Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Hi all,

It looks like Prusa still has not addressed the github filament path alignment issue spelled out here (and elsewhere, including this forum): https://github.com/prusa3d/Original-Prusa-i3/issues/51

So, I've made some modified parts in several different flavors:

Some notes: The N4 parts and the N4A part with the Mk3S filament sensor are compatible with MMU2S setups, as long as the (also provided) modified cover and sensor holder are used.

The N4A parts for the original MK3 filament sensor require a small ball bearing (MF63-zz, can be found here: https://amzn.to/2UwwsLF ) to provide a nice stable surface for more reliable detection. Credit for this idea goes to martin_au on Thingiverse: https://www.thingiverse.com/thing:3223513 . It works like a dream.

.STL and .STEP files are uploaded here, for your modification pleasure!

https://www.myminifactory.com/object/3d-print-86329

Please let me know if you have any feedback or comments! Happy printing!

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Ok, so to break it down for the plebs in the crowd, myself included lol, what is the benefit of this vs the stock mk3s part? I see that there was some sort of shift about .5 mm or so with the gear spacing or filament path or something if I was reading the other forum correctly but never really saw a definitive this does (blank) better, except some gueses about flex filament.

I've got some PETG on the way (only had my mk3s for about 2 weeks now), and was thinking about doing a tear down to upgrade some louder than expected bearings, I'm trying to decide what would be beneficial to replace while I'm at it. Which one of these would you suggest for a person with a mk3s that has no intentions of getting the MMU setup down the road? Does one offer some benefit the others dont?

Thanks!

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Ok, so to break it down for the plebs in the crowd, myself included lol, what is the benefit of this vs the stock mk3s part? I see that there was some sort of shift about .5 mm or so with the gear spacing or filament path or something if I was reading the other forum correctly but never really saw a definitive this does (blank) better, except some gueses about flex filament.

I've got some PETG on the way (only had my mk3s for about 2 weeks now), and was thinking about doing a tear down to upgrade some louder than expected bearings, I'm trying to decide what would be beneficial to replace while I'm at it. Which one of these would you suggest for a person with a mk3s that has no intentions of getting the MMU setup down the road? Does one offer some benefit the others dont?

Thanks!

IMHO I would print with your new MK3s for about a month or 2 giving it quite a lot of prints and with all different filaments, before you tear it down, that way if anything is not to your liking, or if anything fails, you can then kill 2 birds with 1 stone, and also in 2 months things with have progressed again, firmwares etc.

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Thanks for these, perfect timing, just been printing off all the printer parts in PC and these will save me waiting for the MK3s upgrade kit by using my old sensor 🙂

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Ok, so to break it down... what is the benefit of this vs the stock mk3s part?

For me the major change is that shift of the printed part filament path (by 0.35mm, or just less than a perimeter width) to better align the filament with the bondtech gears. During my first two months of printing, I wasn't planning on changing anything on the printer to learn about it and see what the base machine was capable of (@shaun.m3 recommended doing this above - I totally agree!).

I didn't make it two months though... both the R2 and R3 parts squeaked so badly and loudly when printing PETG. It was hard to pinpoint the noise, except that it happened mainly during fast E-axis moves (retract, unretract, fast infill). It also made it impossible to diagnose anything else going on with my printer through the sounds it was making - the squeak was too loud and masked anything else.

If you haven't printed PETG yet, you may not have encountered this squeak (PLA was still quiet for me).

Otherwise, the printer worked fine. I did not test flexible filaments prior to modifying my printer, but the interwebz are littered with complaints that the Mk3 never printed flexibles as well or as reliably as the Mk2 and Mk2S, and folks started complaining that after upgrading to Mk2.5, previously good prints were failing. Who knows if there's any way to pinpoint exactly what caused this change, but maybe it's the change in filament path alignment (4mm was great for a single hobbed gear and smooth idler, but might not be appropriate for the dual drive bondtech system).

One other note: on my printer, there was enough rubbing friction and misalignment for my extruder to be able to push and unload filament without the idler installed. This means that any idler tension adjustment was nearly useless to me, as it had no effect.

TL;DR - all of this work was to fix a squeak that annoyed me.

Which one of these would you suggest for a person with a mk3s that has no intentions of getting the MMU setup down the road? Does one offer some benefit the others don't?

The N4 parts have covers with both the venturi port and without the venturi port. There was some debate about whether the port made a functional difference; this allows those who are so inclined to actually test parts where that is the only change. My opinion is that it makes little to no difference, but the venturi port probably makes heatsink cooling marginally worse.

My pick would be the N4A part, just because it looks great :D. Idea for exposed honeycomb comes from the Bondtech extruder. Airflow across the heatsink should also be marginally improved, but again there's probably little difference.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Are the covers compatible with the stock extruder? I might reprint one without venturi if so, but I don't fancy reprinting and rebuilding my entire extruder 🙂

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Are the covers compatible with the stock extruder?

Not without some extra application of force to 'persuade' the parts together. The feature that holds the E3D v6 heatsink in place is shifted by .35mm relative to the screw holes through the other printed parts.

I might reprint one without venturi if so, but I don't fancy reprinting and rebuilding my entire extruder

Honestly, the easiest way to accomplish this would be use some tape (kapton would probably work well, but regular duct tape or scotch tape would work for a bit at least) to cover the inner surface of the venturi port.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Are the covers compatible with the stock extruder?

Not without some extra application of force to 'persuade' the parts together. The feature that holds the E3D v6 heatsink in place is shifted by .35mm relative to the screw holes through the other printed parts.

I might reprint one without venturi if so, but I don't fancy reprinting and rebuilding my entire extruder

Honestly, the easiest way to accomplish this would be use some tape (kapton would probably work well, but regular duct tape or scotch tape would work for a bit at least) to cover the inner surface of the venturi port.

D'oh.... that's a valid point and a lot easier... Though it may be a moot point either way as I plan to upgrade to the sunon fan at some point which is supposed to mitigate the supposedly marginal performance. Haven't had any issues yet but it's still winter at the moment...

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

I plan to upgrade to the sunon fan at some point which is supposed to mitigate the supposedly marginal performance

Soo... I sit in the camp that likes the noctua fan, and believe it to be sufficient for this application. Sure swapping out for a Sunon fan is a really good choice, and an easy upgrade if you have concerns - but at this point the two times I've experienced jams was because I either a) didn't replace the thermal grease between the hotend and heatsink after a disassembly, or b) the extruder motor heated up too hot and filament got soft above the PTFE tube during a print specifically set up to test for jamming.

My jam test: take my lowest temp softening point PLA filament (prusament, at the time), print slow at .05mm layer heights, on a small part, for two-three hours, in a closed enclosure with internal ambient temps at about 34°C.

The Noctua fan did fine, plus it's warrantied mean-time-before-failure is a lot higher than the sunon fan. I think a lot of the concern about the Noctua fan stemmed from the original R2 (Mk2) style extruder heatsink airflow channel and grille, which definitely did not help anyone. The Mk2 fan had plenty of power to push through the restriction, but the Mk3 (noctua) fan did not. Once things are opened up for good airflow anyway, the Noctua has been fine for me.

I am interested to print again in the summer where I live, though. I received my Mk3 last July, so I already have some experience in summer printing.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

I plan to upgrade to the sunon fan at some point which is supposed to mitigate the supposedly marginal performance

Soo... I sit in the camp that likes the noctua fan, and believe it to be sufficient for this application. Sure swapping out for a Sunon fan is a really good choice, and an easy upgrade if you have concerns - but at this point the two times I've experienced jams was because I either a) didn't replace the thermal grease between the hotend and heatsink after a disassembly, or b) the extruder motor heated up too hot and filament got soft above the PTFE tube during a print specifically set up to test for jamming.

My jam test: take my lowest temp softening point PLA filament (prusament, at the time), print slow at .05mm layer heights, on a small part, for two-three hours, in a closed enclosure with internal ambient temps at about 34°C.

The Noctua fan did fine, plus it's warrantied mean-time-before-failure is a lot higher than the sunon fan. I think a lot of the concern about the Noctua fan stemmed from the original R2 (Mk2) style extruder heatsink airflow channel and grille, which definitely did not help anyone. The Mk2 fan had plenty of power to push through the restriction, but the Mk3 (noctua) fan did not. Once things are opened up for good airflow anyway, the Noctua has been fine for me.

I am interested to print again in the summer where I live, though. I received my Mk3 last July, so I already have some experience in summer printing.

Sure, good to hear it's working fine for folks - it has been for me as well. My "at some point" probably should have been written as "if I have heat-creep related issues". 3d printing is like audio gear; you can always throw more money and upgrades at it but you have to learn to distinguish which ones are good and which ones are just diminishing returns and/or lore and fuffery.

Speaking of... I should start selling oxygen-removed heatbed cables at $100 a pop... 😆

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Speaking of... I should start selling oxygen-removed heatbed cables at $100 a pop...

Quad silver with hand-braided alpaca sleeves, or nothing at all. That's my opinion! Really helps the voltages flow, without any microphonics or capacitance distortion. 😆

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Speaking of... I should start selling oxygen-removed heatbed cables at $100 a pop...

Quad silver with hand-braided alpaca sleeves, or nothing at all. That's my opinion! Really helps the voltages flow, without any microphonics or capacitance distortion. 😆

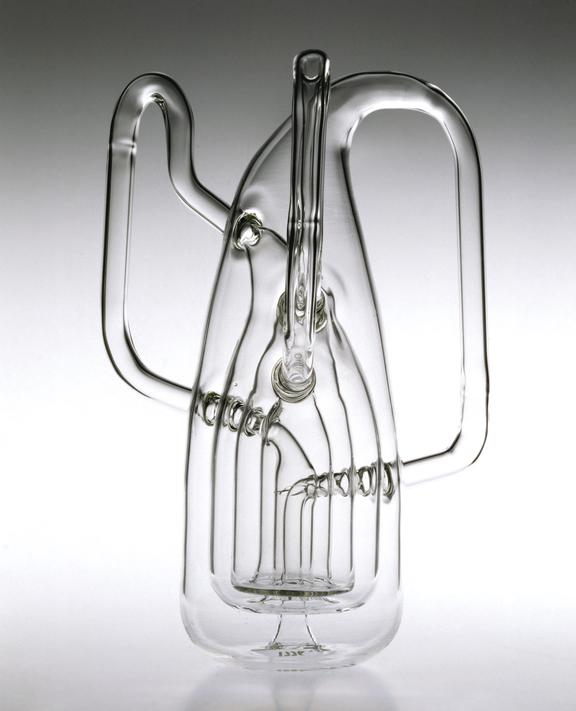

if you move the filiment through the 4th dimension via a klein bottle phase adjustor like this you should achieve a .00001% improvement in the end print.

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Speaking of... I should start selling oxygen-removed heatbed cables at $100 a pop...

Quad silver with hand-braided alpaca sleeves, or nothing at all. That's my opinion! Really helps the voltages flow, without any microphonics or capacitance distortion. 😆

if you move the filiment through the 4th dimension via a klein bottle phase adjustor like this you should achieve a .00001% improvement in the end print.medium_1996_0545__0001_.jpg

SSSSSHHHH! That's how people have gotten the MMU2 to work!

Speaking of... I should start selling oxygen-removed heatbed cables at $100 a pop...

Quad silver with hand-braided alpaca sleeves, or nothing at all. That's my opinion! Really helps the voltages flow, without any microphonics or capacitance distortion. 😆

I don't think I can do that for $100, it's gonna be at least $250. $300 if you want only the finest hand-selected and massaged Andean alpacas.

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

I like you people 😀 😆

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

BIG thanks for designing the new parts. I will try to print them tomorrow. Of course I discovered this issue (amazing that it is ignored...) 2 hours after I finished my MK3S upgrade 😳

Im working on some other stuff also in combination:

1. As I have an enclosure I want to always use it and keep it closed against fumes and noise. Therefore I printed a silent 18cm blower to bring cool air from outside the enclosure, through a lightweight hose to the extruder

2. I made some changes to mount the nozzle blower upside down to the original design, meaning the intake opening points towards the Venturi in/outlet. To me it is strange that the blower is originally mounted so that it takes warm air from the bed; and with my change above, there is enough cool air coming out of the extruder exit and venturi opening to be used by the blower.

I will post a full report plus downloadable files once my printer is fully working again :ugeek:

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Nice! I'd love to see pictures once its complete.

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

I have one design suggestion that I've added to my Mk3h extruder (Mk3s extruder parts with Mk3 indirect sensor).

It may be worth adding a small interlocking tab to the loose end of the front cover by the Pinda mount. I've seen a few reports of this part drooping.

https://github.com/prusa3d/Original-Prusa-i3/issues/124

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Ah, nice! That's a great point. I haven't noticed on mine, but that could be because I've got a silicone sock on my hotend, so radiant heat transfer to surrounding parts is cut significantly.

Are you martin_au on thingiverse? If so, thanks for the design - it's been rock-solid for me. It's nice to have a dependable filament sensor. I hope I've cited/credited you properly!

MyMiniFactory (Functional Parts and Mods): https://www.myminifactory.com/users/butterworthdesign

Thingiverse (Fun Designs and Remixes): https://www.thingiverse.com/uscbutterworth/designs

Twitter: @USCbutterworth https://twitter.com/USCbutterworth

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Ah, nice! That's a great point. I haven't noticed on mine, but that could be because I've got a silicone sock on my hotend, so radiant heat transfer to surrounding parts is cut significantly.

Are you martin_au on thingiverse? If so, thanks for the design - it's been rock-solid for me. It's nice to have a dependable filament sensor. I hope I've cited/credited you properly!

I too have a smidge of droopage, and I do have a sock. 🙁

Re: Modified C1/R4 Mk3S parts - Better Filament Path, and a version for Mk3 Sensor

Ah, nice! That's a great point. I haven't noticed on mine, but that could be because I've got a silicone sock on my hotend, so radiant heat transfer to surrounding parts is cut significantly.

Are you martin_au on thingiverse? If so, thanks for the design - it's been rock-solid for me. It's nice to have a dependable filament sensor. I hope I've cited/credited you properly!

I am indeed. Glad you like it. 😀