Wipe tower gradual raised edges eventually catches nozzle and crashes

Hi

I have recently added the MMU2 upgrade to my Prusa MK3. I've had great fun getting this all setup and I've learned a lot the last few days.

I have got it running smoothly and able to pull in each filament from the MMU to the extruder.

Single colour prints are working fine.

The only problem I seem to have left is a issue with the wipe tower, it is being knocked off the bed by the nozzle or the PINDA.

The crash is being caused by a build-up of PLA where the nozzle is wiping repeatedly on tool change. The nozzle seems to be selecting the same location on the wipe tower to do the load/unload and then wiping through existing layers or oozing? I’m not sure where the excess PLA is coming from but a melted ridge is forming.

After multiple layers a raised edge is visable from what looks like melted PLA. Once this ridge gets to be 2-3mm is catches and knocks the wipe tower of the bed.

The nozzel is clean and not covered in filiment and the print object is loverly and sharp with no excess filiment.

I have searched and searched the forums and google but I’m not able to find anyone else with this problem to give me any pointers.

I’m using the latest available version of drivers Slic3r from the Prusa website (19th December 2018).

I’ve tried the default filament settings for Prusa PLA and Generic PLA with no difference.

I’ve kept the printers settings in Slic3r as the provided one from Prusa for the MMU

Have you any pointers to what is causing this build up when the tool changes?

I’m unable to complete any multi colour prints as eventually this build-up is causing a failure. I’m struggling with this one.

Attached are two pictures of the wipe tower that hopefully shows the ridge and raised edges.

Any help would be greatly apricated,

Re: Wipe tower gradual raised edges eventually catches nozzle and crashes

Hi, thanks for the advice.

I adjusted the setting tonight and set the "Extra loading distance" to -25mm and the wipe tower was perfect and the print finished without a problem.

This looks to of solved the problem. 🙂

I will do some more prints and maybe experiment with the value but right now it looking good.

RE: Wipe tower gradual raised edges eventually catches nozzle and crashes

Hey there, I've been having a similar problem with overextrusion on the wipe tower building up and causing the nozzle to repeatedly collide with the excess material. The problem was so bad that I'd always end up aborting the print because I didn't want to damage anything! The towers looked like this:

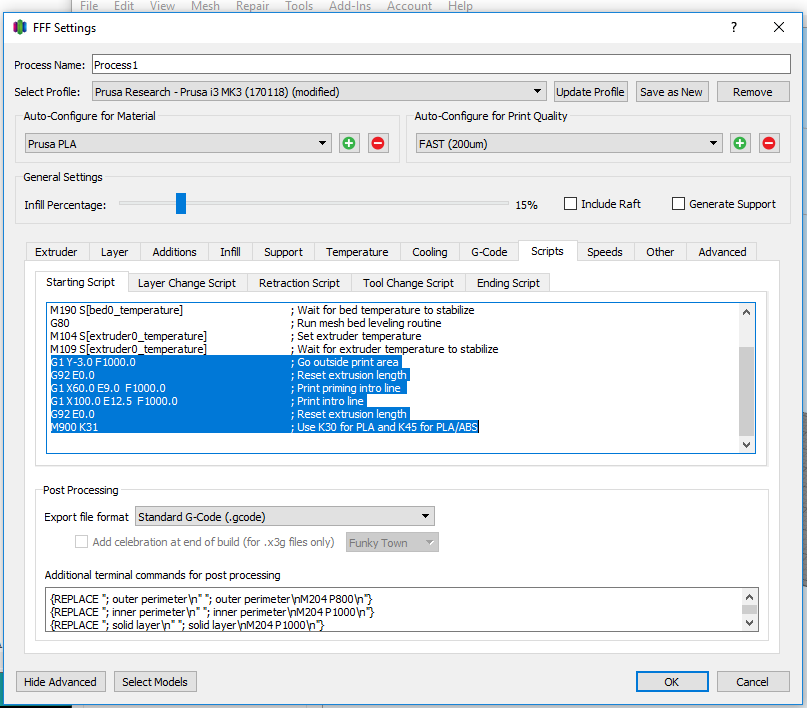

Anyway, I've lurked on the forum for a while now, looking at all of the various solutions people have proposed, but my firmware was up to date and all of my sensors were calibrated properly. I found one solution involving adjusting (correcting?) the length and position of the cooling tube, but that didn't help much or at all:

At least it didn't appear to have any negative effects... It did however get rid of the blob at the beginning of that first strip that the printer lays down at the beginning of every job!

In any case, I found this solution here, adjusted the extra loading distance to -20mm and voila:

A perfect wipe tower! And a pretty nice printed part to go along with it too 🙂 Anyway, I just wanted to share my experience, confirm andrew-b39 and ludovit-o's experiences and give hope to all of the people in the other threads getting no better advice than firmware and sensors!