load to nozzle failing

After working smoothly for some time and now, after a nozzle swap, my MMU2s is failing to load filament to the nozzle.

Observations:

- Menu -> Load To Nozzle -> Any Filament Type -> Any Filament Slot

- MMU pushes filament into selector, triggering FINDA probe

- MMU pull filament back

- This happens 5 times and then the MMU performs the filament CUT sequence

- MMU pushes filament into selector, triggering FINDA probe. (I can see the FINDA light turn off).

- This happens 2-3 times and then the extruder raises up and

- MMU Led 1 - Blinking Red

- LCD prompts: Filament extruding the correct color?

- Selecting 'No' does nothing

- Selecting 'Yes' and the printing seems to think filament is loaded.

- Sensor Status

- PINDA = 0

- FINDA = N/A

- Fil. Sensor = 0

- The printer seems to think a print is in progress but nothing happens.

- Follow instructions regarding slow blinking red LED 1 found here: https://help.prusa3d.com/ja/article/mmu2s-leds-meaning_2187

- Press middle button

- MMU loads filament into selector, triggering FINDA

- MMU retracts filament, FINDA un-triggered

- LED 1 blinking green and red

- Press right button

- LCD Says "Finishing Movements" but nothing is moving.

What I've done.

- Verified that FINDA and IR Filament sensor detect filament and work consistently.

- Double-checked all electrical connections between MMU and MK3s.

- Cleaned the MMU selector according to the maintenance instructions.

- Cleaned the hobbed gears and verified the filament paths for each 'lane' are clear.

- Reflashed MK3s and MMU2s with latest firmware. prusa3d_fw_MK3S_3_10_0_4481.hex and prusa3d_fw_MMU2board_1_0_6.hex respectively.

- Performed a factory reset on the MMU according to the directions found here: https://www.help.prusa3d.com/en/article/factory-reset-mmu2s_1920

Any help would be appreciated. Not sure what is going on or why things changed suddenly.

RE: load to nozzle failing

- MMU pushes filament into selector, triggering FINDA probe

- MMU pull filament back

How far does the filament get pushed? Just as far as to trigger the FINDA or does it get pushed further in to the PTFE tube?

I would think this is a problem with the ir-sensor, but you say you verified that already.

The loading sequence is all about triggering the sensors at the right time and pulley motor rotations.

RE: load to nozzle failing

The filament pushes just to the FINDA, it seems to activate the FINDA and then pull back. It may just be coincidental that the length pushed by the MMU happens to hit the FINDA probe before retracting.

It feels like one of two possible issues, but I haven't seen either before.

- MMU steppers are treating the filament hitting the FINDA ball like a stepper 'crash'. Again, I've never seen this behavior before and I'd expect some hobbed gear grinding or clicking before retracting.

- MMU thinks the bowden length is zero, so as soon as the FINDA is triggered it's checking the state of the IR sensor which is untriggered. This would explain the multiple attempts and the cut behavior but not the subsequent behavior. I would also think it should be resolved by the factory reset I did.

RE: load to nozzle failing

More things tried, still no success.

I disassembled the MMU selector and removed a small 'string' of filament from around the FINDA area. I then carefully re-assembled the MMU selector, ensuring the filament path was smooth and that the FINDA triggered consistently. This did NOT fix the issue.

I then followed some legacy instructions on calibrating the bowden tube length, which is not supposed to be needed for the MMU2s. All this calibration went smoothly and I was able to watch the IR sensor detecting filament consistently. This did NOT fix the issue.

Now reading the MMU firmware source to see how the loading is sequenced.

RE: load to nozzle failing

Ok. That was a rabbit hole I didn't really need to go down.

TLDR: It was the IR sensor calibration after all

MORE:

After reading the mmu firmware source to better understand the load sequencing, I came to the conclusion that either it was a failure of the IR or somehow a communication error between the MK3s and the MMU. Being (over)confident in my initial inspection and calibration of the IR sensor, I set about rechecking all the wiring and when that didn't work I performed a factory reset on the MK3s and the MMU. After slogging through the initial parts of the Mk3s first setup/calibration I came to the IR sensor test, which failed (IR triggered). I quickly adjusted the IR sensor 'chimney' to be certain of an untriggered state and restarted the process. This should have been my indication, but it was lost on me. After doing an 'on-the-fly' IR sensor calibration to allow the first-layer calibration portion of the initial setup to complete, I thought things were somehow fixed. Surprise, it wasn't fixed and my original issue started happening again. At which point in dawned on me that perhaps the IR sensor was the issue. After a few calibration attempts I'm back in business.

Lesson learned... again. Re-check the easy things multiple times before going down rabbit holes.

RE: load to nozzle failing

This is very close to a problem that I'm having as well... I updated to the latest 3.10.0-4481 on my printer. I did NOT reflash the MMU because it was already on 1.0.6-372.

I had recently bought a new Satin sheet and wanted to check out the new Sheets menu. When I went to do first layer calibration it won't actually load the filament. Judging by the sensor info menu the FINDA, Fill Sensor, and PINDA seem to be reporting numbers correctly, but something is causing this load/unload behavior.

Here's a video showing what's going on for me:

I'm not clear what IR sensor calibration you did @jared-keller but do you think that might be my problem as well?

RE: load to nozzle failing

The ir-sensor is the filament sensor in the MK3s extruder. Most of the loading issues are caused by a false trigger or no trigger of one of the sensors in the MMU and the printer.

And sometimes it looks like it does work correctly looking at the menu and adjusting the sensors, but some how doesn't during printing. Both the FINDA and the IR-sensor have a small range where they work correctly.

Have a look at this: https://help.prusa3d.com/en/article/ir-filament-sensor-calibration-mmu2s_2245

And I would reflash the MMU's firmware anyway. Mine did some strange things some times after installing the MMU. It had the latest firmware right out of the box, but reflashing fixed the problems anyway.

RE: load to nozzle failing

@jared-keller

Good to see you got it working again.

RE: load to nozzle failing

@baklin

Yep. I did those things and got the Fill Sensor to report correctly with the hex key. I also reflashed the MMU and tried all sorts of other things to no avail. Eventually it felt like maybe the hotend was clogged so I tried the advice here: https://help.prusa3d.com/en/article/clogged-nozzle-hotend-mk3s-mk2-5s_2008 also to no avail. Then I tried to remove the nozzle per these instructions: but after doing so I started getting a MINTEMP error (e.g. https://help.prusa3d.com/en/article/mintemp-and-mintemp-bed_2169). I factory reset the printer and ran a self-test which now fails with "Heater/Themistor Not connected" ( https://help.prusa3d.com/en/article/selftest-mk3-and-mk3s_2045)

So it seems I've gone from bad to worse... I guess my next step is to disassemble the hotend.

RE: load to nozzle failing

Sounds like you’ve damaged or unplugged the hot end thermistor

RE: load to nozzle failing

@aharbick

Once you've your mintemp issue resolved make sure to check the idler tension screws on mmu and on the extruder. It appears I've been running mine extruder idler screw too tight and it may have been causing a lot of my problems with the mmu.

RE:

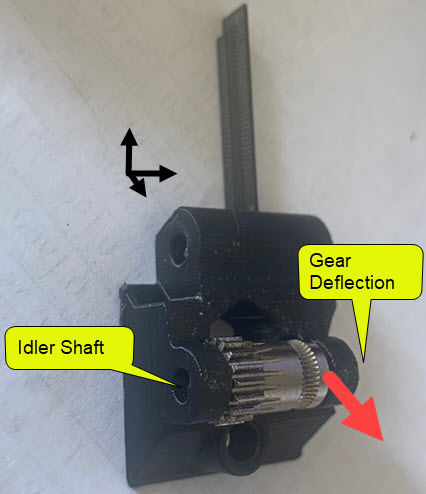

After performing many of the steps and calibrations above (6hr worth), I was visually inspecting the Extruder Idler assembly (gear and shaft -see below)) and could see that the shaft had ever-so-slightly backed-out of the race. This caused the gear to move off axis (perpendicular to the shaft axis). Re-centering the shaft into the races, allowed the gear to again rotating on axis, and the problem(s) were resolved.

A telltale sign or symptom experienced earlier in troubleshooting may have been that the “fil sensor” indicator (menu item -> Support:Sensor Info) would show a "1" when inserting the 1.5 mm Allen key into the extruder BUT would go to "0" when retracting (removing) the Allen key.

Solution: I will probably just melt to PETG into the holes to keep this from happening again.