Capricorn tubing inside extuder cold end (Which one?)

I am redoing my MK3 extruder today with the R3 parts and thought it a good time to replace the PTFE tubing in the extruder. I have both the TL and XS Capricorn tubing at my disposal. The XS being 1.9mm ID +- .05mm and the TL being 2.0mm ID +-.05mm. Cleary I will not be able to see either so translucency is not a concern. Is there a prevailing opinion on which would work better for fairly standard good quality filaments. I don't believe any of the ones I used are far out of tolerance beyond 1.75. Let me know your thoughts? On another note. Is there a better back cover solution for the MK3 than the R2 parts going around. I thought I recall one with an integrated cable relief to take place of the bolt and separate "tail piece". Thanks in advance.

DevDoc

Re: Capricorn tubing inside extuder cold end (Which one?)

I’m using the XS version combined with high quality filament from colorfabb which has a tolerance of +/-0,05 mm. (low quality is usually +/-0,1 mm). For dimensionally accurate parts and good surface finish you need a high quality filament as mentioned for example here: https://precision3dfilament.com/blogs/news/15202543-filament-tolerances

I’m printing sometimes with highly flexible filaments (shore hardness 80A or 60A) and the Capricorn tube helps definitely a little. But if you are not printing flexible and only non/semi flexible filament it is overkill in my opinion (especially on a direct drive system).

Re: Capricorn tubing inside extuder cold end (Which one?)

Thank you for the advice. I appreciate it. I actually bought a combo kit to replace the Bowden tubes on my MK2S MMU, but figured I could put the extra to good use here and there, and I am still using the original tubing in my MK3 extruder, and I think the top is beginning to deteriorate a bit.

Re: Capricorn tubing inside extuder cold end (Which one?)

I use the dark blue stuff in my hotend (V6). Had to bore out a little to fit as I printed my parts as a 2.5 owner (same extruder parts as MK3) but fit the stock V6 parts fine. Just have a drillset and matching drill stoppers handly, in case.

MK2S kit owner since 8/15/2017

Re: Capricorn tubing inside extuder cold end (Which one?)

I use the dark blue stuff in my hotend (V6). Had to bore out a little to fit as I printed my parts as a 2.5 owner (same extruder parts as MK3) but fit the stock V6 parts fine. Just have a drillset and matching drill stoppers handly, in case.

Thank you. What did you need to drill out, and what size did you use? The inlet side to allow for smooth autoloading, or something else?

Re: Capricorn tubing inside extuder cold end (Which one?)

If you are able to modify with precision the STL to adjust the PTFE ports then print a fresh set, that would obviously be a better way. As it is, stock STL at least provided for MK2.5 is too tight for Capricorn XS. It would seem Prusa Research is still developing optimized for ABS which is OK with 0.1~0.2mm clearance but PETG is 0.2~0.3. As seen in the CAD images, the tolerance is way too tight on the extruder-body-R2 part. Likely the new R3 (beta) which is as well.

MK2S kit owner since 8/15/2017

Re: Capricorn tubing inside extuder cold end (Which one?)

I used a smaller drill bit, and it seemed to work fine. In my case the top tube didnt need to be replaced. I wish they'd stop using generic PTFE, the capricorn XS stuff has a better working temperature, and less friction.

I refer to this page:

https://www.captubes.com/safety.html

One has to wonder though, since the e3d V6 1.75mm heatsink is "universal" does one really need a liner?

War... War never changes.

Re: Capricorn tubing inside extuder cold end (Which one?)

The installation guide says you need to chamfer both ends. How do you do this?

--------------------

Chuck H

3D Printer Review Blog

Re: Capricorn tubing inside extuder cold end (Which one?)

The installation guide says you need to chamfer both ends. How do you do this?

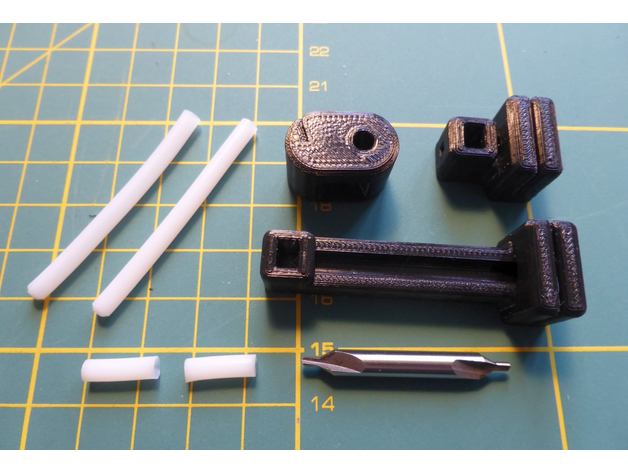

Area51 seen from time to time here on the forum has done this neat kit

[img]  /img]

/img]

https://www.thingiverse.com/thing:3121653

Re: Capricorn tubing inside extuder cold end (Which one?)

Thanks. I will give that a try.

--------------------

Chuck H

3D Printer Review Blog

Re: Capricorn tubing inside extuder cold end (Which one?)

Don’t forget to fit the collet lock at the top e3d fits these as standard if you get an assembled unit from them don’t know why Prusa does not when it builds them. Print one of the small locks some the larger designs on thinkverse won’t fit the space in the extruder housing on the Prusa

cheers