RE: BNBSX Short Ears Extruder vs. Skelestruder

Elmer's ULTRA glue stick actually.

Ah OK, great.

Garage + high temp requirement + winter? I don't think that's going to work out well unless you are in a super temperate region.

I don't plan on doing a lot of heavy-duty PC-type printing, but I would like to on occasion. I've looked at some of the 3D printers that are partially enclosed (think Qidi or Flashforge) and wondered about closing up the sides to create a "printer in a box" that could be moved around for printing smelly or toxic stuff. The garage during winter, outdoors under cover during summer. I'm not in a position to reconfigure my workspace around outdoor exhaust for an indoor printer. The idea of a small enclosed box that could be heated if necessary is appealing, but most of those printers seem to be PLA-only ... or at least not PC-capable.

I ended up building another Prusa out of spare parts and a few more bits from Prusa. Definitely didn't save any money over another kit.

A 2nd Prusa is an option of course, but it would go to waste a lot.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: BNBSX Short Ears Extruder vs. Skelestruder

Sorry had to make a small change in BNBSX motor plate bearing pockets. The new B08i printability improvements create bearing pocket geometries so much cleaner that the previously needed oversizing is no longer needed. Bearings could be too easily pressed in with the cleaner geometry. Bunnies have decrease bearing pocket diameter by 0.2 mm to compensate. Here is the plated for polycarb main components with the little adjustment.

RE: BNBSX Short Ears Extruder vs. Skelestruder

I use rigid. Ink cleaning floss then load some PLA and do an 80 deg cold pull. This remove all trace of old filament reliabily every time. You can see straight through the extruder when you shine a light below the nozzle. Don't forget to clean the outside of the nozzle as well.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: BNBSX Short Ears Extruder vs. Skelestruder

@guy-k2: thank you for the data, informations and your rich experience you share with us!

I will try your data as soon as my boring enclosure parts are ready. Unfortunately the lack enclosure gcode data do not perform out of the box...

So I print original prusament PETG orange with the gcode and messed up

Thanks to chocki and the link to the knowledge base of Rigid.Ink I know now to check the extruder coefficient. The wall thickness is slightly bigger (0.46mm), so I have to adjust this. But I recognized also, that in the first third of the cube the wall thickness is 0.5mm and the density seems higher then rest of the cube, because the transparency is different. There is also a the chamfer at the bed end. So my summery of changes I will do due to the read knowledge base: calibrate the extruder coefficient, increase z distance, decrease bed temperature of about 5°C, decrease max speed to 40 mm/s, increase extruder retraction to 2mm... then I will give it the next try.

So it seems there is a long way to print pc max, but I am hard-bitten...

RE: BNBSX Short Ears Extruder vs. Skelestruder

@guy-k2

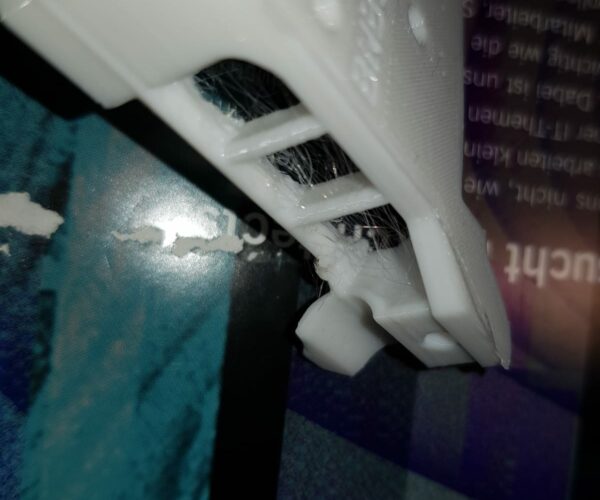

Hello, I have printed the parts with PC-Max. But obviously the bridging quality is very poor at my prints:

After drying the filament and I got this result:

Much better, but there were also several problems with bridging and I got for example a layer shift after this blobb...

What can I change: should I print the parts with support?

Thanks!

RE: BNBSX Short Ears Extruder vs. Skelestruder

I would go with a 20-30% more parts cooling fan and maybe 10% more speed for bridging if I saw that result.

RE: BNBSX Short Ears Extruder vs. Skelestruder

@guy-k2

OK, 20-30% more bridging fan speed or more fan speed in general?

RE: BNBSX Short Ears Extruder vs. Skelestruder

20-30% more bridging fan speed, not in general.

Also 10% faster travel speed. Too slow and you'll sag too much with PC-Max.

RE: BNBSX Short Ears Extruder vs. Skelestruder

@guy-k2

Max fan speed = 30%

bridging fan speed = 80% -> 100%

Bridges speed = 30mm/s -> 33mm/s

OK, I will try...

RE: BNBSX Short Ears Extruder vs. Skelestruder

Once again - thanks for the insights.

I learn a lot, just kibitzing here...

Guy my BNBSX is still sitting in a box, waiting for my MK3S to irritate me enough to change it out.

The darn printer continues to exceed my expectations - and I can't justify a second printer. So I wait.

RE: BNBSX Short Ears Extruder vs. Skelestruder

Hello, im looking to change to the bunny extruder. What speeds i can expect with good quality printing ? i saw few videos and its printing slow there.. With stock i can push the speeds, just overhands going down sometimes. i will do maintenance to the printer so as well might change the extruder. Thanks