MMU2 with E3D Revo Six - Tunning filament tip issue

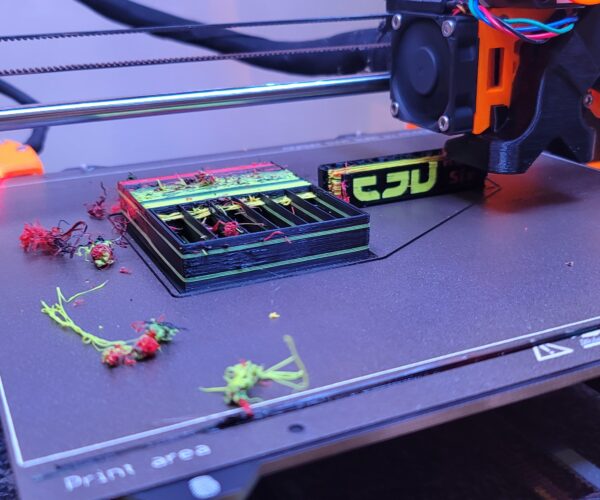

Since I have installed the new E3D Revo Six hotend (rapid change of nozzle), the tip of the filaments (Generic PLA) have a long thin string at the tip during filament changes on the MMU2.

This is more marked when changing filament on the purge tower than when unloading the filament via the LCD menu (these parameters there seem quite correct and the point is as it should be).

Considering the internal design of this new hotend, I think there is a cause.

But how to solve the problem ?

Theses thin strings clogged the system by accumulation after 10-20 filament changes...

Before doing a more detailed explanation, I would like to know if the problem has appeared with other users who have recently installed the Revo Six and tested with the MMU2?

My config:

Prusa MK3S+ with MMU2S

E3D Revo Six hotend, fresh new installed

firmware 3.10.0

PrusaSlicer 2.4.0

Filament PLA, generic and Pusament, dry enough.

Other think to be considered:

The new Revo Six hotend have same external dimensions as the v6 to be installed on the MK3 series, but inside the PTFE tube is approximatly 11 mm shorter (to compare as the 42.3mm config).

My measurement is a total length of 31.0-31.2mm to be installed in the MK3S+ extruder body R6.

Should be theses orignal parameters in PrusaSlicer to be modified ?

This is Generic PLA @MK3 of PrusaSlicer original parameters :

I have already tried to increase "Unloading speed at the start" up to 120, 140 mm/s ==> not better

Also increased "Number of cooling moves" up to 4 ==> not better (even worse, a bulb instead of a thin string)

Filment temperature not changed, 215°C for PLA was OK with previous config.

I don't know what "Ramming" is and how to tune... Maybe something in that to study ?!

This is a subject to talk I think...

Thank you in advance for your experience and help.

Ludovic

RE:

The green tip is from the end of print gcode/firmware script (MMU2 config)

A perfect one !

Would be great to have the same with the purge tower during filament changes.

I have tried some different test, the best I reach is the black exemple.

And the video of unload filament at the end that show cooling moves

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

I haven't reinstalled my MMU yet, but with the change to the Revo I plan to. Previously I ran my MMU using the standard e3d heat break rather than Prusa's stepped version. My experience was that the friction in the filament path and how much movement there was in the PTFE into the back of the MMU was the main culprit with tip issues. I'm expecting similar for the Revo as well since it is effectively a straight heat break as well.

What I mean by movement is that if you are using long tubes to the buffer or to your spools, they can move based on the natural curl of the filament. My experience is that during unloading this movement can cause undue friction that results in poor tip forming. The best solution I found was to use clips that hold the tubes together as a bundle (but without pinching the tubes).

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

Hi,

Here is an answer of E3D about this topic.

I was curious to know if they made some real tests of the Revo with MMU...

James (E3D Online)

Mar 11, 2022, 13:11 GMT

Greetings from E3D Online.Thank you for contacting us with your enquiry.The Revo Hotend range utilises a different internal geometry to that of Prusa V6 specific Hotend, Specifically the heatbreak.The Prusa Heatbreak was designed with MMU compatibility directly.we have not tested the Revo system with the MMU. However, there are reports of the MMU working with Revo Six.However many users have been successful with the Hemera and the MMU system with some changes to the load/unload and ramming sequences.Please note however that this is untested by ourselves.If you have any further questions please do not hesitate to contact us.

Kind Regards

This is the first time I hear that the heatbreak for v6 and MMU was specially made for this application.Another point that gives me hope is that unloading the filament can give satisfactory results. The one from the LCD menu or the gcode end script.Of course, ramming above the board or in the purge tower is certainly not the same, but I hope to find someone (also in the Prusa team) who can transpose this equivalence into the toolchange script.

I've done this weekend some print test in Single MMU mode, with 0.25, 0.4, 0.6 and 0.8 mm nozzle with good results.

XYZ calibrating cube of 20 mm square and a tiny cute cube of 10 mm square with the 0.25 mm nozzle.

Note: native unloading gcode script is to strong to pass the purge (ramming) through the tiny 0.25mm nozzle, extruder pulley grind/skip.

This would be another subject I'll post theses days.

I wish you a nice night,

Ludovic

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

This is the first time I hear that the heatbreak for v6 and MMU was specially made for this application.

Yes. The MK3 heat break from Prusa (it is made by e3d) starts at 2.2mm at the top and reduces to 2mm at the neck. The standard e3d design is 2mm straight through. The reasoning Prusa gave years ago for this step is to help tip forming during unload by the MMU. Many people, however, have had issues with the step trapping, annealing, and then dropping bits of filament which results in a clog. Most commonly this happens with high retraction prints, but I also experienced it quite a bit with 0.1 and shorter layer heights as well. It can be mitigated with higher nozzle temps, but you tend to sacrifice quality and the real fix is the standard heat break. There have been a number of posts over the years in this forum about MMU users making the switch with success. Some people adjust their ramming and unload speed settings and some just dropped it in without having to tweak anything.

Here is a post with some diagrams of the Prusa vs standard: https://forum.prusa3d.com/forum/postid/139023/

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

I've had so few problems with my MMU2S that I didn't even consider that switching to the Revo Six would be a problem. I ordered an R6 last weekend, and it is backordered for several weeks right now. Perhaps I should brush up on how make changes to the ramming and tip forming. I should also look into upgrading the firmware on my printer and MMU as I think both are a release behind.

It isn't uncommon for me to see stringy tips, especially on PLAplus (which I primarily use as a "soluble" support for PETG) and haven't noticed any significant issues with them yet. Are these stringy tips what lead to the hairball in the FINDA? I've only ever had to pull out one of those hairballs after maybe 50k filament changes. Or is more of an issue where the selector gets jammed, or perhaps the FINDA can't untrigger? That hairball may have been only PLAplus though, it as a solid color roughly the same as the PLAplus. Being a "soluble" support, it likely only has a few hundred filament swaps.

The only notable deviations from the stock MMU2S installation is that I used 3mm ID PTFE tubing, this mod, and a completely different buffer.

You stated that the filament was, "dry enough." What does that mean? By far, drying my PETG before using is what has had the most effect on getting good prints without stringing. I live in a relatively (but not super) low humidity region. Until very recently, I was storing my filaments in a vacuum sealed bag with dessicant, inside of a larger container also with about 4 lbs of desiccant in it. Still, throwing my filament into a dehumidifier overnight before using it has made such a drastic improvement to the quality that I almost don't care how or where the filament is stored any more. If it has been more than 48 hours since being thrown in my dehumidifier and I want to print with it, it goes back into the dehumidifier. I wonder how much a stringy filament during printing (such as wet PETG) would correlate to a stringy tip.

Also, am I understanding your comment about the 0.25mm tip such that it won't work with the MMU? I was really hoping to find a way to slice a file such that it'd use a 0.25mm tip for the first several layers then swap tips to the 0.8mm to finish the print quickly. I suspect I should be able to slice twice, then make a python app to splice the two g-code outputs together.

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

Good evening to you,

Here's some news on my settings that work for me.

MMU2S & MK3S+ & E3D Revo Six

Nozzle 0.4 mm

PLA filament (1st layer 215°C, following 205°C)

Prusament PLA, Prusa PLA and Generic PLA.

The main tunning is:

- Decrease Ramming duration,

- Increase the "purge" flow rate,

- Withdraw the filament at an appropriate speed.

=> Purging in the tower a little bit more "punchy"

Contrary to what one might think at the beginning based on various forum topics, the parameters go the other way.I was inspired by the principle of the filament unloading script in the end part of the gcode which basically gave good results.

(clic on the picture for the full size !)

The Revo Six's heatbreak part is about 2.0 mm internal diameter and the diameter of my filament tips are approx. 1.95-2.00mm (not shown in photo). I haven't had for the moment a problem in the PTFE tubes of the MMU module. Normally there should be no wear or increase in diameter contrary to what happens with the PTFE of the hotend in the E3D v6 hotend.

Tested with a 16h00 print with around 120 toolchanges without any issues (photo during print) !

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

What calibration (xyz, Z or other) is required when replacing the nozzle?

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

Hi Dalee,

The differents sizes of Revo nozzle have the same length.

Normally you should not have to recaliber the first layer. Pratically a little tuning of the first layer could be done if you want a perfect print, by using the "Live adjust Z".

But I is not eliminatory or don't cause scratching the bed.

I wish you a nice day,

Ludovic

What calibration (xyz, Z or other) is required when replacing the nozzle?

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

Thanks for the great info!

I should have my R6 tomorrow, so I'll try to recreate your results with PLA filaments. I mostly print in PETG, so I'll try to get similar results for the PETG as what you were able to achieve in PLA. I'll post my results here as well.

Once I'm comfortable with the PETG tips, I'll try out some of the smaller tips.

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

Thank you for your help.

I got it today, and I'm opening the package now.

I have another question before I start to change the heads.

I read in the 'Revo Six Prusa (MK3/S/+) upgrade guide' that I have to cut PTFE tube to 10mm length for MK3S, but how long for MMU2S

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

I did my installation today, and I have an MMU2S. Use the 10mm as the length, just as described in the instructions.

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

These are tips from a couple of my recently dehydrated, Atomic Filament PETG filaments in a 0.4mm nozzle. I used the same settings as you used for PLA. I've pretty much been able to ignore tips in the past, so I don't have a great reference for a normal tip in my mind to compare these to. But, these look pretty good to me. I have some Amazon catch of the day pink and brown that were horrifically stringy with regards to the tips, I might see how those do with these settings.

Testing was done simply by printing out some 0.2mm thick discs with a 5mm diameter. I put four of them on the bed, each with their own extruder selected to be sure it did a proper filament swap. Hopefully that is good enough to use as a starting point.

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

I treied the MMU2 mode

I tried the MMU2 single mode with KoDaKrom's settings. It works perfectly. No Zero calibration was needed when I replaced the nozzle from 0.4 to 0.25

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

KoDaKrom, are you still happy with your settings for PLA? The first tips I was getting were fine, but now I'm having stringing issues and horrific purge block problems. My suspicion is that the higher, initial retraction speed ultimately means that I'm not teasing the material in the nozzle away from the tip, so it oozes out. This is typical of my purge blocks now, an absolute mess.

I'm also getting some stringing on some filament changes. It doesn't look any worse than I'm used to seeing in the past, but it sure is behaving worse. I have to dig out a hairball from the selector every few dozen layer changes. I've also had to open the extruder and dig out a hairball that was transferred to it from the selector.

RE: MMU2 with E3D Revo Six - Tuning filament tip issue

Hello Henry,

Did you configure the same settings as I posted?

I didn't do any additional printing than the dragon. Everything had gone well. No filament ball or "square" tip.

I don't know if from one printer to another there can be change.

Indeed, your impression is catastrophic.

I stayed with my printer for a long time to make sure there was no problem.

Thanks also to Octoprint and the raspberry camera (remote control).

The tuning range seems to be very short with this hotend, I guess...

I only have a short time to dedicate to my 3D printing hobby, but I hope to be able to do more tests and share my experience.

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

Yes, I configured everything just as you had it. I'm using PETG for printing, and the tips mostly look great. Every now and again, I get some stringing. I think that occasionally stringing leads to the hairballs. I'm not surprised that I have different results since it is a different plastic, and PETG is known to string and I believe it is significantly worse with regards to oozing. I'll try to find some time to do some additional tuning.

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

Ok, I haven't tested Petg with Mmu2 prints, only single mode prints and I have good tips at the end of print when unloading.

Did you have tested Mmu2 (with the Revo) prints before in PLA with default prusa profile? What was your results?

My first tests was like descripted in the begin of the post: long stringy tips and accumulation in the bondtech extruder, I had stopped the prints before having string-balls.

My settings as proposed are maybe too much, could be decreased a little to obtain a mid result... I tried to obtain the same analogy with the END Gcode unload script transposed with the purge tower purge to have a starting satisfaction point.

It would be interesting if somebody else could make some tests and give feedback of his experience.

😑 😑For the nexts steps, finding tweaks with other nozzle diameters (0.25, 0.6 and 0.8mm) AND the Mmu2 prints will be another mission !

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

No, I didn't start with the default settings. I saw several posts regarding the R6 and that it wouldn't work well with the MMU, so I jumped straight to what you posted yielded great results. I knew going into it that PETG would likely be different from PLA, but was hopeful. I do plan on starting from the default PETG settings though, perhaps they'll work just fine despite what I've read.

RE: MMU2 with E3D Revo Six - Tunning filament tip issue

I've spent hours, and hours, every day this last week trying to get this to work. I even bought a $400 IR camera to verify the nozzle temperatures. Then I realized that one of the four filaments I have been testing with was actually PLA. Well, at least I can hopefully start making progress now.