fed up with MMU2

Have been trying to get my MMU2S working reliably for the past 9 months (albeit have only had sporadic time to spend on it), and have still not been able to get it to consistently load or unload - have tried a myriad of things, I'm sure it's just something small but I miss my old MK3S that would print without fail.

2 questions:

- Are there any instructions to uninstall an MMU2S and revert back to a vanilla MK3S? Or do you just use the installation instructions backwards?

- Where's the best place to try to sell this? Since it's past the 60 days I can't send it back to Prusa. Also have 2 sealed rolls of soluble filament as well 🙁

RE: fed up with MMU2

I've had similar problems in the past, and especially when doing a lot of printing where I just need the printer 'as-is', and working. The handbook explains the procedure; if you remove the power and data cables (the left two connectors looking from the back of the MMU - the two cables that actually go to the printer) and unscrew the filament line from the printer extruder then the MMU can just be unhooked and put to one side. Like this the MK3S will print just fine; attach the old spool holder and feed the filament into the Festo coupler at the top of the extruder.

Be careful removing the power and data connectors! You need to squeeze the (tiny) lever on the connector, which is facing the MMU casing (bad design - this should be the other way around). It might be easier to remove the electronics board/cover (outer two bolts) and remove the connectors when you can squeeze from both sides. This will leave the two connectors 'dangling' from the main printer logic casing, so tidy them away somewhere. I covered the ends in insulating tape (to stop anything getting in and causing a short) and just folded them out of the way.

I'd advise putting it in a cupboard and having a play again when you feel the need; there's been 'firmware' and part upgrades coming out which make things (a little) better, so eventually everything may work for you. Some people have no issues, others have taken a hammer to the damned thing;-) I'm in-between on the contraption...

RE: fed up with MMU2

If the MMU will not work as intended, there is something wrong, and Prusa support should be contacted. I am a witness to the fact that the MMU2S will indeed work as intended as long as attention to detail is given in assembly and operation.

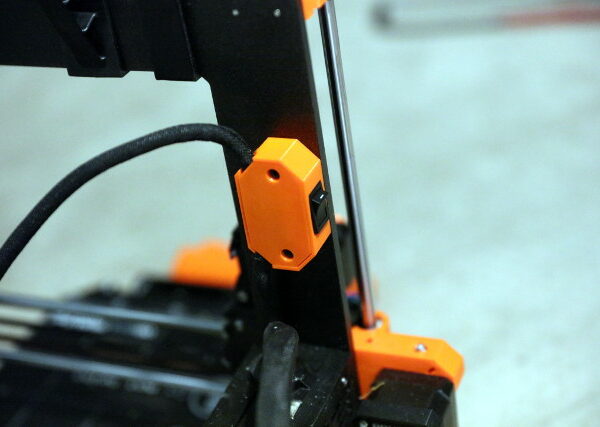

Having said that, I run the machine without the MMU2S most of the time. I've installed a switch that cuts the power to the MMU, and the little enclosure for the switch is in the Prints section here. I used a DPST switch and break both power leads, just like pulling out the power plug from the MMU. There are two unused tapped holes on the I3 frame that almost appear to be intended for something like this.

With the MMU disabled, to autoload filament, just gently press inward on the movable part of the 'tower' to get things going.

RE: fed up with MMU2

Używam MMu2 z MK3S. Też mam problem z posuwem. Jeśli dokręcę śruby na MMU - filament blokuje się, i ekstruder nie jest w stanie go uciągnąć, jeśli poluzuję - filament nie chce się prawidłowo cofać. A jeśli się nie cofnie - wywala komunikat - MMu Problem - I wydruk do śmieci

RE: fed up with MMU2

I agree. This thing is worthless. I have spent tons of hours reading, adjusting, printing and ordering new parts but it just doesn't work as it should. Support did not help.

RE: fed up with MMU2

I agree that the MMU is very sensitive, but as long as the extruder *filament sensor is aligned correctly*, the MMU *tensioning screws are tightened correctly*, and there is *minimal friction* in the PTFE tubes feeding the back of the MMU, then it works fine for PLA and PETG. See my post on this thread for advice;

RE: fed up with MMU2

@stewartr

I've done that. I've ordered a chamfer tool and will swap out all of my tubes. I don't expect this to be 100% all the time but I can't even get a complete print. The MMU truly needs it's own LCD to tell you WTF is wrong.

I also noticed that it looks like the MMU is chewing up the filament so I'm making fine adjustments. So I feel like I have narrowed down the problem a little bit. The other issue is it seems to stop the filament about half way. Then the lights blink fast....

Since I'm watching this live... It does NOT like my Hatchbox Stone PLA! It does feel a touch softer that regular PLA. It prints fine in regular mode. I'll babysit for a while.

I am running the latest firmware on both.

This is really painful. I love the printer but.....

RE: fed up with MMU2

@sneezy

I utterly agree with you on the totally useless diagnostics! "MMU needs attention" is not helpful!!! Given the pattern of flashing lights, I can not figure out why the printer's LCD can't actually tell you what went wrong! Do they not speak to each other? You have to sit with the MMU manual open all the time to figure out what the lights mean.

When I was baby-sitting mine trying to get it to work, I'd often spot a problem long before even the lights started flashing, and certainly manage to fix it before the printer told me that the MMU needed sorting.

But, now that everything's working properly, I just leave it to its own devices. I check up on it as often as I would the raw MK3. And I am very happy with the unit. I am angry that it took so much work to get it to this state though. Especially as one of the critical cures involved printing a replacement for a Prusa-supplied part. I wonder how much it would have actually cost them to put festo-style connectors on the back of the MMU? Maybe added £10 to the price?

If it still chewing chunks out of filament, it could be that there's still too much friction between the MMU and spool...

RE: fed up with MMU2

@stewartr

It's maddening! The tweaks they could have done.

Anyway, thank you for your help. I made my first successful MMU print ever!!!

I've been trying to print a cryptex and didn't like the non-mmu version.

Now I'm going to torture the MMU with a 16 hour print... because I can.

I will finish my tweaks next week.

RE: fed up with MMU2

@marck

I've had mine a week now. I will say that my "build" that got shipped was absolutely a disaster of a print. I've had better prints on my 3 week old Prusa MK3S+ without the MMU than what I got shipped. Heck the parts that came with the printer are better printed. I feel like this is an e-bay rip-off.

That said, I have resin on the way and I have re-printed almost all my printed parts in ABS-Like resin for my MK3S+ just because I trust the resin and I can print loads of replacement parts faster.

Onto the MMU2s, I installed mine, had issues after issues. The filament wouldn't load right, wouldn't load all the time, wouldn't load between prints. I checked and re-checked everything like 10 times I thought.

So, today (yesterday) I basically checked 4 things that now has filament loading and unloading like a boss.

1. Take off the filament switcher piece, the piece that moves back and forth to "load" the filament to the nozzle. Do this by removing the 4 screws on the motor, then turn the lead screw to push the part to position one or farthest to the left. Then set the motor aside, but be careful of the FINDA cable. I then removed the PTFE and housing that feeds to the nozzle. Once that piece is off, I use the 2mm key to push through and make sure there's no obstruction. I turned my piece around and there was filament stuck into the little hole under the blade, and just random clippings in there that didn't drop out.

2. Get some test filament, while the switcher is not attached and run it into the MMU as if it were being unloaded. Make sure you can easily get that filament in and out, like a hot-dog down a hallway. If you have filament loaded or where it's over the gears you can pull that back a bit. Once you checked all 5 ports and they feel good with the filament you're using go to the next step.

3. If you been trying to print a lot and still getting crap pickup, you should have some slight wearing on the bearings from the MMU. Put your filament in from the front and have it cross the gear and make it to the other side, then put the MMU top down and see if that wearing on the gear matches the center of the filament and the gear. If not, adjust how you can. I typically take 1 of the 2mm keys i have and place it in there, then take the second one to move the motor around to the flat side and then go gear by gear trying to make sure they are aligned. (It makes it easy with the 2mm key because you can basically put it at an angle where the <> if you would are facing ^ and v so that way you are centered on the gear, and you can center to the bearing.

4. Clean those gears on the loader if you have been grinding filament, take that brass or wire brush and just have at it.

5. Now that those are aligned, the next part (which is where I come to my "i think i got a shitty print") is where mine was jacking up. Because there's no "end stops" the software uses tension. The print of the MMU on mine was so bad the thing couldn't freely slide from one side to the other without hella resistance. So while the selector's motor is still out, take it, place it in the grooves and slide it back and forth a few times. I did this a few times increasing speed back and forth, well beyond what I thought the actual selector might be doing, and tried to feel for any spot that caught. If it did, I ran back and forth on it to try to pinpoint the spot, and then I took the blue handled flat clipping tool and just kind of clipped anything that was not in line with the rest of the body.

6. Assemble all that shit back together, put your idler (pulley's) back to position 1, put the filament loader thingy back on the lead screw and assemble that shit back in there.

7. What 100% was the truth, was that those screws with the springs, legit just need to be a bit below the level of the case. In my case, I just tighten them just to where I feel maybe a half finger-tip depth.

8. Profit- now you can boldly hit "Load all filament" and that mofo will at least queue up all the filament like it should.

9. Get stuck on your new issue like me... Now that it loads and unloads like a champ, it sends the filament to the extruder and now I just hear a gut retching crunch. I can't figure out what the hell is up. I tried loosening the bondtech gears, tightening. Hell I tried manually pushing the extruder out a few mm just to see what was up. I heated that bitch up, and pushed some filament through manually and it comes out with no issue.

It legit sounds like it's skipping or just eating the filament. That's where I gave up last night, but not before I did get one good print out and gave me hope.

Of the whole system, I think I'm most disappointed in the buffer. The simplist fix for me since my filament hangs on a bar above me is just to print this thingiverse PTFE holder about 4 times and just attach that to the wall so the PTFE tubes aren't moving much.

hope this helps. It seems fun, I'm like you though and I'm like... is the Mosaic Pallette 2s this difficult or are you paying for all the luxury of them handling all that in a single hardware device.

When I take my time spent (4+ days), and the 299$ the MMU2S cost, I would have gladly paid the 599$ for the Mosaic to just put in a few parameters to get filament length and steps right and not worry about buffers and pulley's and purging.

RE: fed up with MMU2

@prusianaggers

This sounds alot like a problem I experienced...

Confirm that your bondtech gear on the extruder shaft is aligned properly (AND secured. This little fella has a tendency to come loose on new printers).

Then during your first filament load to nozzle, take off the PTFE tube at the extruder end and insert the filament directly, then when extrusion is confirmed, rescrew the ptfe holder (I guess it aligns everything just slightly). This step was what caused my printer to go from 0 filament change success to hundreds of toolchanges without a single problem so far.