Re: Enclosure w/ filtration for printing ABS indoors?

Well, the price is certainly appealing on the fan that you bought, but it looks awfully small to do the job don't you think? That said, I'd be very interested if you manage to make it work.

Size don't mean nothing here, thats a aggressive fan and as i said the smaller the fan more static they have.

eg: https://www.aliexpress.com/item/Free-shipping-High-pressure-Mini-24V-DC-3-phase-Brushless-DC-Centrifugal-Blower-Hot-and-Cold/32627597541.html

6 kPa thats 611,829 mm H2O

For instance, this one claims to be 78db, which is pretty loud.

Re: Enclosure w/ filtration for printing ABS indoors?

Actually, the posted links give an interesting overview of available options in terms of power rating, flow, pressure, price and noise.

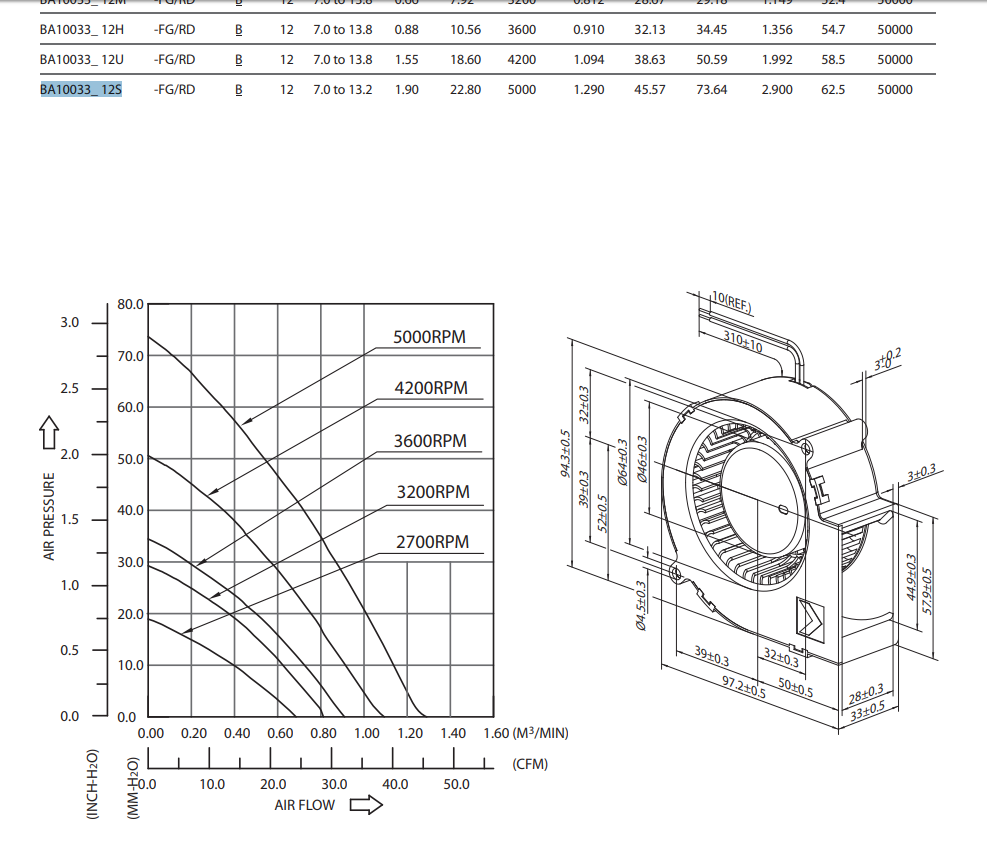

I did not do any calculations or component matching but looking at the specs of the fan it would create an air flow of 0,2m3/min at 30mmH2O = 3 mbar

With my enclosure that would mean That the complete air of the enclosure would be exchanged in about 30s, which sounds about right to me. I want the air motion inside the enclosure to be low to avoid draft effects on the print.

My Idea is to install the filter system into the hollow IKEA Lack table, with air recirculation, and that will require quite some attention to flow speeds. 200l/min is 3,3l/s you need to blow back into the enclosure. That is a lot if I want to keep air speed inside the chamber low. 1m/s is a light breeze, and going by feeling I would rather like to limit the air speed near the print head closer to 10cm/s to avoid cooling and warping issues.

This thread makes me realize better that this topic is not just very interesting but also pretty complex... very valuable. I am curious about the solutions everyone will come up.

Re: Enclosure w/ filtration for printing ABS indoors?

Actually, the posted links give an interesting overview of available options in terms of power rating, flow, pressure, price and noise.

I did not do any calculations or component matching but looking at the specs of the fan it would create an air flow of 0,2m3/min at 30mmH2O = 3 mbar

With my enclosure that would mean That the complete air of the enclosure would be exchanged in about 30s, which sounds about right to me. I want the air motion inside the enclosure to be low to avoid draft effects on the print.

My Idea is to install the filter system into the hollow IKEA Lack table, with air recirculation, and that will require quite some attention to flow speeds. 200l/min is 3,3l/s you need to blow back into the enclosure. That is a lot if I want to keep air speed inside the chamber low. 1m/s is a light breeze, and going by feeling I would rather like to limit the air speed near the print head closer to 10cm/s to avoid cooling and warping issues.

This thread makes me realize better that this topic is not just very interesting but also pretty complex... very valuable. I am curious about the solutions everyone will come up.

You can also read my solution, start here: https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/my-handmade-enclosure-for-prusa-t23384-s30.html

Re: Enclosure w/ filtration for printing ABS indoors?

David, what do you want to grow in your enclosure to use those huge grow tent blowers? 😆

On a serious note, I think radial fans like shown in link 2 and 3 will be better for this application.

An axial fan will produce large air flow with very little pressure difference, a radial fan has lower flow with bigger pressure difference, and we need that pressure to suck the air through the filter.

I bought this fan:

https://www.neuhold-elektronik.at/catshop/product_info.php?products_id=6595

but don't know when I will find time to work on my filter solution...

The fan produces 30mm H2O pressure.

An axial fan with slightly higher power rating has 1/10th of that pressure rating.

Georg,

You've inspired me to try a small centrifugal blower with allegedly up to 72mm-H20 air pressure:

Re: Enclosure w/ filtration for printing ABS indoors?

http://www.rh.gatech.edu/news/614128/research-raises-awareness-indoor-air-quality-risk-3d-printers

Re: Enclosure w/ filtration for printing ABS indoors?

Melting plastic is always not a good thing, even PLA not pleasant to me

I can confirm some senteces with my research:

"When a printing process is initiated, a burst of new particles is created, which then becomes airborne. It’s this initial batch that tends to contain the smallest sizes and the maximum number of UFP concentrations during the entire print job, according to the new research."

Look at the spike on heat up, that peak never happen again during printing

I would like to have a nano particle sensor to make some tests, but i guess they are expensive...

RE: Enclosure w/ filtration for printing ABS indoors?

I'll give it another try, but this time with an axial fan that's rated for high static pressure:

Phanteks 120mm, PWM, High Static Pressure Radiator Retail Cooling Fan PH-F120MP_BK_PWM,Black/White

https://www.amazon.com/gp/product/B00OP2PUB8/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

or

Noctua NF-F12 iPPC 3000 PWM, Heavy Duty Cooling Fan, 4-Pin, 3000 RPM (120mm, Black)

https://www.amazon.com/gp/product/B00KFCRATC/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

If it works no further filter holder design modification would be required.