RE: Profile for a 0.3 mm nozzle

The printer is toasted... Now first layer calibration fails miserably. Not sure if it's the steppers of the motor drivers. Will try a full cleaning process. Tensioning of belts and so on....

RE: Profile for a 0.3 mm nozzle

@frippe75

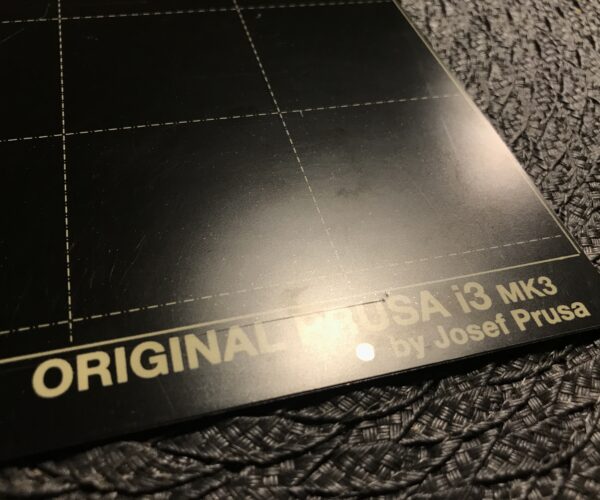

Before offering any other suggestions, a high quality photo of the print sheet is requested.

RE: Profile for a 0.3 mm nozzle

@frippe75

I use a PC, I do not have TAR or 7zip installed. ZIP files are all I will open - just too much spam trying to use anything else that isn't imbedded into the OS - and I haven't built a system with a UNIX/Linux distro in years (well, except my my Rpi).

RE: Profile for a 0.3 mm nozzle

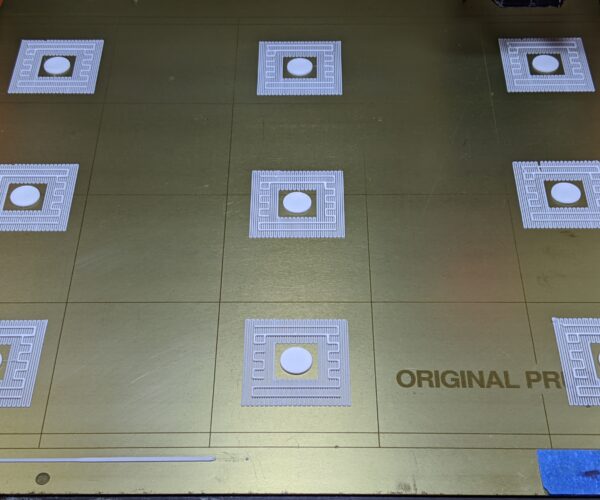

Those problems look more like adhesion issues rather than anything to do with your nozzle settings. There are plenty of posts on bed adhesion and Live-Z about, so look into those. Once you've got bed adhesion and Live-Z worked out, parts like those should not be a problem without resorting to training wheels brims. A properly cleaned and leveled Mk3 should not have problems with lots & lots of small parts, although PLA works better on the smooth PEI sheet.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Profile for a 0.3 mm nozzle

The printer is toasted... Now first layer calibration fails miserably. Not sure if it's the steppers of the motor drivers. Will try a full cleaning process. Tensioning of belts and so on....

Be sure the printer is on a solid surface. If there is too much deviation during the leveling process, the probe will pause before trying again. Vibration can throw it off. Put the printer on the floor and see if it completes leveling better. Does your printer have a PINDA or SuperPINDA installed?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Profile for a 0.3 mm nozzle

@tim-2

When taking the time to look at the sheet I realize that after changing to the 0.3mm nozzle and doing first layer calibration the nozzle has actually touched the sheet leaving marks. I have moved my parts to another part of the print sheet. It's the original Steel Sheet. Should have ordered a new one.... But there is plenty of good parts left. Will have to find a 0.3 mm nozzle calibration gcode and move it off-center as well.

RE: Profile for a 0.3 mm nozzle

@bobstro

Will clean, tension, move the printer to the floor. Try to re-calibrate (off-center) since there are small marks from the 1-layer calibration process where it must have touched the print bed. It have to be regular PINDA since it's a MK3 with the PINDA probe that followed.

The sheet was in perfect condition prior to me switching for a 0.3mm nozzle. Note to self is to start high with a new nozzle and move down...

Ordered on 2018-11

Original Prusa i3 MK3 kit - color : Black and orange, Spring steel sheet : Spring steel sheet with smooth double-sided PEI sheet

RE: Profile for a 0.3 mm nozzle

Ordering a "Double-sided Powder-coated Satin Spring Steel Sheet" which wasn't available when I purchased my print back in 2018. Hoping that is a bit of an upgrade?

RE: Profile for a 0.3 mm nozzle

Found a nice First-layer-calibration pattern on thingiverse which could be minimized to only cover my working part of the steel sheet while waiting for the powder coated satin as well as a new replacement steel-sheet as well. Will post my results tomorrow.

Photo showing an unused area of the steel sheet...

RE: Profile for a 0.3 mm nozzle

When taking the time to look at the sheet I realize that after changing to the 0.3mm nozzle and doing first layer calibration the nozzle has actually touched the sheet leaving marks. I have moved my parts to another part of the print sheet. It's the original Steel Sheet. Should have ordered a new one.... But there is plenty of good parts left. Will have to find a 0.3 mm nozzle calibration gcode and move it off-center as well.

Unless the nozzle deeply gouged the PEI surface, it may work it's way out over time. A bit of acetone can also help remove some marks if filament residue has been ground in. The sheet is reversible, so just flip it for the time being.

If the nozzle is digging in, do be sure that the nozzle has been properly mounted. Examine the nozzle and be sure there is a small (<1mm but visible) gap between the nozzle hex and the heater block. If the nozzle is screwed fully into the block, you are likely going to have leaks. When fully tightened at 285C, it should be impossible to tighten the nozzle snug against the block if you made the change correctly.

If the nozzle is not installed correctly, it might be a bit longer and ding your PEI surface. You might end up adjusting your PINDA, but I'd say that's unlikely to be necessary if you've used any decent brand of nozzle. I go with E3D, P3-d, or at worst, TriangleLab.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Profile for a 0.3 mm nozzle

@bobstro, actually found an older 0.25mm nozzle laying around. Bought some aceton since it was clogged and think I got it back in working order. Still waiting for a new one from Prusa. But what do you know. I set the printer to the Prusa 0.25mm and the Prusa 01.mm detailed print settting and it started printing again to some extent.

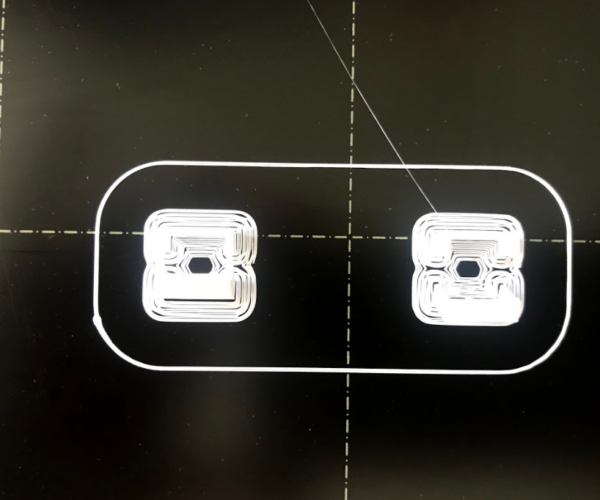

I think it's under extruding or maybe I just need to lower my nozzle during first-layer-cal a bit looking at the skirt.

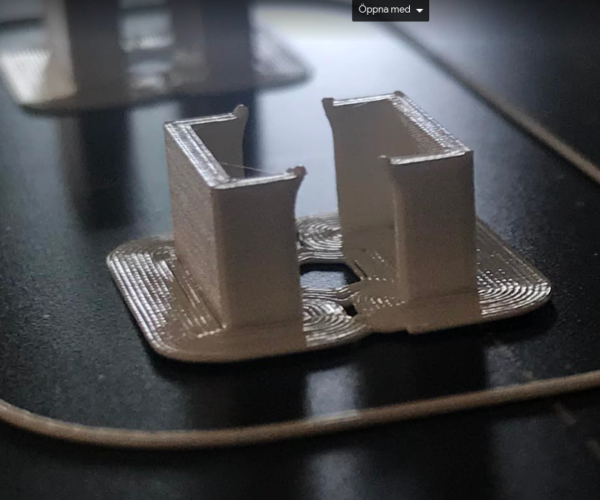

Print was fine up until the overhang part started where it actually start knocking down the parts @ layer 58. I guess adding support could help with that.

Here the bottom left was knocked over. But it feels like an adhesion problem when I try to knock the others over manually

Maybe really obvious here looking at the brim...

Even looking at the skirt in the picture above...

But looking at the Prusa 0.1mm detailed printer profile. First layer is 0.2mm... Should I change this to 0.15 or would that mean even less plastic for the brim first layer??

Also moving the printer to my kitchen bench made the bed leveling work again. The printer was on a shelf which is wallmounted and had been since I bought it. Not sure the later firmware made it more sensitive to vibrations??

RE: Profile for a 0.3 mm nozzle

I think my 1-layer is better now and brim is looking better. But maybe I can even lower it some more?

Prints still keeps getting knocked down as soon as I come to the overhang part.

Even tried with supports. Plastic is warping upward thereby making the nozzle touch the part.

Tried taping it down by pausing the print when it gets to the sketchy area... No success.

So print is failing at the same place leaving me with this 🙂

RE: Profile for a 0.3 mm nozzle

How much could cooling affect the issues I'm facing?

RE: Profile for a 0.3 mm nozzle

So since the printed started working somewhat I decided to print the new version of the nozzle fan. Came out fine...

Then ran the print with supports and lowered first layer a few steps more... Success!

So... My take... A 0.3mm nozzle profile from Prusa would be nice. Using a 0.25mm with the pre-baked printer settings worked out.

Not saying there is something wrong with anyone else just simpler I guess.

Any feedback on my struggle is much appreciated! Other than getting the first layer down correctly. I think moving the printer to a totally solid base was key.

RE: Profile for a 0.3 mm nozzle

The brim & skirt should hold firmly. I'm going to give you a big info dump to read through. I recommend working on these issues 1st. The reason is that, while you've got some definite print issues going on with the "arches", a loose print will aggravate that problem. Cooling is something to look at, but again, after you've got your Live-Z and bed adhesion working properly. Here's the sort of result you're after for your 1st layer:

-

Part warping or lifting along edges.

-

Bumping or knocking noises as the part moves under the nozzle.

-

Uneven vertical surfaces and bulges caused by print lifting and compression of overlying layers.

-

Spaghetti resulting from parts moving during printing.

-

The dreaded "blob of doom" caused by the part lifting and sticking to the nozzle as it extrudes filament.

-

A dirty PEI print surface. Even if you don't think this is the cause, it's always a good idea to make sure your PEI surface is clean before trying any other fixes. If it's a smooth PEI sheet, take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails , and another dunk when acetone fails. Worst-case, use a 3M 7445 ScotchBrite (1200-1500 grit) pad or equivalent on smooth PEI to give it a very light buff, but only infrequently. If you've got a textured powder-coated PEI print surface, the official instructions are to use 91%+ isopropyl alcohol on it only. Rumors persist that some have had good luck getting started with these sheets by giving them a wipe with 100% acetone and a dunk with Dawn. Either way, there's no real warranty on these sheets. YMMV.

-

If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the onboard routine and much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers. You should not be able to peel the lines apart after printing, but the top should be regular.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Profile for a 0.3 mm nozzle

@bobstro

Thanks a bunch for the support here! Much appreciated!

Last print came out fine actually. So happy days!

I do realize it's all about the basics. I was soo sure it was something else. Could be that belt tensioning and cleaning added to the solution.

I have been cleaning the PEI print surface with IpaClean IPA-250 which is isopropanol @ 99.5%. Also bought some more Aceton for nozzle cleaning but also ran it over the print surface... Warm water and soap.. Check... Clean hands... No touch, check 🙂

So now I can actually start modifying some tolerances on my model and iterate of it to get going.

Thanks again!

RE: Profile for a 0.3 mm nozzle

Those parts should print without a lot of problems. Get everything sticking properly first and life gets much easier. Try just doing the Dawn dunk, no alcohol, before printing. There's a feeling of friction to the PEI when it's clean. It's not slick at all. (Of course, test this in an unused corner.) Good luck with it and let us know if you have any more questions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Profile for a 0.3 mm nozzle

@tim-2

A little late, but here it is, Rezipped

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

RE: Profile for a 0.3 mm nozzle

@ringarn67

I think you forgot the file.

--------------------

Chuck H

3D Printer Review Blog