Drybox "nozzles"

I have been printing 'dryboxes' based on the designs posted on this site. In my case, I am hanging them on the wall, then feeding the filament to the buffer, and then to the multi-filament selector. With this arrangement, filament is pulled out of the reel at an angle, and I have had cases when the filament got hung up on the spots provided to stop it from unraveling when not in use. In one case, a 16 hour print failed after 12 hours, so annoying!

So I redesigned one small part in the design, such that the filament is pulled from the center even if at an angle after leaving the box. I was going to attach the files in case someone wanted to use this solution, but the system tells me these type of files can not be attached here. 😕

RE: Drybox "nozzles"

Zip up the file and post the zipped file.

RE: Drybox "nozzles"

I have been printing 'dryboxes' based on the designs posted on this site. In my case, I am hanging them on the wall, then feeding the filament to the buffer, and then to the multi-filament selector. With this arrangement, filament is pulled out of the reel at an angle, and I have had cases when the filament got hung up on the spots provided to stop it from unraveling when not in use. In one case, a 16 hour print failed after 12 hours, so annoying!

So I redesigned one small part in the design, such that the filament is pulled from the center even if at an angle after leaving the box. I was going to attach the files in case someone wanted to use this solution, but the system tells me these type of files can not be attached here. 😕

Pictures of the failure and first layer might help also.

--------------------

Chuck H

3D Printer Review Blog

RE: Drybox "nozzles"

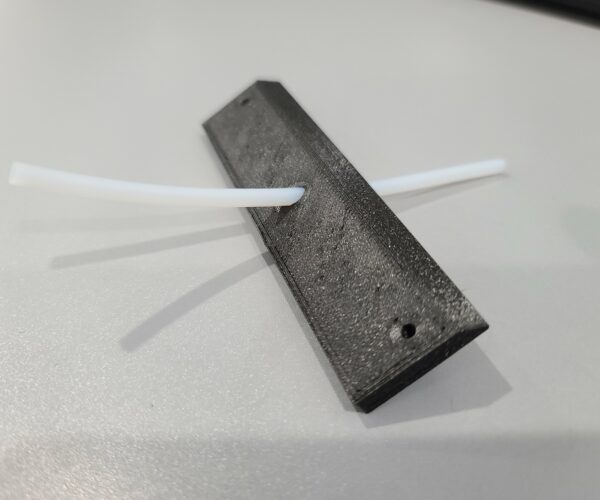

Great, the zip file is below. It contains the STL, the GCODE, and the Fusion 360 archive to print your own copy/version. The nozzle mounts inside the box, replacing the original one which contains a wide slot. The center hole in the nozzle is designed to hold a short piece of tubing as shown in the photo below. When using this change, the plastic (with the slit) is omitted and when storing, a bit of filament will block the passage of air into the box.

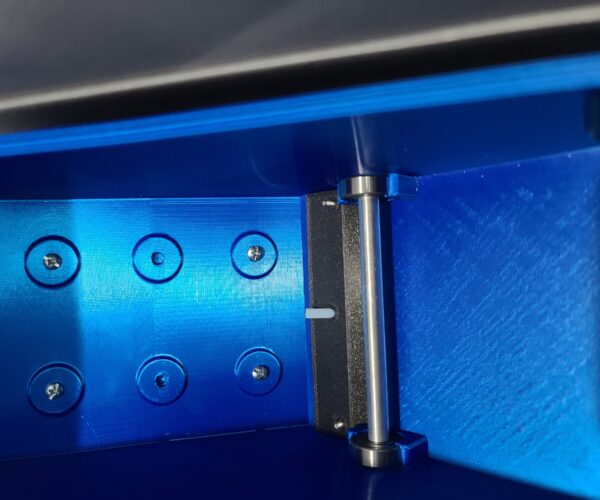

This second image shows the modified part mounted inside a drybox. I recommend only a very short bit of tubing inside the box.

RE: Drybox "nozzles"

@cwbullet

Thank you for your reply. Those pictures would not be helpful. What happened is the filament was stuck, IE more could not be pulled off the reel. But both filament sensors were still reporting the presence of filament, so the printer continued going through the motions. It was 'printing' many centimeters above the model, but no filament was being extruded. About 25 cm had been successfully been printed before the problem occurred.

The detect a problem like this, the printer would need another kind of sensor. One that measures the MOVEMENT of filament, not just its presence. Apparently some advanced computer controlled sewing machines have a wheel, over which the thread is pulled. If the wheel stops turning, the machine stops so the operator can fix the problem.

RE: Drybox "nozzles"

@robert-2

Thanks. You description was not clear to me what the problem was.

It is not possible to detect if a filament is feeding with the MK3S or Mk3S+ Without an additional sensor or some other charge. I have had one of my printer pick itself up when the filament would not feed.

--------------------

Chuck H

3D Printer Review Blog