Re: New toy from bondtech

Looking at the parts and manual this seems to be a temporary add on solution while the extruder body is reworked to take the new sensor arrangement natively. It reminds me of the first indirect sensor mod solutions that were effectively a box added on top of the extruder before they were integrated into it.

Hopefully a fully integrated solution will be forthcoming for those of you that are interested in the Bondtech extruder.

Regards,

Martin

I hope so too. I wouldn’t mind paying a little extra money for a new SLS printed part.

Re: New toy from bondtech

I hope so too. I wouldn’t mind paying a little extra money for a new SLS printed part.

Same, I would pay for updated parts.

Re: New toy from bondtech

I would really like to see how the Bondtech extruder does in terms of extrusion consistency. Periodic alterations in stepper motor monotonicity creates the diagonal surface pattern seen on flat vertical surfaces (aka 602 artifact). Non-monotonic stepping also creates Vertical Fine Artifacts. They are the same issue, but e-cycles are on totally different distance scales for the e and xy axes. On the extruder, the changes are over a large distance and that is why you see them as diagonal waves. On xy, they are very short distance and appear as fine, vertical lines.

At any rate, the Bondtech extruder changes the extruder motor arrangement and it would be interesting to see whether the extruder motor, diagonal wave artifact is improved.

On a direct drive extruder with Moon's 1.8 degree motor I get...

You can see the diagonal wave from the extruder motor not being exactly monotonic. This print is actually an improvement over the stock LDO motor.

I have attached my ecore towers for both PETG and PLA below. My towers are a bit easier to read than the Prusa ecore tower, but take longer to print. If someone could print with the new Bondtech extruder, it would be a good test of the new extruder's consistency. Less diagonal wave means better consistency.

Re: New toy from bondtech

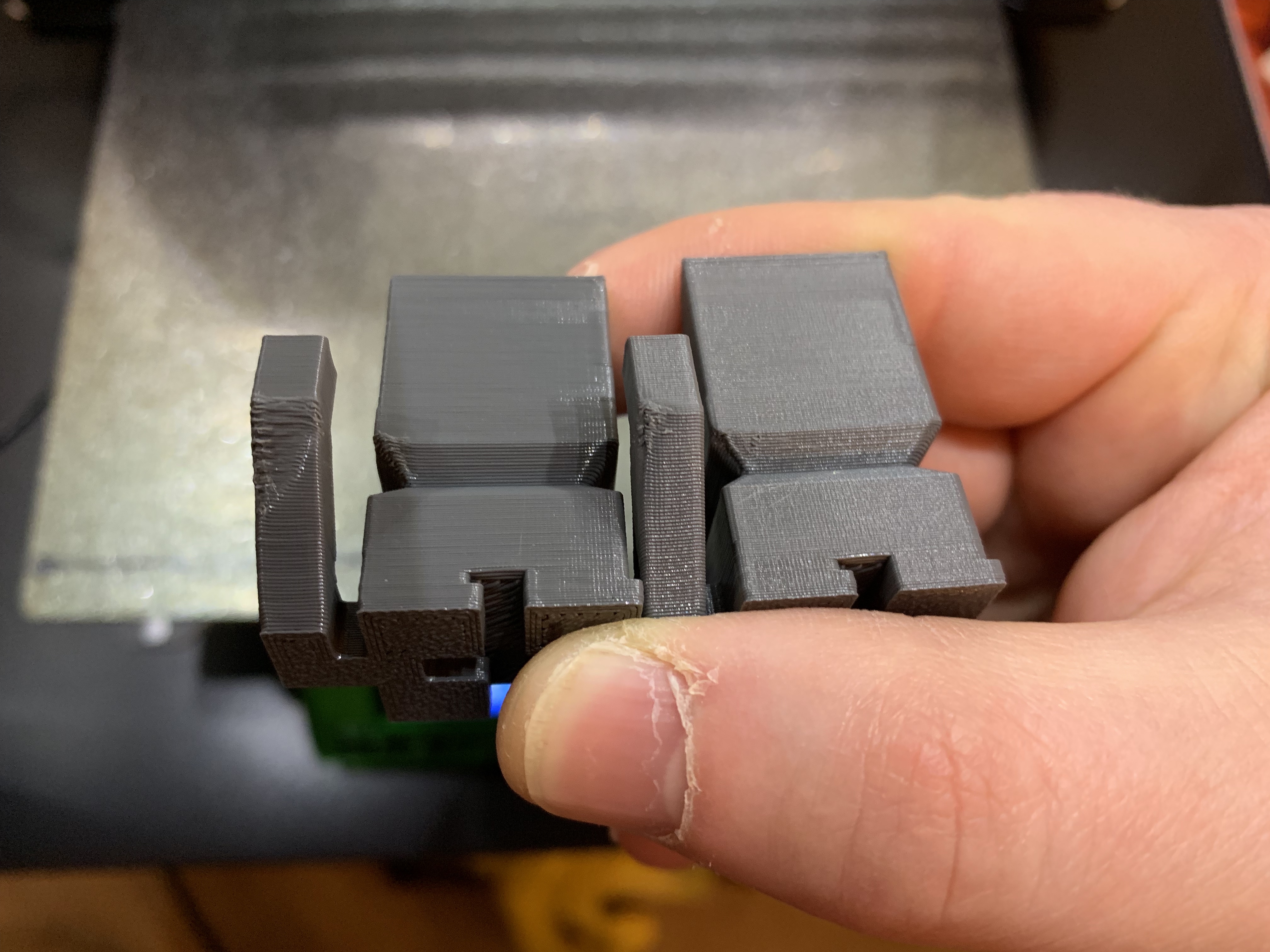

Let’s play a game called “Same GCODE, which extruder”. One print was printed with the R3 extruder and the other was printed with the Bondtech. I printed the test objects, replaced the extruder, updated the esteps for the Bondtech, and printed the same GCODE using the same filament.

Re: New toy from bondtech

Looks like bondtech is doing a better cooling job. Can you also show us all sides?

BTW: Thanks for the big effort on doing this tests. Switching extruders is very time consuming.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: New toy from bondtech

I hope so too. I wouldn’t mind paying a little extra money for a new SLS printed part.

Same, I would pay for updated parts.

As would I. Now I have to wait sicne I already installed the Mk3S

--------------------

Chuck H

3D Printer Review Blog

Re: New toy from bondtech

Looks like bondtech is doing a better cooling job. Can you also show us all sides?

BTW: Thanks for the big effort on doing this tests. Switching extruders is very time consuming.

Sure thing. I'll take some more photos. There definitely is a big improvement on how clean the layers look but there's still improvement needed on cooling. I did replace the blower with a 7,200 RPM one vs. the stock 5,000 RPM fan. I'll try a new fan shroud later on as well.

Re: New toy from bondtech

So, people install an extruder with the intent of improving extruder consistency, but nobody thus far wants to print a tower specifically designed to check extruder consistency? Please, let us get a test done so we can evaluate more fully.

Re: New toy from bondtech

Do you have a link to that test print? I looked through this thread and didn't notice one.

So, people install an extruder with the intent of improving extruder consistency, but nobody thus far wants to print a tower specifically designed to check extruder consistency? Please, let us get a test done so we can evaluate more fully.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: New toy from bondtech

Look at the bottom of my post. Test towers are in attached file of that post

Re: New toy from bondtech

Hmm. I'm not seeing as dramatic improvement compared to my stock R2 prints:

(Ignore the elephant's foot, I've been swapping flex sheet surfaces. Also, must order some benchmark silver filament.)

This guy is getting much better results with his stock Mk3s configuration:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: New toy from bondtech

This guy is getting much better results with his stock Mk3s configuration:

Yes that was me, but the work done by guy.k2 https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles-f65/stepper-motor-upgrades-to-eliminate-vfa-s-vertical-t28098.html shows that the problem is in the X/Y axis too.

I think I have better than average result, is due the the fact that my printer is little well assembled. not to rigid no too soft for what I'm concluding from guy.k2 research is that the stock steppers have a somehow irregular motion that in conjunction causes the 602 issues.

Thinking loud:

Let's think I'm trying to find a mechanical solution... this could be resolved with an inertial mass, but will cause a greater harm on the acceleration and deceleration, a loose belt could help damping, but again it will create other kind of artifacts. A flexible coupling is another solution that could bring some benefits, but will be bad for the responsiveness.

Lubing the rods with a high viscosity fluid, I'm sure this will reduce the artifacts, but will put more effort on the motors and increase tension on belts. this will be somehow difficult to maintain but Something to try...

This irregular motion caused my the stock steppers are difficult to compensate without ruin all the cinematic of the printer. The mechanics need 's to be very responsive to the steppers output, its difficult to see a dampening effect being used with a good result.

Re: New toy from bondtech

Just to be clear though: The pics you posted on Reddit are an un-modified Mk3s, correct? I just wanted to point out that people are getting better "before" results off stock configurations than were shown in the comparison pics earlier in this thread. From what I'm reading, the Bondtech extruder upgrade doesn't gain Mk3/Mk3s owners a lot in comparison finish-wise. My understanding is that the extruder is better with some materials.

[...] Yes that was me, but the work done by guy.k2 https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles-f65/stepper-motor-upgrades-to-eliminate-vfa-s-vertical-t28098.html shows that the problem is in the X/Y axis too.

I think I have better than average result, is due the the fact that my printer is little well assembled. not to rigid no too soft for what I'm concluding from guy.k2 research is that the stock steppers have a somehow irregular motion that in conjunction causes the 602 issues.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: New toy from bondtech

Just to be clear though: The pics you posted on Reddit are an un-modified Mk3s, correct? I just wanted to point out that people are getting better "before" results off stock configurations than were shown in the comparison pics earlier in this thread. From what I'm reading, the Bondtech extruder upgrade doesn't gain Mk3/Mk3s owners a lot in comparison finish-wise. My understanding is that the extruder is better with some materials.

[...] Yes that was me, but the work done by guy.k2 https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles-f65/stepper-motor-upgrades-to-eliminate-vfa-s-vertical-t28098.html shows that the problem is in the X/Y axis too.

I think I have better than average result, is due the the fact that my printer is little well assembled. not to rigid no too soft for what I'm concluding from guy.k2 research is that the stock steppers have a somehow irregular motion that in conjunction causes the 602 issues.

It's a stock machine freshly assembled machine. I didn't put does rubber feet.

Re: New toy from bondtech

I am contemplating a bondtech purchase, but I have to admit that the results I am seeing are not pushing me to rush out and purchase one.

--------------------

Chuck H

3D Printer Review Blog

Re: New toy from bondtech

Today I finally got my Bondtech Extruder working together with the MK3S Sensor. The problem is that the new 3.7.0-RC1 Firmware for MK3S expects a longer Z-Axis due to the change in design of the rear x-carrier cover. This means that if you want to combine Bondtech Extruder with MK3S sensor, the wizard and the Z-calibration will fail on the z-axis.

I reported this problem on github and also posted a link to a solution. Prusa won't resolve that issue (which is understandable), so Bondtech users must install custom firmware in the future.

Re: New toy from bondtech

Spacemarine. That is unfortunate, needing custom firmware.

Could you please print one of my linearity waveform test towers and post a pict of the results. The tower is specifically designed to make motor non-monotonicity more visible than a normal print object.

Getting one printed on the new Bondtech would be very helpful in objectively evaluating whether it is actually more monotonic than the stock extruder.

I have attached PLA and PETG versions. It is just under a two hour print for the full tower. The towers' startup code intentionally waits for bed warmup before mesh and again after mesh to heat up the nozzle. So, don't be alarmed by the slightly different and longer sequence before printing actually begins.

Re: New toy from bondtech

Getting one printed on the new Bondtech would be very helpful in objectively evaluating whether it is actually more monotonic than the stock extruder.

I posted my analysis in the other, probably more appropriate thread:

https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/stepper-motor-upgrades-to-eliminate-vfa-s-vertical-t28098-s100.html#p135183

Quick summary: The Bondtech extruder with 0.9° stepper driven at 16 microsteps shows no VFAs in comparison the the old stock MK3 extruder.

Re: New toy from bondtech

More in other thread, but updated summary is....

Extruder monotonicity is remarkably good based on Spacemarine's prints of my ecore test tower. Basically I cannot see any diagonal waves due to extruder irregularities. That is quite a nice improvement over the stock motor and extruder.

VFA's remain present, but that is to be expected because they are purely XY motor monotonicity issues - not affected by extruder. Once he learned what VFA's look like, Spacemarine was able to see the VFA's.

RE: New toy from bondtech

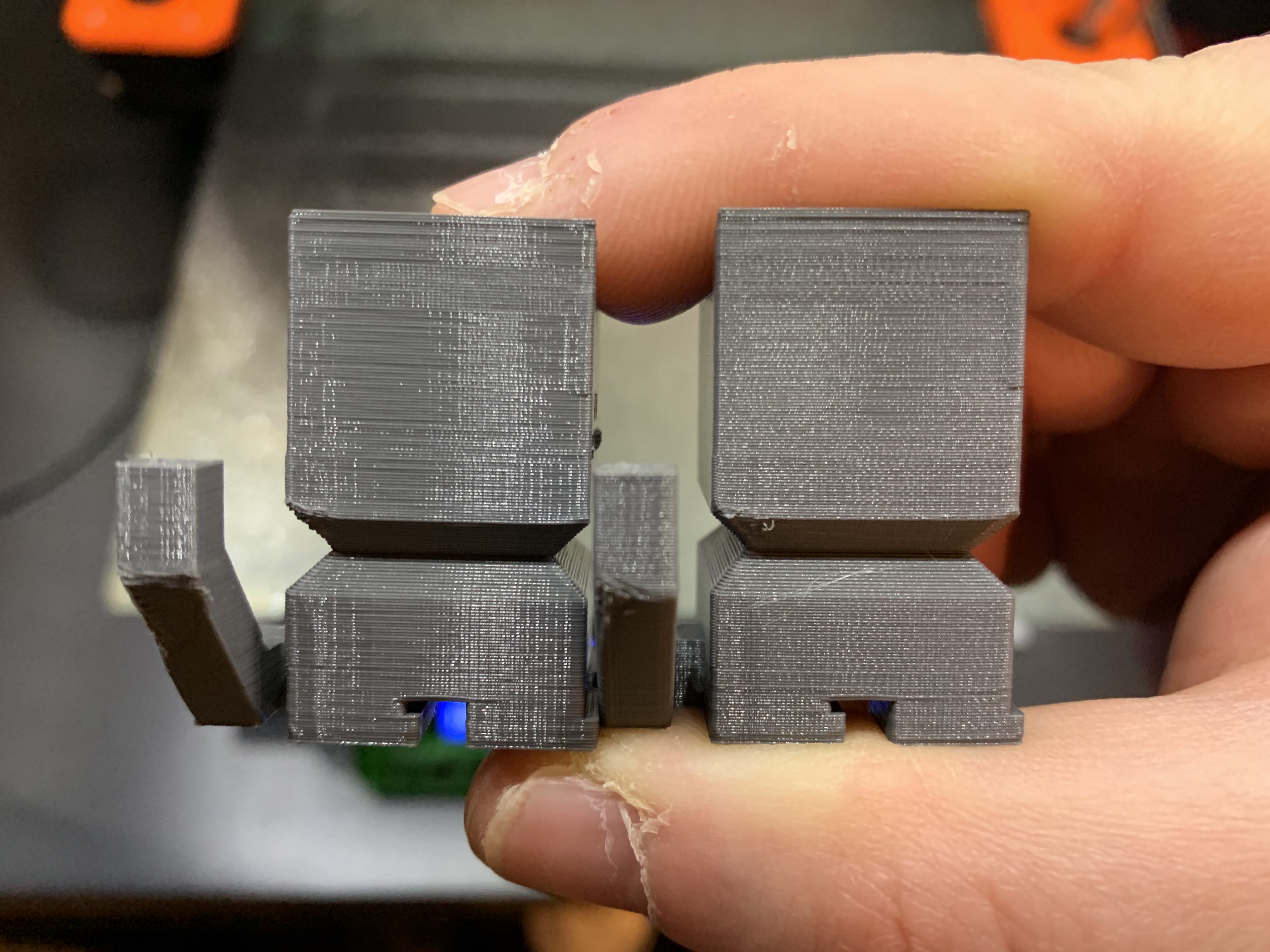

Just wanted to post an update after I’ve spent a little time tweaking the extruder and using custom firmware. The following calibration cube was printed using a community 3.7.1 1/16 microstepping firmware with 415 Esteps: