Q: Printing actual different materials using MMU

I have failed to get a good answer on this, so I'll try to post it on this forum.

Can you print different materials using the MMU2.0 (or the old MMU even)?

As in rubber-like + PLA, or ABS+dissolvable, with different hot end temperatures?

I have seen prusa videos about working with dissolvable, so I guess that should work somehow?

Which material combinations work? What's the experiences here?

(Or is this a job for a dual extruder, and in that case is there a recommended one to put on a prusa printer? A 2xMMU2.0 dual extruder would be nice...)

Re: Q: Printing actual different materials using MMU

I don't think there's an "official" answer to your question.

Based on my experience using the Palette+ filament splicer with the MK3, I think the answer will be that you can use different materials under limited circumstances:

I'm expecting that soluble support with PLA/PVA will be possible, and I think there's a good chance you will be able to get PLA/TPU to work if you want to mix rigid and flex materials.

But keep in mind that mixing materials with the MMU is going to be varsity-level 3D printing (just like printing with multiple extruders). Maybe after some months of tinkering and refinement it will get to the point where you can just hit Print and get reliable results, but I certainly don't expect that out of the box.

Re: Q: Printing actual different materials using MMU

So in general, "multi material" means "different colours, single material" and if not, there'll be lots of tweaking involved...?

Re: Q: Printing actual different materials using MMU

So in general, "multi material" means "different colours, single material" and if not, there'll be lots of tweaking involved...?

Pretty much, yes. That's going to be the case with any "multimaterial" solution for 3D printing at the hobby level, even multiple extruder printers. I see no reason to expect that the Prusa unit will be much different. There's no magic bullet.

Again, this is based on my experience with the Palette+, which splices segments of filament together to give you multimaterial prints from a single extruder. The Prusa MMU is a different approach, but you're still going to struggle if the filaments aren't fusible or have to extrude at significantly different temperatures. Having multiple extruders makes it easier to extrude at different temperatures but doesn't eliminate the need to have compatible plastics, and multiple extruders gives you a whole new set of problems with registration and vertical alignment.

I don't want to be too discouraging. I've done soluble support (PVA + PLA) using my Palette, so it can be done. But it was not a push-the-button-and-make-it-go experience. I had to spend some time experimenting with the materials to find the right settings, and the results were not as consistent as I would have liked. Some of my problems were because the Palette still has some gremlins, and I'm hoping that the MMU will prove to be a better approach. But you just can't get around the fact that trying to build a single print that incorporates multiple different types of plastic is not a plug-and-play process.

Re: Q: Printing actual different materials using MMU

There is indeed a question of differents printing temperatures but I think that the MK3 is quite fast for increasing it, especially with a sock. I think a 20 or 30 degrees increasing should be handable during the filament changing process if it's well programmed.

About the compatibility of materials, I think it's possible to combine unfusable ones if you had "traps" for materials in each other, like it's done for overmolding. Personally I design l my own parts most of the time so it's not hard to do that when modeling. It's just a guess, we will see if it works but i'll try for sure, I would love to combine PLA and TPU !

Re: Q: Printing actual different materials using MMU

This is possible but if the temps are more than 10 degrees different, you will need to use additional G-code to wait for temp changes at certain points during the filament change.

This is not so easy with Slic3r; you would have to manually edit the G-code. KISS on the other hand... 🙂

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Q: Printing actual different materials using MMU

For what I see in this video , the filament change took like 25 seconds, from 1:50 to 2:15, I think it's enough to ensure thermal transitions. But of course you have to set the new temperature as soon as the filament left from the extruder, I think PRUSA will think about it 😀

Re: Q: Printing actual different materials using MMU

But of course you have to set the new temperature as soon as the filament left from the extruder

No, that's not correct.

Consider this:

You are printing with a filament at 240 degrees; the new filament requires 200 degrees, but there is still about 40 mm^3 of old filament remaining in the nozzle. If you reduce the temp when you unload the old filament, the nozzle will not be sufficiently hot to purge the old filament with the new.

In this situation, you can only drop the temp near the end of the purge.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Q: Printing actual different materials using MMU

You're right ...

So the main problem is extruding material with a too low temperature, but too high isn't really a problem on short term.

An idea would be to change the temperature at the begining of the changing process if it has to increase, and at the end if it has to decrease.

Ex :

- Printing PLA at 210°C

-Stop

- Change temperature for 240°C

- Retract PLA and insert ABS (~ 20s)

- Extrude the ramaining 40 mm^3 PLA in purge or infill at 240°C

- Printing ABS at 240°C

- Stop

- Retract ABS and insert PLA

- Change temperature for 210°C

- Extrude the ramaining 40 mm^3 ABS in purge or infill as the temperature goes down

- Printing PLA at 210°C

It doesn't seem too hard to program.

But I agree that high temperature differences like 40 or 50 degrees seem difficult to handle.

Re: Q: Printing actual different materials using MMU

An idea would be to change the temperature at the begining of the changing process if it has to increase, and at the end if it has to decrease.

Actually, an ideal situation is to change the temps several times during unload and load.

What you need to do is to unload the filament with a clean tip whilst pulling out as much as possible.

So the "ramming" before unload cools the nozzle slightly to help with this, but I also turn off the extruder heater while moving to the purge tower.

I then turn on the heater near the end of the "ramming" and overheat for the new filament, gradually cooling (to avoid "undershoot") during the purge.

Seems to work quite well:

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Q: Printing actual different materials using MMU

I'm counting the ability to print things like wood, carbon and other materials in PLA as "materials". If I can get flexible and rigid materials to mix, I'll be satisfied. Dissolvable supports count in my book. I never understood "multi-material" to mean "mix and match anything you can think of". To be honest, I'm not sure why you'd want to mix materials with radically different physical characteristics into the same print, although I'm sure there are use cases for it.

So in general, "multi material" means "different colours, single material" and if not, there'll be lots of tweaking involved...?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Q: Printing actual different materials using MMU

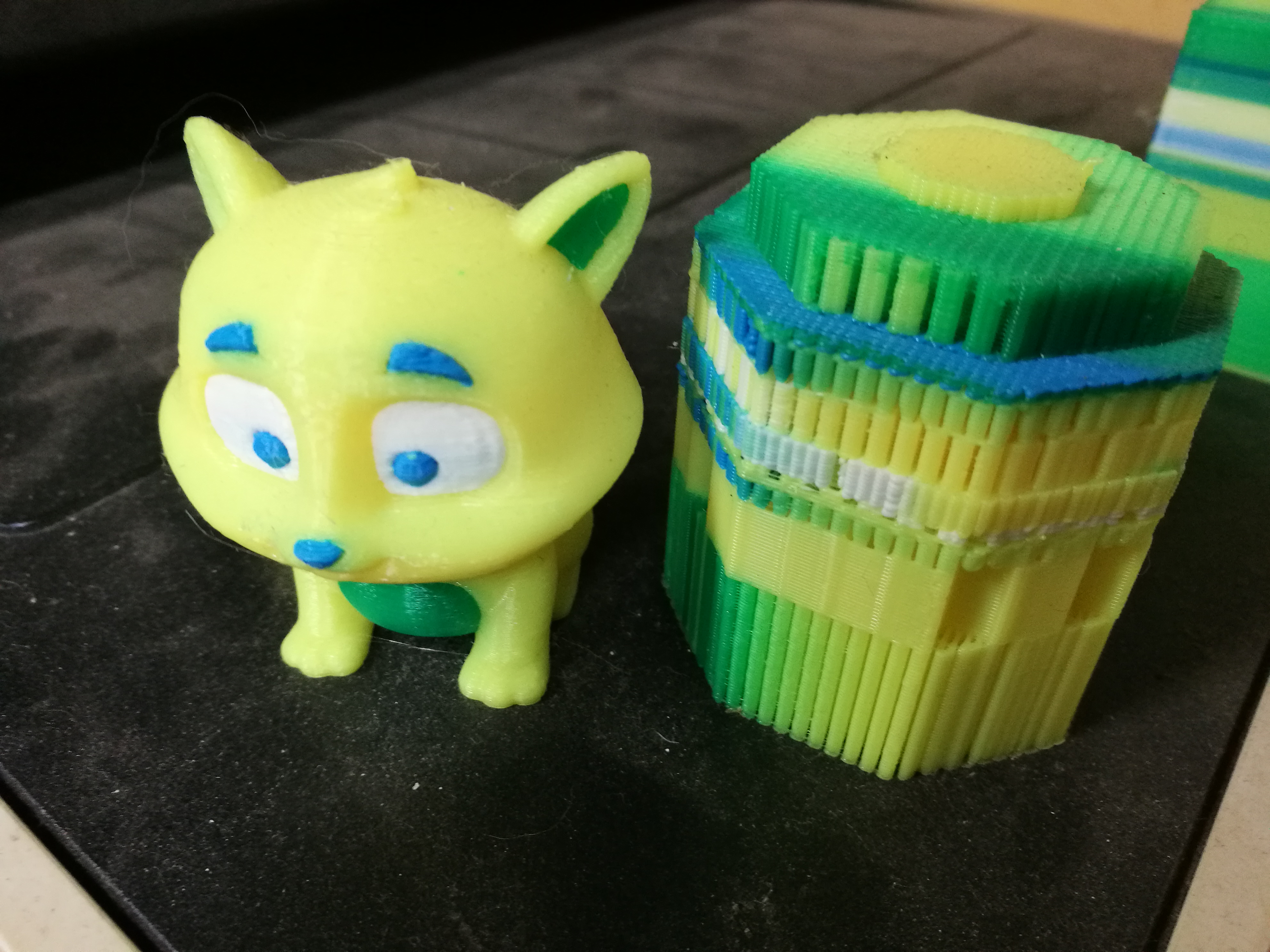

PLA and TPU?

ok this was on my mk3

dont see why it shouldn't work on an mmu

sorry about the upside down print

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Q: Printing actual different materials using MMU

Yes, exactly. I'm saying if MMU2 does those things, it's met my expectations for multi-material. (Joan, some of your pics led me to pull the trigger on the MMU purchase back in January, so you're responsible.)

PLA and TPU?

I am curious though... Your pic appears to show PLA just over-laid on top of the TPU. I'd anticipated having the print channels or grooves for a good grip. Do they stick together well? Would using TPE/TPU as a "hinge" between 2 rigid layers work? That would sure make lids easier.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Q: Printing actual different materials using MMU

Hi Bobstro.

I have never tried a butt joint on TPU / PLA joint

the example above was a small overlap. and seemed to stick well...

being inherrently lazy I just did the TPU 0.2mm thick, one layer, sainsmart black tpu

had another play,

two layers 0.2mm TPU, butt joined to 1.6mm PLA ends[attachment=0]20180714_230114[1].jpg[/attachment]

overlap gives much better joint strength

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Q: Printing actual different materials using MMU

If it's that simple, I'll be quite pleased. About all I was hoping for with MMU was:

I don't recall Prusa alluding to anything else.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Q: Printing actual different materials using MMU

This seems good enough for me, I ordered a mk3 and a MMU2.0. (I know it's hilariously long waiting time.)

Thanks for the help. I hope this discussion continues with experiences, because it's interesting.

Isn't slic3r open source? I haven't looked at it yet, but it seems like it should be able to be programmed for generating good material switching sequences?

Re: Q: Printing actual different materials using MMU

Hi Pontus.

the delay is so hilarious I have been laughing since last October... 😯

Prusa decided to revise the setup, and MMUv2 looks more promising.

understand that they are in Beta testing now so shouldn't be too many years to wait!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Q: Printing actual different materials using MMU

At least it seems like they will ship the printer first, within a month or two.

Re: Q: Printing actual different materials using MMU

nice picture, the added print in any color will rock. 100% easily paintable

I have a Prusa,therefore I research.

RE: Q: Printing actual different materials using MMU

ASA / Nylon work good for multi color functional parts. PC and ninja flex bond together good and makes all my dreams come true!