RE: Profile for a 0.3 mm nozzle

@tim-2

One more try

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

RE: Profile for a 0.3 mm nozzle

@cwbullet

I noticed that, I think i clicked "Add Reply", and then the "Choose File" button 😀

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

RE: Profile for a 0.3 mm nozzle

@ringarn67 - thanks for the retread!

@frippe75

Those parts easily print on a clean PEI sheet without resorting to brims (I have a batch going right now). They are extremely easy to slice and print parts - I'm using 100% PLA defaults with a 0.4 nozzle with 0.20 layers (with the exception of my start code). And you can see I haven't cleaned my sheet in a while.

Read through Bob's info - between the seemingly hard lessons of how to 1) properly clean a print sheet and 2) adjust live-z to make layer one 0.20mm thick when set to 0.20mm in slicer - printing is generally quite easy.

I also think you are missing some of the basic points of printing and making things harder on yourself. Pick up the printing handbook that came with your printer and read it cover to cover - it's a goldmine of information - I even resort back to it from time to time.

After looking at your choices of settings for slicing these parts. There is no reason to change layer one to 0.23 mm on those parts or with a 0.25 nozzle. As a matter of fact, there are several reasons why a 0.23 mm setting for layer one is a terrible idea when using a 0.25 mm nozzle. Because of settings like that you have made an easy print a nightmare for yourself.

It's also good advice that gets handed down to use the defaults until you can predict the outcome of changing a setting. The profiles that come with Prusa printers are excellent and rarely need adjustments except to make minor improvements to certain print details or to compensate for plastic type or brand peculiarities. And as you can see: the default PLA profiles worked quite well on your parts - well, the parts are small and could benefit from a smaller nozzle.

RE: Profile for a 0.3 mm nozzle

Sorry, I fell asleep. I was able to successfully print it on an MK3S and Mini.

--------------------

Chuck H

3D Printer Review Blog

RE: Profile for a 0.3 mm nozzle

@tim-2

Thanks for taking the time to test-print my parts! I think the 0.4mm nozzle wont make for functional prints if I were to guess.

I had to adjust the smaller parts somewhat to reach my required tolerances.

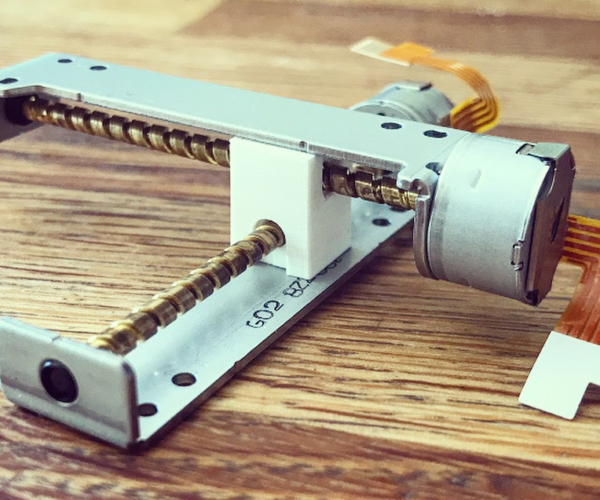

Just so you know. Now you have parts to create a REALLY small XY-table 🙂

Pretty stoked when I realized the clean and small design. The design is somewhat flawed in terms of the load it can carry. But I will be using it to position a supersmall item so for me it seems to work. Having one of the axis in the end-position still does not generate too much load on the other one.

RE: Profile for a 0.3 mm nozzle

@frippe75

Very cool design. Elegance in simplicity, really. Are those servos or steppers?

RE: Profile for a 0.3 mm nozzle

@tim-2

Thanks! Those are stepper motors coming from old DVD/CD-players.

RE: Profile for a 0.3 mm nozzle

[...] Just so you know. Now you have parts to create a REALLY small XY-table 🙂

Wait... are you building one of those tiny 3D printers? I thought this was to print car dash panel covers!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Profile for a 0.3 mm nozzle

@bobstro

Haha.. That could be a possibility I guess. But the accuracy would be quite limited I guess due to slack to allow the rods to move. Maybe preloading using a spring... Hmm.

No. I'm using it to create a dataset to train an AI model. I have a few sensors where I need to move an object and then use a camera to determine position and label my data ... So automating my Data acquisition.

RE: Profile for a 0.3 mm nozzle

This is what came to mind when I saw your mechanism.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Profile for a 0.3 mm nozzle

@bobstro

RE: Profile for a 0.3 mm nozzle

@frippe75

Wow. That is small. What hotend will yo use? That would have to be small.

--------------------

Chuck H

3D Printer Review Blog

RE: Profile for a 0.3 mm nozzle

@cwbullet

Its not gonna be a 3D printer so no hotend 🙂

RE: Profile for a 0.3 mm nozzle

So there is someone a functional print profile for 0.30 mm nozzle? I purchased a nozzle of 0.25 for printing details (for H0 model rails) but at my MK2.5 still becomes separated after 30min up to 4h 🙁 (original 0.4mm nozzle without problems) (Currently PLA Prusament Grey) .14 days testing - depressed my and my women :-)- replacing the heater from 30W to 40W- Thermistor OK- PID calibration- Complete disassembling Hot End - all clean and correctly composite (nozzle gap, ...)- New PTFE tube- adjustment of temperatures down and up, increasing and reducing print speed and retractionThere is always a nozzle partly or completely. Then either by pulling the filament at 80°C or when printing occasionally, just press the filament - to help the stepper motor and printed further. Occasionally, the extrusion of the filament stops only one layer, but then the printout of course in the layer is low - unusable. I tested other filaments - ASA Filamentum, PLA PM Mladec - all the same.