The calibration is killing me!

Dear Prusa i3 users, dear support,

the calibration on this printer is a nightmare. I have no idea whether the glass bed is bent or maybe the heat bed but tightening or loosening one corner screw is breaking the other one that is on the other side. Only moving the clips to the middle of the glass bed made it possible to adjust those screws. I did not manage to calibrate the printer with clips positioned near the corners which is unlucky because they may be in the way of the wires while printing. They screws on the corners are by the way just jumping out of their holes while calibrating and the printed part around the screws is coming of again and again which makes me furious as it is not easily accessible with my fat fingers. It would be fantastic to get automated calibration before each print.

If s.o. has a dirty hack how calibration can be done a lot easier, please tell me.

Kind regards

b0rski

Re: The calibration is killing me!

Hi b0rski

The symptons you describe are typical of a twisted Y frame. First off, you need to remove the felt pads on the feet and ensure that all 4 feet are flat on the table.

Once you have done this, you need to look at the heated bed, but one step at a time...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: The calibration is killing me!

Hi Peter,

I have no idea what twisted Y frame is. Could you show me a picture? The printer came pre-built and I hoped to just plug&play 😀

Additionally I have no idea what felt pads are however I am sure that the printer is standing flat on the table and there is no room for swinging to the sides.

Kind regards

b0rski

Re: The calibration is killing me!

OK, if you bought the printer pre-built, then you are entitled to full support from Prusa Research.

It may be that the printer has been mis-handled during delivery, as it will have had at least a calibration and print prior to leaving PR.

There is one felt pad underneath each corner of the Y frame which sits on the table. With these in place it will not be possible to tell if the Y frame is twisted (ie one of the feet not in proper contact with the table top).

You may wish to contact Prusa Research to discuss your calibration issues - use the "Live Chat" facility on the shop pages. They will get your problems sorted quickly.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: The calibration is killing me!

A troll

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: The calibration is killing me!

A troll

Nigel, sorry, I disagree. Please have a tad more patience with posters on this forum.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: The calibration is killing me!

Hi b0rski,

I've purchased the plus version too (already assembled by Prusa Factory) but the first thing i made, was to read and study the service manual and the assembling manual.

These are the felt pads:

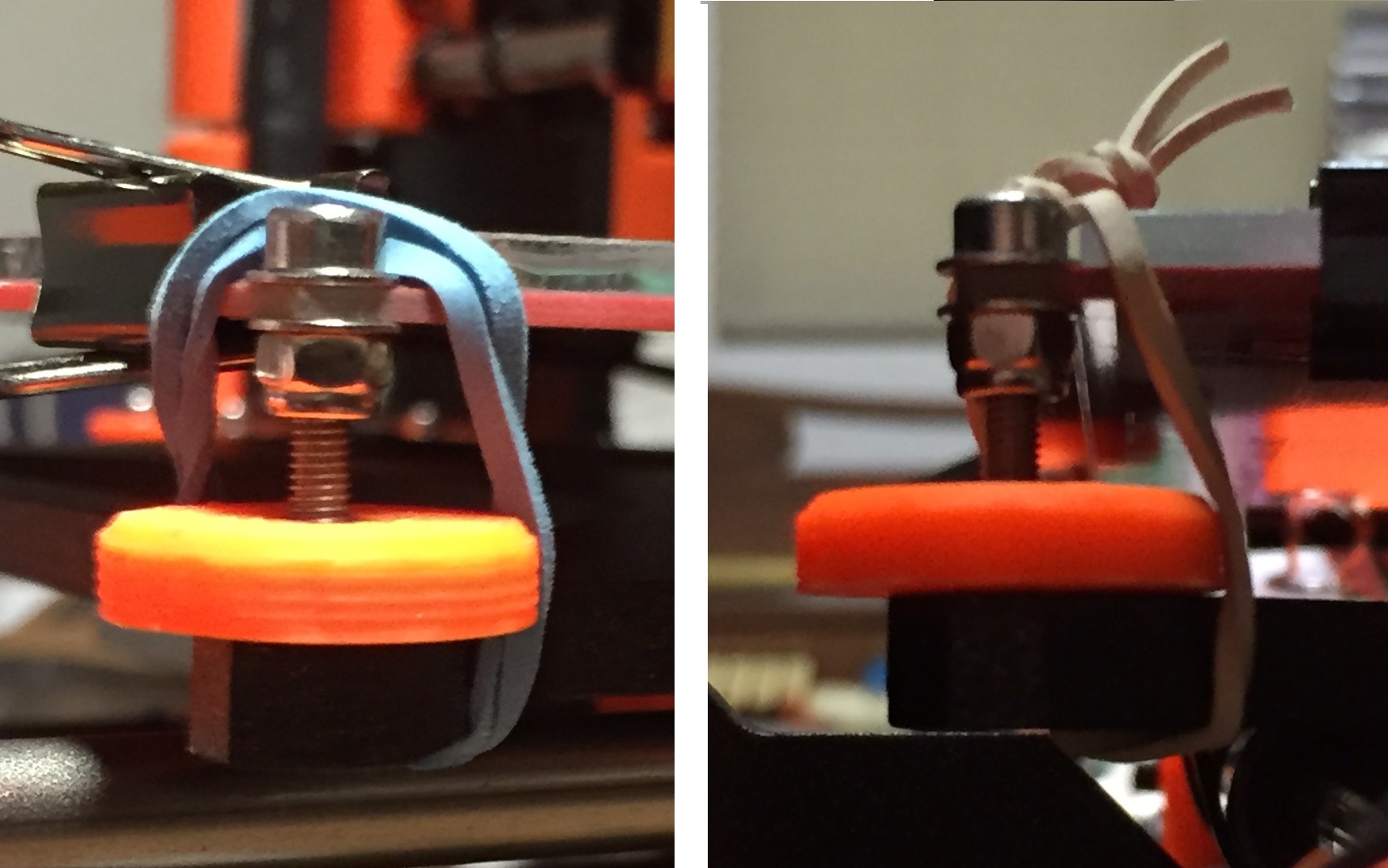

You wrote, "The screws on the corners are by the way just jumping out of their holes while calibrating...".

To avoid it (while turning the adjusters), make use of elastic bands like that:

They help, trust me. You can leave them in place during the print process.

Ciao

Re: The calibration is killing me!

Ok my bad. I totally apologise to b0rski, Funny how this bed levelling issue is causing a lot of angst here!

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: The calibration is killing me!

Hi Paolo

I like your use of elastic bands. A kiss solution 🙂 the ethos of the genuine Prusa I3 build.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: The calibration is killing me!

The clearances under the Y plate interfere with obvious bed levelling solutions. Clones have solved this and provide a better Y plate solution. Follow some of the clones maybe?

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: The calibration is killing me!

Hi Paolo

Wow brilliant find 😛

Well done.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: The calibration is killing me!

Hi Nigel,

Elastic bands are poor but effective method 😀

But thanks to the notice came from richard.I now i'm going to put on these:

Above all, thanks to Thingiverse...

Ciao

Hey, can you provide a link? I can't find it on Thingiverse.

thanks!

Re: The calibration is killing me!

Hey, can you provide a link? I can't find it on Thingiverse.

thanks!

Here you go!

http://www.thingiverse.com/thing:1530686

Re: The calibration is killing me!

Thanks much!!!

Re: The calibration is killing me!

Hello, today solved first layer attachment issue and now next one 😀

I use for test preloaded PLA Prusa logo, Speed set at 80, everything else is as standard.

I have attached 2 photos. First one after first calibration, second after second 🙂

It looks like there are strange gaps and they are not due to poor calibration but something else. Also i have attached hight item from presets, layers after several centimeters higher not well aligned to each other... that caused crash after 7 hours...

Thank you!!!

Re: The calibration is killing me!

Hi Nigel,

Elastic bands are poor but effective method 😀

But thanks to the notice came from richard.I now i'm going to put on these:

Above all, thanks to Thingiverse...

Ciao

Hey, can you provide a link? I can't find it on Thingiverse.

thanks!

Here you go!

http://www.thingiverse.com/thing:1530686

Thanks so much for pointing these out!! I've printed a set out in PLA at 200um and the fit perfectly. What a difference they've made, the calibration is so much easier now! I'm finally able to print things out first go instead of needing several attempts because of the bed wobbling! This will keep me going until my MK2 upgrade kit arrives!

Re: The calibration is killing me!

Hello, today solved first layer attachment issue and now next one 😀

I use for test preloaded PLA Prusa logo, Speed set at 80, everything else is as standard.

I have attached 2 photos. First one after first calibration, second after second 🙂

It looks like there are strange gaps and they are not due to poor calibration but something else. Also i have attached hight item from presets, layers after several centimeters higher not well aligned to each other... that caused crash after 7 hours...

Thank you!!!

If your still having issues try checking out this page at Simplify3D's site: https://www.simplify3d.com/support/print-quality-troubleshooting/

There's a lot of useful info there...

Re: The calibration is killing me!

Yury, the lack of plastic seems like repeating patter, check your filament drive gear if its clean and that idler springs are tight enough.