Prusa bombed on the mmu2s

What happened to all the great quality control? Why are there so many filament load-unload problems. Why are there so many problems in general? I have a Palatte2 and did not have very many issues, however,palette dose not seem to like water solubles. I liked the idea of mmu and 5 color option. My mk3s work great...since the mmu2s is is a mess. I have tried reloading FW, factory resets, hours of forum reading . At this point i am ready to trash the mmu and go back to the palatte and forget soluables.

RE: Prusa bombed on the mmu2s

It's a beast...I am now on the 6th week with tweaking and calibration...but finally starting to see some progress. Doing these now in priority order and having great progress https://forum.prusa3d.com/forum/original-prusa-i3-mmu2s-mmu2-general-discussion-announcements-and-releases/successful-mmu2s-modifications-re-upload/

There should have been a warning on this product - it is not ready for normal consumers. I am biased - a love-hate relationship. When it works it's magic, when it do not I want to crush something....hopefully not my Prusa!

RE: Prusa bombed on the mmu2s

What, very specifically, is it not doing properly?

Yes, it's quirky and tempermental, but I've found that with one assembled paying strict attention to detail and operated with equal attention to detail, it performs as expected. I have not yet tried soluble supports, but I have some soluble filament I ordered and when I have an appropriate project, I will try it.

If you haven't done so, start slow, with printing things like the multi-color test 'puck' and the sheep. If those do not print properly, STOP and figure out what's wrong before proceeding. For these tests I would be sure to use only known-good filament which has otherwise given you good results.

RE: Prusa bombed on the mmu2s

@jsw

Hi

For me it was...I guess everything. First off the feeding solution was giving me problems with way to much friction causing the mmu unit to have trouble getting the filament down to the extruder. I then designed my own feed system which looks promising but will not publish it until I have tested it thoroughly.

Then I had isses with the IR sensor on the extruder - signals being unstable causing everything to crash. I followed the guide above and no more issues here.

Then I had issues with filament getting stuck. After tuning this helped but once in a while the tip is juuust a bit to big causing everything to crash - again. Problems have been mostly with "non-prusa" filaments BUT my goal is that I should be able to throw any filament on this unit. Prusa filaments shipped to Norway costs a fortune so I must be able to use cheaper materials sourced directly. I now have followed the guide above and printed new extruder parts with PTFE tube going all the way down to the bond gears, and a PTFE tube with larger diameter. This fix I believe is a game changer. I have now started a print and up to now it has done around 40-50 filament changes with NO issues!

So my hate/love relationship with the MMU unit is now more love/hate with less and less of the latter 🤣

Brgds

Christian

RE: Prusa bombed on the mmu2s

Where do i begin...re-calibrated everything, took the unit 1/2 apart and reassembled. Some times it loads sometimes it does not. Sometimes loads to extruder sometimes it dose not. Sometime it extracts from the extruder sometimes it does not.

If i have to spend weeks to get this remotely reliable....thats not right. I use the mk3s for building rc plane parts, drone parts and jigs for my work. I wanted multiple filaments for complex prints needing soluble supports. Also, the idea of doing colored prints for fun......this is not fun.

It is not our job to redesign parts to make this functional. I expect some tweaking, not this many issues.

I just hope I can get the mk3s back to where it was before mmu2s.

RE: Prusa bombed on the mmu2s

Here are my suggestions ...

If, for some reason, the MMU2S does not seem to have enough 'oompf' to push the filament down into the extruder, something is most definitely wrong. I would first be sure that the gears on the MMU shaft are properly aligned and the MMU top is properly tensioned.

Next, until you get things working correctly, I would put EVERYTHING back to stock and get it working as intended, looping in support if needed, before you try any mods.

One thing you can try if you think there's too much friction in the system is try one of those test 'puck' things without the buffer, using a few loose coils of filament. That was my first test print. I used some randomly-selected Amazon sample pack coils, all PLA. The thing should smoothly 'swoosh' one filament back to the MMU and 'swoosh' another into the extruder very smoothly on each filament change. If it clicks or grinds or just doesn't move the filament smoothly, STOP and figure out what it is, again, looping in support if needed.

I have a feeling that some of these frustrating MMU2S issues may be simple cases of cumulative tolerance, and if you indeed have a 'lemon', they should stand behind it. Also, the vibes I've gotten from those who have these too-common issues indicate that they may not have fully RTFM'd, did not pay very close attention to detail when assembling, and neglected to do things such as chase out the holes in the printed parts, smooth rough edges, etc. Many users do have these things working more or less as intended, so we know that they are capable of doing what they are intended to do.

RE: Prusa bombed on the mmu2s

I really tried everything using stock for the first week, but could not get around the obstacles of friction in feeding system, trouble with unstable IR sensor and issues with getting the filament down through the bond gears.

Finally - today I had the first multicolor print with hundreds of filament changes - and only three interventions. I have done all the mods described in the link exept the MMU selector https://forum.prusa3d.com/forum/original-prusa-i3-mmu2s-mmu2-general-discussion-announcements-and-releases/successful-mmu2s-modifications-re-upload/

The interventions was of the type "MMU unit needs user attention". Not easy to understand why this happens but it was easy to overcome. A giant step forward. Not saying that these mods should be done by everyone - but for me they worked.

Here is my machine in action:

RE: Prusa bombed on the mmu2s

The vast majority of MMU issues come down to the filament path (the entire path, from spool to nozzle) or the IR sensor giving false readings. Anything that impedes filament movement increases the potential for tool change issues. Here are the most common issues:

- Kinks in the PTFE tubes causing binding. Replace any kinked sections.

- Tight curves in the PTFE causing binding. Make the tubes as straight as possible and any curves that are required should be long and gentle.

- Compression joints on the buffer and input for the MMU can cause binding if you screw them in too tight. Switch to pass through festos.

- Cheap PTFE (like comes with the MMU) doesn't have great tolerances and can cause binding if the ID narrows too much. Switch to a higher quality PTFE or PTFE with a larger ID.

- The PTFE not being properly seated and locked in the hotend can allow fat tips to form which will bind up in narrow PTFE tubes. Re-seat PTFE and use a locking clip to ensure it doesn't come loose.

- Any binding can cause improper movement during unload which can allow tails to form and annoy the FINDA. Find and fix the binding issues.

- The IR sensor will send false filament out messages if the idler door is not adjusted "perfectly". Print with the MMU unpluged until you are confident the runout function is working perfectly. Doing the LED mod on the IR board is also extremely helpful for getting it dialed in correctly.

The MMU is by no means perfect and there are things that Prusa needs to improve (like making it more clear that it is still very much a WIP that can require a lot of dedication to get working correctly), but it actually does work very well when you find that right set of variables for how you have things set up.

RE: Prusa bombed on the mmu2s

That is a very good link you posted, Gnat, thanks.

The one thing that I was super paranoid about when I assembled mine, from reading all of the construction comments, was the filament sensing. I actually printed out a spare stock 'flag' part and a remix with an adjustment screw before I tore apart the machine to install the MMU2S.

Fortunately, I did not need it, but I did many cycles of checking with the filament sensor, since that seemed to be one of the major issues. I did not proceed until I was highly confident that it would sense the filament, or lack of same, first time and every time.

RE: Prusa bombed on the mmu2s

Okay....completely dismantled, and reassembled...read all the comments and made adjustments(as before). Rereamed the filament paths...again. Reflashed printer and mmu FW. Got filament 1 to the extruder(prusa pla)...printed first layer calibration. When it was done the mmu extracted the filament part way down the extruder to mmu tube. It took alot to get it out...there was a blob on the end of the filament that would not allow the filament to pass. There seems to be to many tolerance issues with the parts. At least I have the Pallatte 2 to fall back on!

RE: Prusa bombed on the mmu2s

@richard-l12

Hm a big blob... So does not sound like your problems are related to mechanics but more to settings in prusaslicer? Have your tried doing pure load/unload on the printer - what happens then? And bond gears are perfectly aligned?

RE: Prusa bombed on the mmu2s

Okay....completely dismantled, and reassembled...read all the comments and made adjustments(as before). Rereamed the filament paths...again. Reflashed printer and mmu FW. Got filament 1 to the extruder(prusa pla)...printed first layer calibration. When it was done the mmu extracted the filament part way down the extruder to mmu tube. It took alot to get it out...there was a blob on the end of the filament that would not allow the filament to pass. There seems to be to many tolerance issues with the parts. At least I have the Pallatte 2 to fall back on!

By "blob on the end" I assume you mean that the tip was too big to pass nicely? If so, check the PTFE in your hotend to make sure that it is oriented correctly, seated completely, and the collet is raised to the locking position. Why Prusa didn't supply the locking clip that comes with all E3D heatsinks is beyond me, but you can print versions from Thingiverse and that will help make sure the collet doesn't get bumped and unlocked when you assemble the extruder.

RE: Prusa bombed on the mmu2s

@richard-l12

First of all I would recommend to search for issues step by step. Rebuilding/changing a lot of stuff at once doesn't bring any success as you might introduce new/different issues.

As you mentioned big blob filament tip, this would be my first step. Check you've installed the PTFE tube in the extruder which was included in the MMU2 upgrade. Make sure this is not moving and sitting flush. Once you've ruled out the mechanical part, load filament to nozzle, extract some filament and do the unload. Check the shape and the width of the filament tip. Post a picture, so we can double check.

Once your filament tip will have correct shape, you can do the next step and adjust the IR sensor and FINDA. It might sound easy, but to find the right spot takes some time and experience. It took me many print hours to find the right spot for my unit, so don't be disappointed if it's not working perfectly right away.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Prusa bombed on the mmu2s

@jsw

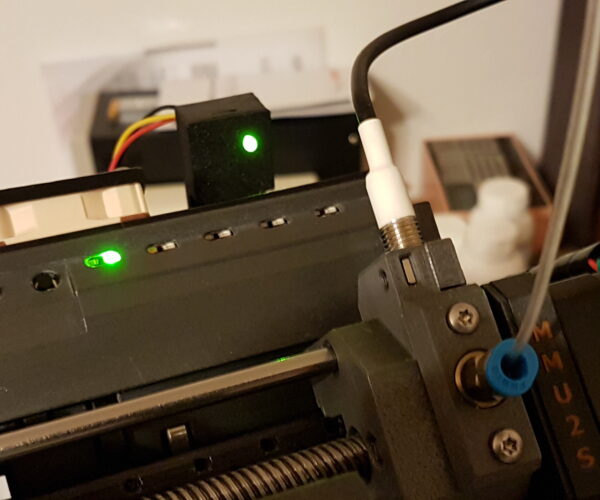

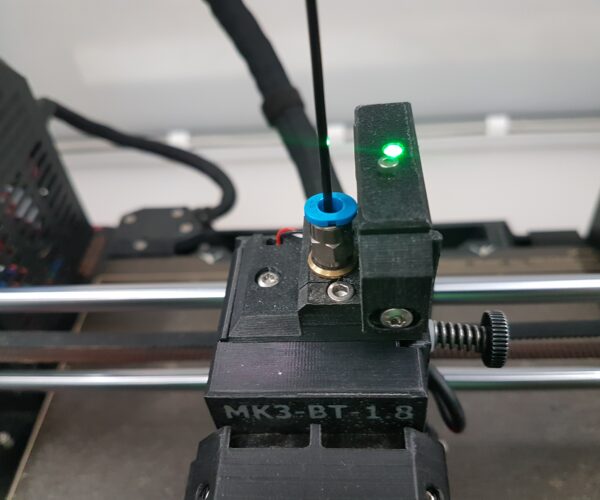

The sensors of the printer and the MMU2 are everyday topics of conversation here in the Prusaforum. Not properly adjusted this leads to various consequential errors and you often search in the wrong place. For this reason I have equipped both sensors with a control LED and modified them in a way that they can be easily adjusted with an adjustment slider. I equipped the MMU2 sensor with a neodymium magnet, so that gravity is supported a little bit and the steel ball falls back better into the original position when unloading the filament.

Attaching the LED's is a bit of work, but can be very helpful 👍

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Prusa bombed on the mmu2s

@richard-l12

One thing I'll do when working on my tips or (more commonly) finessing the IR sensor is to remove the PTFE between the MMU and extruder. Then when the MMU loads filament I'll stick some scrap filament in the selector to trip the FINDA and then manually insert filament into the extruder. This can help isolate your work so you are fighting fewer issues at once (e.g. if you were having IR sensor and friction issues at the same time).

RE: Prusa bombed on the mmu2s

@gnat

"remove the PTFE between the MMU and extruder"

We recently had a discussion about PTFE connection MMU2 and extruder:

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Prusa bombed on the mmu2s

Not a slicer problem...have not done a print yet...still working on first layer calibration. Never said big blob..said blob. The end is smaller than the joints from the pallatte. I rebuild the extruder to a mk3s last year and has worked flawlessly ever since. I can try to replace the tube in the extruder...more concerned about the ID consistency of the menu to extruder tube.

RE: Prusa bombed on the mmu2s

@gnat

"remove the PTFE between the MMU and extruder"

We recently had a discussion about PTFE connection MMU2 and extruder:

Ugh. I HATE the stock festos! I had to cut a new length of my Capricorn XS tubing because those damn things wouldn't come off 🤬

I switched to the same M10 PC4 festos I use on my buffer and the rear of the MMU when I replaced my extruder.

RE: Prusa bombed on the mmu2s

@gnat

I had nothing but tr0uble with the festo's chewing through the PTFE as the print head goes from side to side, on the Mk1 MMU but there were 8 festo's on that set up, 4 at the top on the extruders and 4 on the bottom on the multiplexor, all chewing away at the PTFE.

Grrrrr....

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Prusa bombed on the mmu2s

I can not understand why there are so many issues. After I installed the MMU2S I had issues, too. I identified the cause and fixed it. Every cause could be found as a user fault in the built process. I was able to fix it in minutes and after 6 itterative steps the unit performs like a champ. I hadn't a single issue since.

I use the printer for commercial use, so I can say that it runs a lot but in this case only one filament change per 4h print is necessary. Only a few prints are 'normal' multimaterial prints (~3/month) with 1 or 2 filament changes per layer, but as I said, not a single issue.

I love the product.