RE:

BTW you should print the Mk3s+ versions. They have a better belt tension mechanism and fitment for the idler pulley.

Or print the community designed bear-style ones where you clamp the bearings with tightening screws.

Also when fitting the idler pulley, instead of using a regular m3x12 screw, use an m3x30mm shouldered screw chopped to the correct length with a Dremel. The shouldered part of the screw provides a more secure anchoring of the idler bearing. You can do the same on the Y-axis pulley. Ideally, the bearing inner would be jam-tight against the screw and the load would be isolated to the rollers inside the idler's bearing cartridge. This is the one major design flaw of the Prusa printer. The rollers inside the bearings are not really used at all - instead, the screw acts as an axle and the inner of the bearing cartridge acts as a bushing.

I’m re-printing the X gantry parts. Not sure what happened, but the bearings are so loose in there that they slide right out. Used my Ender 3 the first time but I’m having some issues with it. Re-printing on my mini.

RE:

Thanks Dan. I didn't realize that. I just finished printing using the mini, and the bearings seems fine. I'll look at it if I have any issues.

RE: Fysetc MK3S Bear Clone

About belt tension.. I think the best solution is to use official BEAR parts:

y_idler_mount

y_idler_tensioner

and y_belt_holder

-which makes adjusting belt tension much easier.

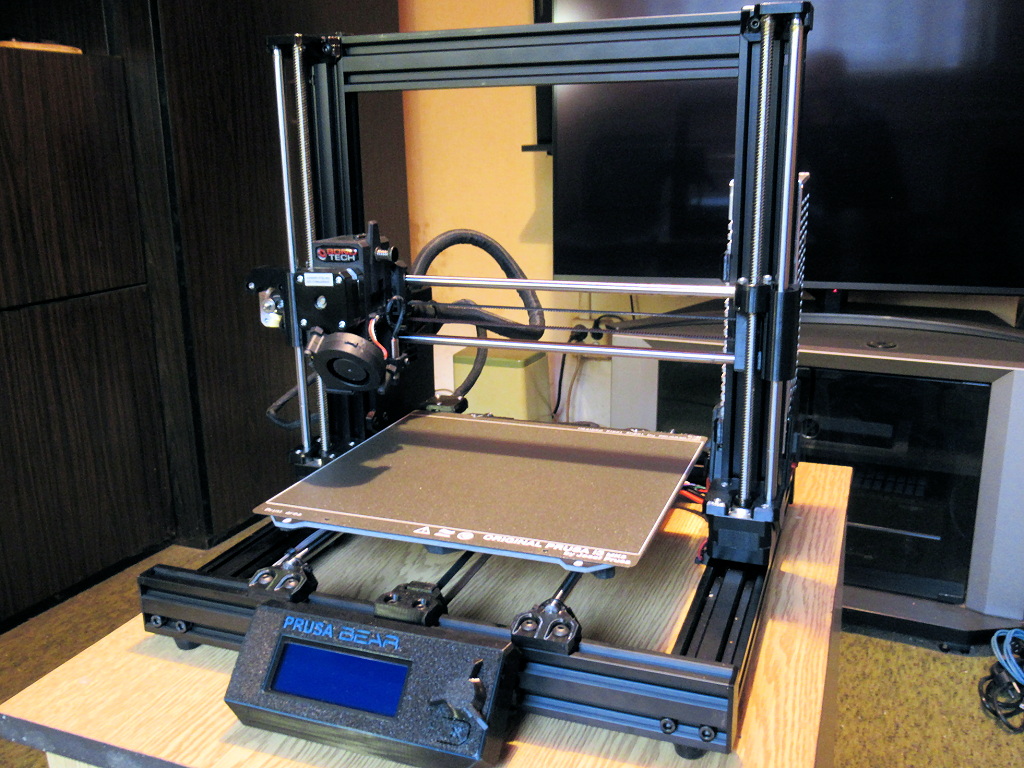

[Mini+] [MK3S+BEAR]

RE: Fysetc MK3S Bear Clone

About belt tension.. I think the best solution is to use official BEAR parts:

y_idler_mount

y_idler_tensioner

and y_belt_holder

-which makes adjusting belt tension much easier.

Thank you. These parts should work with the FYSETC Bear frame?

RE: Fysetc MK3S Bear Clone

These parts should work with the FYSETC Bear frame?

Yes, I used these three parts on my FYSETC Bear frame:

[Mini+] [MK3S+BEAR]

RE: Fysetc MK3S Bear Clone

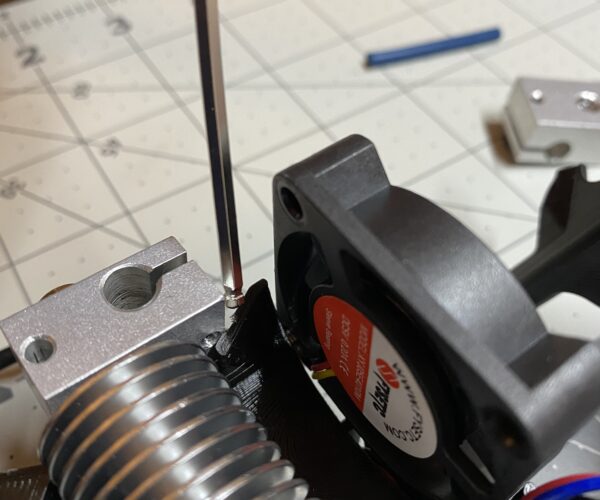

Okay, getting my bottom kicked. I installed the heatbreak and the block with nozzle IAW Prusa instructions. No matter what I do, the heat block is physically touching the plastic going around it. Pretty sure that’s not right.

Any ideas? Not sure what I’m doing wrong here.

RE: Fysetc MK3S Bear Clone

Okay, getting my bottom kicked. I installed the heatbreak and the block with nozzle IAW Prusa instructions. No matter what I do, the heat block is physically touching the plastic going around it. Pretty sure that’s not right.

Any ideas? Not sure what I’m doing wrong here.

Kinda hard to tell, but it looks like the heat block is upside down and rotated 90 degrees from where it should be.

RE: Fysetc MK3S Bear Clone

Ignore me……had block 90 degrees off.

sigh….

RE: Fysetc MK3S Bear Clone

Hello! I've built quite a few Fysetc clones and wanted to ask, you're not using the hot end that came with it right?

RE: Fysetc MK3S Bear Clone

Own Goal, eh!

Valuable learning point.

have you completed the build now?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE:

Hello! I've built quite a few Fysetc clones and wanted to ask, you're not using the hot end that came with it right?

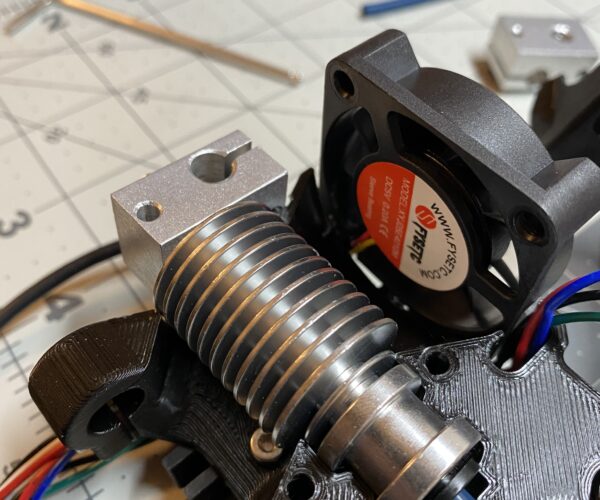

For now, yes, but just the heatsink and block. I'm using an actual E3D all metal heatbreak and E3D 40W Heater cartridge and Thermistor.

I have ordered a TRiangleLabs hotend and will swap for that one soon (after it arrives.)

RE:

Hi Joan!

At the wiring stage:

Own Goal, eh!

Valuable learning point.

have you completed the build now?

regards Joan

RE:

To be honest, not a big fan of the V6 hot end. Nothing holding / clamping the heatsink in place. It can "spin" in the extruder assembly. Everything is tight but I can still move it. With the bulky cables from the heater cartridge, it is slightly crooked. Not perfectly straight.

Has anyone else noticed this? Any way to rectify it?

RE: Fysetc MK3S Bear Clone

With the V6, I add a thin piece of electrical tape in the groove to hold it tight.

--------------------

Chuck H

3D Printer Review Blog

RE: Fysetc MK3S Bear Clone

Good tip. I will try that. Thank you.

With the V6, I add a thin piece of electrical tape in the groove to hold it tight.

RE: Fysetc MK3S Bear Clone

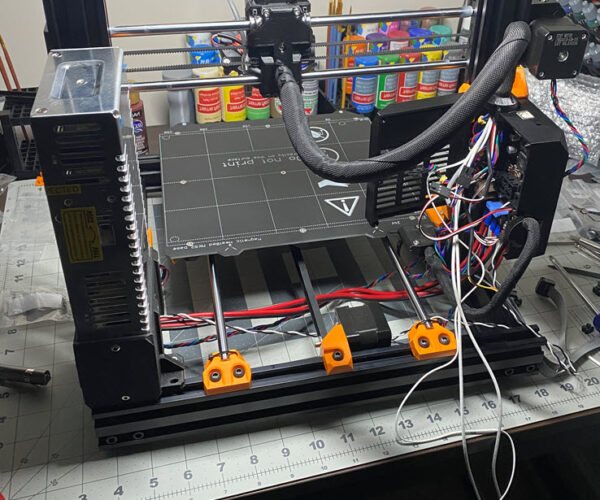

@urshurak776

I hope you won't leave wiring as shown on you photo - here's how to do it properly.

[Mini+] [MK3S+BEAR]

RE: Fysetc MK3S Bear Clone

No, that picture was just running everything and trying to figure out best way to do it I have it done now, but could use a little work still

@urshurak776

I hope you won't leave wiring as shown on you photo - here's how to do it properly.

RE: Fysetc MK3S Bear Clone

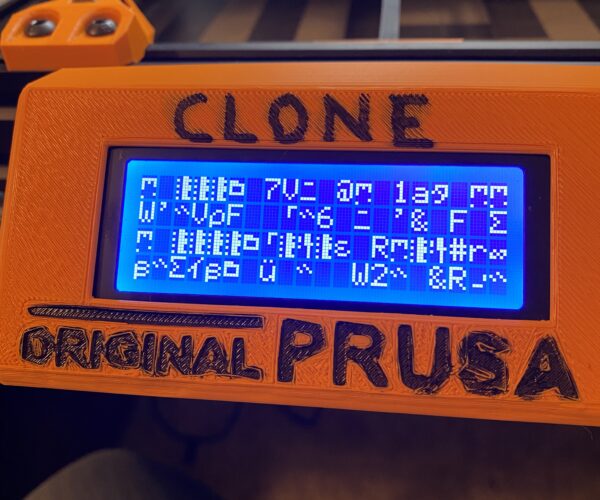

So, fought with the PINDA a bit. Took a few tries to get calibration correct.

after it was all done, my screen garbled. Turned off power and checked everything. Turned it back on and all was fine. Did my first print (just a screw.). Came out great. Need to do some PID tuning and some flow calibrations. Ever seen the screen do this?

RE: Fysetc MK3S Bear Clone

I guess such screen happens in case of bad display connection.

But.. on what printer did you print your LCD cover? First layer is just terrible... you know you just need to print it again, right? 😏

[Mini+] [MK3S+BEAR]

RE: Fysetc MK3S Bear Clone

I know……..

ender 3 with a raft Having some issues with the POM wheels under bed.

it will get reprinted 🙂

I guess such screen happens in case of bad display connection.

But.. on what printer did you print your LCD cover? First layer is just terrible... you know you just need to print it again, right? 😏