MM2 print fails with no indication

I'm trying to understand just want the issue is.

It sliced fine.

The printer seems to think it completed the print. There is no message on the lcd to check the MMU.

Both filaments were retracted but the print did not complete. Ends of the retracted filaments look fine.

There was a few times there were issues. The LCD referred me to MMU. Each time I re-fed the filament and it happily continued on. Had all gone well, it should have taken 8h 44min. (I wasn't in the room all the time and the first time it sat there for a few hours with the error.) I let it continue over night and when I took a look in the morning, I got the results as indicated.

Why did this fail? How can I prevent it? Any ideas?

Re: MM2 print fails with no indication

Hi Chuck,

can you please share your STL and G-code? I will check it 😉

/ Knowledge Base

The guy behind Prusa assembly manuals...

Re: MM2 print fails with no indication

While jakub checks the gcode, and assuming it is good, I'd check the filament path through the extruder.

If debris or strings were impeding the path near the bondtech gears in the extruder, you could get this. The MMU2 is happily feeding filament, but it's not quite getting to the bondtech, or the bondtech is unable to push it to the nozzle. The MMU2 keeps swapping filaments and the printer thinks everything is fine.

Possible debug: if it isn't too late, check the tips of the two filaments. If you see tipped over strings and not a nice clean tip, they could both have started jamming at the extruder at the same time. (seems like an unlikely coincidence, but possible). If they are clean, look to see if there is any indication that the bondtech gears were grinding on them (curved erosion just back from the tip).

Also: open your extruder door on the right side and glance in to see if it looks clean/free of debris. With it open, shove a piece of filament in from above and make sure it slides freely through.

(While you are there, make sure your bondtech gears are perfectly lined up with the PTFE tube below. Any misalignment there can cause this type of jam).

BTW, until that point it looks like a beautiful print. Hang in there, you'll get it.

Re: MM2 print fails with no indication

Hi Chuck,

can you please share your STL and G-code? I will check it 😉

Here are the files. The stl files are from the sample folder. Thanks in advance for your help!

Re: MM2 print fails with no indication

While jakub checks the gcode, and assuming it is good, I'd check the filament path through the extruder.

If debris or strings were impeding the path near the bondtech gears in the extruder, you could get this. The MMU2 is happily feeding filament, but it's not quite getting to the bondtech, or the bondtech is unable to push it to the nozzle. The MMU2 keeps swapping filaments and the printer thinks everything is fine.

Possible debug: if it isn't too late, check the tips of the two filaments. If you see tipped over strings and not a nice clean tip, they could both have started jamming at the extruder at the same time. (seems like an unlikely coincidence, but possible). If they are clean, look to see if there is any indication that the bondtech gears were grinding on them (curved erosion just back from the tip).

Also: open your extruder door on the right side and glance in to see if it looks clean/free of debris. With it open, shove a piece of filament in from above and make sure it slides freely through.

(While you are there, make sure your bondtech gears are perfectly lined up with the PTFE tube below. Any misalignment there can cause this type of jam).

BTW, until that point it looks like a beautiful print. Hang in there, you'll get it.

I had had problems with getting all the filament positions feeding and went through all the stuff in https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f54/2nd-filament-fails-to-reach-extruder-after-bowden--t24755.html

and this adjustment: https://manual.prusa3d.com/Guide/Service+menu+-+bowden+length/821 . This got all the positions feeding.

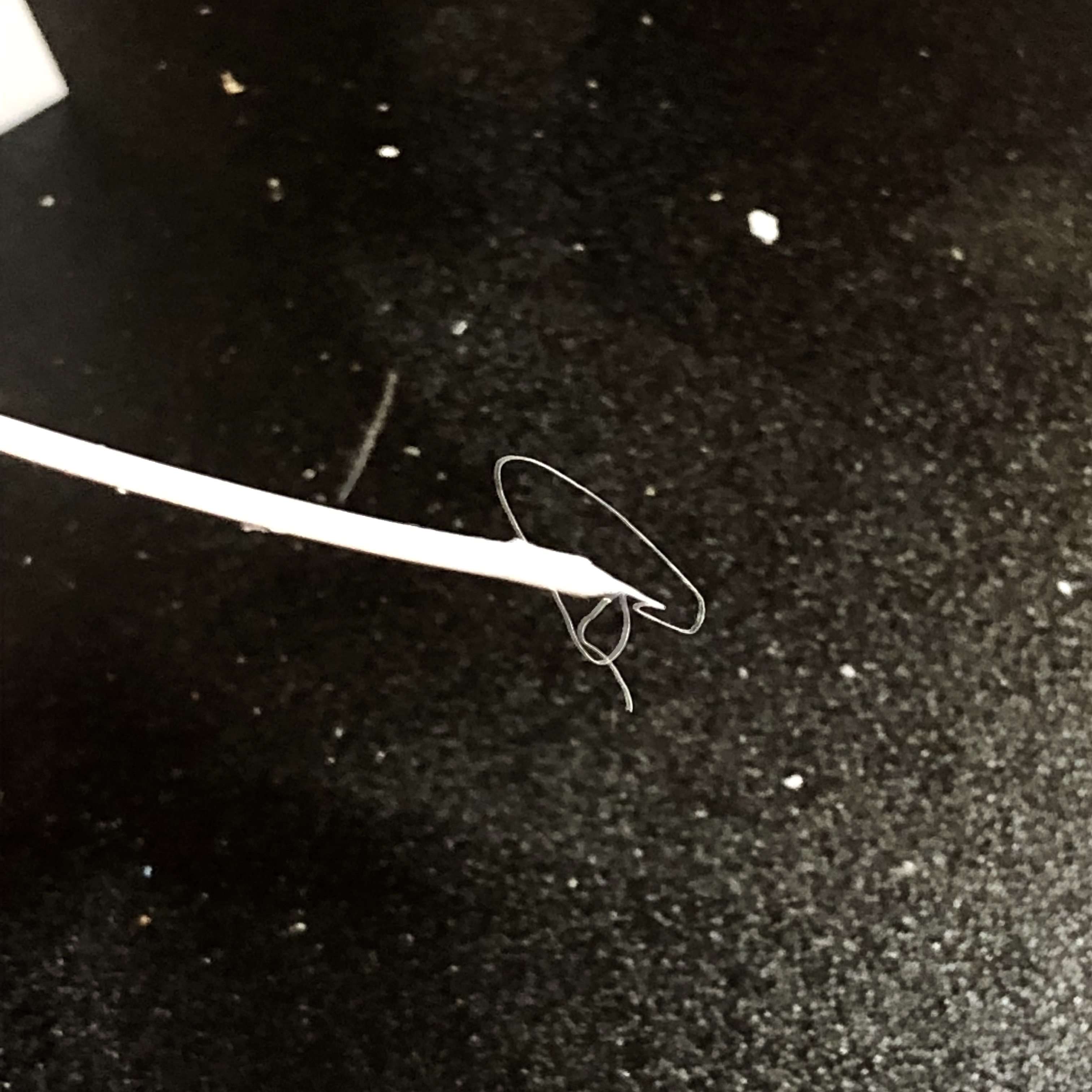

That being said, there were a few white chips by the first bondtech gears. I should have taken a photo of the chips before I blew them away. Here are some pictures of the filaments.

RE the pictures... you can see really really thin strings from the tip and the black has a slightly larger tip but seems to feed through without problems.

There was a tiny divot and thin string on the white filament.

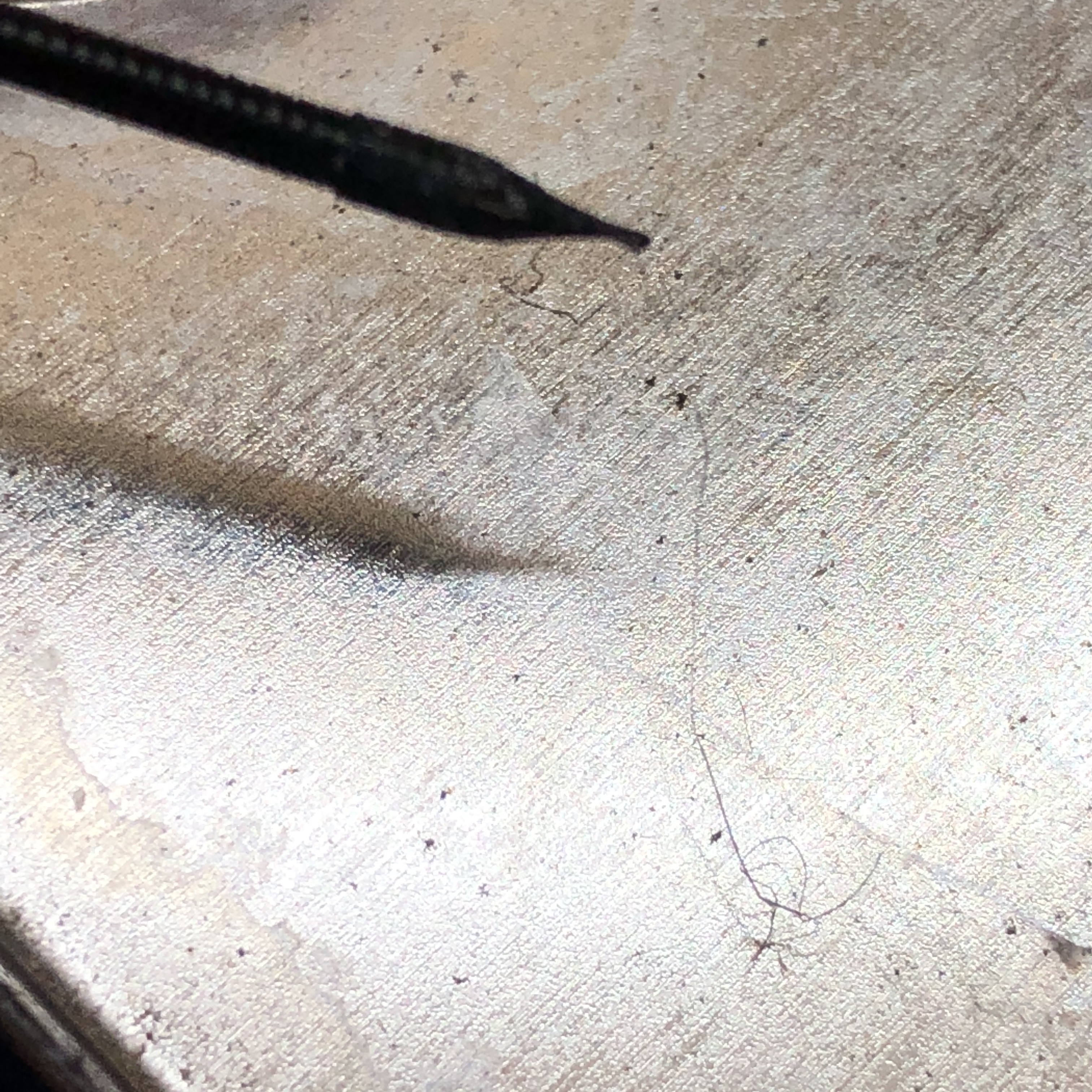

There was no divot on the black filament but there were tiny ridges along the length where the bondtech gears feed. I assume this is normal.

I could try to redo the starting filament length adjustment that was posted in https://manual.prusa3d.com/Guide/Service+menu+-+bowden+length/821

Is there documentation regarding the filament tips and how to change the profile?

Thanks!

Re: MM2 print fails with no indication

The ridges in the black are normal, but if they are too deep they can deform the filament and prevent feeding into the nozzle. Follow the troubleshooting guide make sure your bondtech gears are providing correct tension.

The white is your problem: Any tip that long and stringy is a jam waiting to happen (I know, I've seen lots of those). All it takes is for the tip to angle the right when when entering the bondtech for it to not engage (either catching above or below the bondtech). Either you had that happen for both black and white at the end, or a string fell off in the hot end and both started catching on it.

I would try lower temperatures (I've been using 200C for PLA and having better luck), and/or tweak the load/unload/ram settings a bit (see the end of the Inland PLA settings thread for some good pointers).

Re: MM2 print fails with no indication

The ridges in the black are normal, but if they are too deep they can deform the filament and prevent feeding into the nozzle. Follow the troubleshooting guide make sure your bondtech gears are providing correct tension.

The white is your problem: Any tip that long and stringy is a jam waiting to happen (I know, I've seen lots of those). All it takes is for the tip to angle the right when when entering the bondtech for it to not engage (either catching above or below the bondtech). Either you had that happen for both black and white at the end, or a string fell off in the hot end and both started catching on it.

I would try lower temperatures (I've been using 200C for PLA and having better luck), and/or tweak the load/unload/ram settings a bit (see the end of the Inland PLA settings thread for some good pointers).

Thanks! Dropping the temperature to 200C fixed the tip issue. I didn't re-print the sheep but I did print a 3 color cube that involved 3 colors per layer. It printed with no interuptions! Looks pretty good! Good enough to use as my Avatar picture!

Re: MM2 print fails with no indication

The failure hasn’t happened again. I’ve switched to octoprint because I’ve been having sd card problems. I’m starting to think the real problem with it failing with no indication was loss of connection with the sd card.

There definitely were filament tip issues, and that caused me to have to refeed the filament a lot.

Since my printer was under warranty, Prusa replaced the control panel. Still trying to rely on octoprint though.

Thanks everyone for your help!