fat tips would come back.

The fix that worked for me was removing the MK2s heartbreak and changing it to the MK3/S, MK2.5/S, MMU2S heatbreak. This new heatbreak is narrower at the nozzle end and wider at the top filament intake end. This results in narrower filament tips and easier insertions.

With this change I went from fat tips and gear grinding at the extruder every few tool changes to multiple days of tool changes (100s of them) without a single jam; I'm printing with various colored Hatchbox PLA with default Prusament PLA MMU2 settings in the slicer.

I'd argue this new heatbreak should be part of the MMU2S upgrade kit or be part of the MK2.5S upgrade kit. I don't see how the MMU2S can print reliably without it.