Optimal enclosure temperatures

What's the optimal enclosure temperature for PC Blend? This article says that a good enclosure temperature for ABS is 60C. I've noticed that the Printed Solid enclosures for my Mk3s+ printers only reaches 35C for prints with PC Blend. My parts warp a lot, so I'm planning to add heating with temperature control to my enclosures, but I would like to know what temperature to aim for without having to do trial and error (minimizing warpage on one hand and avoiding sag on the other hand?). For example, is the optimal enclosure temperature for PC Blend also around 60C? And while we're at it, it would be good to know the optimal enclosure temperature for ASA, PC Blend Carbon Fiber, and PA11 Carbon Fiber.

RE: Optimal enclosure temperatures

I tried running a PC Blend print with the enclosure at 60C. The PINDA probe sagged a lot, X axis belt tension was lost, and the hotend clogged. I now know that the PETG parts in Prusa printers don't have the temperature resistance needed for running prints with the enclosure at high temperatures. It would be great if Prusa specified a maximum enclosure temperature. Also, it would be great if Prusa offered a version of their printers with the plastic printed parts made of a more temperature-resistant material than PETG.

RE: Optimal enclosure temperatures

We're not talking about the same thing. I'm talking about enclosure temperature, not bed temperature. PLA printing would be impossible with an enclosure at 60C.

RE: Optimal enclosure temperatures

Replying mostly to get copied on replies because it is a great question. Material tables show you recommended nozzle and bed temperature, but I haven't seen anything that specifies ideal ambient temperatures. I have printed PC successfully in a LACK enclosure which reaches 36 degrees but have also seen (minor) warping. My gut instincts are that 50 to 60 degrees feels like a good target, with zero empirical evidence to support it.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Optimal enclosure temperatures

@fuchsr I have had the same experience and also feel like an enclosure temperature closer to 60C is probably preferable for printing with PC Blend. Unfortunately, Prusa printers can't handle this enclosure temperature. I contacted Prusa support about this and they recommended against printing with an enclosure temperature higher than 40C (it'd be nice if this info was available elsewhere, such as in the product page of their enclosure). I suggested that they offer a version of their printers with parts printed out of a more temperature resistant material than PETG.

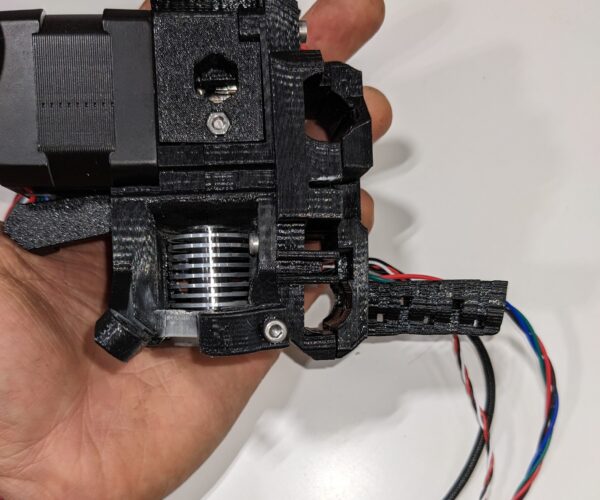

Here are photos showing deformation in the PETG parts of the extruder as a result of attempting to run a PC Blend print with the enclosure at 60C. The PINDA mount is heavily sagged and the whole extruder body seems partially collapsed on the hot end part. The plan now is to rebuild the extruder with parts printed out of PC Blend.

RE:

I don’t think it’s necessary to go as high as 60C to print reliably PC, ASA or ABS. I also use a Lack enclosure. Printing PCblend or ASA in summer, with a room temp, about 30C, I get around 40-45C inside the enclosure. No problems with warping. For PC blend I use the smooth sheet and Dimafix as adhesive/release agent. No problems either printing ASA with 3Dlac on the satin sheet.

My extruder hasn’t deformed at all, but that might be because I’m not using the Prusa stock unit but a Bondtech LGX, with plastic parts printed in a nylon filament that withstands heat much better than PETg or ASA.

Not a bad idea to reprint the extruder parts but take into account that PC, if tougher than PETg, it’s also more brittle and some parts might crack if mechanically stressed too much (for instance, over tightening a screw ). Therefore, be extra careful when assembling the parts,

As an alternative, I believe that ASA or ABS would also be fine if you don’t go higher than 50C inside the enclosure. Those filaments are more flexible than PC and less prone to crack. If you go 60C or even higher, then PC seems a better idea, but in this case other parts of your MK3s+ printed in PETg, eventually might deform a bit, so you’ d have to reprint most of the plastic parts to be on the safe side.

Another factor to consider with an enclosure temp. around 60C might be overheating the steppers or the Einsy board, but I have no idea if that would be a real issue.

RE:

@Artur5

I also use a Lack enclosure. Printing PCblend or ASA in summer, with a room temp, about 30C, I get around 40-45C inside the enclosure. No problems with warping.

I have tried printing PC Blend parts with the enclosure at 45C and got significant warping. I expect there to be less warping at higher temperatures, such as 60C.

In my experience, PC Blend parts are not brittle - it's quite the opposite.

This source says that 60C is a good enclosure temperature for printing ABS. PC Blend is extruded at even high temperatures and is even more temperature resistant, so I would expect 60C or even higher to work well for PC Blend.

You're right that other parts in the printer will warp. I've already seen this actually. I may rebuild the entire printer with PC Blend parts. This would make it an interesting Mk3s+ printer.

RE: Optimal enclosure temperatures

Here's another relevant bit of info. The Flashforge Creator 4 has a temperature-controlled enclosure and their marketing material suggests that 65C is a good enclosure temperature (presumably for higher temperature materials like nylon and polycarbonate): "The advanced thermal-control system of Creator 4 keeps the print chamber at 65℃, which effectively reduces model shrinkage, warping at corners, and furnish breakage." https://www.flashforge.com/product-detail/flashforge-creator-4-3d-printer

RE: Optimal enclosure temperatures

In my Lack-enclosure I use acrylic panes only for the front side. The other 3 sides are made of isolating foam sheets. When printing bigger parts in ABS I reach a max. inside temperature of 53°C. For my projects this was so far enough to prevent warping but you must realize that warping tendencies apart from the material differences are mainly caused by the form of the part to be printed. Generally you must avoid massive material areas. If the part is well designed this will prevent most warping-headaches.