Strange first layer problem

Hi everyone, I just got my i3 MK2 and am having a strange 1st layer issue.

To start, my printer was assembled at the factory, so I followed the shortened setup instructions in the manual.

The Prusa logo appeared to print fine using the provided Prusa silver filament.

I tried to print some other files using Simplify 3d and Slic3r (both with the Prusa provided profiles) and started to see strange 1st layer results.

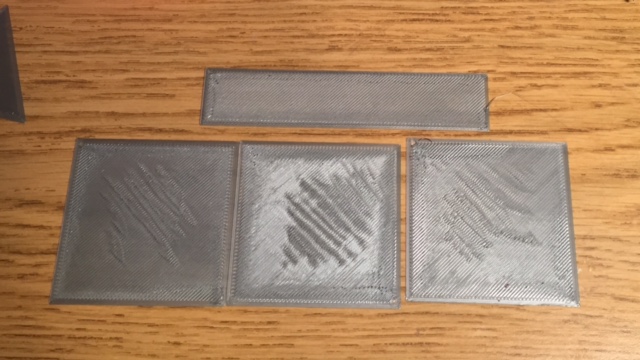

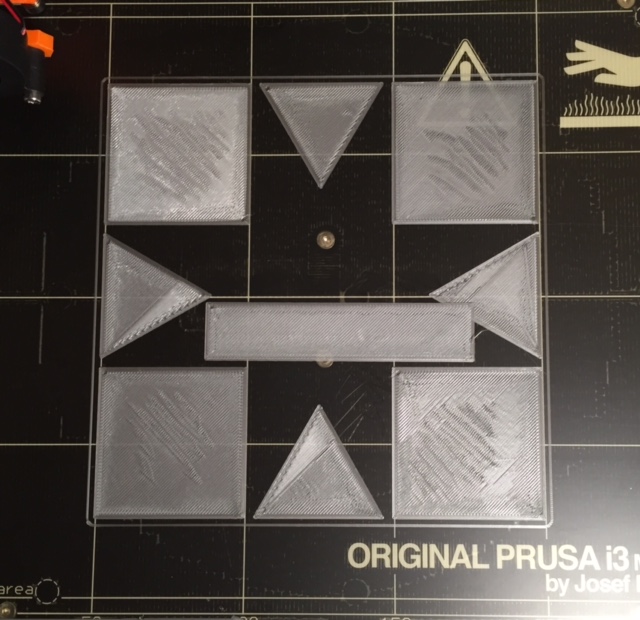

The first thing I noticed was that the Prusa logo file on the disk printed at 210 degrees, while the profiles are set to print at 200 or 205. I changed these to print the entire job at 210, but still had 1st layer issues. Next I reprinted the Prusa logo file and stopped after the first layer was down. I then printed a single layer test file from Thingiverse. The Prusa logo layer looked pretty good (that is the rectangle in the pictures) while the calibration file appears to need a Z-adjustment.

I'm thinking about using this process - http://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/life-adjust-z-my-way-t2981.html- to do the z adjust but wanted to get some others thoughts. I would have thought the Z height would have been pretty good coming from the factory. Also I'm not sure why the Z prints nice with the logo but goes bad with a file from one of my slicers.

Re: Strange first layer problem

Since Prusa logo prints OK, it looks more like some kind of overextrusion caused by slicer settings. If you open gcode file of Prusa logo sample in favourite text editor, you can find slicer settings used to generate the file. You can compare those settings with current settings of your slicer.

Re: Strange first layer problem

David, I'm still pretty new to g-code. What command lines would I be looking for?

Re: Strange first layer problem

David, I'm still pretty new to g-code. What command lines would I be looking for?

There is comments section at the end of the file (many lines beginning with semicolon). Those comments say all used parameters quite in human readable form.

Re: Strange first layer problem

I checked the extrusion multiplier in the file and in Slic3r, they are both set to 1 so I think I am back to looking at a Z height adjustment using the live Z.

One thing I noticed is the 1st layer speed in the file is 60% as opposed to the Prusa Slic3r profile which is 70%, I don't think that would make that much of a difference. Another thing that is different is the print temps, I confirmed that the file sets print temp for 1st and other layers at 210, while the profile has 1st layer at 215 and others at 205.

Strange.

Re: Strange first layer problem

Nothing strange about any of this.

The z-adjustment is something that you need to monitor with almost every print, it depends on bed and nozzle temp.

It is not to be expected to be perfect from factory setup / build.

Lift the live z-adjust by 50 -100 micrometers and the waves will disappear.

Re: Strange first layer problem

I adjusted the live Z last night. It's original setting was -0.545, changed it to -0.500 and the layer looks nicer. It still feels a little "ridgy" but it looks like many of the artifacts are no longer there. I was looking at the Simplify 3d Prusa profile and it has the 1st layer height set at 200%. I haven't looked at the Slic3r profile yet but I'm curious to see if that is set to 200% also.

I compared this to the Robo R1 profile I have for my other printer and its 1st layer height is set at 90%. I know they are two different machines so they can't be directly compared to each other but 200% seems really high. I'm going to buy a set of calipers this week and check the actual layer thickness. For some reason it feels a little thick by touch.

Re: Strange first layer problem

The first layer height percentage in simplify3d varies in relation to the layer height. So if i were using 50 micron. 0.05 mm. I would make 1st layer 400%. Equal to the minimum first layer height of 0.2m

Regards joan.

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Strange first layer problem

I have the same issues, lifting the Z by 50 microns just makes that the first layer does not stick any longer to the bed, dropping it by another 50 will make the first layer complete crushed so that I think I have the correct setup. Temps, speed and extrusion are like shown. I am using the Prusa red pla, upto now, since 3 weeks of printing, 90 % of my prints cannot be used. Either the first layer does not stick to bed, after adjusting z, first 5-6 lines stick, then one corner suddenly pops off the bed, going lower with z adjust is impossible as first layer completely crushed and torn away by nozzle on half way. Calibration ok, everything perpendicular. The only files from the bundle that can be printed are the whistle and the Prusa logo, I did never manage to finish any of the other files for above reasons.

Re: Strange first layer problem

I have the same issues, lifting the Z by 50 microns just makes that the first layer does not stick any longer to the bed, dropping it by another 50 will make the first layer complete crushed so that I think I have the correct setup. Temps, speed and extrusion are like shown. I am using the Prusa red pla, upto now, since 3 weeks of printing, 90 % of my prints cannot be used. Either the first layer does not stick to bed, after adjusting z, first 5-6 lines stick, then one corner suddenly pops off the bed, going lower with z adjust is impossible as first layer completely crushed and torn away by nozzle on half way. Calibration ok, everything perpendicular. The only files from the bundle that can be printed are the whistle and the Prusa logo, I did never manage to finish any of the other files for above reasons.

Maybe a bed cleaning issue?

Try to use acetone and scrub the PEI sheet with super-fine steel wool or a plastic pot scrubber sponge, then wipe clean again with acetone.

Try to increase the bed temperature to 60C or 65C and see if it sticks then.