0.6 Nozzle First layer and some other questions

Hello,

i have some questions about my prints with the Prusa i3 mk3.

bevor i changed the nozzle to 0.6mm i haven´t had non of these problems.

The first thing i am not shure if its needed or how i can make is a first layer calibration with an 0.6mm Nozzle?

If there is a guide please help me and give me an link but google doesn´t find a solution...

Because the first layer is to thin and now i have an elephant foot.

The second problem is the top layer has some strange very tiny holes. Did anyone know this and how to fix it?

I sliced with Sli3er PE newest Version 0.6 Nozzle and changed the Layer high to 0.3mm and 4 Lines Perimter. 30% Infill. Prusament PETG.

I hope someone can help me 🙂

Kind Regards

Re: 0.6 Nozzle First layer and some other questions

make yourself a new first layer model, using the setup for your 0.6 mm nozzle in preference to the original 0.4 mm nozzle, and consider increasing the infill/perimeters overlap to address the pinholes

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: 0.6 Nozzle First layer and some other questions

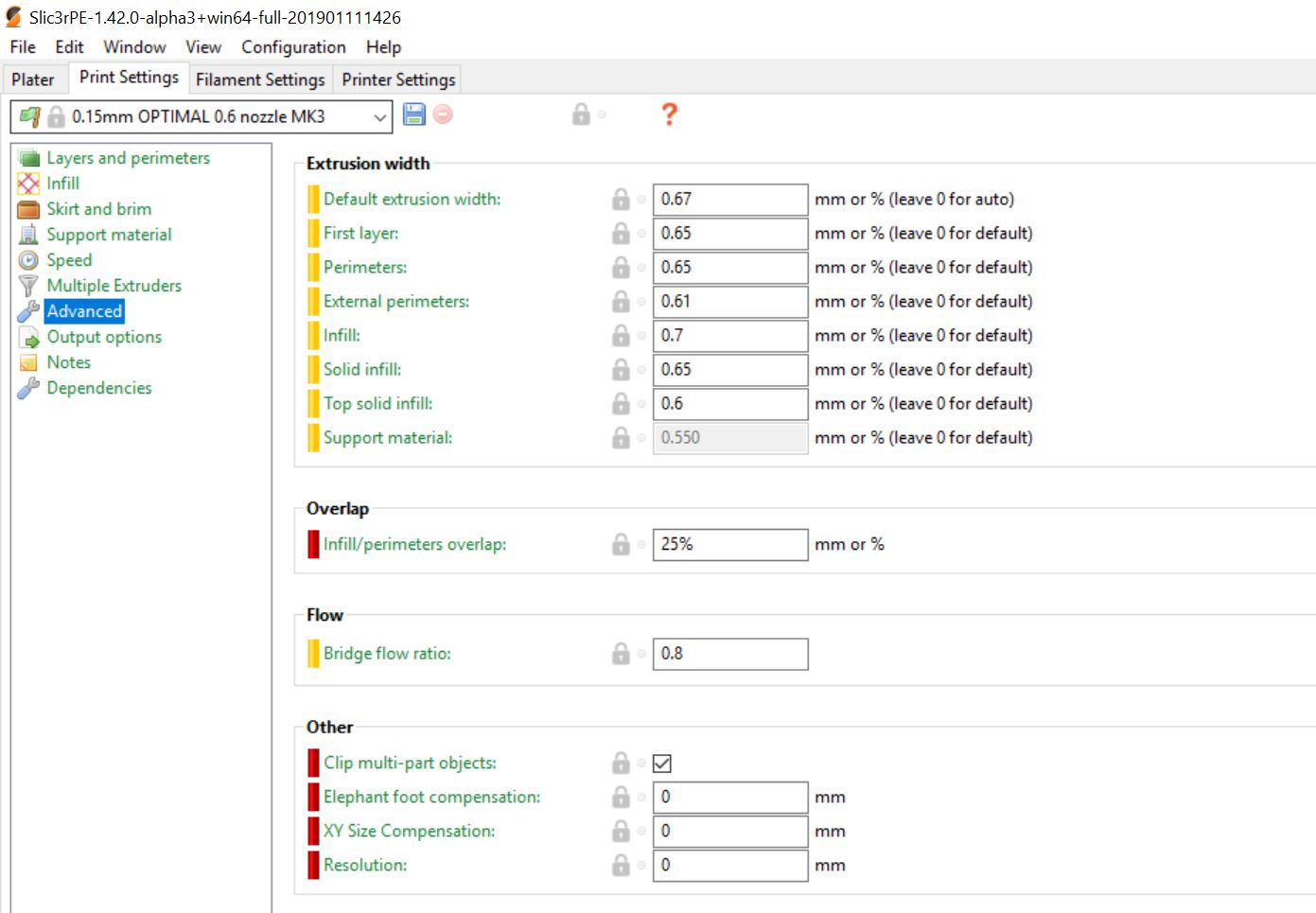

by the way, have you used a profile with the corrected extrusion width values, for a 0.6mm nozzle?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: 0.6 Nozzle First layer and some other questions

Thank you for you reply. 🙂

I used the Original profile for 0.6mm Nozzle the only thing i change are the Infill and the layer hight.

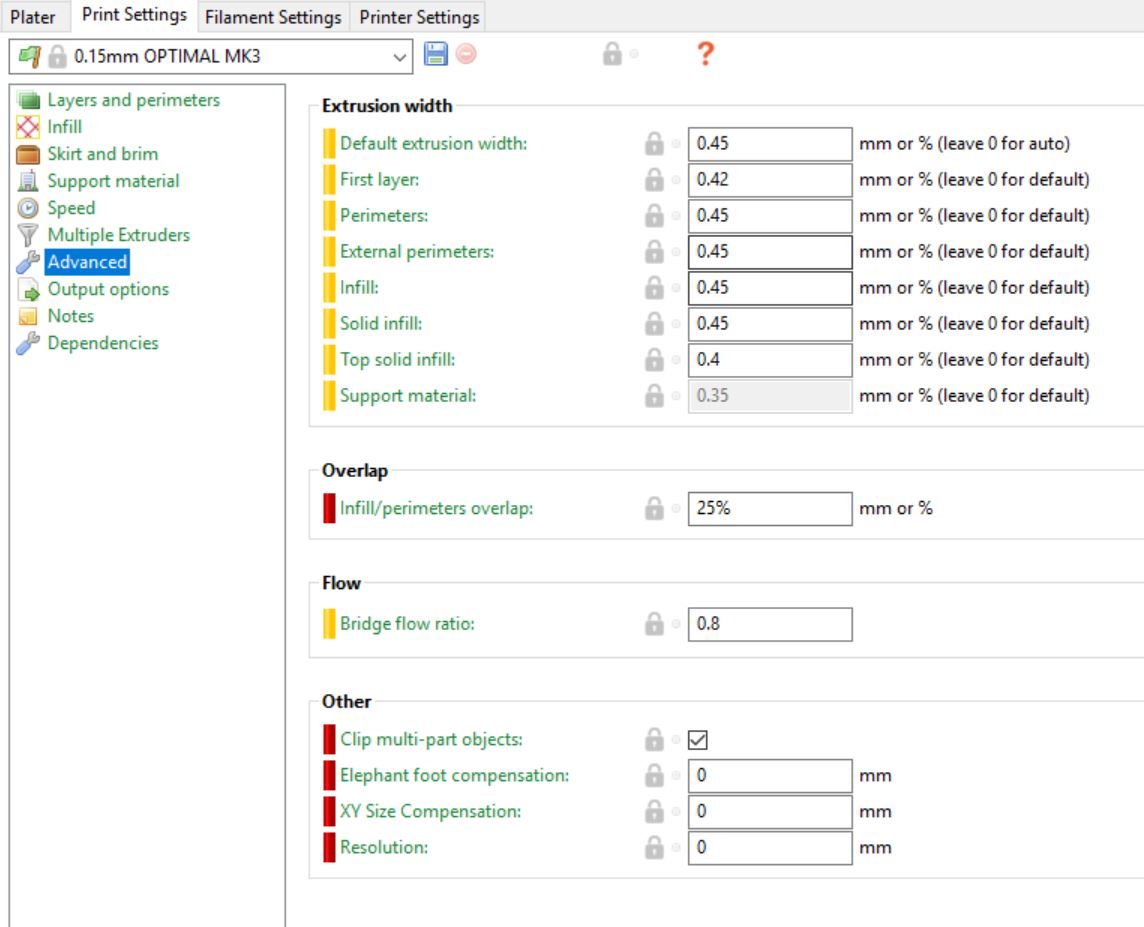

This is what i used:

Should i change infill/perimeters overlap?

Re: 0.6 Nozzle First layer and some other questions

Jeff Jordan's "Life Adjust" method is by far the easiest to use and understand for first layer calibration. He's generously included pre-generated gcode models, but those are all for 0.40mm nozzles. I've generated equivalent prints for a variety of nozzle sizes and materials that you're welcome to use.

[...] The first thing i am not shure if its needed or how i can make is a first layer calibration with an 0.6mm Nozzle?

Because the first layer is to thin and now i have an elephant foot.

I don't have that problem after using the "Life Adjust" 1st layer calibration method.

The second problem is the top layer has some strange very tiny holes. Did anyone know this and how to fix it?

Try adjusting Print Settings->Advanced->Overlap->Infill/perimeters overlap. I've got mine set to 25% and have eliminated that issue. This may also be affected by your extrusion multiplier.

I sliced with Sli3er PE newest Version 0.6 Nozzle and changed the Layer high to 0.3mm and 4 Lines Perimter. 30% Infill. Prusament PETG.

4 lines perimeter is going to give you some very thick walls. Not necessarily bad, but probably not necessary. 30% infill is also likely overkill, especially with 4 X 0.72mm perimeters! If you drop those down, your prints will be much faster. I've got a lot of notes on my experiences using different nozzle sizes that might be useful.

A quick note on extrusion widths. You can let Slic3rPE calculate the width for you. For some reason, this is not recommended by the developers, but I have had good luck setting extrusion widths to 0, allowing one layer height profile to be used with nozzles from 0.15mm to 1.00mm (with 1.25mm and 1.50mm on the way). For fine detail, you'll want more precise control, but I've found this shortcut very handy when experimenting with a variety of nozzle sizes without having to duplicate otherwise-identical layer height profiles for each one.

Have fun with the big nozzles. Even with the lowly E3D V6 hotend on the Prusa i3 Mk3, you can get some fantastic results. I've been doing a lot of large prototype modular birdfeeder tests with good results using 0.80mm and 1.00mm nozzles with 0.48mm layer heights.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: 0.6 Nozzle First layer and some other questions

by the way, have you used a profile with the corrected extrusion width values, for a 0.6mm nozzle?

extrusion width 0.6mm nozzle.JPG

regards Joan

Joan. Is this a profile you have made or is this available somewhere?

Thanks

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: 0.6 Nozzle First layer and some other questions

Hi John, it's a standard Prusa 0.6mm profile

if you click on configuration, then configuration wizard, in Slic3r PE... you should get the options

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: 0.6 Nozzle First layer and some other questions

Thank you very much for you help.

I will make that first layer calibration later that day and i am shure after this the first layer will be perfect. Yippi 😀

How much do you think i should increase that value? Because i already printed this with 25% overlap.

The parts i print are grips and need to be very strong that´s why i thing i need 4 perimeters and 30% Infill.

I think i don´t need the whole part to be that strong, but i insert some metal clips and they should sit very tough.

Is it possible to print only that area stronger?

Kind regards

Re: 0.6 Nozzle First layer and some other questions

I think maybe i damaged the hotend while changing the Nozzle. I was very carefuly and watched the video bevor.

Here is a video i made how the hotend is moving around. Can someone verify that this is not normal. I also write the support about this problem and where i can buy a new hotend.

Here is the video:

Re: 0.6 Nozzle First layer and some other questions

[...] Is it possible to print only that area stronger?

Yes. See this thread for details.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: 0.6 Nozzle First layer and some other questions

Thank you very much for you help.

I will make that first layer calibration later that day and i am shure after this the first layer will be perfect. Yippi 😀

How much do you think i should increase that value? Because i already printed this with 25% overlap.

The parts i print are grips and need to be very strong that´s why i thing i need 4 perimeters and 30% Infill.

I think i don´t need the whole part to be that strong, but i insert some metal clips and they should sit very tough.

Is it possible to print only that area stronger?

Kind regards

Inherently this section you highlighted is a weak spot as it will want to break along the plane of the layers. Ideally the island should be printed with the layer plane vertical.

One way is to print the part on its edge but I realise this will make the recess less clean. Another way could be to print the island separately and insert it into a recess in the other part.

You might be lucky but it all depends on how the metal part interacts with the print.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: 0.6 Nozzle First layer and some other questions

Hello,

i have some questions about my prints with the Prusa i3 mk3.

bevor i changed the nozzle to 0.6mm i haven´t had non of these problems.

The first thing i am not shure if its needed or how i can make is a first layer calibration with an 0.6mm Nozzle?

If there is a guide please help me and give me an link but google doesn´t find a solution...

Because the first layer is to thin and now i have an elephant foot.

The second problem is the top layer has some strange very tiny holes. Did anyone know this and how to fix it?

I sliced with Sli3er PE newest Version 0.6 Nozzle and changed the Layer high to 0.3mm and 4 Lines Perimter. 30% Infill. Prusament PETG.

I hope someone can help me 🙂

Kind Regards

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: 0.6 Nozzle First layer and some other questions

Thank everyone for your replys 😀

Yesterday i tried to level the first layer with the Link fom mupped labs http://projects.ttlexceeded.com/3dprinting_live_z_calibration.html

The result was very confusing to me. Because on the left edge of printbed the Nozzle was to hight and on the right edge the nozzle was to low.

Now i go somewhere in the middle but why is this so?

Should the PINDA sensor not prevent such a case?

I also disasemble the Extruder and tighten the heatblock a little bit stronger into the V6 cooler and now the heating block is fixed.

But the little holes on the top and the bottom are still be there. So now i need to adjust the Infill/perimteres overlap. But everything else on the print looks fine. How much would you recomme to increase the value? 27% 30% 40%?

Thank you 🙂

Re: 0.6 Nozzle First layer and some other questions

[...] Should the PINDA sensor not prevent such a case?

In general, yes. You can check for bed warping by placing a straight-edge diagonally across your bed and shining a light from behind. If you see light underneath, your bed may be warped. Contact Prusa support if still under warranty.

[...] But the little holes on the top and the bottom are still be there. So now i need to adjust the Infill/perimteres overlap. But everything else on the print looks fine. How much would you recomme to increase the value? 27% 30% 40%?

Does your extrusion look even on other parts? Get your overall extrusion looking good, then you can bump that setting up a few % at a time. I've got mine at 25% and don't have those gaps with larger nozzles.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…