RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

By any chance did you accidentally uncomment, but with a 1.8 degree motor installed?

//#define E_AXIS_MOTOR_09 //kuo exper EXTRUDER

Doing that with a 0.9 degree extruder motor would cause over extrusion. BTW, I don't recommend a 0.9 motor on a geared extruder due to risk of inadequate torque during rapid filament moves.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Looking back through the firmware, there are some missing #define EXTRUDER_GEARED.

Please download new copy and see if that helps.

May need to factory reset to get new microsteps to take effect.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Should show for 0.9 on xy and 1.8 on E, 3.5 skelestruder

Send: M503

Recv: echo:Steps per unit:

Recv: echo: M92 X100.00 Y100.00 Z400.00 E473.00

Recv: echo:UStep resolution:

Recv: echo: M350 X8 Y8 Z16 E16

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

BTW, 3.9.0 will have the homing reset bug fixed; there was a corner case that caused a buffer underflow in certain circumstances.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I wanted to say a big THANK YOU to everyone still making this firmware train stay alive. You guys are the reason why open source works so well.

It is greatly appreciated.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Grrrr. Word Press kept throwing errors when I was posting earlier. When I angrily pasted for the 5th time, I forgot to edit the e step value

Send: M503

Recv: echo:Steps per unit:

Recv: echo: M92 X100.00 Y100.00 Z400.00 E490.00

Recv: echo:UStep resolution:

Recv: echo: M350 X8 Y8 Z16 E16

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

xD know after i got my 1.8 stepper on the extruder and reuped your config the printer failed every time on XYZ calibration:

always on the z calibration where he moves to the bed and wants to check the 4 points.

calibration starts through the wizard.

Also he doent stops overe the marked location on the heatingbed where the Pinda should be.

The pinda has an offset of 5 mm to the left and 3mm to the front.(viewed from displayside)

//====== Kuo Uncommented def(s) below specify 0.9 degree stepper motors on x, y, z, e axis

//Motors used should be 1 amp or lower current rating to avoid overheating TMC2130 drivers in Stealthchop.

//Kuo recommended 0.9 degree motors for X, Y, or direct drive E are Moons MS17HA2P4100 or OMC 17HM15-0904S

//

#define X_AXIS_MOTOR_09 //kuo exper X axis

#define Y_AXIS_MOTOR_09 //kuo exper Y axis

//#define Z_AXIS_MOTOR_09 //kuo exper Z axis

//#define E_AXIS_MOTOR_09 //kuo exper EXTRUDER

//====== Kuo Uncomment ONLY ONE or NONE of below for geared extruders

//Don't forget to also send gcode to set e-steps as detailed earlier

//Reversion back from geared extruder requires sending M92 E280 & M500 to printer

//

#define SKELESTRUDER // Uncomment if you have a 3.5 ratio Skelestruder. Also applies the patches for load distances and Z height.

//#define BONDTECH_PRUSA_UPGRADE_MK3 //Kuo Uncomment for Bondtech MK3 extruder upgrade. 3:1 extruder. This also sets Z_MAX_POS 205.

//#define BONDTECH_PRUSA_UPGRADE_MK3S //Kuo Uncomment for Bondtech MK3S extruder upgrade. (Note the S!!!!) 3:1 extruder. This also sets Z_MAX_POS 205.

//#define EXTRUDER_GEARRATIO_30 //Kuo Uncomment for extruder with gear ratio 3.0.

//#define EXTRUDER_GEARRATIO_3375 //Kuo Uncomment for extruder with gear ratio 3.375 like 54:16 BNBSX.

//#define EXTRUDER_GEARRATIO_35 //Kuo Uncomment for extruder with gear ratio 3.5 like 56:16 Bunny and Bear Short Ears.

//====== Kuo E3D Volcano Support

//#define E3D_VOLCANO //uncomment to adjust Z_MAX_POS to accomodate 8.5 mm greater Volcano extruder height

//====== Kuo Slice Support

//#define SLICETHERMISTOR //uncomment for Slice Thermistor

//#define SLICEMAGNUM //uncomment to adjust MMU2S filament laod/unload distances for Slice Magnum

//====== Kuo extrude before unload filament

#define EXTRUDE_BEFORE_UNLOAD //uncomment to always extrude filament a short distance before unloading. Forms smaller tip.

//---------------------------- Kuo End of defines one normally needs to change ----------------------------

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I suspect it's not happy with your Z distance, there's some weirdness there surrounding how the Mk3S handles the changed Z distance over the standard Mk3. (Mk3 needs a Z-height correction for the skelestruder, 3S does *not*) Symptoms are either the nozzle hitting the bed, or starting the search too high, depending on your particular combo of printer flavour and firmware Z-height.

The XY calibration should not need adjustments, I've run it with my own skelestruder without issue after servicing the heat bed.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Mh. i would say the nozzle stands perfekt above the bad. 1,5 mm. the weirdness ist that the printer worked yesterday, but after i upfated the firmware today it want calibrate the z-Axis.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

You could still be having the issue. I think they fixed the non-safe Z descent since I looked at it; bottom line is the PINDA is not triggering where the firmware expects it to.

Make sure you've flashed the correct variant to your printer (3S vs Mk3)

Recalibrate sounds familiar. I think the printer forces that if you change the printer type via flash.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

TBH I should say my memory is fuzzy here; Guy's done some fantastic work but I no longer run his firmware, for me stock firmware + load distance changes for skelestruder works absolutely fine with my 0.9 degree motors now that M350 is supported for X/Y/Z.

I do have it up on github for reference ( https://github.com/prusa3d/Prusa-Firmware/compare/MK3...vintagepc:Skelestruder-MMU2S?expand=1 for the differences with stock firmware) but I would not recommend using it because a) it's my test ground and I offer no support for it, and b) it's not updated regularly, if at all. I just use it as a working base into which I merge a selection of feature/dev branches for the end product.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

How do you use the M350?

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Okay i looked again into the firmware and i am using the correct config. I tried to upload again an run the wizard and the same Error shows up.

Very confused because yesterday it worked fine.

After i continued to the menu after the error showed up and wants to drive the stepper manually i saw that he is on 5mm + but actuelly stands 1,5mm above the heatbed.

so i think it has something to do with the wrong max Z-Hight for the z-Axis.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

@cybrsage

i am using the terminal on my Octoprint

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

How do you use the M350?

Set steps per mm first, then do

M350 X8 Y8

to set both X and Y to 8 microstep resolution.

Then M500 to save it to EEPROM.

Note this alters the steps/mm value to stay constant, e.g. if you drop from 16 microsteps to 8 (halving the resolution), it also halves the steps/mm count since your step size is now twice what it was.

Same general principle as for the extruder apply - don't go far above 100 steps/mm on X/Y, X/Y travel moves are much,much faster and the einsy simply can't keep up at higher travel speeds, leading to skipped steps. It definitely can't handle 200, but if you have a different pulley size on the motor then 110, 120 would probably still work.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

okey i have now set the z-axis height to 215mm and now he also does the z_axis calibration

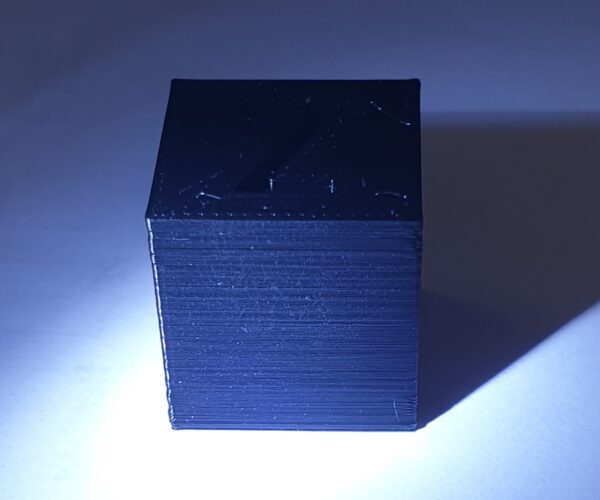

So for my MK3S with all Taurus mods I need 215mm z-axis height. I now print the test cube and write the result.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

I'd say the print is pretty good. A little more adjusting the belt tension and the print options and then it should work fine.

The drivers were running at about 40-50 C°, so everything is ok.

If someone else has the PRoblem with the Z-axis calibration. Look, after the error occurred, in the menu of the manual Z-axis movement and if there is a positive value, it must be subtracted from the entered maximum value in the firmware.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Yeah, you should be able to get a little better out of it. I don't have any pictures on hand, but on my own skelestruder + 0.9 degree setup I get prints that look damn near perfect, except at the most extreme light angles

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Yes, it's not optimized per se, but it's working. I was in a hurry and with the 0.2 mm option in the Prusaslicer I put full speed^^.

So I also see what temperature the drivers have.

RE: Stepper Motor Upgrades to Eliminate VFA's (Vertical Fine Artifacts)

Hi, been reading this thread for the past few hours and I want to upgrade the x&y steppers to get rid of some vertical artefacts. I'm looking at the moons 1.8 and the trinamic QSH4218-51-049 1.8 (not looking at 0.9 atm, sorry) and was wondering which one would be better for reducing vfas. And what extra things will I need? I have read that the moons will need another cable like these: https://www.amazon.com/gp/product/B07CBV8DVZ

But what about the trinamic ones? Sorry for lack of knowledge at the moment. Only just started considering upgrades.