RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I will post my fork as well, which I arrived at via a different path, and at this time only provide the MK3S/MK3S+ variant file.

Original Source(s): After running Guy's v3.8.1 firmware for a while, I wanted to update to V3.11.0 for Super PINDA support. I merged all of Guy's updates commented with 'KUO' across seven files from his v3.8.1 fork, into Prusa's official 3.11.0 release.

Guykuo - https://github.com/guykuo/Prusa-Firmware/tree/0.9-Degree-Stepper-Support

Prusa - https://github.com/prusa3d/Prusa-Firmware/tree/MK3_3.11.0

Updates/Additions: I added a few new variables to Configuration_prusa.h (Comment with CLX) for motor tuning and to support Bear X-Axis heights (passes calibration)

- 0.9 stepper type (Moons or OMC). I did this because testing showed a small variance in ideal feed rate, for Moons vs OMC.

- Trinamic QSH4218-51-049, if uncommented instead of Moons/OMC, will use all default parameters for 3.11.0, except increase current as suggested by Vojtěch. I have these running on an otherwise stock MK3S, however still having occasional Y-Axis crashes. More tuning maybe in order here.

- Option for 'Bear X-Axis' which sets Z_Max_Hop to 202, which passes calibration with a BMG extruder on Bear Frame/X-Axis.

I had looked at and tested the BMG releases, before deciding to do a full update based on Guy's earlier work. What differs from BMGs release beside sub-versions;

- Support for Skelestruder (Merged, not tested - lacking HW))

- E3D Volcano Hotend (Merged, not tested - lacking HW)

- Extruder loading and unloading process

- Guy's separation of XY settings into separate X and Y setting,

- Guy's extra M-Codes for trouble shooting and tuning (M919-M222) (Enabled in this Fork)

- Guy's TMC2130 Updates for 0.9 degree optimization

- Guy's options for Slice Magnum tuning with Prusa MMU

Github link for Custom v3.11.0 firmware

https://github.com/Clixster/Prusa-Firmware/tree/MK3_3.11.0_CLX

Github link includes a simple readme, with link to Guykuo's original v3.8.1 fork for installation and configuration details. Be sure to run a PID tune after installation, as included values Slice HT thermistor at 255 degrees.

Validation/QA Systems:

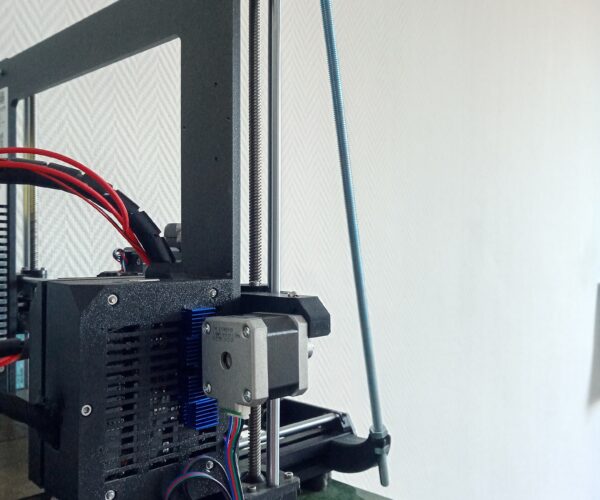

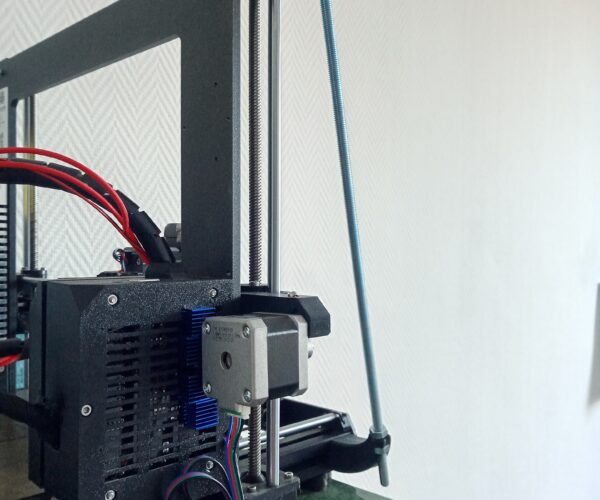

- Machine #1: MK3S+ full Bear frame, Bear X-Axis with BTMM-HT extruder, Misumi rods and bearings, 9mm Y-Axis belt, OMC X&Y Steppers, Linearity Correction @+1.130 and Einsy Heatsinks

- Machine #2: MK3S+ stock frame, Trinamic QSH4218-51-10-049 steppers on X&Y & BTM extruder, Einsy Heatsinks (Getting occasional Y-Axis crash, may need more tuning)

Given this code, includes updates for hardware that I do not have, a portion of this fork is not yet validated. I will make an effort to post any updates or minor changes needed, should need arise and receive notification.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Thanks alot for all the info @Gabe & @HBPrint! (@HBPrint unfortunatly I am not allowed to answer your message right now, I think it´s because my account is new and still being verified...). So I think its helpful to explain my situation with a little more detail. I have the original MK3 without the S, I don´t know if this makes a difference software vise. You will probably have to be a little bit patient with me on the software front since I have only little knowledge of coding in general. I was able to create a simple algorithm to generate custom gcodes in the past but thats about it. In general, I am interested in coding for 3d printers but have a lot of respect of the time and effort that has to be put in besides everyday work... So what I did on the MK3 so far is follow guy´s instructions to install his 3.8.11 firmware. I downloaded Audrino, at first the latest version, which saw some random number definition errors in guys firmware when compiling. So I downloaded the Audrino version recommended by Prusa and everything worked. right know I just put the moons on the x- and y-axis so it was fairly easy to just uncomment the mentioned lines in the code.

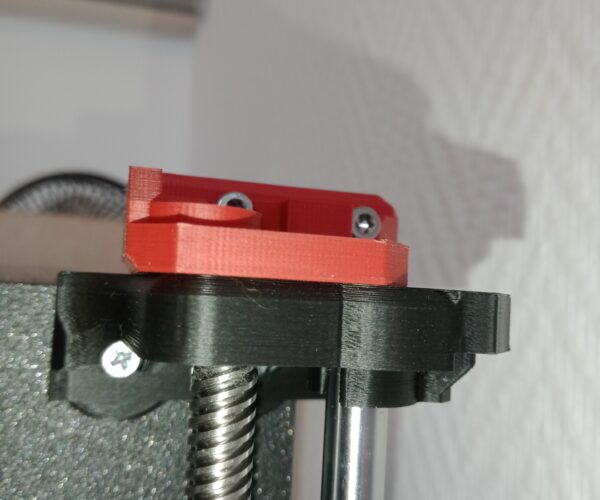

Now, I am changing all the other hardware components involving axis movement. I decided to go with Taurus Prusa axis parts and changed the z-axis including the extra stabilizing z-rods so far without problems. Printing the parts is done with greentech pro material from extrudr. On paper it has better mechanical properties than PLA, but it will be interesting to see how the parts will handle the extra heat from the moon stepper motors and heatbed. So in the future I would like to heat treat PLA after printing, but it will be difficult to retain the right dimensions of the parts I think. Next, I would like to put the bondtech LGX extruder on there with taurus x-axis, misumi parts and a reinforced belt.

If I understood right it should be possible to take the latest prusa firmeware and compare the code with guy´s 3.8.11 firmware and replace the lines commented with KUO right? Since I have the moons and next a bondtech LGX extruder I would then just uncomment the specific lines for moons and bondtech? How would you compare the two firmewares and make the right adjustment, would comparing be possible directly in Audrino? I am sorry for all the questions, but like I said I don´t habe alot of experience with coding, so I can totaly understand if this is too much to ask for.

Attached are some pics of the rebuilt and a comparison of the z axis top printed on stock MK3 in red and with stock + moons below in black.

hdr

hdr

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Mosephus, the main difference (excluding extruder) between an Mk3 and MK3S is the filament sensor (maybe cable), and to then update to an MK3S+ is a Super PINDA and metal bearing clips for Y-Axis. If you update the sensors, you can use a modified MK3S/MK3S+ variants file.

Regarding merging of Guys updates from V3.8.1 into 3.11.0, this is exactly what I did with the fork I linked above. Be certain that you review all files for delta, as Guy made changes to separate XY variables to individual X & Y lines, allowing for more granular tuning and motor testing. He also added M-Code values for motor tuning. I've noted and merged changes in seven files (Configuration_prusa.h, ConfigurationStore.cpp, Marlin_main.cpp, mmu.cpp, thermistortables.h, tmc2130.cpp, tmc2130.h). Plus the normal language attribute setting in config.h.

I have not reviewed an LGX extruder yet, so I am not clear if the height or steps need to be adjusted differently than the BMG.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Hey @mosephus. In addition to what @hbprint has said, I've run an LGX Mosquito successfully with a SliceHT, 0.9 X & Y motors, and Bear upgrade. You can check out my changes. I've added slightly more current, +2, to the X and Y motors since I was getting some false crash detections and it works great. You can check my variant file when the time comes, it's Bondtech-MK3S-16-EINSy10a-LGX-Slice_HT-Mosquito-09xy. You will have to take the MK3 file and compare with Notepad++ or similar and make your changes, but it should be fairly straightforward. If you need help, just ask!

In terms of compiling, I used a Linux subsystem following Prusa's guide and it was very straightforward. It should be in my GitHub readme!

I may do linear guides next but I will need to design it for the LGX carriage. I plan on modifying this:

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Thanks for this, saves me some work.

Just for anyone else, please note HBPrint's version is for the MK3S ONLY, if you own an MK3 it will not work without changes to the Configuration_prusa.h file

The version on Github does not have all the necessary variants included.

It's easy enough to compare and modify though with a MK3 version.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

@Chocki - I've added a variant file for MK3, and tested that it will compile. I do not have a printer to test function on.

Tuning current for crash detection, as Gabe mentions, may need to be addressed per machine. On my MK3 Bear with OMC steppers, it is very sensitive to alignment and 9mm Y-axis belt tension. There is a sweet spot within which works, which is at 60-64Hz using the Piano Tuner methodology for belt frequency. This is lower that what is specified in the build guides. For X-Axis an 80Hz tension works fine. I have not messed with increasing the current yet.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Thanks for the great support! I checked out your changes @Gabe and I think I can understand most of it. With my little knowledge of coding it seems to me that it makes sence to use your code and just compare the prusa stock firmware 3.11.0 for MK3 and MK3S and add the remaining changes to your code. Concerning the current increase I read something earlier in this forum from guy, that he was reluctant to increase current of the steppers because the EINSY may not be able to handle, but I am not able to judge on this. I regually got random crash detection and filament sensor errors on my MK3 stock so I turned them off because usually when you have a skip or filament traction problem the print is trash anyway. So maybe it´s even possible to use your fork completly unchanged with the filament sensor and chrash detection turned of? Would you recommend? About compiling, would it be possible to compile with audrino like I did with guy´s firmware? Also I have the stock thermistor, did you change anything for SliceHT in the code? I couldn´t see anything. I am also curious if SliceHT and the moscito hotend gave you any major improvements in addition to the bondtech. I read some in another thread, most people said that the moscito gave alot of improvements but nobody showed really any hard evidence. With the gearing and stepper of the bondtech it´s straight forward, but the hotend is mostly there for cooling, so if you don´t print crazy hot, I would think that the sliceHT and a good nozzle should give the most added value. Also the moscito hotend is crazy expensive with the same price as the bondtechLGX...

RE:

So, I will try to address all of your questions:

- The current addition probably did not have to happen. Early in my testing I had a couple of crash detections that messed up my prints. I added a minor increase in current and turned off crash detection in the settings of my printer. You have to consider, 0.9 motors have less torque, and for me I thought that increasing the current might bypass these issues. I haven't printed extreme overhangs that might curl up and cause an actual crash detection, so it's kind of experimental. Regardless, it's been running great for me. I do run my belts at 90 Hz as stated in the bear upgrade build guide (that I have).

- You can compile however you would like to. I just found the Linux Subsystem to be the easiest, as you don't have to download the Arduino IDE. I programmed in Visual Studio and it was much easier to keep track of changes since that is what I am used to. It's all personal preference. If you need me to run you through it, just let me know!

- There is a definition for the Slice HT in the variant file. it should be #define TEMP_SENSOR_0 800. If you are running a stock thermistor you should be able to find it in a variant file that is stock Prusa. Then it will be #define TEMP_SENSOR_0 <number>.

- The Mosquito hotend is awesome, but the major downfall is that it is pretty expensive. I like that I can use their torque wrench and change nozzles on the fly without having to secure the block. I hated that E3D hotend would twist a little and become loose. I switch between normal and abrasive filament and change nozzle sizes a lot so for me the upgrade is worth it. I also think that the print quality is better.

- I don't think the Slice Thermistor (SliceHT) is even available anymore (or maybe on backorder?). I got it a long time ago with their high power heat cartridge as I wanted quicker heating times. It's supposed to be for extreme temps and that just isn't a use case for most people.

- The most quality improvements IMO will come from the extruder gearing, 0.9 X Y motors, and a Bear Frame (to make the printer more structurally rigid). A lot of people have had great results with a BMG extruder that you can print and source yourself! I actually had a BMG before and designed my own extruder for it. I am just a perfectionist and want the best so I got a LGX and I don't regret it, lol.

Let me know if you need anything else!

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Thanks @Gabe for all the info, you guys are super heplful!!! I like the current increase a lot in general since the moons are kinda weak in stealth, I just wanted to know in detail because of what was said earlier... Thanks also for the info on the mosquito, nozzle change is really tiresome and my temperature sensor cable is already bend all the way, it will definetly break sometime in the future, so the mosquito update will come 😉

So I will compare the bondtech firmware for MK3 and MK3s and add the changes to your file plus a change to #define TEMP_SENSOR_0 <number>.

Hope it will work out... If not, I thought about checking my current guy MK3 firmware if his bondtech extruder changes are the same you recommended for LGX (LGX extruder; changed TMC2130_USTEPS_Z to 16 and DEFAULT_AXIS_STEPS_PER_UNIT to {100,100,3200/8,400}). I would change these if I have to and miss out on LA v2 and the super PiNDA. Bed leveling works great for me right now after calibrating Z at the right tempereature and reducing the z-yerk alot to slow down the sensing movement. I don´t have an issue with LA v1, I was actually very suprised how well it works on corners and detail.

@HB print: the process I described for guys firmware should also work with your MK3 addition right? But since you have different steppers and extruder I would hace to add the right machine settings or would it be more compicated.

Just trying to find out which process would create the least issues since I don´t really know what I am doing I wouldn´t be able to do any troubleshooting...

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I will post the changes to the variant file of Gabe once my github account is up. Would be cool if somebody could check. I basically defined the printer type back to MK3, commmented back //#define PSU_Delta and changed the filament sensor definition back to #define PAT9125 and #define TEMP_SENSOR_0 <number> back to 5... All the other files I left untouched. Compiling was successful with Adruino. I will print the taurus x-axis parts the next days and give it a shot with the bondtech LGX if you see no problems in the code and things I am doing... Since this fork is not based on guy´s, do you have to set the language settings as well? i guess no becuase i couldn´t find any config.h and also in guy´s manual the extruder micro steps and e values are defined once again manually. This also applies here or can be left out?

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Hey @mosephus! Sorry I was away for the weekend. One thing that I would do is check against the variants that the original file was based on here:

https://github.com/BondtechAB/Bondtech-Prusa-Firmware/tree/Bondtech-MK3-FW3110/Firmware/variants

You want to make sure your branch correct one, in this case FW3110. That being said, I immediately see that you should remove #define BONDTECH_MK3S, as you have an MK3. I could be wrong as I need to see what the definition actually does. It probably enables the Filament sensor on the printer and settings!

I will look over your config file and see what the definitions do in code to confirm. You're on the right track though!

RE:

Other than that it looks good but I need to see what EXTRUDER_ALTFAN_DETECT and EXTRUDER_ALTFAN_SPEED_SILENT does, as well as BONDTECH_MK3S

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I see that in the MK3 (non s) there is no BONDTECH_MK3S, EXTRUDER_ALTFAN_DETECT , and EXTRUDER_ALTFAN_SPEED_SILENT.

The Bondtech_MK3s is for the mmu distances. The altfan ones will automatically detect if you have a Noctua or alternative fan, but for the MK3 I would probably just remove them.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

This is a great article!

I have a MK3S+ and it has the BT BMG with Mosquito & Moon 0.9* (MS17HA2P4100) X&Y stepper motor upgrades.

Is there a 3.11 firmware link that has these hardware modifications?

Thanks in advance.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I installed your firmware and very carefully followed the instructions and have experience with Arduino setting my hot end probe to a PT1000. However, after 4 attempts of carefully following the instructions, my moons stepper will not function correctly. When I manually move them they are glitchy and act like they are completely jammed. What am I doing wrong?

RE:

Hey smibble! What does your cable pin out look like going into the moons motors and control board? I'm wondering if it's not correct. Unfortunately I am not at my printer right now so I'm just referencing some photos and it looks like black, green, red, blue into the motor. Not sure into the control board.

Could you also post your variant file for me to look at?

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I verified the cables are connected the same way the existing color coded ones were.

https://github.com/smibble4/Moons_0.9_FW3.11_BMG_Mosquito_PT1000.git

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I found the issue. The cables I purchased for the Moon steppers had the green and red wires switched in the connector from factory...