How to load correctly at least one filament and start printing?

Hello guys.

Question: Can someone please explain to me, step by step, how to load at least one filament correctly and print the Calibration Z snake?

I have followed assembly manual very carefully and double checked if everything is assembled correctly.

Firmware and software are up to date.

Finda, Pinda and IR sensors react nicely, giving correct values on Support/Sensor Info screen

Filament slides easily through buffer.

However, it seems that I can't get to load filament to the nozzle.

I tried to load only Filament No 1.

Filament path is clear,I even managed to load filament through Idler and Selector manually, but problem occurs when I try to load filament to the nozzle.

If filament is loaded and passing selector ( it is visible in PTFE tube, but not all the way to extruder ), pulley is rotating in OPOSITE direction, like it

wants to unload the filament,but the bearing in Idler is not touching the right gear on the pulley ( it lays above Filament 1 ). So it does nothing.

Then it starts to blink red, and if I touch any of 3 buttons on MMU, it does the same thing for few seconds and then nothing. Than it stays blocked with

" MMU needs user attention...". And I can't do anything further.

RE: How to load correctly at least one filament and start printing?

Hello guys.

Question: Can someone please explain to me, step by step, how to load at least one filament correctly and print the Calibration Z snake?

I have followed assembly manual very carefully and double checked if everything is assembled correctly.

Firmware and software are up to date.

Finda, Pinda and IR sensors react nicely, giving correct values on Support/Sensor Info screen

Filament slides easily through buffer.

However, it seems that I can't get to load filament to the nozzle.

I tried to load only Filament No 1.

Filament path is clear,I even managed to load filament through Idler and Selector manually, but problem occurs when I try to load filament to the nozzle.

If filament is loaded and passing selector ( it is visible in PTFE tube, but not all the way to extruder ), pulley is rotating in OPOSITE direction, like it

wants to unload the filament,but the bearing in Idler is not touching the right gear on the pulley ( it lays above Filament 1 ). So it does nothing.

Then it starts to blink red, and if I touch any of 3 buttons on MMU, it does the same thing for few seconds and then nothing. Than it stays blocked with

" MMU needs user attention...". And I can't do anything further.

Hello and welcome to the Prusaforum!

If you have no experience with MK3, I would recommend printing without MMU2 for now. Only when you are familiar with the printer and the slicer settings are correct i recommend to add the MMU2.

Very important are correctly adjusted sensors (PINDA, FINDA). If they do not switch correctly you will have a lot of troubles.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: How to load correctly at least one filament and start printing?

Also had some major problems with loading and unloading.

Fixed the loading problem by moving the MMU back 3cm ( https://www.prusaprinters.org/prints/30254-mmu2s-holder-extended)

Fixed the unloading problem by changing the PTFE tube in the extruder because it was damaged by constantly trying to pry out filament and adding a PTFE locking clip to hold the tube in place ( https://www.thingiverse.com/thing:3559874)

Haven't had a loading/unloading problem since !!!

Mind you I have only used my MMU2S in single colour mode because I mostly do functional prints, but plan on dabbling into multi colour prints once my workplace has been organized.

Having problems with bed adhesion every morning...

RE: How to load correctly at least one filament and start printing?

@karl-herbert

Dear Karl,

Thank you for your reply. I've been using MK3s for quite sometime ( and various types of 3D printers in general, for years ). All sensors are giving positive feedback. It is strange that MMU2S is not working at all, even if I follow all the steps and basic principles of 3D printing. If I can't load filament ( which should be no brainer operation ), how should I proceed?

RE: How to load correctly at least one filament and start printing?

@yveske

Thank you for your feedback. I will try with the holder, and new PTFE tube in the extruder ( I remember the comment about that in the assembly guide ). Still working out how to load filament to the nozzle correctly ( without the need to push it manually etc ).

RE: How to load correctly at least one filament and start printing?

Hello guys.

Question: Can someone please explain to me, step by step, how to load at least one filament correctly and print the Calibration Z snake?

I have followed assembly manual very carefully and double checked if everything is assembled correctly.

Firmware and software are up to date.

Finda, Pinda and IR sensors react nicely, giving correct values on Support/Sensor Info screen

Filament slides easily through buffer.

However, it seems that I can't get to load filament to the nozzle.

I tried to load only Filament No 1.

Filament path is clear,I even managed to load filament through Idler and Selector manually, but problem occurs when I try to load filament to the nozzle.

If filament is loaded and passing selector ( it is visible in PTFE tube, but not all the way to extruder ), pulley is rotating in OPOSITE direction, like it

wants to unload the filament,but the bearing in Idler is not touching the right gear on the pulley ( it lays above Filament 1 ). So it does nothing.

Then it starts to blink red, and if I touch any of 3 buttons on MMU, it does the same thing for few seconds and then nothing. Than it stays blocked with

" MMU needs user attention...". And I can't do anything further.

I had this error and it drove me batty as i had been printing no issues with it until i changed the filament to PLA+

Pull the filament out manually and check the surface. It had actually ground the surface down so the MMU was trying to push it through but obviously had no grip on it. By this point I had also tried clearing the nozzle as I thought that was the issue. Use it like a standard Mk3 and push a piece of filament into the extruder whilst loading (I was quite forceful with this)

Once i had done that and cut a chunk from the filament and fed it back into the MMU it all worked.

RE: How to load correctly at least one filament and start printing?

Have you tried the holder ? Moving the MMU 3 cm back makes the filament take a more straight path instead of an S curve.

I've used to have the same problem with the filament grinding (pun intended) to a halt halfway the PTFE tube.

Having problems with bed adhesion every morning...

RE: How to load correctly at least one filament and start printing?

@yveske

Fingers crossed I haven't had an issue since. Stacked the buffer vertically, fitted parts to in and out on the buffer using PTFE quick connects and it all seems fine. Made sure any holes filament runs though are slightly enlarged and am waiting on 4mm PTFE with larger 2.5mm ID.

RE: How to load correctly at least one filament and start printing?

@stev-19

I was thinking of getting me a larger inner diameter PTFE tube at first, but I was told not to use them, because that also forms the ends of the filament upon retraction.

Having problems with bed adhesion every morning...

RE: How to load correctly at least one filament and start printing?

@yveske

A lot is said, but I can only say that I have been using 4/2.5 PTFE's everywhere (including MMU2) except in hotend for years and never had any problems.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: How to load correctly at least one filament and start printing?

@stev-19

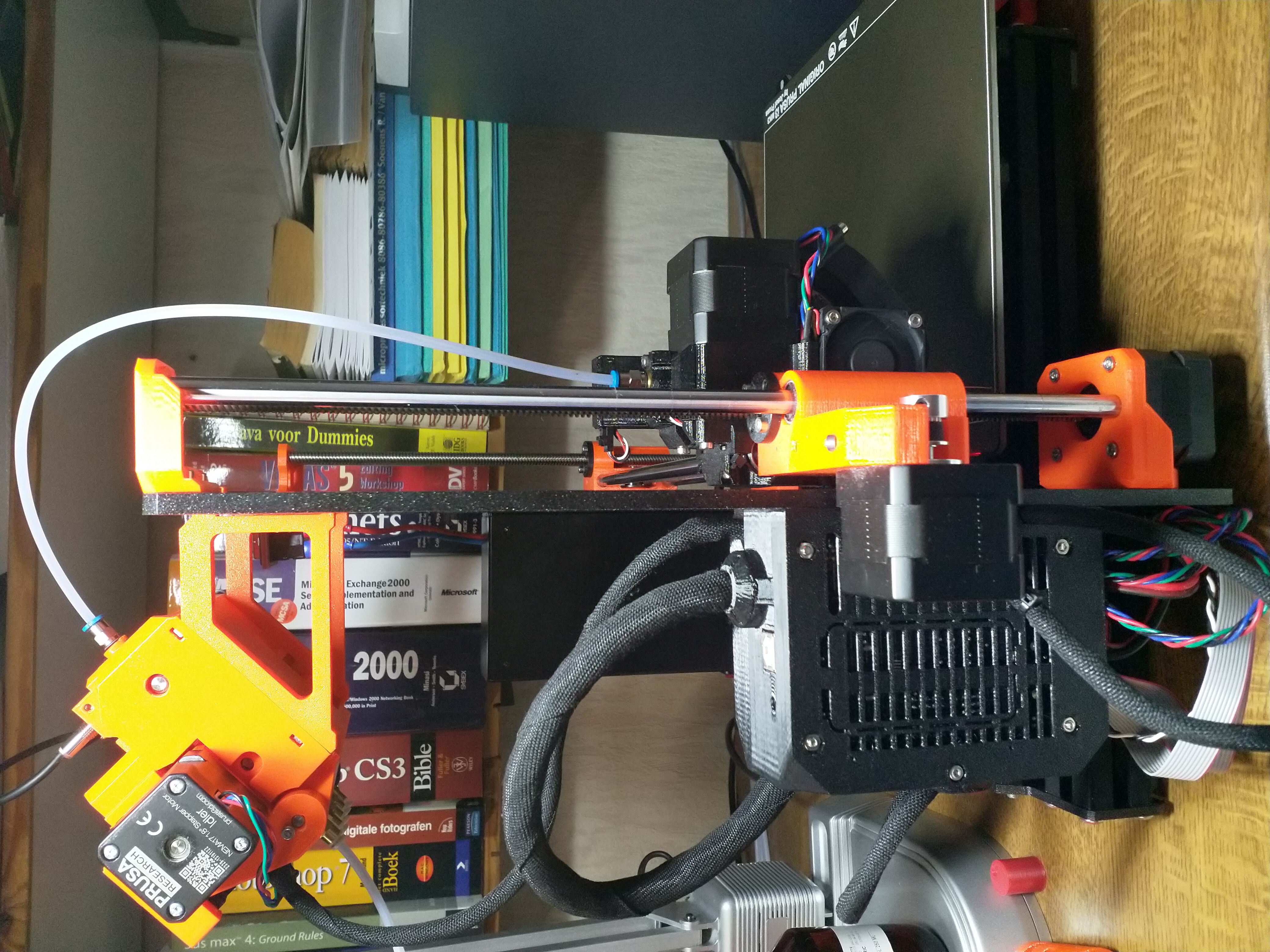

Hi bud, could you possibly stick a few photos up of what you have done, enquiring minds need a peek 🙂

Thanks.

RE: How to load correctly at least one filament and start printing?

@matt-b-atkinson

Not sure what you want pics of? Printer is busy so can't even restep and take pics just now. It's easy to describe tho...

I lifted the top on the MMU, pulled the filament out and cut off the end. I could see where it had ground the filament so cut that section of the end.

Then unscrewed the PTFE quick connect from the top of the extruder and removed it. Use the LED to select Load Filament. This heats it up and then jam a length (Different colour) into the top and push it through to dislodge any crap. Once the new colour comes through, choose Unload Filament to remove it.

Put the quick connect back on the extruder then reload using the MMU.

make sense ?