I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

(CLARIFICATION: some extrusion issues i see on this Forum are, not all of them.)

Ok, so update on my custom scratch built MK3s (2x MK3 machines)

I built two printers, both are very stable, rigid and accurate machines, and i could finally get one to print after battling with software issues on both machines the whole week

(since i'm using standard parts instead of custom made Pusa parts the MK3 uses.)

My Printers are called Viking and Spartan.

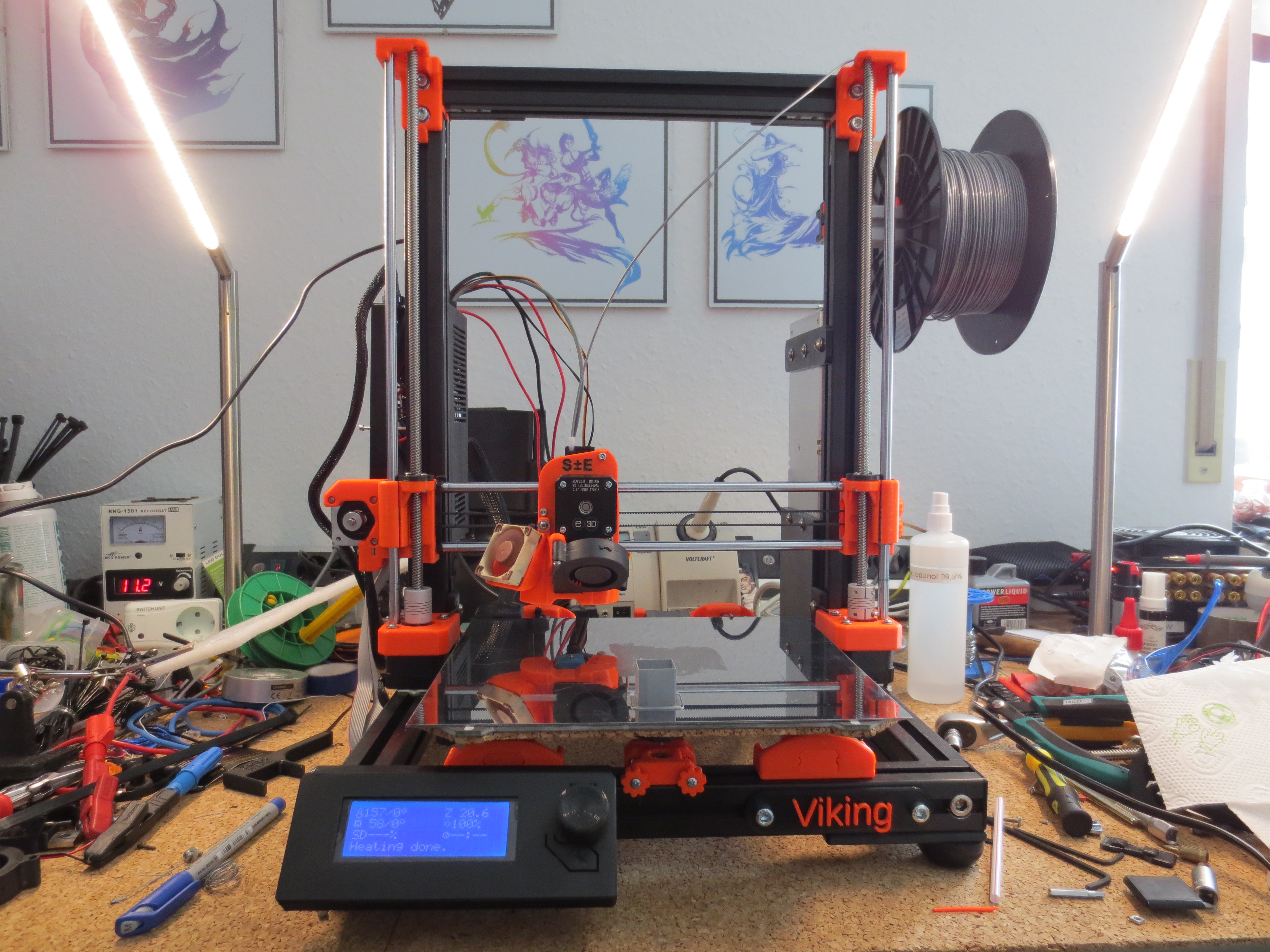

This is Viking (first picture)

(please excuse the mess, also Spartan has a few other software hiccups at the moment)

Viking and Spartan have a 320mm high build volume, only the Einsy, the magnetic board and the fans are from Prusa.

Everything else is made by me, including the flexible buildplate (currently blank flex steel, will add the PEI sheet when i have it working 100%

Standard Parts are from Amazon or Aliexpress.

3D Printed parts are from the MK2-X, the Haribo, the Zaribo and other projects from thingiverse, with about 30% scratch made by me.

Viking uses the new and fixed E3D Titan (look "Bearinggate" on google), with a step/unit resolution of 1626 E Steps.

I used my original Step resolution of 812.95 of my MK2 Titans at first, but got only 50 % extrusion length. Then i remembered they doubled the microstepping to 1/32 from 1/16 the MK2 used.

Btw, the MK3 has 280 E steps with the 1/32 microstepping, and the MK2 had an about 161.30 steps value (uncalibrated) with 1/16 microstepping.

So if you go by logic here, the MK3 has +120 more E steps/unit, but only because of microstepping. (read my thoughts about microstepping here)

If you halve the MK3's microstepping to the MK2's value, the MK3 would have 140 E Steps, so the bondtech gears have a lower gearing then the stock the hobbed pulley the MK2 had.

Anyway, back on Topic.

With 1/32 microstepping, a 3:1 gear ratio and a 0.9 degree stepper, i'm now at about 1626 E steps for the E axis.

Way the fuck more than i wanted, but whatever.

If somehow this configuration can't keep up at 150mm/sec i'll switch to a 1.8 degree stepper. But most likely i'll tone down the microstepping once i figured my way around in the firmware.

I calibrated the extrusion real quick and printed a test cube.

I installed the newest MK3 software package and set a test cube with 0.15 layer height, 1 wall, no top/bottom/infill

Silver Prusa PLA, although this roll is only used for test prints since silver shows either no errors when the light is from the front, or all possible extrusion errors if the light is from above. Also this roll is more than 2 years old, perhaps it got some moisture. Will try some other filament shortly.

Second picture shows the cube

Third picture shows the ripples on the cube when the light shines from above. (worst picture i could get)

I can get a lot smoother prints out of my MK2 with the Titan, so it's my humble opinion, that the MK3 has some extrusion issues that are software related.

Viking and Spartan are not finished yet, im about 90% done with the hardware, and about 30% done with the software.

(Most of my problems are TMC2130 and with the motor endstops)

Will update on this and post the build when i figure out what's causing my endstop issues.

TL;DR: MK3 software has some extrusion issues, cannot get it away with completely different hardware.

Can i say for sure after only one print? I can, since i spent lots of time tweaking really everything on these machines.

(Build time was about 1 month/printer...)

I will tweak the extrusion further, but i'm hoping for a software update on the Einsy board that whips the TMC drivers into shape.

...

...

...

...

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

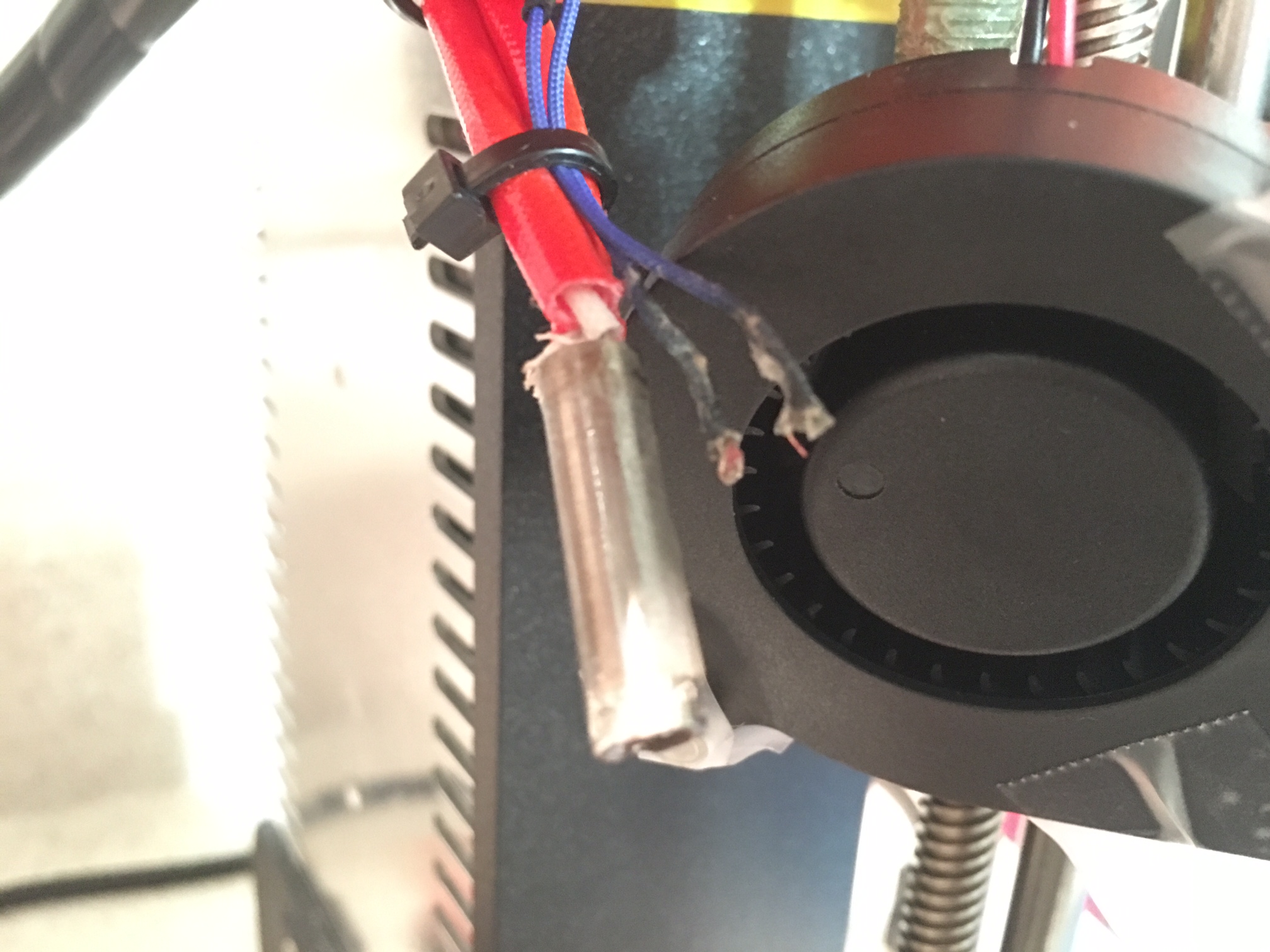

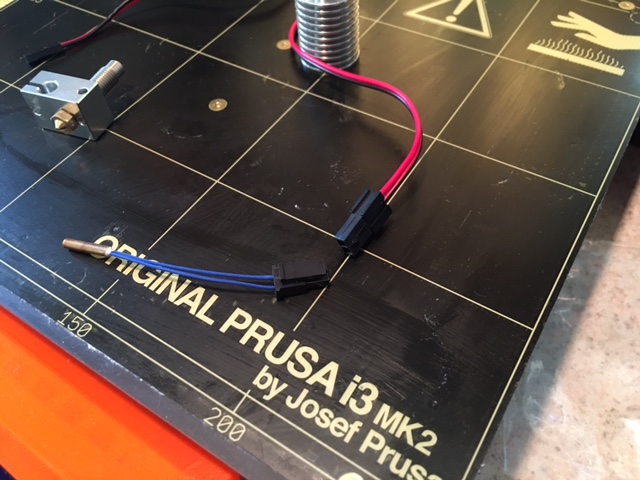

These are both Printers again.

(I'm currently messing around with Spartan's hotend)

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

These look freaking amazing. 🙂

I am both disheartened and happy to see your single wall cube results. Disheartened for you for building these and running into the same issue, but happy to see we can pretty likely rule out hardware being the cause. I will post these in the issue.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

These look freaking amazing. 🙂

I am both disheartened and happy to see your single wall cube results. Disheartened for you for building these and running into the same issue, but happy to see we can pretty likely rule out hardware being the cause. I will post these in the issue.

First tall vase Print goes still to you for the firmware 😀

Maybe i could ask you again for 3.2.0 final if i do not get the hang of it until then.

I will also explore loading stock Marlin onto this in the future, but not now.

Finally got one of them to print after i started this project two months ago. (also my wallet isn't happy, i could buy 4 or 5 MK3 kits for the cost of these two)

Next step is going to see if i can get rid of the blasted ringing that plagued me so on the MK2.

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

These look freaking amazing. 🙂

I am both disheartened and happy to see your single wall cube results. Disheartened for you for building these and running into the same issue, but happy to see we can pretty likely rule out hardware being the cause. I will post these in the issue.

First tall vase Print goes still to you for the firmware 😀

Maybe i could ask you again for 3.2.0 final if i do not get the hang of it until then.

I will also explore loading stock Marlin onto this in the future, but not now.

Finally got one of them to print after i started this project two months ago. (also my wallet isn't happy, i could buy 4 or 5 MK3 kits for the cost of these two)

Next step is going to see if i can get rid of the blasted ringing that plagued me so on the MK2.

Sure thing, just shoot me a message with what you need. I still have that git branch on my machine, and I was able to rebase the 3.2.0-RC1 changes into it. Attached, if you're curious to try it out.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

Sure thing, just shoot me a message with what you need. I still have that git branch on my machine, and I was able to rebase the 3.2.0-RC1 changes into it. Attached, if you're curious to try it out.

I had to go with 320mm height (your first firmware), 330mm wouldn't fly.

If you want me to do a comparison test print with these two, give me a call.

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

Sure thing, just shoot me a message with what you need. I still have that git branch on my machine, and I was able to rebase the 3.2.0-RC1 changes into it. Attached, if you're curious to try it out.

I had to go with 320mm height (your first firmware), 330mm wouldn't fly.

If you want me to do a comparison test print with these two, give me a call.

320 version attached. Pretty certain that test print will be the same with 3.1.3 or 3.2.0, the linearity correction in this one may do something for you if you have any moire though.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

Just because it's getting closer to a wider release, but I do NOT want to attract extra attention to his project I'm not gonna say what it is outright, but @devilhunter and @Brigandier should at least know. (3.5:1 gear ratio)

@Devilhunter - This is the results I've had. With 3.5:1 I have virtually ZERO "morie" effect. I mean it's there... kinda... sometimes... I catch what I think is a glimpse of it. But it's "fleeting" I can never find it again easily, and I have NOT gotten a picture of it. (and this is LOOKING for it, with the light at correct angles, with the EVIL Prusa silver.

I'm not that worried, I have my slop below 0.05mm, and I can actually with a fair bit of force, put a 1mm pin, into a 1mm hole. a 1.05mm hole is perfect, and a 1.1mm hole is loose. That tells me my "slop" is somewhere around 0.025, and I'll credit that to the X and Y steppers, as that's the neighborhood of their precision.

What I wanna know, is what does adjusting the amperage do on the direct drive? I would test it myself, but, I can't cause I've got the 3.5:1.

@Brigandier has tested nearly turning off microstepping, and it still does it. (I think it was 8microsteps he tried) (and turned off the 256 nano-stepping stuff too)

So either the issue is still apparent with 8 microsteps... OR, there's a "torque" issue.

I noticed with cheap PLA that oozes a LOT. (you break 220c, and it's like a leaky faucet) But if you can keep the nozzle moving, and not have retracts, that stuff printed BEAUTIFULLY at 230c.

I found the Prusa silver AMPLIFIED the issue.

I also found that even at 240c, it really didn't "ooze".

(and when I say ooze, I don't mean moisture induced oozing, I mean, runny like water, totally molten, and you can pull spiderweb style strings off the nozzle for as long as you care to pull on it)

I honestly think that "cold/stiff PLA" is over-torquing the motor at the current settings, which is why gear-reduction is fixing it.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

Just a little info on the side.

The custom MK3's are pulling 290 Watts from AC during heatup.

How big dimensioned are the original MK3 PSUs again? Oh yeah, 240 Watt...

And oh my god, this thing is silent.

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

Thanks for sharing! Would

It be hard to get one working with the standard marlin to Compare the results?

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

Thanks for sharing! Would

It be hard to get one working with the standard marlin to Compare the results?

I think it should be fairly easy, since the Einsy from the MK3 was added to the 1.1.x-bugfix branch of Marlin already some time ago. Pretty sure a few people run it on their MK3's already. Probably a matter of downloading it and specifying the Einsy mainboard, compiling and flashing.

My MK3 will take a few more days to arrive, otherwise I would do it and test.

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

320 version attached. Pretty certain that test print will be the same with 3.1.3 or 3.2.0, the linearity correction in this one may do something for you if you have any moire though.

Thanks for the firmware, but it seems a lot of people who use this one have their nozzles dig into the bed during xyz calibration... 🙁

Gonna skip this one, but the commits to the 3.2 firmware sound very worthwhile. (even if they didn't implement Linear Advance 1.5 which fixes a lot of extruder issues)

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

Last one for now, printed another cube at 0.20 stock settings after calibrating temperature and extrusion as good as i can.

settings:

40x40x40 cube

0.20mm layer height

220 deg temp

2 shells

10% infill

5/6 top bottom layers

0.95 extrusion multiplier (since Slic3r overextrudes by 5% on default)

Second picture shows the usual uneven extrusion, but you can really see this only when the light is right.

I wanted to show you something else however, there is a big difference in quality when printing in normal mode vs stealth mode.

You can see this in the first picture.

On the few bottom layers, i had stealth mode active, and the layers looked smooth and good.

I switched to normal mode about 4mm in height.

All layers printed with normal mode looked rough, and the ringing on the corners was a lot more than the ringing on the corners in stealth mode.

Halfway in i switched back to stealth mode, and all outer wall layers were smooth and shiny again, and the ringing on the corners is much less.

I can't show this with my crappy camera, but the outer layers printed with normal mode have a slightly rougher texture, and the outer layers printed with stealth are smooth and shiny.

It's like i can see the microstepping artefacts in the normal power layers, and they are about 2/3 less when i switch to stealth mode.

A Software guy here that knows what exactly they are doing in stealth mode?

Metacollin, any idea what's going on?

...

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

Thanks for the firmware, but it seems a lot of people who use this one have their nozzles dig into the bed during xyz calibration... 🙁

Gonna skip this one, but the commits to the 3.2 firmware sound very worthwhile. (even if they didn't implement Linear Advance 1.5 which fixes a lot of extruder issues)

I had updated to the 3.2 and my nozzle was getting to close to the heat bed but lowering the Pinta probe just a hair solved that.

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

Last one for now, printed another cube at 0.20 stock settings after calibrating temperature and extrusion as good as i can.

settings:

40x40x40 cube

0.20mm layer height

220 deg temp

2 shells

10% infill

5/6 top bottom layers

0.95 extrusion multiplier (since Slic3r overextrudes by 5% on default)

Second picture shows the usual uneven extrusion, but you can really see this only when the light is right.

I wanted to show you something else however, there is a big difference in quality when printing in normal mode vs stealth mode.

You can see this in the first picture.

On the few bottom layers, i had stealth mode active, and the layers looked smooth and good.

I switched to normal mode about 4mm in height.

All layers printed with normal mode looked rough, and the ringing on the corners was a lot more than the ringing on the corners in stealth mode.

Halfway in i switched back to stealth mode, and all outer wall layers were smooth and shiny again, and the ringing on the corners is much less.

I can't show this with my crappy camera, but the outer layers printed with normal mode have a slightly rougher texture, and the outer layers printed with stealth are smooth and shiny.

It's like i can see the microstepping artefacts in the normal power layers, and they are about 2/3 less when i switch to stealth mode.

A Software guy here that knows what exactly they are doing in stealth mode?

Metacollin, any idea what's going on?

...

The difference is speed or acceleration CAP in stealth mode. print slower if you want higher quality, it's just a basic rule that works 99% of the time except or extrusion issues of course 🙂

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

The difference is speed or acceleration CAP in stealth mode. print slower if you want higher quality, it's just a basic rule that works 99% of the time except or extrusion issues of course 🙂

It looks like the speed and acceleration is the same in stealth mode and normal mode (unless you can show me where this is in the firmware), and it just switches the Trinamic SpreadCycle to StealthChop.

https://help.prusa3d.com/l/en/article/8LLgVlD01q-loud-printer

Video here:

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

I noticed something during my second print yesterday.

My Z couplers are moving from side to side even on straight lines. That means the Z axis is slightly moving up and down midprint. (My leadscrews are docked against the motor shaft in the Z couplers to minimize the effect of Z-Hop)

You probably cannot see this on your machines, since you are using integrated leadscrews, it's much harder to see there.

(The ones on the Z axis that connect the stock motor shafts with the standard threaded rods, Prusa only used these integrated without couplers)

Perhaps sticking a long piece of Tape on your leadscrews shows this effect.

The way they move from side to side when printing straight lines weirded me out at first, but i think these need to do that to compensate for a slight skew in the bed parallel to the X and Y axis.

But, they seem to move a bit more than my 0.07° skew that's displayed in the menu. Or why are they moving for print moves in the Z height above the first layer at all?

The fact that the Z axis are moving up and down mid print could very well explain the layer lines.

Z axis moves slightly up = thinner looking layer

Z axis moves slightly down = layer gets squished

This is not just for the first layer, it's for every layer.

Perhaps this is cause of a problem?

Overcompensating for skew correction?

Wouldn't it make more sense to correct a Z angle skew on the first layer, and leave all other following layers without this skew correction?

That way the layers on top of the first one are as consistent as they can be, leaving only skew correction from the X and Y axis.

I don't know where to post this, so i'll post this here and in the inconsistent extrusion topic.

3x pictures of the XYZ skew correction included, and one very large and very LOUD video, hosting is on MEGA

(my camera makes slight noises very loud, sorry)

https://mega.nz/#!DXwC2RKA!QiCqc8XvafRg6bR5RdyQLK7JkmvDpHI-qK4FcgXfTpk

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

In stock Marlin when you use software auto bed level correction you can choose a height to fade the correction out by (so the z doesn't keep moving throughout the entire print: M420 Z0.2 or something like that) I have no idea whether the mesh bed corrections are faded out after a while in Prusa's firmware or not. If they aren't, then yes the z would keep moving along the mesh for the entire print. If they are faded out, there is a specific point in the print where the z will not move along the corrections anymore.

http://marlinfw.org/docs/gcode/M420.html

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

In stock Marlin when you use software auto bed level correction you can choose a height to fade the correction out by (so the z doesn't keep moving throughout the entire print: M420 Z0.2 or something like that) I have no idea whether the mesh bed corrections are faded out after a while in Prusa's firmware or not. If they aren't, then yes the z would keep moving along the mesh for the entire print. If they are faded out, there is a specific point in the print where the z will not move along the corrections anymore.

http://marlinfw.org/docs/gcode/M420.html

Then we have found our culprit/one of our culprits for the extrusion issues.

I'm currently 10cm high into a print, and the couplers still wobble from side to side.

The MK2 feverishly locks down the Z motors with a high holding current, so that the motors get hotter when holding then they would moving.

And guess what, the old MK2 firmwares does not have this problem.

The MK2.5 firmware, same old board, introduces this problem for the older machines.

So a software dev most likely half baked this feature into the firmware versions above 3.1.x somewhere.

Re: I made custom + scratch built MK3 clones, and yes your extrusion issues are software related

In stock Marlin when you use software auto bed level correction you can choose a height to fade the correction out by (so the z doesn't keep moving throughout the entire print: M420 Z0.2 or something like that) I have no idea whether the mesh bed corrections are faded out after a while in Prusa's firmware or not. If they aren't, then yes the z would keep moving along the mesh for the entire print. If they are faded out, there is a specific point in the print where the z will not move along the corrections anymore.

http://marlinfw.org/docs/gcode/M420.html

Then we have found our culprit/one of our culprits for the extrusion issues.

I'm currently 10cm high into a print, and the couplers still wobble from side to side.

The MK2 feverishly locks down the Z motors with a high holding current, so that the motors get hotter when holding then they would moving.

And guess what, the old MK2 firmwares does not have this problem.

The MK2.5 firmware, same old board, introduces this problem for the older machines.

So a software dev most likely half baked this feature into the firmware versions above 3.1.x somewhere.

I might be wrong but I’m sure someone has already run prints with out and mesh levelling and it had no affect on the out come. Or am I mixed up and thinking you mean more to do with skew correction? If the frame is perpendicular Then I guess it won’t try to correct anything.

Marlin definitely can fade out the levelling over, it’s set by gcode I used to use it all the time once you get the first couple of MM of z down on the build