Re: Still zero successful prints

so "zero beast" is working real good I take it.

I have a Prusa,therefore I research.

Re: Still zero successful prints

😆 😆 😆 😆 😆 😆 😆

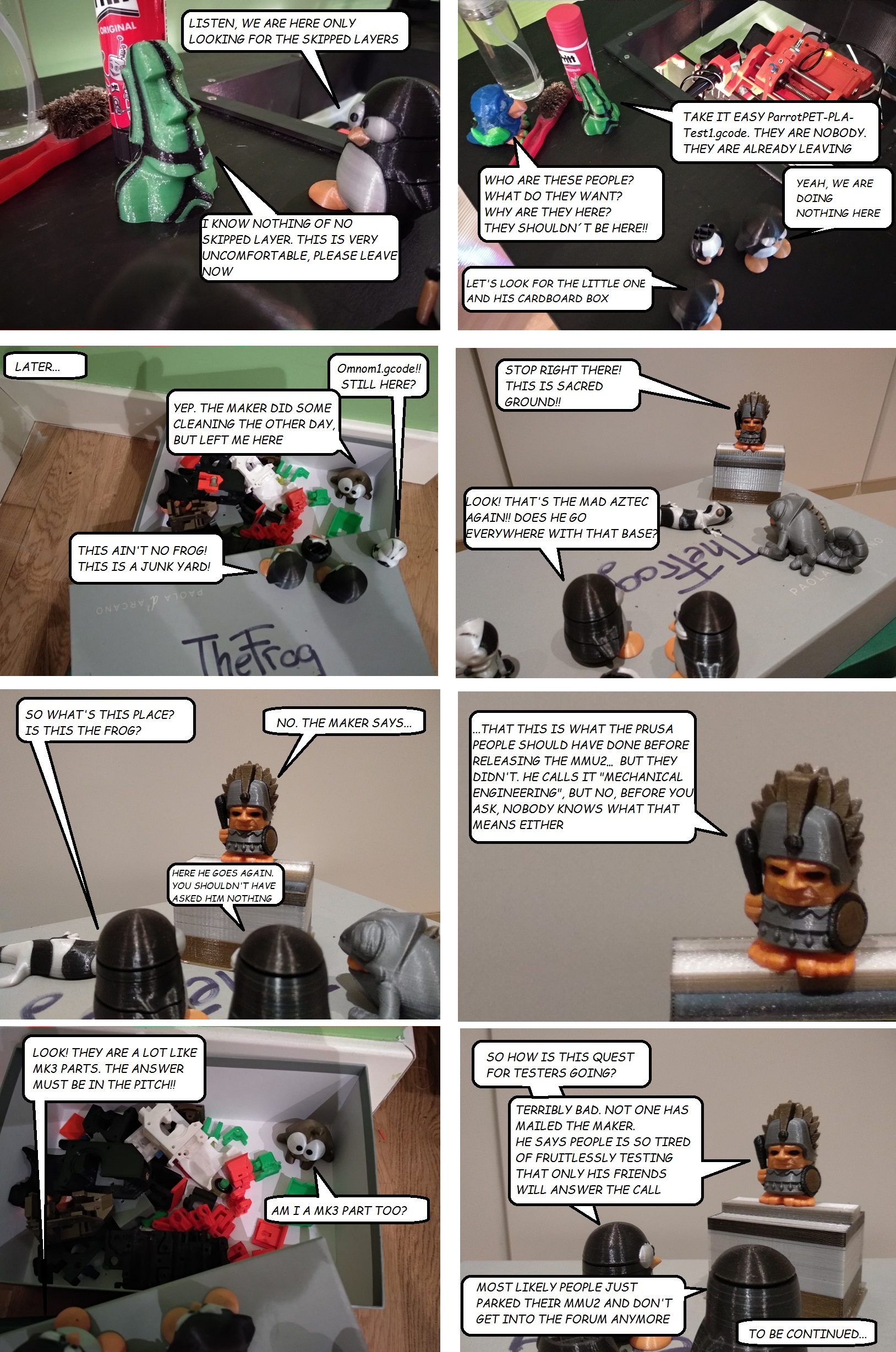

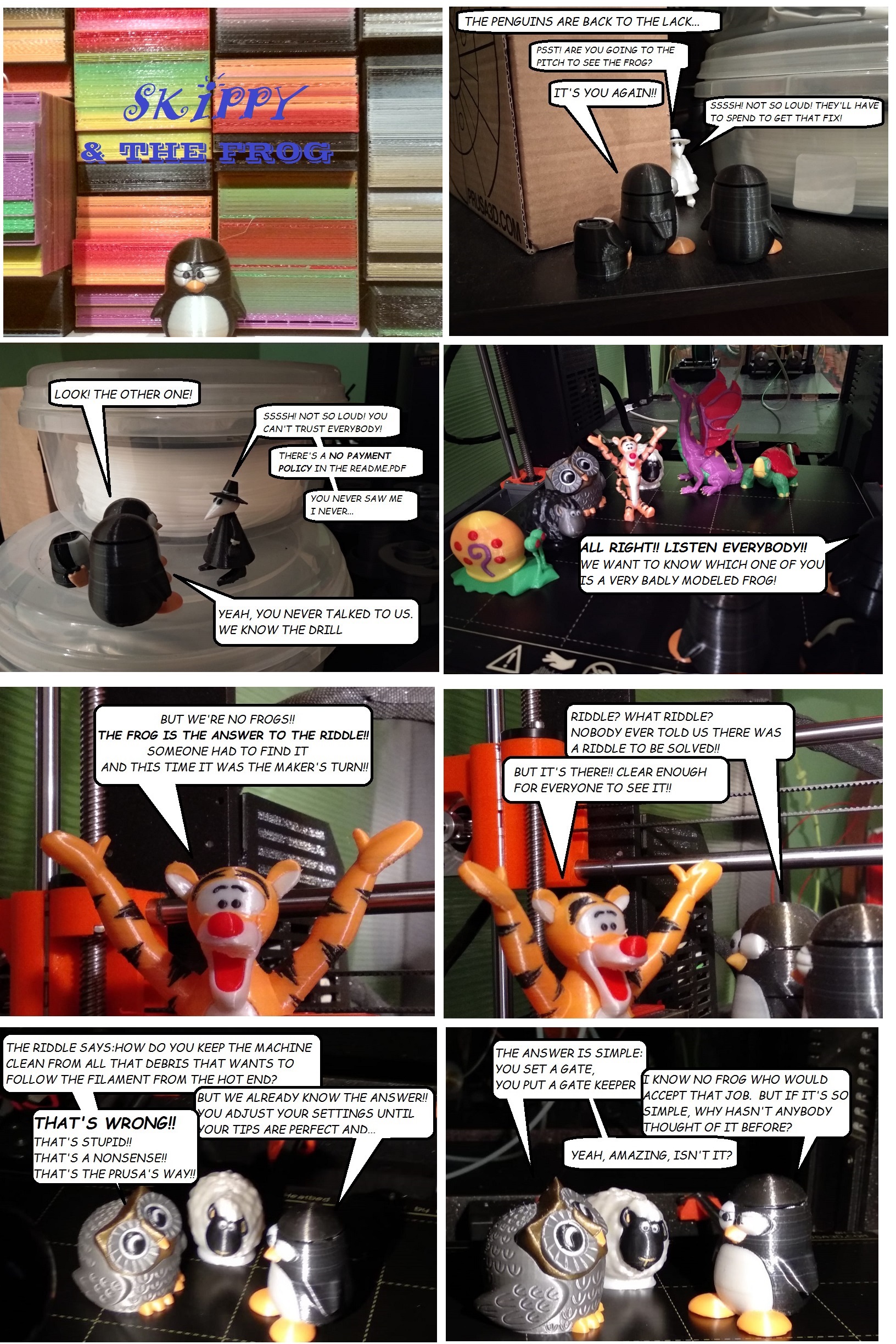

I take it, you don't like cartoons, or at least you did not like mine

But congrats!!! now we all know you made it to the very end of the first vignette.

You're not obliged to read next one. so just don't

so "zero beast" is working real good I take it.

Re: Still zero successful prints

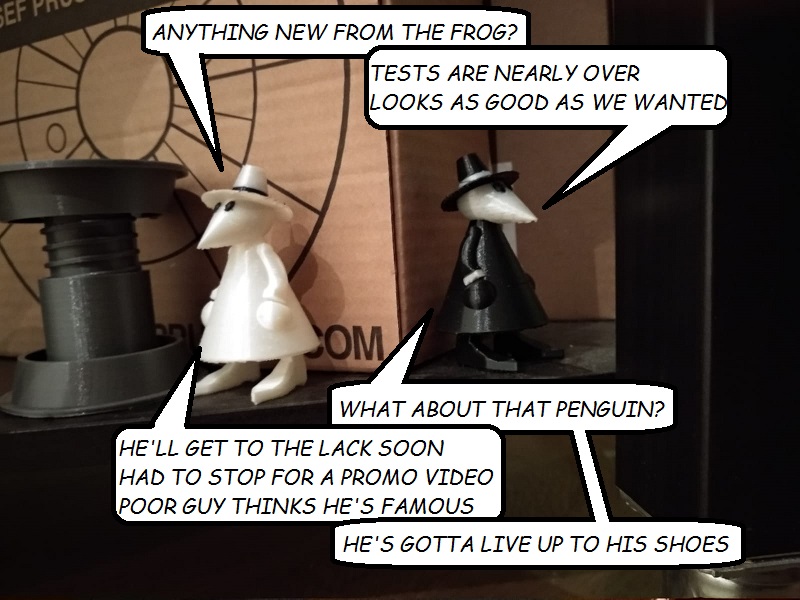

TheFrog in Github: https://github.com/raavhimself/The-Frog

TheFrog in CGtrader; https://www.cgtrader.com/3d-print-models/hobby-diy/other/the-frog-the-prusas-mmu2-hairless-extruder-fix

TheFrog in YouTube:

For those of you who do not like music in the videos and prefer much more the soothing sounds of life (traffic, a dog barking, a child crying far away...), just turn off the volume and listen to your own life's soundtrack. I'm sorry but the video has music, for those who enjoy it just like me. Pink Floyd in fact.

From now on TheFrog is moving to the mods section of the forum.

Re: Still zero successful prints

Sorry, I don't get it. What is the function of it? I assume you get with the default settings hairy filament tips. Would be great if you can describe how this "frog" handling it during load/unload.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Still zero successful prints

Sorry, I don't get it. What is the function of it? I assume you get with the default settings hairy filament tips. Would be great if you can describe how this "frog" handling it during load/unload.

The function of it is making the machine work reliably, and it accomplishes its function.

I'd tell you to look at the drawings and maybe you could perceive how the device works, but I know that some people is just not capable to understand the works of mechanical devices when they involve timing and all sort of different things happening at the same time.

As a summary, it works. No hairs. No jams.

Re: Still zero successful prints

The function of it is making the machine work reliably, and it accomplishes its function.

I'd tell you to look at the drawings and maybe you could perceive how the device works, but I know that some people is just not capable to understand the works of mechanical devices when they involve timing and all sort of different things happening at the same time.

As a summary, it works. No hairs. No jams.

It's fine if you don't want to describe it in detail. What I'm asking for is a generic description. Many people here have engineering background and maybe like me would like to understand the idea behind it. My printer MK3+MMU2 is absolutely reliable with stock parts but I'm always open for improvements.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Still zero successful prints

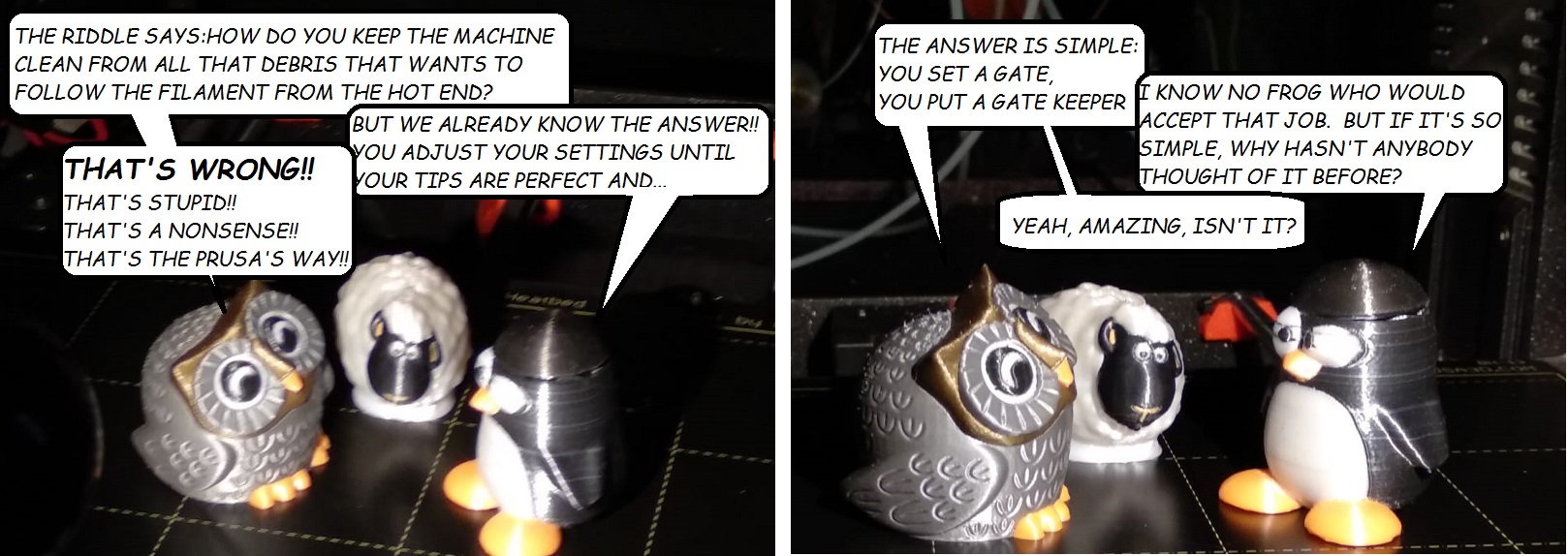

Ok, I'll try to describe briefly how it works:

1- Loading - The filament tip displaces the slidercart. This causes the blade holder to retract ant the gate opens. The filament can get into the extruder with no impediments

2- Unloading - When the filament retracts, the slider cart advances to its former position, and this causes the blade holder to advance too, closing the gate and impeding the pass for all the hotend debris to the upper parts of the machine. That is: no strings. Now the only thing left is making the bottom part of the machine extremely resilient to jams and very easy to clean. That's TheFrog

Re: Still zero successful prints

The function of it is making the machine work reliably, and it accomplishes its function.

I'd tell you to look at the drawings and maybe you could perceive how the device works, but I know that some people is just not capable to understand the works of mechanical devices when they involve timing and all sort of different things happening at the same time.

As a summary, it works. No hairs. No jams.

It's fine if you don't want to describe it in detail. What I'm asking for is a generic description. Many people here have engineering background and maybe like me would like to understand the idea behind it. My printer MK3+MMU2 is absolutely reliable with stock parts but I'm always open for improvements.

Ok, I'll try to describe briefly how it works:

1- Loading - The filament tip displaces the slidercart. This causes the blade holder to retract ant the gate opens. The filament can get into the extruder with no impediments

2- Unloading - When the filament retracts, the slider cart advances to its former position, and this causes the blade holder to advance too, closing the gate and impeding the pass for all the hotend debris to the upper parts of the machine. That is: no strings. Now the only thing left is making the bottom part of the machine extremely resilient to jams and very easy to clean. That's TheFrog

If you're really interested I'd tell you to have a look at the info in the git or the video in youTube

Re: Still zero successful prints

If you're really interested I'd tell you to have a look at the info in the git or the video in youTube

Thanks for the explanation. I did. But it's very hard to see the details. As far as I understand you cut the strings during the unloading procedure similar to what MMU2 unit suppose to do. Two questions:

1. Where do all the cut pieces reside? If I have 500+ tool changes with strings, there will be 500+ pieces. That's a lot.

2. What happens to the long strings. They are actually the most critical. In the current stock configuration they are usually blocking the FINDA area. With TheFrog setup they might block in the extruder PTFE tube which is in my understanding more dangerous.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Still zero successful prints

If you're really interested I'd tell you to have a look at the info in the git or the video in youTube

Thanks for the explanation. I did. But it's very hard to see the details. As far as I understand you cut the strings during the unloading procedure similar to what MMU2 unit suppose to do. Two questions:

1. Where do all the cut pieces reside? If I have 500+ tool changes with strings, there will be 500+ pieces. That's a lot.

2. What happens to the long strings. They are actually the most critical. In the current stock configuration they are usually blocking the FINDA area. With TheFrog setup they might block in the extruder PTFE tube which is in my understanding more dangerous.

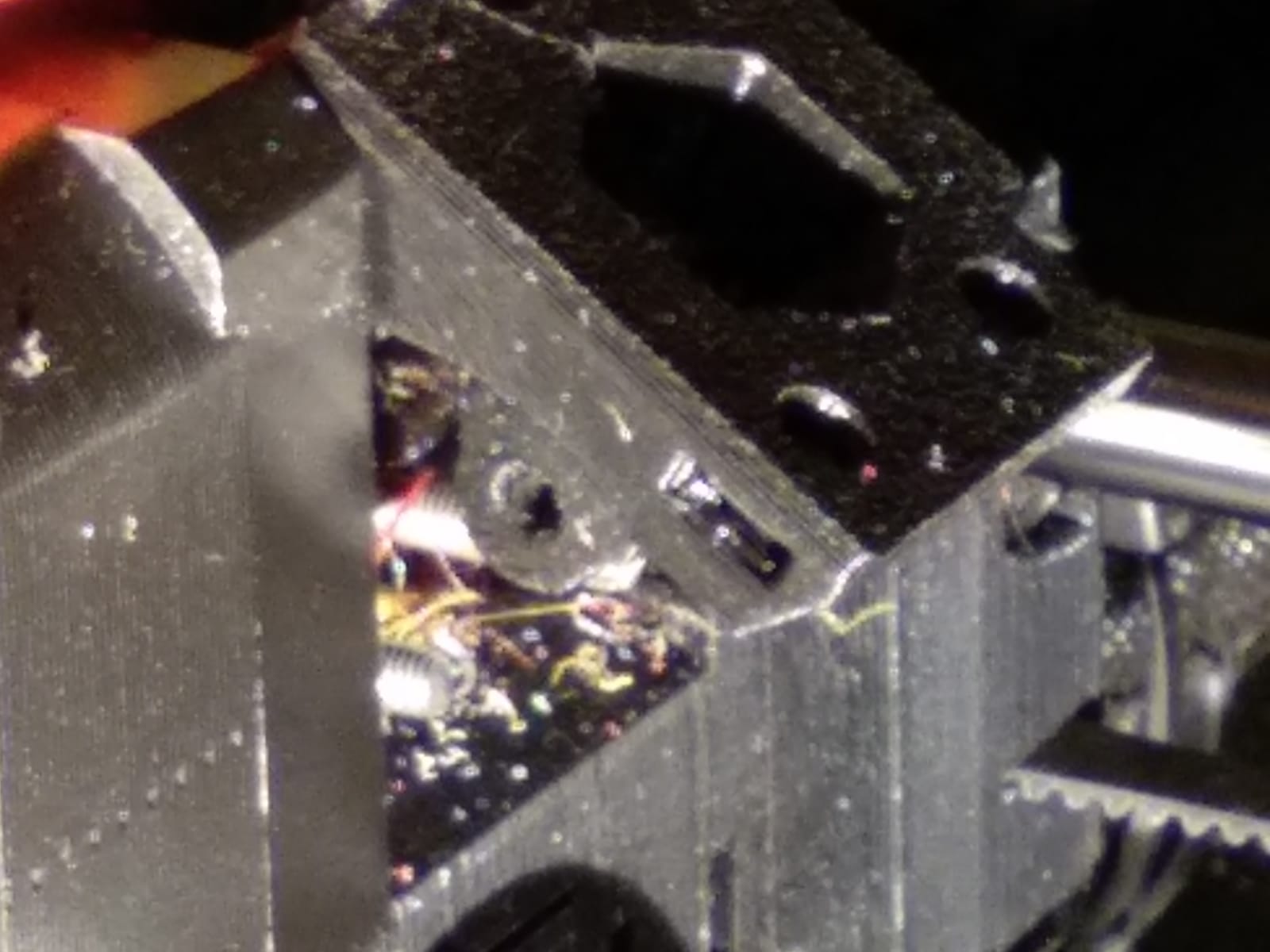

1 - These are the rests of a 40 hour UNINTERRUPTED AND UNASSISTED print. Most of it was founf in the iddlers, rather than in the front trap

That was a 1300 filament change part.

I think that when the tail is cut,if if is connected to the hotend pit , it ends up there. There's nowhere else to go. If the tail is not connected to the hot end, when it's cut (more ripped than cut, in fact), the best thing is that the piece falls to the iddler area where it does no harm. If it ends in the fronttrap area it can trigger a false sensor reading and pause the machine. One time it happened (in about 500 hours so far) that a glob got struck in the openning of the PTFE tube beyond the bondtech gears. The firmware of the Zerobeast paused the machine and protected the print.

2- Long Strings. There are no long strings with TheFrog. That simple.

I once found a ball of fluff dragged by the tip from the front trap that cheated the FINDA. Again, the firmware protected the print.

Re: Still zero successful prints

That was a 1300 filament change part.

I think that when the tail is cut,if if is connected to the hotend pit , it ends up there. There's nowhere else to go. If the tail is not connected to the hot end, when it's cut (more ripped than cut, in fact), the best thing is that the piece falls to the iddler area where it does no harm. If it ends in the fronttrap area it can trigger a false sensor reading and pause the machine. One time it happened (in about 500 hours so far) that a glob got struck in the openning of the PTFE tube beyond the bondtech gears. The firmware of the Zerobeast paused the machine and protected the print.

2- Long Strings. There are no long strings with TheFrog. That simple.

I once found a ball of fluff dragged by the tip from the front trap that cheated the FINDA. Again, the firmware protected the print.

Thanks for the images. It looks even worse then I thought. This small particles can do a lot of damage around the idler, gears and the sensor.

Regarding the long strings it's not a matter of hardware. It depends on the filament and temperature and will occur. Maybe not for you but for other people as we have seen different filament tips from different people with the same settings.

The fluff is usually generated by the tiny middle size strings. But the long strings can generate in your setup blocked extruder. I've tested couple different filament types with different settings just to see how the tips might look like and how they affect different parts. Two kind of tips are the worst.

1. The fluffs generated by tiny hairs are forming a blob. They can block any part of the filament path. In the stock setup they prefer to stay either in the FINDA area or around the bond tech gears.

2. Really long strings (>10mm). In the stock setup they're blocking the orange PTFE tube.

Both issues can be either catched by the firmware or cleaned up easily by the operator in the stock setup. But they can also be missed by the stock firmware and generate missed layers. For this cases I don't see it resolved by "TheFrog".

Anyway I'm glad you found a solution for you and can enjoy the MMU2 prints. This is actually the most important thing everybody is trying to achieve. I prefer stock firmware and stock hardware. The issue with the tips I was able to solve with proper configuration for the filament I use. But if someone gave up or doesn't know how to proceed, your solution might be an option.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Still zero successful prints

Well, I've owned the MMU2 for 4 months now and have precisely 1 successful print. A small one. The next print I tried with the same settings failed quickly and it appeared to be from debris from the one successful print. So really that good print was probably destined to fail if it had been much bigger. 4 months of failures. I have a large pile of failed prints. I could almost make a new spool from all the filament ends I've had to cut.

I am now trying to print a two color print using two Prusa PLA (I've only been using PLA in MMU). I can get a setting that one likes but not the other. Meaning, one short tail and one long stringy one. I change settings and it reverses. No sweet spot found. Now 1.04 firmware has really made it unreliable. So sad.

Re: Still zero successful prints

That was a 1300 filament change part.

I think that when the tail is cut,if if is connected to the hotend pit , it ends up there. There's nowhere else to go. If the tail is not connected to the hot end, when it's cut (more ripped than cut, in fact), the best thing is that the piece falls to the iddler area where it does no harm. If it ends in the fronttrap area it can trigger a false sensor reading and pause the machine. One time it happened (in about 500 hours so far) that a glob got struck in the openning of the PTFE tube beyond the bondtech gears. The firmware of the Zerobeast paused the machine and protected the print.

2- Long Strings. There are no long strings with TheFrog. That simple.

I once found a ball of fluff dragged by the tip from the front trap that cheated the FINDA. Again, the firmware protected the print.

Thanks for the images. It looks even worse then I thought. This small particles can do a lot of damage around the idler, gears and the sensor.

Regarding the long strings it's not a matter of hardware. It depends on the filament and temperature and will occur. Maybe not for you but for other people as we have seen different filament tips from different people with the same settings.

The fluff is usually generated by the tiny middle size strings. But the long strings can generate in your setup blocked extruder. I've tested couple different filament types with different settings just to see how the tips might look like and how they affect different parts. Two kind of tips are the worst.

1. The fluffs generated by tiny hairs are forming a blob. They can block any part of the filament path. In the stock setup they prefer to stay either in the FINDA area or around the bond tech gears.

2. Really long strings (>10mm). In the stock setup they're blocking the orange PTFE tube.

Both issues can be either catched by the firmware or cleaned up easily by the operator in the stock setup. But they can also be missed by the stock firmware and generate missed layers. For this cases I don't see it resolved by "TheFrog".

Anyway I'm glad you found a solution for you and can enjoy the MMU2 prints. This is actually the most important thing everybody is trying to achieve. I prefer stock firmware and stock hardware. The issue with the tips I was able to solve with proper configuration for the filament I use. But if someone gave up or doesn't know how to proceed, your solution might be an option.

Hahahahahahaha 😆 😆 😆 😆 😆 😆 😆 😆 😆 😆 😆

The real only thing worse than I can imagine is you being so partisan with this brand!!! Anyone of the people who is reading your posts thinks they know who is filling your wallet. I do

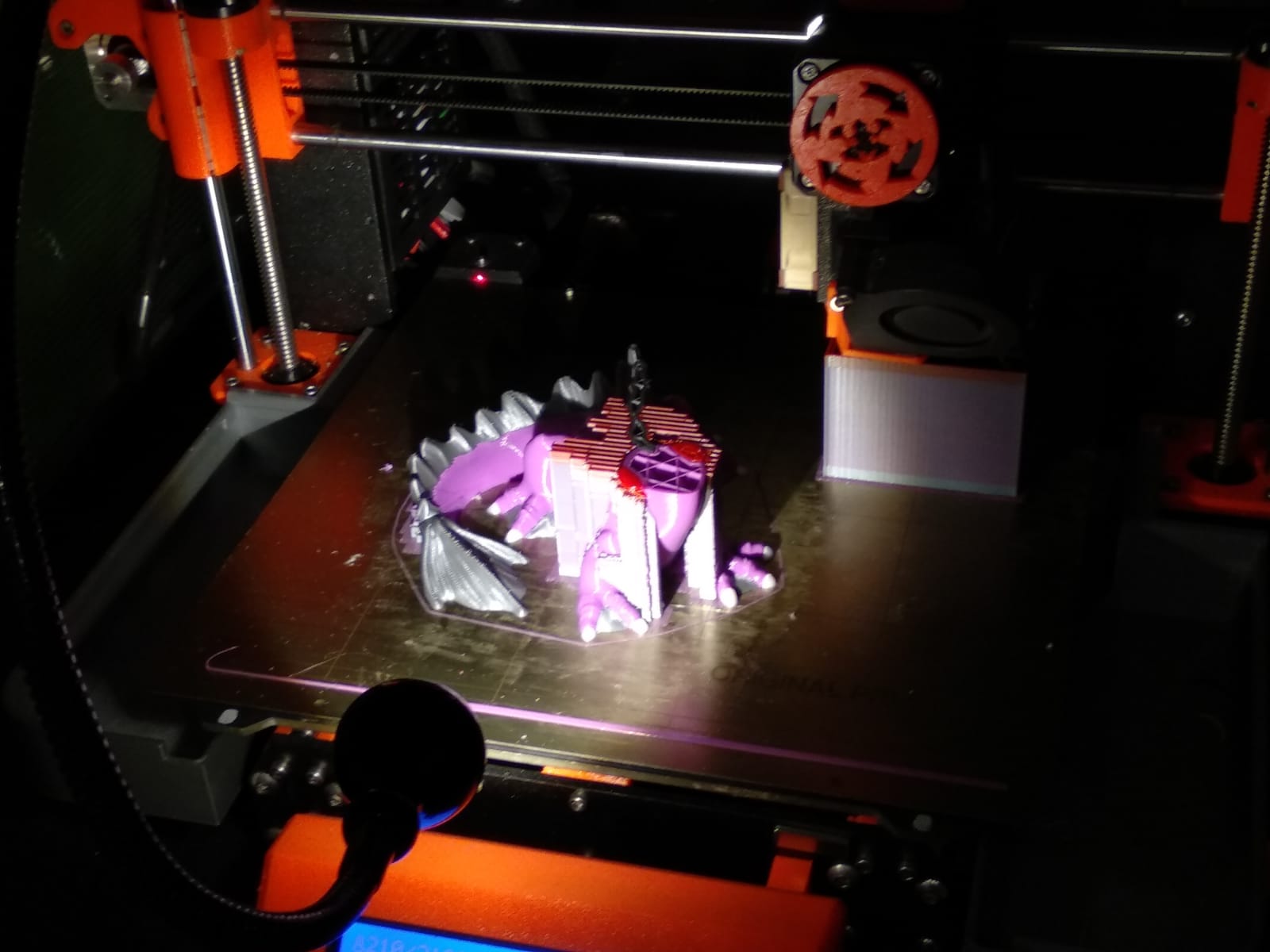

Worse than you can imagine!!! I don't know how long are your prints. It looks like 40 hours is not long enough for you. Well I am now doing a 47 hour print. Will that be enough? Surely not for you.

You should know that you are for sure one of the few humans that has made the MMU2 work reliably. Most of us are just as dumb as jltx and have wasted months working with the MMU2 without success. Look at me, I had to change the machine's firmware and hardware to get a reliable device, but you are trying to convince us that your machine is completely reliable as it came from stock...

My experience, and that of many others contradict your words.

I don't want you to try the frog. I don't need it, but I think you are trying to mislead people into not fixing their machines, and I don't like that

Re: Still zero successful prints

...

Worse than you can imagine!!! I don't know how long are your prints. It looks like 40 hours is not long enough for you. Well I am now doing a 47 hour print. Will that be enough? Surely not for you.

Based on my experience print time doesn't really matter after 8 hours / 200 tool changes. Once everything is running smooth, you could also print a week. That's why I didn't mentioned that.

You should know that you are for sure one of the few humans that has made the MMU2 work reliably. Most of us are just as dumb as jltx and have wasted months working with the MMU2 without success. Look at me, I had to change the machine's firmware and hardware to get a reliable device, but you are trying to convince us that your machine is completely reliable as it came from stock...

This was your way and perfectly legit. I went a different route and also documented it here. If you check my other MMU posts, there were things I had to adjust but except of the spool holders every other part is still stock. Sharing my thoughts, helping people and discussing about my hobby, that's the only reason why I'm here.

My experience, and that of many others contradict your words.

I don't want you to try the frog. I don't need it, but I think you are trying to mislead people into not fixing their machines, and I don't like that

How that? By describing two issues which are present with stock MMU2 solution and are still present with your solution, I'm just saying there is no perfect "MMU solution"TM and there are still cases where it will fail. I can repeat myself: "But if someone gave up or doesn't know how to proceed, your solution might be an option."

PS: Maybe you might rethink the strategy how you answer the support questions to your product.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Still zero successful prints

So your best advice for the people is to keep on tunning their settings until they get to this magical nirvana point where all the prints come out perfect, and by chance this is what it has happened to me...

I passed the 8 hour barrier a month and a half ago. I went public when I was confident with a 40 hour print,

I can detect the aggressiveness in your responses to my posts since I published the second comic strip, so don't try to sell me air now

You are trying to defend a poorly engineered machine, and I have the feeling that if I had left my design with a CC license you would be more open minded, wouldn't you?