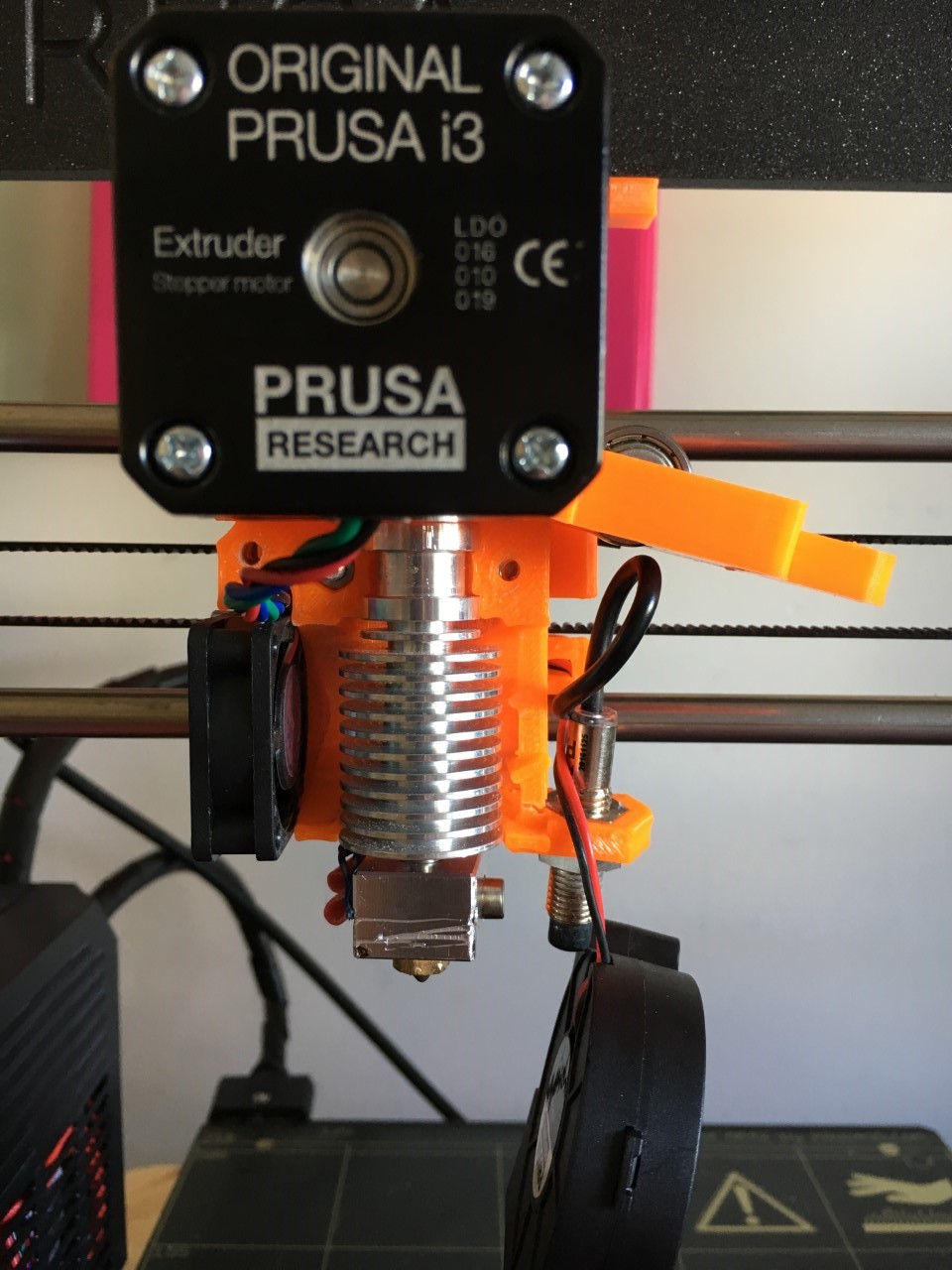

skip layer problems forcing me to shelve my MMU2.0 unit for now

With time and tweaking, I've seen some great results from my MMU2.0.

Prints <20mm of height often complete perfectly without user intervention.

I can also now regularly get long (20-30 hour) 5 color prints to complete successfully.

But, these prints look terrible and are sometime structurally flawed due to skipped layers.

For instance, I've never made it through a 5 color benchy without having at least 3 skipped layer events.

In each event, one color will stop printing for a handful of layers (3-5). The filament makes it past FINDA (or there would be a load error), but does not engage in the primary extruder's gear and is thus never inserted down to the hot end during the filament change.

I've spent countless hours and many kg of filament trying to find a solution to no avail.

The skipped layers do not correlate to a certain filament brand or color within a brand.

They do not correlate to specific filament feed positions (have had errors on all 5).

The feed lengths were calibrated individually (multiple times) and appear correct when tested.

Changing MMU tension does not seem to help (tried 5 different values set with a torque wrench)

My best guess is that things sometimes end up on the wrong end of a tolerance stackup between a hobbed gear and diameter of the filament it is feeding. The problem with this explanation is that the issue always resolves and feeds correctly again after a few layers.

After all of my experiments, I now believe that the MMU will never be reliable enough to work correctly across many hundreds of filament changes as long as the MMU has to make assumptions/guess about the position/state of the filament at the other end of the tube.

The annoying thing to me as an engineer is that this (and many other problems I previously experienced and still read about others having on these forums) would have been easy to prevent through design.

Put simply, the MMU2.0 should have been a two part unit. The existing unit is fine and does a pretty good job of multiplexing filaments into a tube. But, there should have been a small second component of the MMU at the other end of the tube, right above the primary extruder.

This missing second half desperately needed a filament sensor and could perhaps have been the right place to put a tip cutter. Knowing the filament state at both ends of the tube could have prevented a great many of the problems people have/are experiencing. Being able to cut bad tips before trying to pull them back up the tube would have made the system a lot less sensitive to materials and their quality.

I still hold out hope that PR will eventually find a way to solve this problem. They could make the existing filament sensor data (assuming it can be made reliable enough) available to the MMU for load/unload operations. They could also introduce another version of the filament sensor cover that incorporates an additional sensor (2nd FINDA?) with a cable going directly to the MMU (would avoid the firmware communication, but add cost).

Until that time, I must unfortunately shelve my MMU2.0 as I cannot afford to sink any more time or resources into solving a fundamental design problem that is unsolvable by the end user.

I will also keep recommending that even enthusiast avoid the MMU2 as it is unable to give them anywhere near the experience they have received from their i3 MK3.

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

This firmware enables the MK3 filament sensor for exactly the reasons you described:

https://github.com/TheZeroBeast/MM-control-01/

This will prevent skipped layers, but it's still better to solve any physical issues that might be causing it, so you don't wake up and find the print has been paused all night long due to a failed load.

To solve the physical issue, we need to know exactly what happens when it fails - where is it getting stuck? And having this firmware will make it easier to catch that, because it will pause the print instead of continuing blissfully unaware.

In my case it was the idler had a bit too much friction due to a burr of plastic that was rubbing against the idler body. Once I fixed that, I've been running 30+ hour prints with 0 load/unload issues, no pauses, no manual intervention required, no skipped layers.

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

This firmware enables the MK3 filament sensor for exactly the reasons you described:

https://github.com/TheZeroBeast/MM-control-01/

This will prevent skipped layers, but it's still better to solve any physical issues that might be causing it, so you don't wake up and find the print has been paused all night long due to a failed load.

To solve the physical issue, we need to know exactly what happens when it fails - where is it getting stuck? And having this firmware will make it easier to catch that, because it will pause the print instead of continuing blissfully unaware.

In my case it was the idler had a bit too much friction due to a burr of plastic that was rubbing against the idler body. Once I fixed that, I've been running 30+ hour prints with 0 load/unload issues, no pauses, no manual intervention required, no skipped layers.

I too shelved my MMU because of the inconsistencies with filament feed from the MMU. My MMU either fed too much filament, causing it to grind in the idler, or too little where it caused a missed layer. Calibrated all 5 filament paths on the old firmware and continued to have issues.

I'll test the RC firmware and see if using the optical filament sensor resolves the issue. My hopes aren't too high though.

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

i don't know how your spools are setup but if not right they can cause big problems that you will never stop fighting.

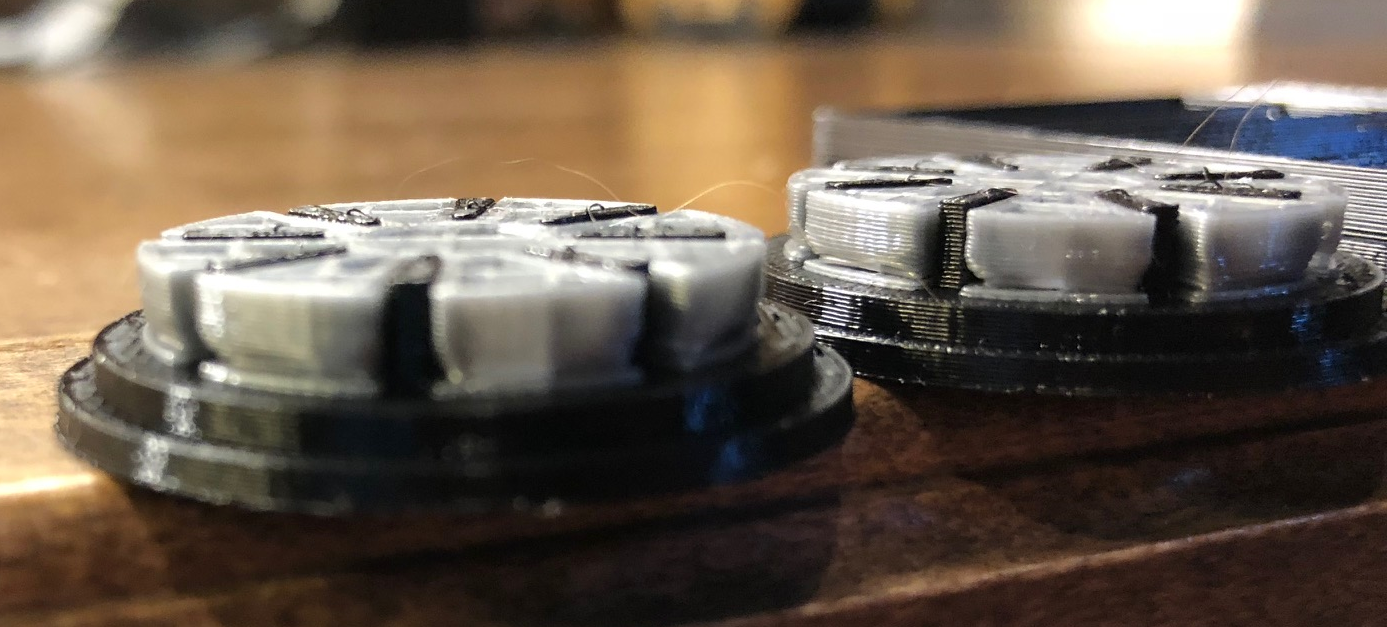

problems on all 5 then you have to go to the common problem, from the selector down to the extruder something is catching. if the filament hangs on anything for any reason it will skip steps at the pulley or worse will wear a spot into the filament. it may save it self a couple of times but each time it gets out of step leads to a cascade failure. i spent quite a long time reshaping my extruder next to the filament sensor carefully with a round tapered file. i tested entrance from the tube to the pulleys at every angle and with different cuts on the ends rotating it 360 degrees from different angles until i stopped feeling it hit anything solid.

prusa printed these parts at a very course resolution there are many places that can catch the filament and there is no overload torque protection. it rams gets hung up and then the timing of the entire machine can go wrong.

the selector body can have issues at the entrance and should be cleaned up as well.

eventually with some hours on the machine the filament will start to wear and polish areas and it should run better.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

ya, I had to clean mine up allot. I am tempted to run some proto pasta metal filament thru for a few big prints. that should shave anything down. but for now its working good for me. allot of filing

I have a Prusa,therefore I research.

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

Until that time, I must unfortunately shelve my MMU2.0 as I cannot afford to sink any more time or resources into solving a fundamental design problem that is unsolvable by the end user.

Hey Greg,

I was at that point as well. Nearly throwing it out of the window. Try these two things, it will help!

What I learned:

a) make sure every filament can roll easily. Very easy! My solution:

TUSH into these butter dishes and PTFE pieces into Amazon Festos. Works like a charm. No friction whatsoever.

It did many prints until now with many color changes.

This allows also to use the IKEA enclosure:

b) I did a lot of testing and got help here in the german part of the forums.

My specs in Slic3r:

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

all.......thanks for taking the time to respond with suggestions. they are greatly appreciated.

jettoblack.........I was aware of robert.m28's FW branch. But, it appeared to be pretty early and raw when I first saw it. I've gone back through that thread and now see that it has become an interesting solution and even appears to be staying in sync with the PR releases. I'm excited to give this a try as I'm convinced that a sensor at the extruder end of the tube is a big piece of the ultimate solution.

jettoblack and daniel.a6.......I unfortunately have no clue how it fails and where the filament gets stuck as the current FW is ignorant of the situation and continues. I'm glad to hear that the robert.m28's FW detects and stops in this condition as I'd love a chance to examine a failure to see if I can figure out what is going on. I did quite a bit of smoothing to my selector and the areas around the hobbed gears on the pulley body, But, I never touched the extruder body. daniel'a6's suggestion about smoothing the top part of the extruder body makes a lot of sense to me and I will investigate my parts this afternoon.

daniel.a6 and ThaliaFP.........I agree that spool setup is a big part of the problem. Abandoning the bits that came with the MMU and designing my own was one of the important steps in getting to my current state.

My spools are directly behind the printer (unfortunately turned sideways and taking up the entire desk). I made my own bearings holders, designed a modified version of the PR cam/lever setup, and mounted it all to a single laser cut plywood piece. My cam/lever setup has much less friction the the originals, uses fittings for the PTFE tubing, and is oriented vertically so the loops will not have a chance to tangle.

The low small diameter rods still have a lot of friction, so I was in the process of converting over to a center roller solution and have already printed the center hubs.

I will continue down that path and also try out ThaliaFP's PTFE solution at the same time. I had not thought of leaving the filament unconstrained between two sections of PTFE. It is clearly much simpler than my cam/lever setup and must have almost no added friction. I already have some of the pass through fittings, so it should be easy to trial.

ThaliaFP.............I had seen many suggestions on slic3r settings to help with bad tips. But, I had not seen anything suggesting that these settings could help with skipped layers. So, I appreciate the suggestion and will give them a try as well.

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

This firmware enables the MK3 filament sensor for exactly the reasons you described:

https://github.com/TheZeroBeast/MM-control-01/

Flashed the newly released MMU and MK3 firmware and still had missed layers when the print was 1.5mm tall or so.

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

wanted to provide an update....

I modified my filament setup to look very much like ThaliaFP's. I made a cable groomer for the PTFE tubes and ditched my cam/lever setup for a simple pass through fitting and short segment of PTFE. I have not been able to get to the laser cutter as of yet, so I am still using my small rods rather than the center hubs mentioned last time.

This is clearly a better solution with much lower friction and will only improve once I am able to ditch the small rods.

I pulled the latest drop of robert.m28's FW from his guthub repository on Friday AM (11/23) and flashed my MMU and printer. Slic3r settings were also modified as recommended.

I see some strange behavior at power-on / initialization, but will post that in his thread for assistance.

My print started up without problems. But, when I checked on it a bit later, I saw that I had a skipped layer. All 4 instances of the model (and the purge block) skipped a layer of silver at about 4mm print height. The next few layers of silver "pulled in" as they had nothing to adhere to and followed the path of the extruder.

I was really surprised to see this as I had expected this branch of the FW to stop and allow me to investigate the root cause rather than simply continuing.

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

I flashed the new firmware releases for the MK3 and MMU2 yesterday and re-calibrated all 5 filament paths. I had missed layers where the print got 1.5mm tall. I'm continuing to shelf the MMU until there's a firmware that makes this thing reliable.

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

i really don't think it is the firmware. i'm having much less problems as i kept tuning the mechanical end of things.

the spools are a big key in making the machine work but there are other areas where the machine needs clean up in the filament path.

it could also just be the filament itself. i'm having good luck with hatchbox PLA and not mixing pla from different manufacturers.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: skip layer problems forcing me to shelve my MMU2.0 unit for now

ThaliaFP.............I had seen many suggestions on slic3r settings to help with bad tips. But, I had not seen anything suggesting that these settings could help with skipped layers. So, I appreciate the suggestion and will give them a try as well.

Jepp, do that. It will also help. If the tip is narrower and can slip easier through the PTFEs, a skipped layer is less likely. If there is a little too much friction, the tip will just not arrive at the bondtechs and the filament sensor will not notice. It just does not print the layer, but all other behaviour is normal for the firmware.

Last improvement: The big rolls. This will help a lot!