Re: An incomplete list of MMU2 failure modes I've seen

nice, im trying to study everything people are doing, im sure I will have to fight with something when I get my MMU, but lessions from people that got it early should help greatly. thanks for sharing stuff.

I have a Prusa,therefore I research.

Re: An incomplete list of MMU2 failure modes I've seen

Getting better at troubleshooting and tweaking my mmu2, but still having the layer skip issue with certain filament.

Prusa please actively detect missing filament using the laser filament sensor already in the mk3 extruder, which is marketed as being able to detect moving filament.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: An incomplete list of MMU2 failure modes I've seen

Prusa please actively detect missing filament using the laser filament sensor already in the mk3 extruder, which is marketed as being able to detect moving filament.

Unfortunately, that is not a guaranteed solution. Filament may trigger the sensor and still not reach the Bondtech 🙁 And as we know, not all filaments are detected by that sensor.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: An incomplete list of MMU2 failure modes I've seen

Prusa please actively detect missing filament using the laser filament sensor already in the mk3 extruder, which is marketed as being able to detect moving filament.

Unfortunately, that is not a guaranteed solution. Filament may trigger the sensor and still not reach the Bondtech 🙁 And as we know, not all filaments are detected by that sensor.

Peter

Correct PJR. My intention is to highlight the issue, and hope that Prusa does something about it. Especially since there is no ramming guide, nor can they except every1 to have a perfectly tweaked and calibrated mmu2.

Prusa MK3 > MK4s

Prusa MK2.5 kit > MK3 > MK3s > MK4s

Prusa SL1 3D printer + Curing and Washing Machine (day1 order)

Taz6 - taken apart for space

CR10s4 - upgrading

Delta 3ku - dont use

Re: An incomplete list of MMU2 failure modes I've seen

I've never seen a case where the optical filament sensor couldn't detect the filament at all, even for things like transparent PETG. It's just that it wasn't totally reliable when used continuously while printing. It seems like they could enable it temporarily during filament change to ensure that the extruder gears have engaged the filament, then turn it back off.

Re: An incomplete list of MMU2 failure modes I've seen

maybe ill hook up my scope and see what the filament sensor sees. for science!

I have a Prusa,therefore I research.

Re: An incomplete list of MMU2 failure modes I've seen

Same here.

I have nearly managed all issues, loading, unloading, spool placement etc.

Only problem now is the silent killer : skip layers.

There is no warning that the printer is printing in mid air.

Enabling optic sensor might be useful but as someone else has pointed out, false positive can happen especially when the tip is not well formed and with lots of stringing.

Looking for guides to help decrease stringing and having a consistently well formed tip. (Choice of filament, any preliminary test, ramming setting etc)

Re: An incomplete list of MMU2 failure modes I've seen

I've got another interesting failure mode that some people may be experiencing and not realize the cause. I had a problem where the idler assembly seemed to be getting confused and would start to select the wrong filaments and just generally behave oddly. In other words, the selector would be at the correct location, but the idler bearings would be pressing against a totally different filament. Also, sometimes it would fail to grip the filament properly.

It turns out that the two screws that attach the idler to the stepper shaft had started to loosen up, which caused some slop in the idler position. I added some Loctite, screwed the screws down tight, and things were happy again... for a little while, and then it started to happen again. So I tightened the screws, and it happened again, and I tightened the screws, and it happened again. It turns out that the screws were not backing out. I think the plastic was getting soft from the heat of the stepper motor. My MMU2 is black, so this probably made things worse.

In the end, because of how it is build, the idler for #1 filament was also being pulled back from my constant tightening of the screws and would no longer reliably grab the filament. I printed a new idler assembly in polycarbonate and have yet to have the problem again. Hopefully this helps someone out there wondering WTF is going on with their idler.

Cheers!

Re: An incomplete list of MMU2 failure modes I've seen

It turns out that the two screws that attach the idler to the stepper shaft had started to loosen up, which caused some slop in the idler position. I added some Loctite, screwed the screws down tight, and things were happy again... for a little while, and then it started to happen again. So I tightened the screws, and it happened again, and I tightened the screws, and it happened again. It turns out that the screws were not backing out. I think the plastic was getting soft from the heat of the stepper motor. My MMU2 is black, so this probably made things worse.

I second this one. I cracked my first drum overtightening the screws (got ahead of the instructions, AND the warning). I printed a second in black PETg.

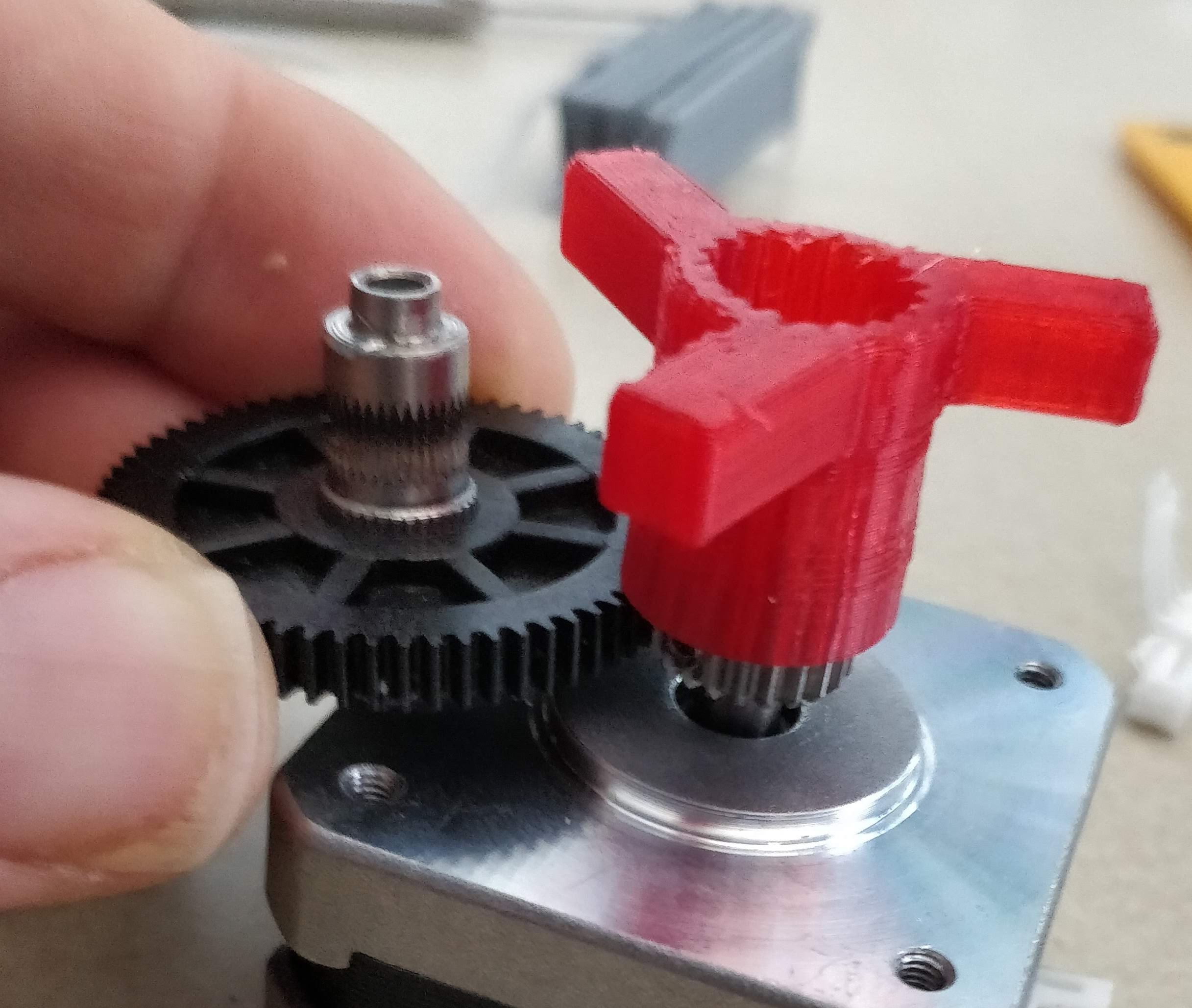

After a day, I had similar issues, and found the screws WAY loose - which I thought was due to my undertightening. Snugging them up helped, and so far it hasn't come back... I something could be done there, perhaps even designing in a small metal part (gear) to grip the shaft and provide a better interface for the plastic. The cheapest of gears would do, I've used this trick in the past.

I think it'd solve the problem. In this case, 98A TPU held a lot better than PLA/PETG D-rings which fit the motor shaft ever did.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.

Re: An incomplete list of MMU2 failure modes I've seen

I've got another interesting failure mode that some people may be experiencing and not realize the cause. I had a problem where the idler assembly seemed to be getting confused and would start to select the wrong filaments and just generally behave oddly. In other words, the selector would be at the correct location, but the idler bearings would be pressing against a totally different filament. Also, sometimes it would fail to grip the filament properly.

It turns out that the two screws that attach the idler to the stepper shaft had started to loosen up, which caused some slop in the idler position. I added some Loctite, screwed the screws down tight, and things were happy again... for a little while, and then it started to happen again. So I tightened the screws, and it happened again, and I tightened the screws, and it happened again. It turns out that the screws were not backing out. I think the plastic was getting soft from the heat of the stepper motor. My MMU2 is black, so this probably made things worse.

In the end, because of how it is build, the idler for #1 filament was also being pulled back from my constant tightening of the screws and would no longer reliably grab the filament. I printed a new idler assembly in polycarbonate and have yet to have the problem again. Hopefully this helps someone out there wondering WTF is going on with their idler.

Cheers!

Still no problem with the idler in polycabonate?

I get skipped layers of the first filament a couple of hours into a print so I am thinking of implementing your fix.

Re: An incomplete list of MMU2 failure modes I've seen

[*]The filament unloads but the FINDA doesn't register the unloading. This may be because of a bit of debris in the path, a filament thread that keeps the ball from dropping, or the ball just gets stuck for unknown reasons. The printer will ask the operator to clear the problem. Usually I will recut the tip of the filament and remove any debris I find, to try to keep it from happening again right away.

I struggled with this a lot last night and calibrated the FINDA height with the printer / MMU on.

1) I loosened the idler and the FINDA screw so I could push the filament freely in the path and adjust the height of the FINDA easily.

2) With the filament in the path, I lowered the FINDA until the red light on the probe was off, indicating that it was sensing the metal ball.

3) With the filament still in the path I backed off the FINDA until the red light came on, indicating that it was no longer reading the metal ball, and then backed it in slowly until the FINDA light went off when sensing the metal ball.

4) I tightened everything down and no longer ran into an issue.

I hope that helps someone because I was going nuts last night because sometimes the MMU exchanged filaments fine and other times it kept retracting the filament all the way out.

Re: An incomplete list of MMU2 failure modes I've seen

I had a brand-new failure mode last night!

Apparently I didn't tighten the bowden tube fitting enough at the extruder end. Usually I just hand-tighten it, since it has to be taken off fairly regularly, and it worked its way off at some point overnight. I came back to find the tube dangling in midair and the printer happily air printing.

Fortunately an easy fix. This is another failure mode which could be detected if the extruder's filament sensor can be made to work with the MMU.