RE: Under extrusion after upgrade

Sometimes the theoretical values (400) may differ from the practical (due to manufacturing tolerances) values.

If this fits, you can at least rule out an error.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Under extrusion after upgrade

Yeah, after several tries it is exactly 400. So that is fine. But actual printing is still a no go.

Sometimes the theoretical values (400) may differ from the practical (due to manufacturing tolerances) values.

If this fits, you can at least rule out an error.

wbr,

Karl

RE: Under extrusion after upgrade

Are you using original PrusaSlicer presets for your filament?

Just to rule out some things:

Are the slicer settings correct?

- Filament diameter

- Nozzle diameter

- Extrusion factor 100% (no M221)

- layerwidth settings

- max volumetric speed

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Under extrusion after upgrade

My settings from Prusa slicer:

Filament diameter: 1.75 - (filament settings)

Nozzle diameter: 0,4 mm - (printer settings)

Extrusion factor 100% - (M221 removed from start gcode)

Extrusion layer width 120% - (print settings)

Max volumetric speed 11.5 - (filament settings and print settings)

Are you using original PrusaSlicer presets for your filament?

Just to rule out some things:

Are the slicer settings correct?

- Filament diameter

- Nozzle diameter

- Extrusion factor 100% (no M221)

- layerwidth settings

- max volumetric speed

wbr,

Karl

RE: Under extrusion after upgrade

I changed to a brand new slice 300 degree termistor, just to be sure. Did a PID-tune after that.

The nozzle I am currently using is a Bondtech CHT 0.4.

RE: Under extrusion after upgrade

Try printing the 20x20x20mm calibration cube. If you still have problems with under-extrusion, please post the gcode. I would also test your gcode on one of my MK3 printer.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Under extrusion after upgrade

I tried but I'm not even close. I just end up with a melted ball on the nozzle.

Try printing the 20x20x20mm calibration cube. If you still have problems with under-extrusion, please post the gcode. I would also test your gcode on one of my MK3 printer.

wbr,

Karl

RE: Under extrusion after upgrade

Trying to attach the gcode here but I cant get it to work through the forum.

RE:

https://drive.google.com/file/d/1-N8xh5grZf1YNtzo6zXzUuEiVUnjOCTl/view?usp=sharing

My gcode for the cube.

RE: Under extrusion after upgrade

I could perhaps also try your cube gcode?

Try printing the 20x20x20mm calibration cube. If you still have problems with under-extrusion, please post the gcode. I would also test your gcode on one of my MK3 printer.

wbr,

Karl

RE: Under extrusion after upgrade

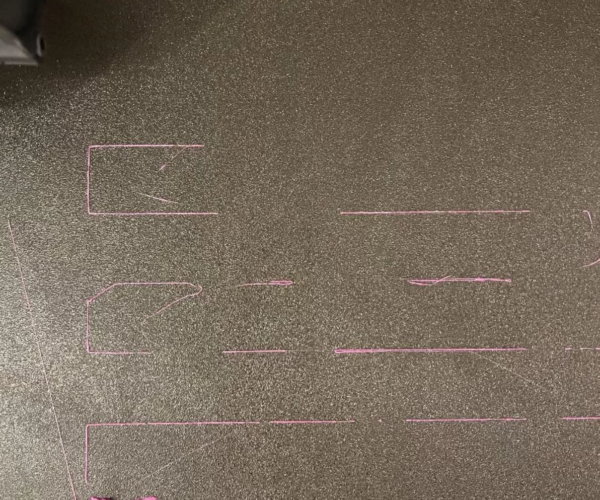

Hmm, if I up the flow in the menu during first layer calibration it works better. I tried flow of 400 and then it looks way better but not okay.

RE: Under extrusion after upgrade

Hmm, took flow down to 300 and now the first layer calibration looks OK. Very strange. Still can't really print though.

RE:

I briefly checked the gcode (cube not printed) and found an error:

; external perimeters extrusion width = 0.45mm

;perimeters extrusion width = 0.45mm

; infill extrusion width = 0.45mm

; solid infill extrusion width = 0.45mm

; top infill extrusion width = 0.40mm

; first layer extrusion width = 0.24mm

You should replace the last line (first layer extrusion width = 0.24) with a value about 0.42 to 0.45

Give it a try.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Under extrusion after upgrade

Trying now!

I briefly checked the gcode (cube not printed) and found an error:

; external perimeters extrusion width = 0.45mm

;perimeters extrusion width = 0.45mm

; infill extrusion width = 0.45mm

; solid infill extrusion width = 0.45mm

; top infill extrusion width = 0.40mm

; first layer extrusion width = 0.24mm

You should replace the last line (first layer extrusion width = 0.24) with a value about 0.42 to 0.45

Give it a try.

wbr,

Karl

RE: Under extrusion after upgrade

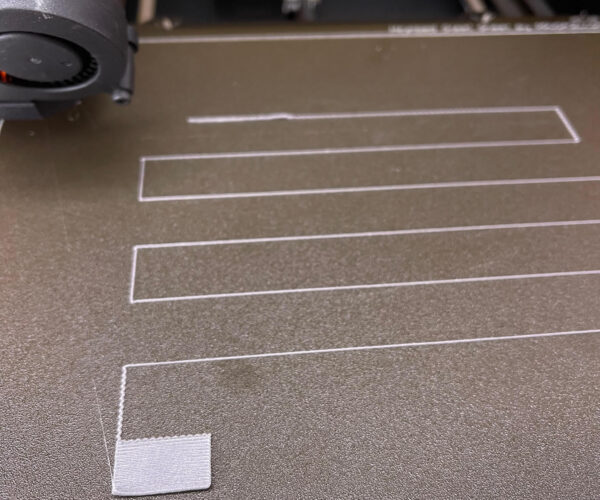

So, I am getting closer.

Right now I am printing the calibration cube. I need to have around 200 flow for it to be able to print.

RE:

After something like 7 layers the cube comes loose from the bed. I'll keep trying with fine tuning of Z, flow and temp.

RE: Under extrusion after upgrade

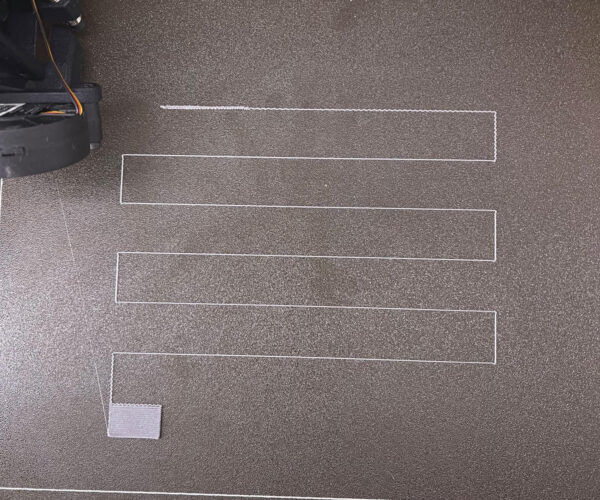

After some more fine tuning I'm down to about 120 flow with 1.1 extruder multiplier. So starting to look ok.

RE: Under extrusion after upgrade

Would you briefly summarize what were the most important changes that led to the current result?

Thanks!

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.