Tungsten Carbide Nozzle, torque/temp?

just got a Tungsten Carbide Nozzle from 3DMaker, and the instruction says to heat 20 degree above print temp and use 1.5 N/m torque. i have a MK3S

1) is it normal to use that low(1.5N/m) of torque, prusa and e3d says to use around 2.5-3 N/m?

2) i print petg(240-250c) mostly, so i think it says to use temp of 270c (250c+20c) to tighten with, i am assuming i can use temp of 285c(as per prusa instruction) and be fine?

RE: Tungsten Carbide Nozzle, torque/temp?

I torque it like a regular brass nozzle.

RE: Tungsten Carbide Nozzle, torque/temp?

I'd torque at as high a temp as you are willing to risk with the stock thermistor: 285c according to E3D. But Semitec says their thermistor is good for 300c; then again, E3D encapsulates it into that metal can, so ... ymmv.

RE: Tungsten Carbide Nozzle, torque/temp?

just got a Tungsten Carbide Nozzle from 3DMaker, and the instruction says to heat 20 degree above print temp and use 1.5 N/m torque. i have a MK3S

1) is it normal to use that low(1.5N/m) of torque, prusa and e3d says to use around 2.5-3 N/m?

2) i print petg(240-250c) mostly, so i think it says to use temp of 270c (250c+20c) to tighten with, i am assuming i can use temp of 285c(as per prusa instruction) and be fine?

I use exactly the same nozzle (tungsten carbide from 3dmaker) and use the same temperatures and tightening torque (3Nm) as the E3D brass nozzles - works perfectly with all materials (ASA, PETG, ABS, PC, Nylon, PEEK...)

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Tungsten Carbide Nozzle, torque/temp?

just got a Tungsten Carbide Nozzle from 3DMaker, and the instruction says to heat 20 degree above print temp and use 1.5 N/m torque. i have a MK3S

1) is it normal to use that low(1.5N/m) of torque, prusa and e3d says to use around 2.5-3 N/m?

2) i print petg(240-250c) mostly, so i think it says to use temp of 270c (250c+20c) to tighten with, i am assuming i can use temp of 285c(as per prusa instruction) and be fine?

I use exactly the same nozzle (tungsten carbide from 3dmaker) and use the same temperatures and tightening torque (3Nm) as the E3D brass nozzles - works perfectly with all materials (ASA, PETG, ABS, PC, Nylon, PEEK...)

what heatblock and heat break are you using with the TC nozzle?

i ask because i have had all my TC nozzles leak from different manufactures, only nozzles that seem to work for me are brass nozzles i get from prusa specifically for some reason...... :{

RE: Tungsten Carbide Nozzle, torque/temp?

@muo

I use the titanium heatbreak and nickel-plated copper block from E3D.

https://e3d-online.com/products/v6-titanium-heat-break

https://e3d-online.com/products/v6-plated-copper-heater-block?_pos=2&_sid=5499eafd4&_ss=r

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Tungsten Carbide Nozzle, torque/temp?

@karl-herbert

ah.. nice i use the titanium heat break as well but i am using the stander aluminium heat block from prusa which i think is e3d. i might get the copper heat block to see if it will hold it in right and not leak.

if you have used it have you had any issues using aluminium block with TC nozzles or other non brass materials?

RE: Tungsten Carbide Nozzle, torque/temp?

@muo

I do not use aluminium heating blocks, only copper or nickel-plated copper, even on the Mini. The TC nozzle in combination with the titanium heatbreak and the nickel plated copper heating block is tight. Nothing leaks. Nozzles tightening torque is 3Nm.

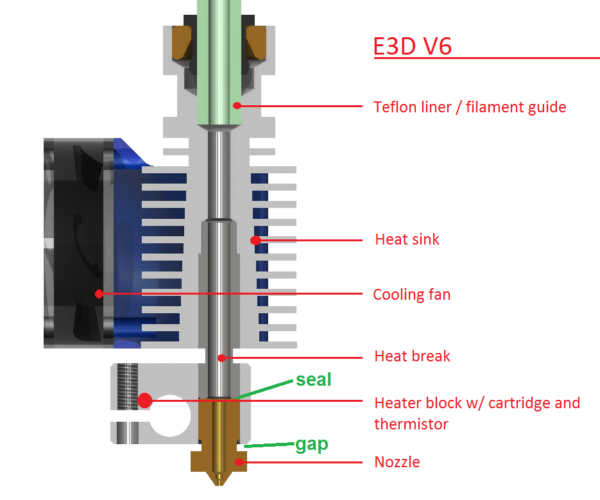

Of course a clean seal between nozzle and heatbreak is important:

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Tungsten Carbide Nozzle, torque/temp?

@karl-herbert

ya it seems like it does make contact with heat break when cold tighten and hot tighten due to the gap and nozzle not touching the block leaving no gap, also the leaks dont happen immoderately they happen after few hours.........

based on a conv i had with prusa it seemed like to me that maby the non brass nozzle were not given enough torque perhaps wile the brass nozzles have a heat expansion so they can get away with less torque

unfortunately i ruined my last heat block some how by getting the titanium heat break stuck (this things are tough it seems to be ok after taking it out, amazing) in there cross threading maby or something due to either to much torque or the block keeps slipping from the wrench and moved left and i readjusted and tightened thinking that would be ok.

i am going to test out a few things and see what happnes.....

RE: Tungsten Carbide Nozzle, torque/temp?

@muo

I screwed the TS nozzle at a temperature of 250 degrees C. into the nickel-plated copper heating block with titanium heatbreak and tightened it with 3Nm. Now I'm printing with the TS for 3 months and nothing has come loose and nothing leaks.

For loosening and tightening the nozzle there is a practical tool to buy, which I use among other things (no wrench):

This reduces the risk of ruining surrounding parts.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Tungsten Carbide Nozzle, torque/temp?

The Z-Catch is AWESOME!

--------------------

Chuck H

3D Printer Review Blog

RE: Tungsten Carbide Nozzle, torque/temp?

@karl-herbert

interesting did not know about this, from the video it seem like you can hand screw it with the parts that give you but is there a way to insert adjustable torque wrench so you know the force your applying is around 3nM or needs to be done by feel?

example maby insert this with the Z-catch some where

or does the zcatch allows you to see or feel the the right amount of 3nM?

RE: Tungsten Carbide Nozzle, torque/temp?

[...] does the zcatch allows you to see or feel the the right amount of 3nM?

One reviewer notes you still want to use a torque wrench for final tightening. They are selling a 1.5nm "donut" torque adapter.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Tungsten Carbide Nozzle, torque/temp?

@bobstro

wonder why they just wouldn't make a 2.5nM or 3Nm torque limiter instead, why 1.5nM is that just the minimum tight it need to be?

RE: Tungsten Carbide Nozzle, torque/temp?

[...] wonder why they just wouldn't make a 2.5nM or 3Nm torque limiter instead, why 1.5nM is that just the minimum tight it need to be?

No idea. It seems an odd value to me as well. Then again, I'm getting good results just using thumb-and-finger to tighten the nozzle. Once you get a feel for it, leaks are not a problem.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Tungsten Carbide Nozzle, torque/temp?

@bobstro

well let me ask this then i got a Tungesten carbide nozzle from 3dmakerengenering and they said to use no more then 1.5nM torque....wonder if they meant to say 2.5nM or maby nozzles are suppose to be tightened at low torque if they are different material..

have any of your TC Nozzle or other material nozzle suggested to use lower torque?

RE: Tungsten Carbide Nozzle, torque/temp?

@muo

I have one of these on one of my printers. I works well. no issues of degradation or heat creep./.

--------------------

Chuck H

3D Printer Review Blog

RE: Tungsten Carbide Nozzle, torque/temp?

@cwbullet

same 1.5NM toque?

if so i wonder why you would get a nozzle leak at higher temp and torque

fyi: this guys also have low torque settings for there TC nozzles

https://docs.dyzedesign.com/nozzles.html#install-your-tungsten-carbide-nozzle

RE: Tungsten Carbide Nozzle, torque/temp?

@muo

I have several wrenches - 1.2, 1.5, and 1.7 NM. For most, I use 1.5, but I try to use 1.2 if there is no info provided by the seller.

--------------------

Chuck H

3D Printer Review Blog

RE: Tungsten Carbide Nozzle, torque/temp?

@muo

I use a torque between 2.5 and 3Nm to tighten the nozzle, as indicated at E3D. You can use the Z-catch to tighten the nozzle and check the torque with a torque wrench to get an approximate feeling. To do this you could print an adapter with a square for the Z-catch handle to apply the torque wrench.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.