1,4mm nozzle - settings

hello,

so i bought this 1,4mm nozzle and am about to learn how to calculate and adjust the slicer settings. what i miss: which nozzle size do i choose in the printer menu - maximum there is 0,8mm ) latest firmware)? does someone know that? (prusa help pages did not help, nothing found in forum).

thx and greetings

mk3.5, mk4s, pla & petg only

RE: 1,4mm nozzle - settings

A 1.4mm nozzle for Prusa MK3s? There is afaik no such thing. .8mm is maximum diameter. You've probably got a nozzle for another printer.

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE:

i bought this one: https://www.3djake.com/bondtech/cht-coated-nozzle-m6-x-175-mm?sai=11431 - v6 system, compatibility according to the shop: mk3s+ . so the offer is wrong?

prusa itself gives advise hot to print with more than 0.8mm:

https://help.prusa3d.com/article/different-nozzle-types_2193#other-nozzle-diameters

https://blog.prusa3d.com/everything-about-nozzles-with-a-different-diameter_8344/

mk3.5, mk4s, pla & petg only

RE: 1,4mm nozzle - settings

The nozzle should fit and print. So technically the advertising info is correct. However I think its pretty pointless to use on a MK3 printer. The whole thing behind large nozzle sizes is moving lots of plastic. The E3D V6 fitted to a Mk3 just cant move that much. The CHT nozzles do increase the total throughput of the hotend by getting more heat into the plastic but you still need the oomph behind it from a more powerful heater. On a V6 the CHT up to about a 0.8 will get you some benefits.

For a big boy like that 1.4 you need a seriously powerful hotend, something like a Volcano or similar. With a hotend that has got a limited throughput then to not exceed that you are going to have to print very slowly.

To set it up though you will first need to modify a Printer profile with the new nozzle size defined. You will probably also end up having to change the retraction values and speeds too eventually. Then you will need to set up a new print profile with the new extrusion widths defined at a minimum.

Before you can do that you are going to need to work out the max volumetric flow the new system is capable of, so with the new nozzle, the filament you are going to use and the heater cartridge etc. CNC Kitchen has some good info on how to determine that. Once you know the maximum amount of plastic you can push out then you can configure the rest of the profile info.

Then its some test prints to determine the usual stuff like retraction, best speeds etc.

Its a straight forward process but one that requires time and a bit of knowledge.

If you don't mind me asking what is your end purpose for such a big nozzle ?

RE: 1,4mm nozzle - settings

thank you! glad to hear, that i did not buy something wrong.

why 1,4mm? well... i like to try out the extremes, what can i do. a 0.25 nozzle is lying around too, but the big ones are also tempting. a real usecase could be vase mode - printing big and thin objects should work better with a big nozzle and provide more stable models? big models (loudspeaker stands e.g.) can be printed faster and get a unique aesthetics with these bubblish layers. bigger models, where the look doesn't matter, get printed faster...

that was the theory. if i need to print slower because of what you mentioned, i still see advantages. so investing the time for the adjustments could be fun.

i did not mention yet, that i originally went for the 1,8mm nozzle, but that's thicker than the filament itself and so i stopped that.

mk3.5, mk4s, pla & petg only

RE: 1,4mm nozzle - settings

oh, and still: what nozzle size do I choose in the menu on the printer itself? .8? does it even matter?

mk3.5, mk4s, pla & petg only

does it even matter?

Yes. The slicer bases a lot of internal calculations on this value together with an accurate filament diameter figure.

Cheerio,

RE:

sounds like "bigger is better" even if it's not the correct value.

mk3.5, mk4s, pla & petg only

RE:

well, i started now printing with this big boy - and i am quite suprised in a positive way. i did not even start to fine tune, just reduced printing speed in prusa slicer about 20 to 40%. i started with 295 degree temperature (temp alarm went off immediately) but quickly went back to normal values for the filament - because they just work. the print in the right was done with 230° c first layer and 220° c second layer.

all adjustments were made based on the 0.8 nozzle profile - in slicer and in the printer.

so, for me the throughput of material is not a problem at the moment, but i am not looking for high speed printing here. i will now have a look to make the prints more beautiful, so the top layers are presentable as well. no regrets of going for 1,4mm so far.

mk3.5, mk4s, pla & petg only

RE:

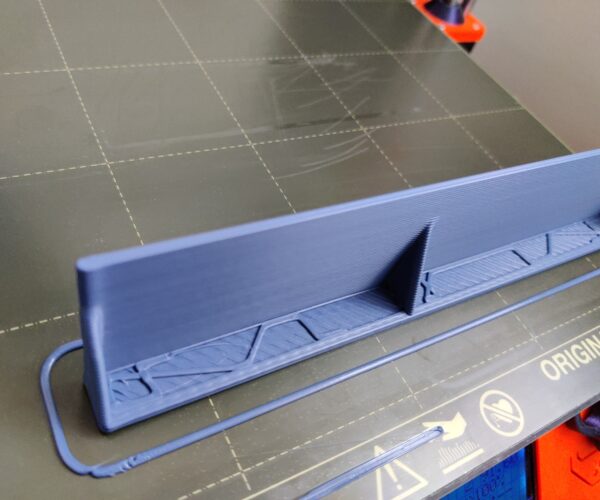

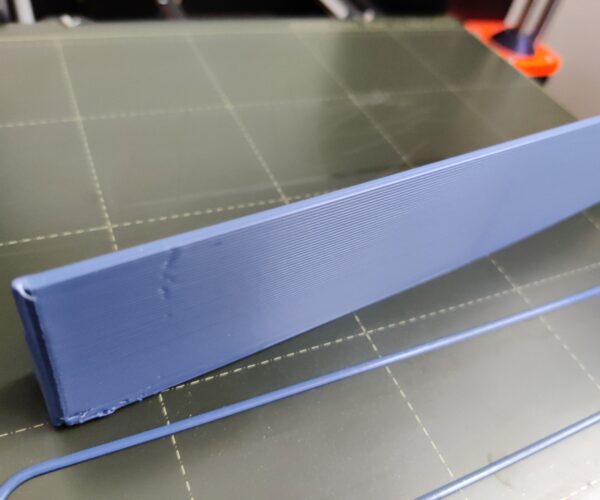

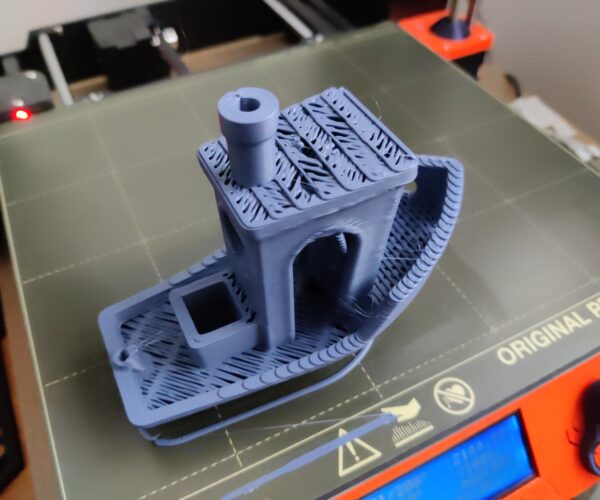

still fiddling around like a fool with a tool with really rough adjustments and a lot of fine tuning needed. but clear for me already: printing with a 1,4 mm nozzle on a mk3s+ definitely works.

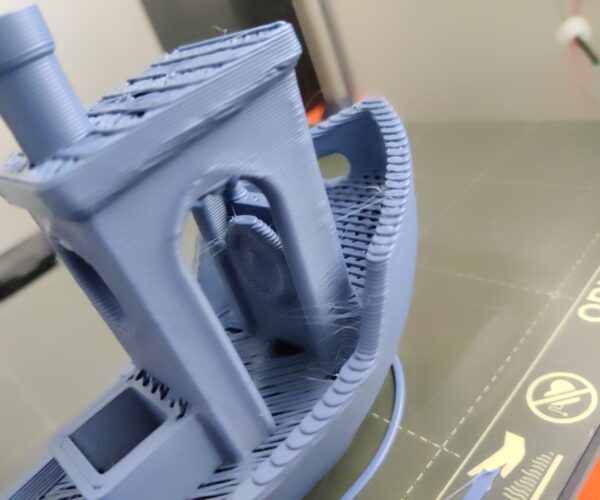

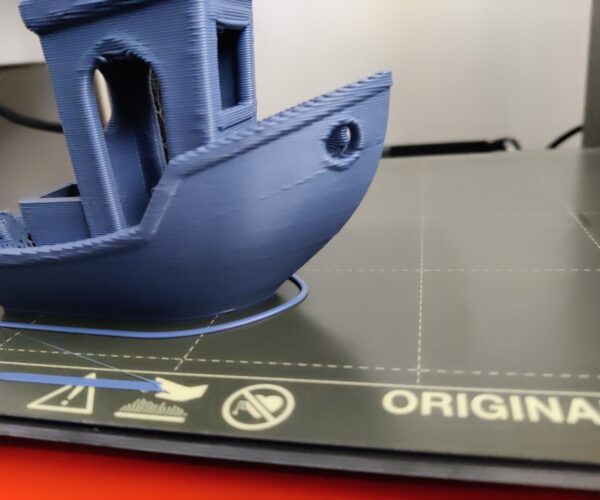

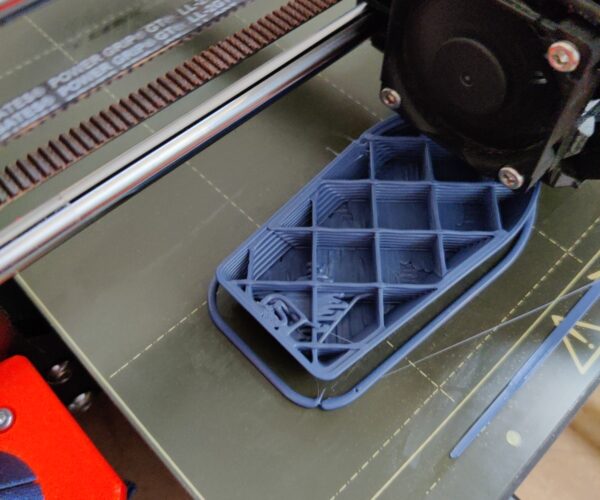

going for fine details and sophisticated designs in smaller scales does not makes sense of course. the vaccum robot stopper and the weird 200%-scaled benchy were printed between 200 and 210°c temperature. stopper at 0,8 layer height, benchy at 0,6. benchy took 90 minutes, robo stopper 30 minutes. for the benchy i expected way worse results in hangovers and slopes.

now let's try vase mode.

mk3.5, mk4s, pla & petg only

RE:

vase mode = fun. video shows a bottom layer printed with 250% speed at 250° c temperature (video direct link, if not shown here: https://forum.prusa3d.com/wp-content/uploads/2023/05/VID_20230506_202210.mp4).

still no problem with delivering pla.

the last test was going to 0.4 mm layer height, which worked well, though the speed may need to be slower on more complex models.

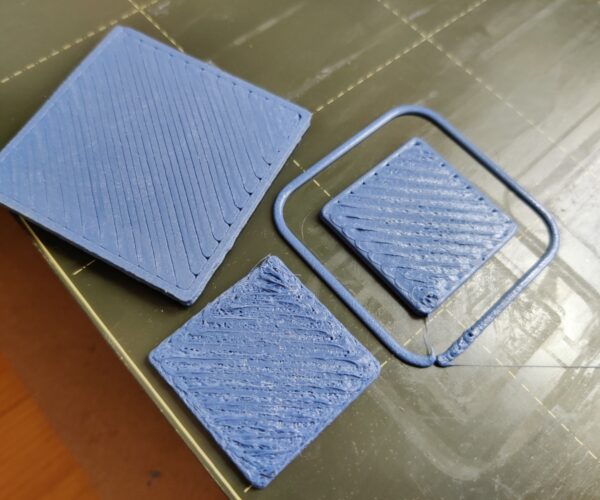

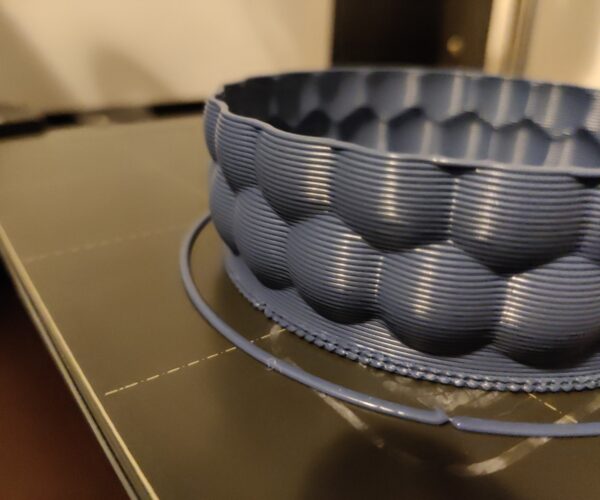

comparison .4 layer height and .9 layer height

thick nice .8 layers

vase bottom and wall (watertight)

mk3.5, mk4s, pla & petg only

RE: 1,4mm nozzle - settings

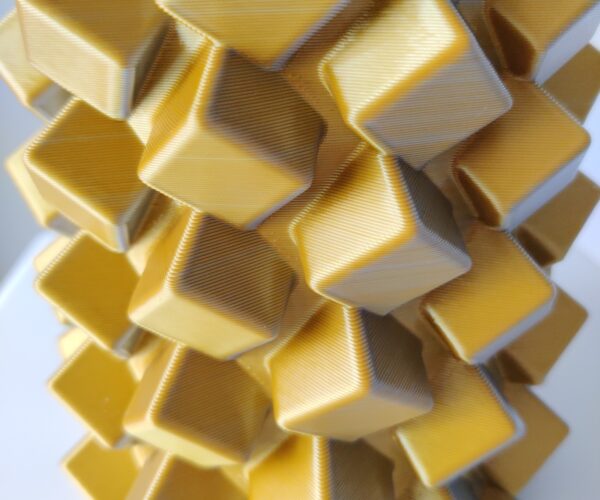

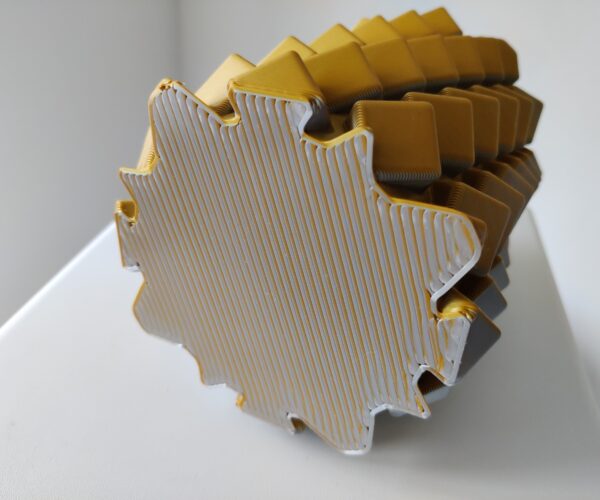

finally did my vase print. outcome was a superstrong thing with 0.4 layer height. (not my design).

tradeoffs:

- this one is not watertight - the thick lines at the bottom leave tiny gaps. maybe ironing could help, going slower or something else. should be good for a planter, still. (I think i glue thin patch of the same shape on the bottom and hope for the best).

- layer visibilty: they are visible. take it as part of the design or you will be disappointed.

i'll stop my experiment here. i know that i have a huge nozzle for tough jobs in my toolbox - don't regret the buy.

mk3.5, mk4s, pla & petg only

RE: 1,4mm nozzle - settings

Thank you for posting your tests. I find this really interesting.

For some time now I’ve been contemplating designing something that embraces the layer lines. As with current tech of extrusion printers they cannot be completely removed it would be interesting to go the other way.