Just How Multi-Material Is The MMU2S?

https://www.antalife.com/2020/07/project-just-how-multi-material-is.html

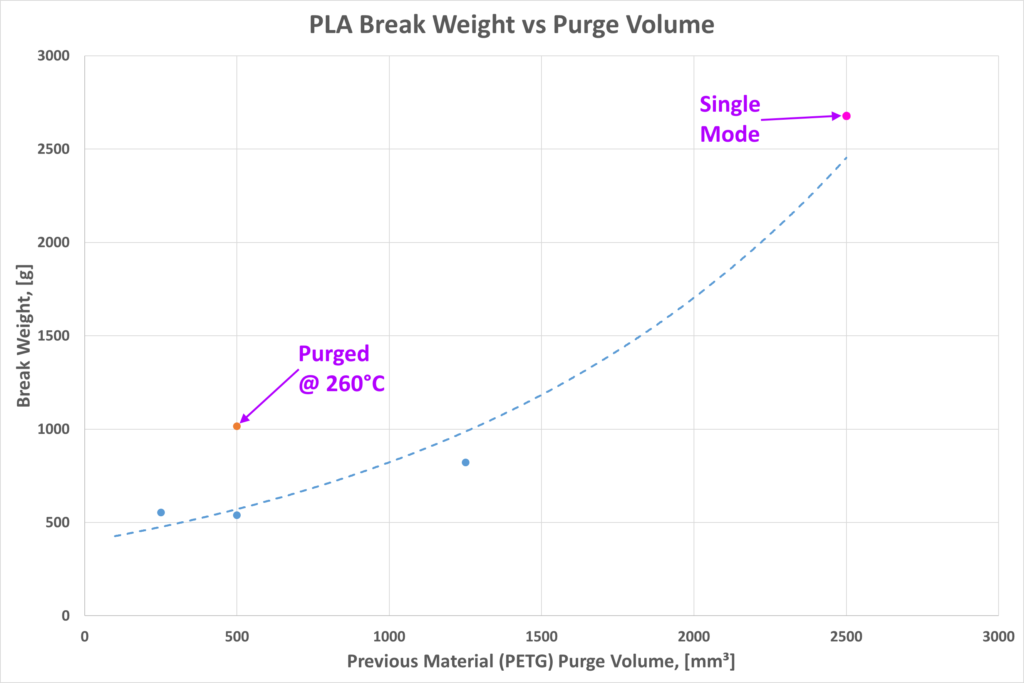

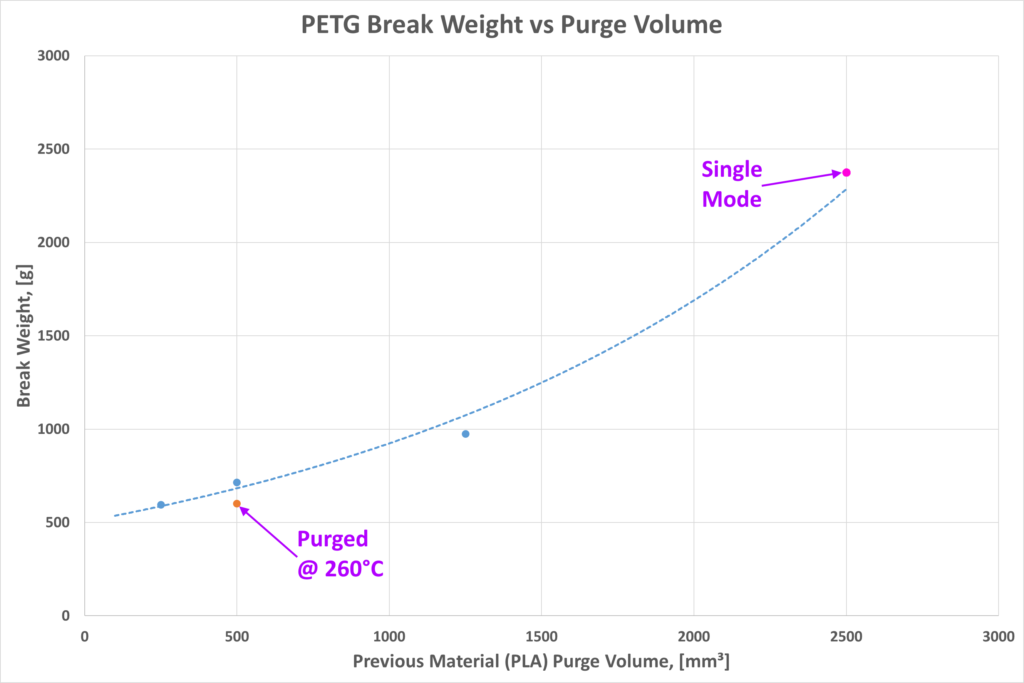

After doing heaps of PLA/PETG test on my MMU2S my conclusion is that the "Multi-Material Upgrade" should really be called the "Multi-Colour Upgrade", as printing in different materials requires crazy amounts of purging (>2500mm³) between swaps

Hence, if you want true multi-material capability then you need a printer with at least two separate hotends, otherwise if you are printing in single material then the MMU2S is perfect

With that said, am keen to hear what other's have experienced with the MMU2S

www.antalife.com

RE: Just How Multi-Material Is The MMU2S?

Also am really hoping to be proven wrong, as I was wanting to use the MMU2S to print "soluble" supports out of PLA/PETG

www.antalife.com

RE: Just How Multi-Material Is The MMU2S?

I see the MMU2S more as MCU2S (MultiColor...)... trying to use materials which require different hotend temperatures is just pain in the a**. I have finetuned the temperatures for each filament brand/color I am using so my single material prints are almost perfect, but trying to combine them using MMU2S is just a nightmare, the overall quality goes down.

RE: Just How Multi-Material Is The MMU2S?

@pporozin

Oh man too true! I am able to get multi colour PLA prints just fine but trying anything fancier like PLA body & PETG supports just makes whatever I print weaker

Also if you are having issues with load/unload temperature then I suggest giving PrusaSlicer 2.2.0 DRIBBLING by antimix a go

www.antalife.com

RE: Just How Multi-Material Is The MMU2S?

@antalife

Driblling fork, Superslicer fork,... Too many forks to use them all. I.e. I am using the Superslicer to finetune the spacing between the objects on the bed (Prusaslicer keeps huge amount of free space between the objects and manually aligning 50 objects just sucks), ironing of the surfaces etc. would love to have all the features in one slicer, but Prusa is not able to implement them all, matter of priorities I would say...

The MMU2S is for me a HUGE disappointment. While in theory you can print using multiple filaments (materials and colors), the reality requires huge amount of time to fine-tune all small details for each filament brand/color and each MMU2S unit or to rely on luck. Well, yes, MK3S is kind of budget friendly but with all the time spent on fine-tuning you can afford a pro printer for 5x more money without wasting the time.

RE: Just How Multi-Material Is The MMU2S?

@antalife

Not that it would currently be an economical savings or even a current supported slicer option, but I wonder if a "cleaning" filament flushed through the extruder between color/material changes could reduce required purge amounts. (i.e. something like eSun cleaning filament)

If it actually helped then maybe Prusa or another filament manufacture could determine if they could produce such a filament at higher volume & lower cost than what's currently available / sold.

RE: Just How Multi-Material Is The MMU2S?

@corfam

Good suggestion! Wonder how easy it is to purge the cleaning filament though, as most people tend to use these for cold pulls

www.antalife.com

RE: Just How Multi-Material Is The MMU2S?

@corfam

Smartfill has a 1kg of cleaning filament for ~$60.

RE: Just How Multi-Material Is The MMU2S?

@pporozin

Interesting. Still rather expensive, but if only a small amount was needed for each cleaning cycle it's probably not as bad as it first sounds. Upon quick search I couldn't find anyone that sells Smartfill here in the US. Have any sales links...in US or otherwise?

@antalife

I agree that the cleaning filament would need to be able to be purged itself easily with the filament that follows. I'm hoping since the cleaning filament is designed for flushing that it would itself also flow out quickly upon next filament change. The Smartfill cleaning filament tech sheet that I found after pporozin's suggestion says the temperature should be set 10C higher than previous filament hot end temp so that itself seems reasonable.

RE: Just How Multi-Material Is The MMU2S?

I totally agree with antalife,

When I first ordered the MMU2, I was convinced that I would be able to print complex objetcs with soluble support material.

The reality is quiet different, if in fact we can manage to print PVA with the MMU2, the biggest downside is the impact on the printed part inter-layer adhesion, it's nearly impossible to avoid the PVA to not contaminate the part you are printing and weaken it.

It's the same with other materials like PLA and PETG, despite a huge purge volume, in all my testing the parts always broke straight in line the material change layer.

My conclusion is, if you print objects like figurines or decoratives objects, yes the MMU2 can do the job, but if you want to print functional objects that require strenth, the MMU2 is not the answer, without having tested it, in my opinion a dual extruder printer would be more appropriate.

I definitely gave up with multimaterial support, I just print multicolor objects, and for this purpose the MMU2 works very fine.

MK4/MMU3 - VORON 2.4 350 Stealthburner

RE: Just How Multi-Material Is The MMU2S?

@lichtjaeger

Does TPU stick well to PETG? If so then you won't need to worry about this issue

The only time when you will need to worry is when you print materials that are not meant to permanently adhere to each other. For example printing the body in PLA and supports in PETG/PVA/BVOH

www.antalife.com

RE: Just How Multi-Material Is The MMU2S?

@antalife

First of all thanks for sharing your results. To get a clean transition with non-sticky to each other materials is really not easy. Here are my thoughts in regards to the results:

* You're printing PETG really cold at 225C. I would go up to 250C.

* You're printing very small objects. So you have a very low flow rate. This might be part of the issue.

* As far as I understand the dribbling slicer is doing a lot of back and forth movements. So he is mixing the filament in the nozzle

* Temperature transitions are not stable in the dribbling slicer. As you've already noticed both filaments are being heated up and cooled down out of their defined temperature range. Especially PLA is getting very sticky at higher temperature. Check out the description of my script. The purpose of that is to handle each filament (doesn't matter if lading/purging/unloading) in their specified temp. range.

* Try to improve your measurement setup and do many tests to get the error variance.

My suggested setup:

* Set PLA to 200C

* Set PETG to 250C

* Start with 200mm^3 purge volume

* Use bigger test objects

* Use my script

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Just How Multi-Material Is The MMU2S?

PS: Use my script with default PrusaSlicer and settings.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Just How Multi-Material Is The MMU2S?

@nikolai-r

Thanks heaps for the suggestions, here is what I think:

* You're printing PETG really cold at 225C. I would go up to 250C.

- The PETG I use can be easily printed at 225C, I ended up at this temperature after doing the "temperature tower" test

* You're printing very small objects. So you have a very low flow rate. This might be part of the issue.

- Very good point, I also think the issue would not be as big if I was to print a smaller object. The reason why I went with a smaller object is to simulate what happens when I want to print finer details, for example a finger on a small hand

* As far as I understand the dribbling slicer is doing a lot of back and forth movements. So he is mixing the filament in the nozzle

- That is true, but the filaments are going to be mixed anyway when you change from one another?

* Temperature transitions are not stable in the dribbling slicer. As you've already noticed both filaments are being heated up and cooled down out of their defined temperature range. Especially PLA is getting very sticky at higher temperature. Check out the description of my script. The purpose of that is to handle each filament (doesn't matter if lading/purging/unloading) in their specified temp. range.

- Hmm, dribbling slicer seems much more stable than stock PrusaSlicer? For example when I tell the slicer to purge the nozzle at 235/260C it does exactly that. Plus when I purge PLA (changing to PETG) I kinda need to have a higher temperature (235C) to properly get the PETG into the nozzle? Also from what I can tell dribbling slicer is using the same logic as your script ( https://github.com/workinghard/mmuGcodeParser )?

* Try to improve your measurement setup and do many tests to get the error variance.

- 10 samples of each seems to be quite good for me?

* Set PLA to 200C

- Yup

* Set PETG to 250C

- Not with this one

* Start with 200mm^3 purge volume

- No point as my 250mm^3 data shows

* Use bigger test objects

- No point as am trying to simulate what happens when we print finer details that need support

* Use my script

- Can you tell me how is it different from dribbling slicer, especially for temperature transitions?

www.antalife.com

RE: Just How Multi-Material Is The MMU2S?

- That is true, but the filaments are going to be mixed anyway when you change from one another?

Sure they will be mixed. But ideally you're leaving very little filament behind. From my understand dribbling slicer is using the whole nozzle to ram back and forth in order to create nice tip. If you're doing this for example with PLA @235C, you're creating a nice sticky mess in the hot nozzle section.

- Hmm, dribbling slicer seems much more stable than stock PrusaSlicer? For example when I tell the slicer to purge the nozzle at 235/260C it does exactly that. Plus when I purge PLA (changing to PETG) I kinda need to have a higher temperature (235C) to properly get the PETG into the nozzle? Also from what I can tell dribbling slicer is using the same logic as your script ( https://github.com/workinghard/mmuGcodeParser )?

Dribbling slicer is doing it different and I don't know the details how. antimix might shed more light. I remember he has done his implementation after my script was implemented and we had one discussion about this. But I don't remember the outcome and couldn't find any description about the magic is happening there.

* Try to improve your measurement setup and do many tests to get the error variance.

- 10 samples of each seems to be quite good for me?

Sorry, missed that table. Looked only at the graphs with one dot's.

I might be completely wrong and your measured values is the reality, doesn't matter how you change the material. Just throwing some ideas what can be tested a different way to get maybe different results.

If you want to stay with dribbling slicer, then try to set purge temp for PLA 200C and PETG 225C. The idea behind it is to remove the filament in the coldest state as possible. This way you take out a lot more filament out of the nozzle. My script is even lowering a temp during unload and it's independent of the purge temp. Purge temp should be IMHO always a print temp (for the particular filament).

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Just How Multi-Material Is The MMU2S?

@nikolai-r

Thanks again for the explanations/suggestions!

Sure they will be mixed. But ideally you're leaving very little filament behind. From my understand dribbling slicer is using the whole nozzle to ram back and forth in order to create nice tip. If you're doing this for example with PLA @235C, you're creating a nice sticky mess in the hot nozzle section.

Ah I see what you mean, when you dribble PLA at 235C (outside recommended PLA temp) you are going to mix OK PLA with one that has been heated up "too much". But the thing is that my dribbling temperature is 180C for PLA and 205C for PETG, so I would not be running into the issue you have described. The nozzle is only heated up to 235C when it's purging into the block

I might be completely wrong and your measured values is the reality, doesn't matter how you change the material. Just throwing some ideas what can be tested a different way to get maybe different results.

Nah this is perfect, I was hoping to create a discussion and see what other people have experienced. Also I have asked Prusa to comment so will be interesting to see what they say too

If you want to stay with dribbling slicer, then try to set purge temp for PLA 200C and PETG 225C. The idea behind it is to remove the filament in the coldest state as possible. This way you take out a lot more filament out of the nozzle. My script is even lowering a temp during unload and it's independent of the purge temp. Purge temp should be IMHO always a print temp (for the particular filament).

Yup, for the tests I have done my dribbling temperature is 180C for PLA and 205C for PETG. If I purge PLA at 200C (changing to PETG) then my loaded PETG will never fully get into the nozzle, while if I purge PETG at 225C (changing to PLA) then it should be fine

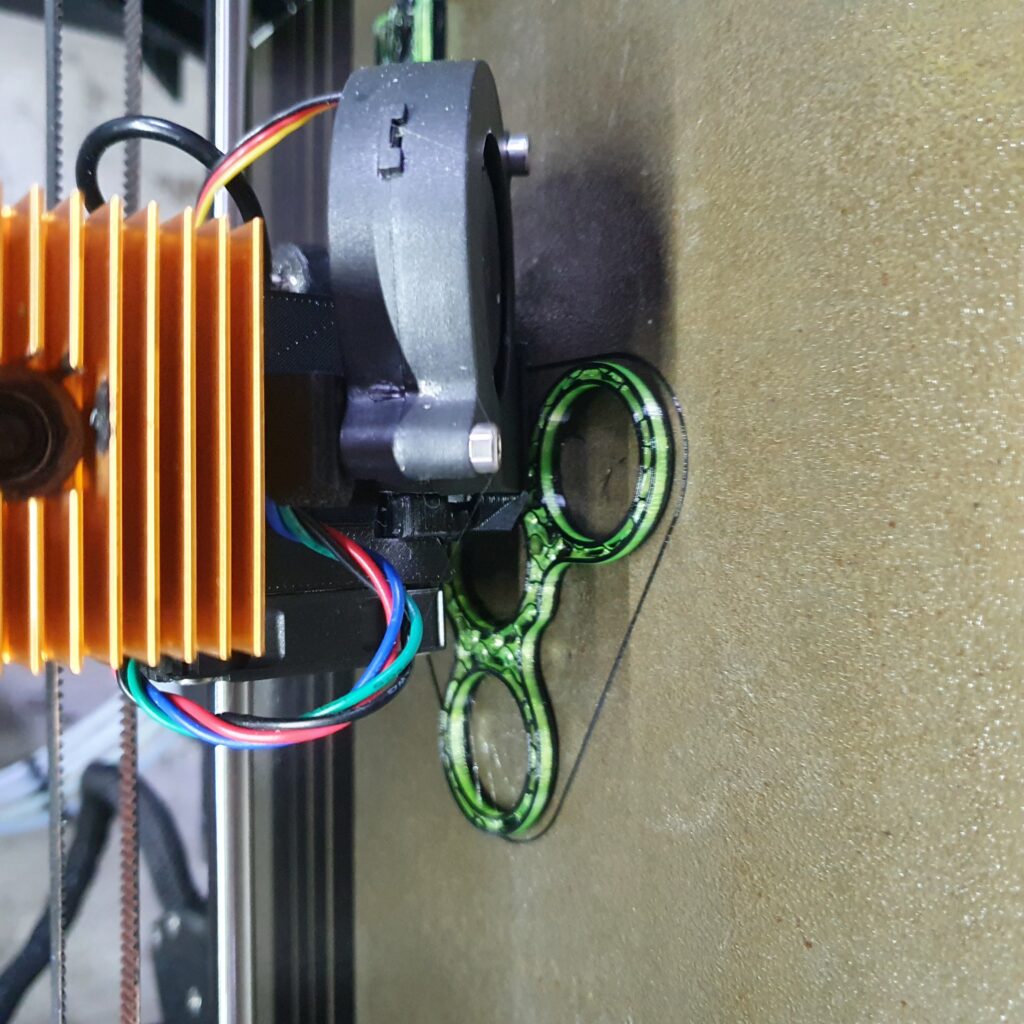

Also when I tested dribbling temperatures I found that I get best results when I dribble at -15C of printing temperature, otherwise my tips would be horrible:

https://www.antalife.com/2020/07/project-prusa-i3-mk3s-mmu2s.html

www.antalife.com

RE: Just How Multi-Material Is The MMU2S?

I have tested some PLA-PET-PLA-PET iterated prints. The hotter the process is, the better results and less concern about contaminations. Both @ 240-245*C (no difference between materials to save cooling time) and I'd rathet say that models broken in random places than on material change lines. Very important is to put next layer just on previous, with minimal cooling. Of course PLA loses some details. Printing model and supports from PET and support interfaces from PLA gives nice results. Yes, it sticks nicely with PET but it's still easier to [cut|sand]out from PET.

RE: Just How Multi-Material Is The MMU2S?

@igor

Righto, do you mind showing what you were printing?

www.antalife.com

RE: Just How Multi-Material Is The MMU2S?

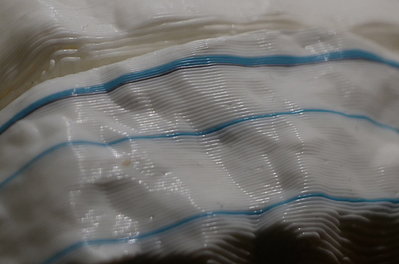

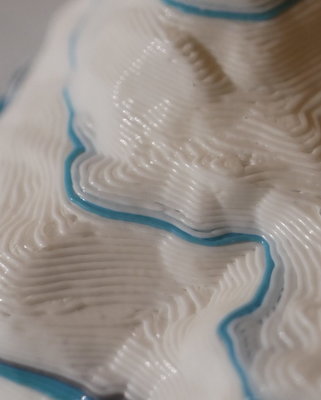

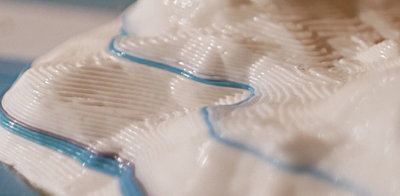

Test models went into trash bin, the final print was given as a birthday gift to my colleague. Few photos left. White and grey Prusament PLA, blue Prusament PET-G. 0.3mm layer, "0.3mm DRAFT" profile plus some speed parameters raised, top/bottom/perimeters only 2 layers, 104% flow, running @ 150% speed (from printer's panel), temperatures for both materials set to 240. Whole effect was intended and I made some extra tests for it to look as it looks. It was decorative model of iceberg, a gift for geographer/glaciologist, who is familiar with level lines like in maps.

First photo shows two models sticked bottom to bottom, so very big visual difference. Even on second photo, awesome inter-layer diffusion is visible. Stock Mk3s with MMU2s.