Under extrusion after upgrade

I have upgraded my extruder to a Bondtech LGX with Mosquito hotend.

I did a firmware update to Bondtech’s latest firmware and then a factory reset and then went through the setup wizard. No errors at all everything looks fine.

But on the last step, the first layer calibration, the printer under extrudes. Or at least thats what I think is happening. The filament coming out is thin and round and will not stick to the build surface (Prusa original steel sheet). I have tried so meny heights of the nozzle. It seems like there is not enough filament coming out of the nozzle.

I have tested:

New PLA filament (totally dry)

Three different nozzles

Esteps calibration (was perfect at 400 steps @ 16 bit resolution)

PID tuning

Pinda tuning

Manually pushing through filament with no gears (gears on loose setting) on the filament. Works perfect, the filament coming through easily is the right size and shape.

Using the menu to extrude filament also works and the filament coming through looks perfect.

BUT, as soon as I try to print something or do the first layer calibration it just puts out this thin stringy stuff that wont stay on the build surface.

I have tried going down and up in temperature, but there is no difference. When I go really low in temp the extruder gears start clicking and that goes away as soon as I raise the temp again.

Could it be software/gcode related somehow? Like if the first layer STL and gcode in the Prusa is not compatible with this upgrade?

RE: Under extrusion after upgrade

Photos might help.

--------------------

Chuck H

3D Printer Review Blog

RE: Under extrusion after upgrade

Sure! I can get photos and video if that helps. To be sure, what is the things I should focus on? Anything special I should get photos of?

I can make a video of first layer calibration to show how stringy and thin the extruded filament looks.

Photos might help.

RE: Under extrusion after upgrade

I don't think your problem is software/gcode related. I installed the same upgrade: LGX+ Mosquito. After updating the firmware to Bondtech 3.10.0 and performing a factory reset for all values, everything was fine from the start.

Something is amiss with your setup, but I can't see where you went wrong. You seem to have done everything according to Bondtech's instructions.

RE: Under extrusion after upgrade

Can you contact Bondtech support? This doesn't sound like a software problem.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

Probably not software but I am grasping for straws at this point. I have put in about 10 hours of troubleshooting and I just can’t find any physical problem.

I don't think your problem is software/gcode related. I installed the same upgrade: LGX+ Mosquito. After updating the firmware to Bondtech 3.10.0 and performing a factory reset for all values, everything was fine from the start.

Something is amiss with your setup, but I can't see where you went wrong. You seem to have done everything according to Bondtech's instructions.

RE:

I have done that about two weeks ago. So far I have gotten two replies.

First reply: The nozzle is to close to the build plate (it was not)

Second reply: There might be a problem with ecool or altfan, turen them off in the experimental menu. (They were both off).

Still waiting for a third reply.

Can you contact Bondtech support? This doesn't sound like a software problem.

RE:

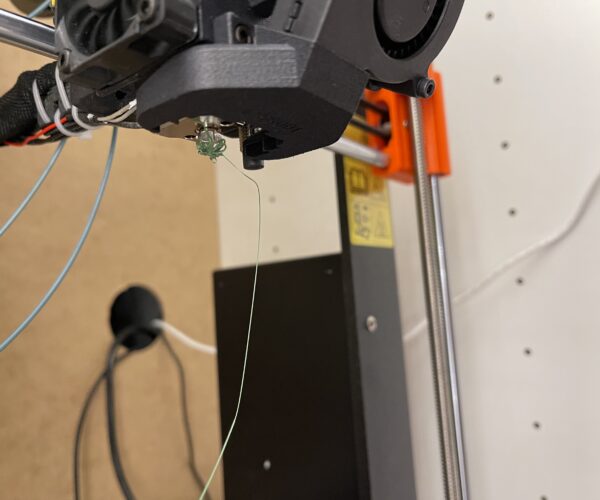

https://www.youtube.com/shorts/EiRoNmntlNQ

Notice how the filament gets thinner almost instantly and the detaches from the build surface. I think even from the start that it's too thin. Sorry for the bad video.

RE: Under extrusion after upgrade

You are getting a partial jam. Either there is gap in your assembly somewhere or you are getting heat creep. I had this for a while when I was overheating for filament.

--------------------

Chuck H

3D Printer Review Blog

RE: Under extrusion after upgrade

Ok, is it possible that this partial jam only shows up while printing? Because if I raise the Z-axis and just extrude through the menu of the printer it extrudes just fine. I have checked and double checked the assembly.

You are getting a partial jam. Either there is gap in your assembly somewhere or you are getting heat creep. I had this for a while when I was overheating for filament.

RE: Under extrusion after upgrade

That does sound more mechnical. Have you tried adjusting the tension screw?

Ok, is it possible that this partial jam only shows up while printing? Because if I raise the Z-axis and just extrude through the menu of the printer it extrudes just fine. I have checked and double checked the assembly.

You are getting a partial jam. Either there is gap in your assembly somewhere or you are getting heat creep. I had this for a while when I was overheating for filament.

--------------------

Chuck H

3D Printer Review Blog

RE: Under extrusion after upgrade

The LGX extruder has a tension lever and I have tried a few different tensions with that, right now I am using the recommended setting (for PLA) on the lever. Can't really see a difference between the different tensions.

RE:

Purge line. Does not really stick to the plate. Seems a bit thin.

RE:

If you tried 3 different nozzles, in all logic the problem isn’t there. This is a puzzling issue.

Try to perform a cold pull and see how it looks, if the filament is clean and the tip almost conical. Then, release the tension lever (position 0 at right). Now, with the filament path clean, you can insert a 1.5mm. steel rod or Allen wrench from the filament entry at the top and push it easily all the way down to the tip of the nozzle. If there’re unwanted particles inside you’ll notice an extra resistance when pushing the rod.

Also, taking advantage of the modularity of the LGX , remove the IR sensor housing, the motor plug and the two screws at the sides of the extruder. The whole LGX body can be now pulled upwards and removed from the plastic frame. Inspect the filament path inside the LGX to check for brims of filament stuck in there. Inspect the gears rotating the front wheel. Finally, with the LGX removed is easy to check if there’re small obstructions inside the teflon tube. There’s a small chance that the teflon tube is too short or too long. See if the top of the tube looks OK ( not smashed or deformed).

RE: Under extrusion after upgrade

Thank you, I will check. The strangest thing (to me atleast) is that manually extruding filament through the settings menu works fine. It just keeps extruding a big fat line of filament. Would it really do this if any of the problems you mention is present?

If you tried 3 different nozzles, in all logic the problem isn’t there. This is a puzzling issue.

Try to perform a cold pull and see how it looks, if the filament is clean and the tip almost conical. Then, release the tension lever (position 0 at right). Now, with the filament path clean, you can insert a 1.5mm. steel rod or Allen wrench from the filament entry at the top and push it easily all the way down to the tip of the nozzle. If there’re unwanted particles inside you’ll notice an extra resistance when pushing the rod.

Also, taking advantage of the modularity of the LGX , remove the IR sensor housing, the motor plug and the two screws at the sides of the extruder. The whole LGX body can be now pulled upwards and removed from the plastic frame. Inspect the filament path inside the LGX to check for brims of filament stuck in there. Inspect the gears rotating the front wheel. Finally, with the LGX removed is easy to check if there’re small obstructions inside the teflon tube. There’s a small chance that the teflon tube is too short or too long. See if the top of the tube looks OK ( not smashed or deformed).

RE: Under extrusion after upgrade

Yes, it doesn't makes sense. If the filament extrudes well using the menu, no reason why it shouldn't do likewise in regular prints. That's why it's a puzzling problem.

Anyway, you don't loose anything checking that the filament path all through the extruder and the hotend is free from stuck particles.

RE: Under extrusion after upgrade

Yes, it doesn't makes sense. If the filament extrudes well using the menu, no reason why it shouldn't do likewise in regular prints. That's why it's a puzzling problem.

Anyway, you don't loose anything checking that the filament path all through the extruder and the hotend is free from stuck particles.

Yeah, I will check for sure! Per request from Bondtech I have also sent my start gcode for them to look at.

RE: Under extrusion after upgrade

Bondtech advised me to run this command in the terminal M907 E550 and then M500 to raise the current. Then to remove the three lines in the start gcode:

M221 S{if layer_height<0.075}100{else}95{endif}

{if print_settings_id=~/.*(DETAIL @MK3|QUALITY @MK3).*/}M907 E430 ; set extruder motor current{endif}

{if print_settings_id=~/.*(SPEED @MK3|DRAFT @MK3).*/}M907 E538 ; set extruder motor current{endif}

I did that and sliced a new Benchy, still no improvement. I have also verified that the whole path for the filament is clear and there is no blockage at all.

RE:

To be on the safe side, I would run this extruder calibration test again: extruder calibration

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Under extrusion after upgrade

Ok, I will try that. E-steps is perfect though 400 steps exactly.

To be on the safe side, I would run this extruder calibration test again: extruder calibration

wbr,

Karl