BVOH Failing w/MMU2

Hi all, I had some successful 2-color prints with my MMU2 using PLA. I'm now trying to use Verbatim BVOH for soluble supports. I'm experiencing inconsistent eject / reload, where the MMU2 fails to either fully load BVOH filament down to the extruder's bondtech gear OR it fails to fully eject the filament and I have to intervene by tugging the filament from the PTFE tube for the eject sequence to complete.

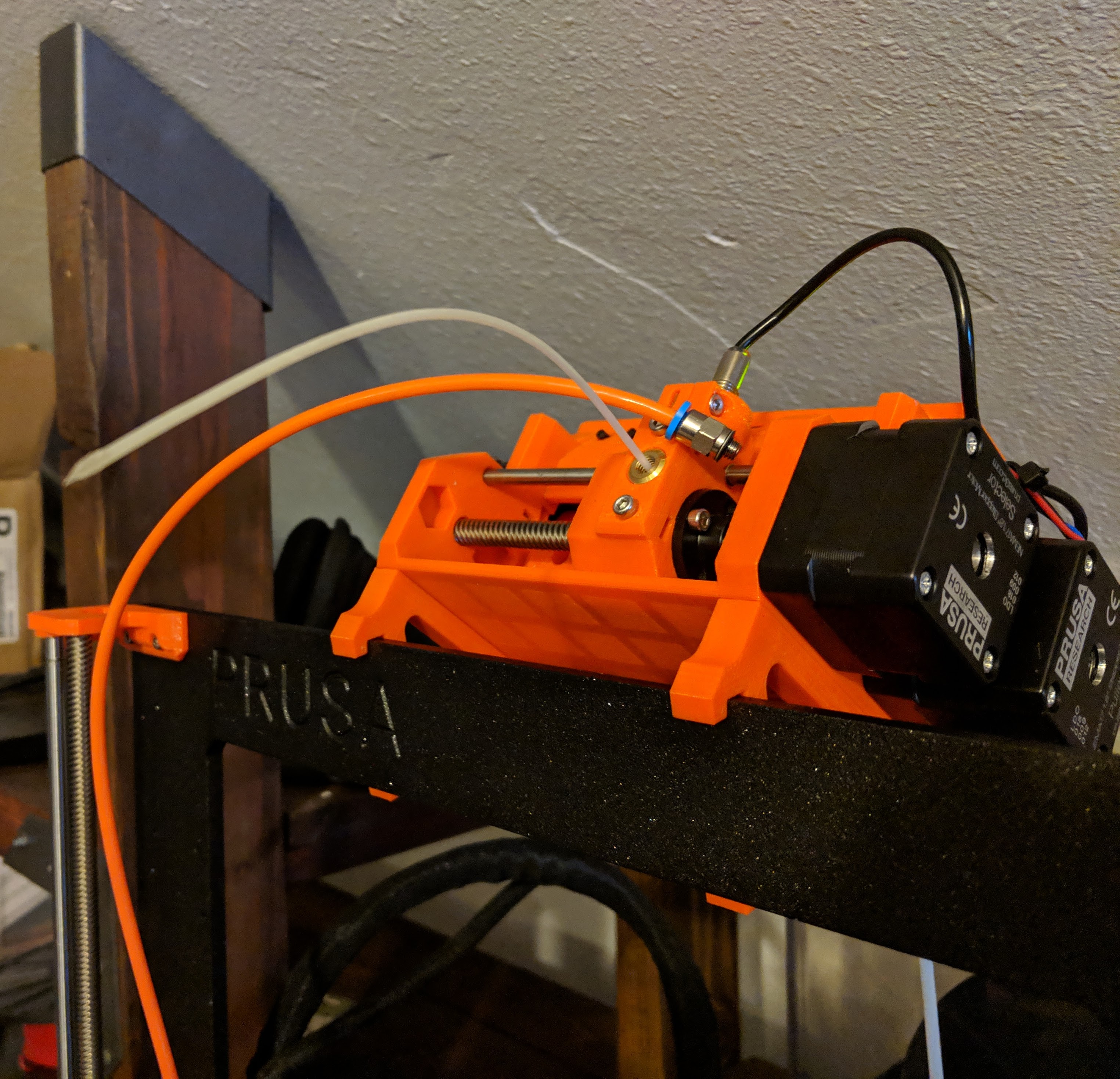

In the attached image, I've just started a new print. 2 layers of PLA and BVOH printed successfully. During the 3rd layer while print BVOH support, I noticed that I couldn't see filament at the idler. I paused the print and removed the orange PTFE tube to double-check. There is 6 inches of filament coming out of the MMU2, where it would require ~16 inches to reach the extruder's bondtech gear.

Just before this print, I did the individual filament calibration and was able to successfully load the BVOH from F5 3 times, so I hoped it would be okay.

During eject for the previous layer, I could hear that the gear in the MMU2 wasn't fully gripping the BVOH during the high-speed part of the process.

I am using Slic3r with the default BVOH profile, but I have increased the print temperature to 205C, because this seemed to help in my first couple of attempts. I have a lot of slack on my BVOH spool, so I don't think spool resistance is the issue.

Is anyone successfully using BVOH with their MMU2? Anything you can share that might help? Thanks!

Re: BVOH Failing w/MMU2

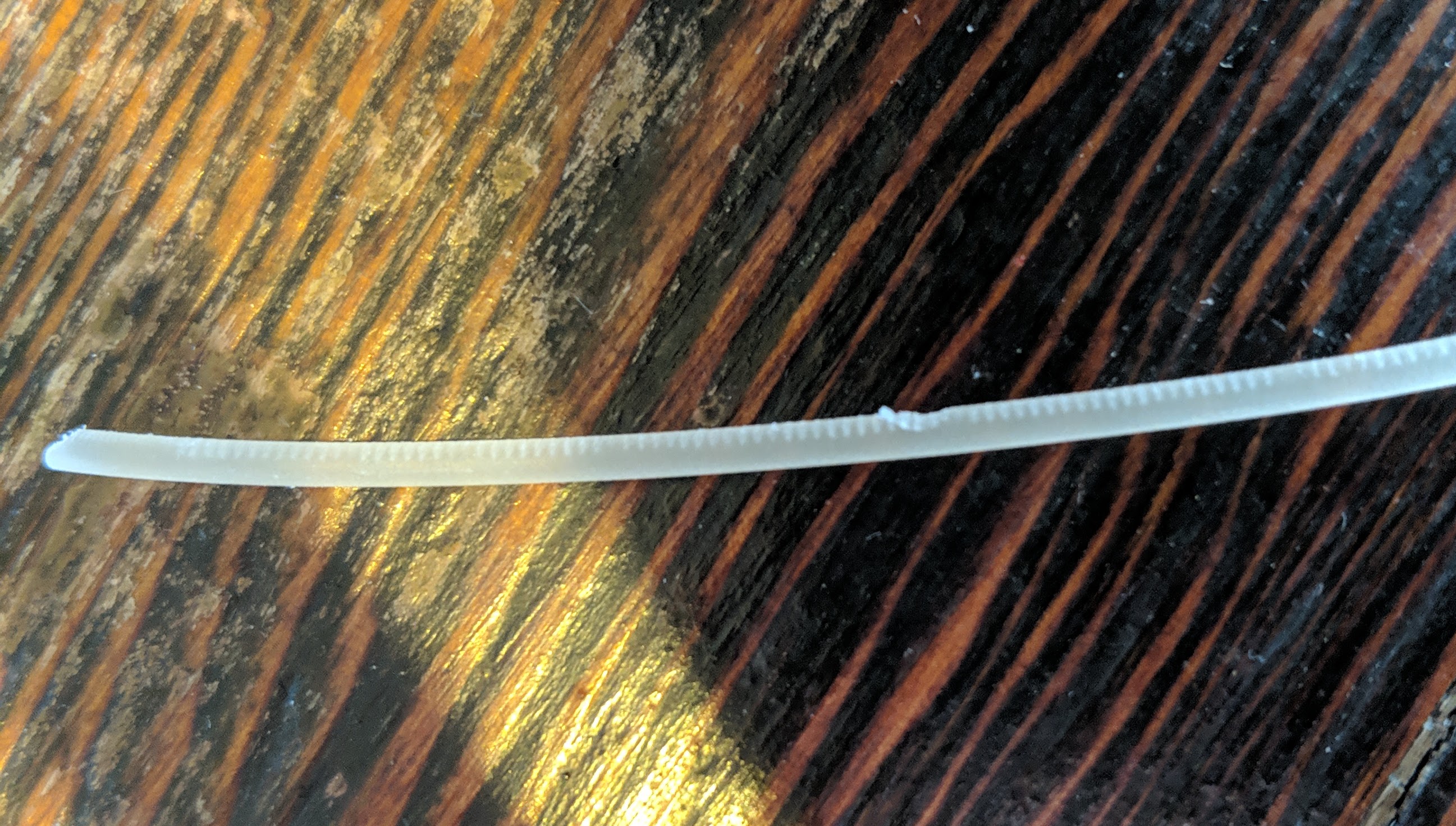

The tip is not in focus in the image. Could you measure the diameter of your tip and check if you have strings on it? I am printing a lot with bvoh lately. My main problem right now is that I get stringy tips sometimes. With bvoh it gets a lot more complicated because the tip formation doesn’t just depend on the ramming settings but also on the dryness of the filament itself.

Re: BVOH Failing w/MMU2

Thanks for the reply. I have repeated a few times and I think my issue is caused by a blob formed at the end of the filament that causes resistance in the small PTFE tube above the extruder's bondtech gear and in the orange PTFE tube. This causes 2 problems:

1) Sometimes ejection fails (actually, a lot of the time for me right now for BVOH).

2) When ejection fails, the bondtech gear in the MMU2 slips and carves a "half moon" out of a segment of filament. When I "fix" the ejection issue and the my Mk3 and MMU2 proceed to the next layer, the MMU2 will fail to grip the filament at the half moon, so the load will never successfully reach the extruder. There's no feedback when this happens, since (if I understand correctly) the filament sensor is disabled when the MMU2 is active (which seems crazy to me...).

For now, it seems like I can best address my issue by reducing the size of this blob. I think I can do this by increasing the extrusion temperature (at the cost of stringing) or by adjusting the ramming settings for BVOH in Slic3r. I'm curious if others are using the defaults for BVOH in Slic3r or if you've made changes? What are your observations from changes you've made?

I have mostly extruded BVOH at 200C and 205C. I definitely see more stringing at 205. I haven't yet confirmed that it really helps with the blob.

Re: BVOH Failing w/MMU2

The tip doesn't look terrible, but I saw this before. Loose flakes will form in the lowest PTFE tube, flake off as retracted past bondtechs and next PTFE tube.

Replacing the lower tube will likely help.

Also, you can adjust tension on the screws in MMU, change loading speeds/accelerations (you may need to step away from Prusa FW which uses stepped acceleration), and make SURE you're not grinding on loads. Typically, that's where these divots start, then the failed reload or subsequent load will follow.

I maintain an informal list of San Diego, CA 3D printing enthusiasts. PM me for details. If you include a contact email and I can add you to the informal mailing list.