Re: Problems fine tuning MK2 kit.

James

I think that the Live Adjust is only available during the first layer; it is not relevant after this.

Filament twisting shows the importance of buying only good quality filament and thereafter never letting go of the enh - always hold the filament end and insert it into one of the holes in the spool.

With regard to the changing Z Adjust value, I have never seen that happen so I cannot comment.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems fine tuning MK2 kit.

I think that the Live Adjust is only available during the first layer; it is not relevant after this.

I used the wrong terminology last night. The Settings move Z option is missing after I have cancelled the failed print.

Filament twisting shows the importance of buying only good quality filament and thereafter never letting go of the enh - always hold the filament end and insert it into one of the holes in the spool.

I am using the filament provided by Prusa so I hope it is good quality. I was not aware of the need to not lose control of the filament end, but it explains why I see so many filament clips in the online 3D libraries.

With regard to the changing Z Adjust value, I have never seen that happen so I cannot comment.

I am wondering about the control board. I am going to try reflashing the firmware just to see what happens. The problem is that it seems random when it occurs.

Re: Problems fine tuning MK2 kit.

Regarding your extruder.

I occasionally run into problems where the filament won't extrude, I've had success adjusting temperature as well. I think sometimes the filament gets too soft and the teeth no longer get a good grip.

Regarding your z adjust problem.

I had this exact issue, unfortunately I don't remember my fix. It was either adjusting the PINDA, doing a complete recalibration, or fixing the physical axis of the printer.

Re: Problems fine tuning MK2 kit.

I had a problem with slippage of the filament when I first setup the printer. In my case the screws tensioners were too tight. I read in the build guide that the screws would be about 13mm once screwed in. I did that and it was way way too tight. I had to back off the screws significatly and now everything is fine. So, you may want to see if yours are still too tight.

Re: Problems fine tuning MK2 kit.

I had a problem with slippage of the filament when I first setup the printer. In my case the screws tensioners were too tight. I read in the build guide that the screws would be about 13mm once screwed in. I did that and it was way way too tight. I had to back off the screws significatly and now everything is fine. So, you may want to see if yours are still too tight.

The tensioner screws are at 18mm and have not had any slippage since the last adjustment I made last week. The problem recently has definitely been tangled filament on the spool. I am not watching the problem closely.

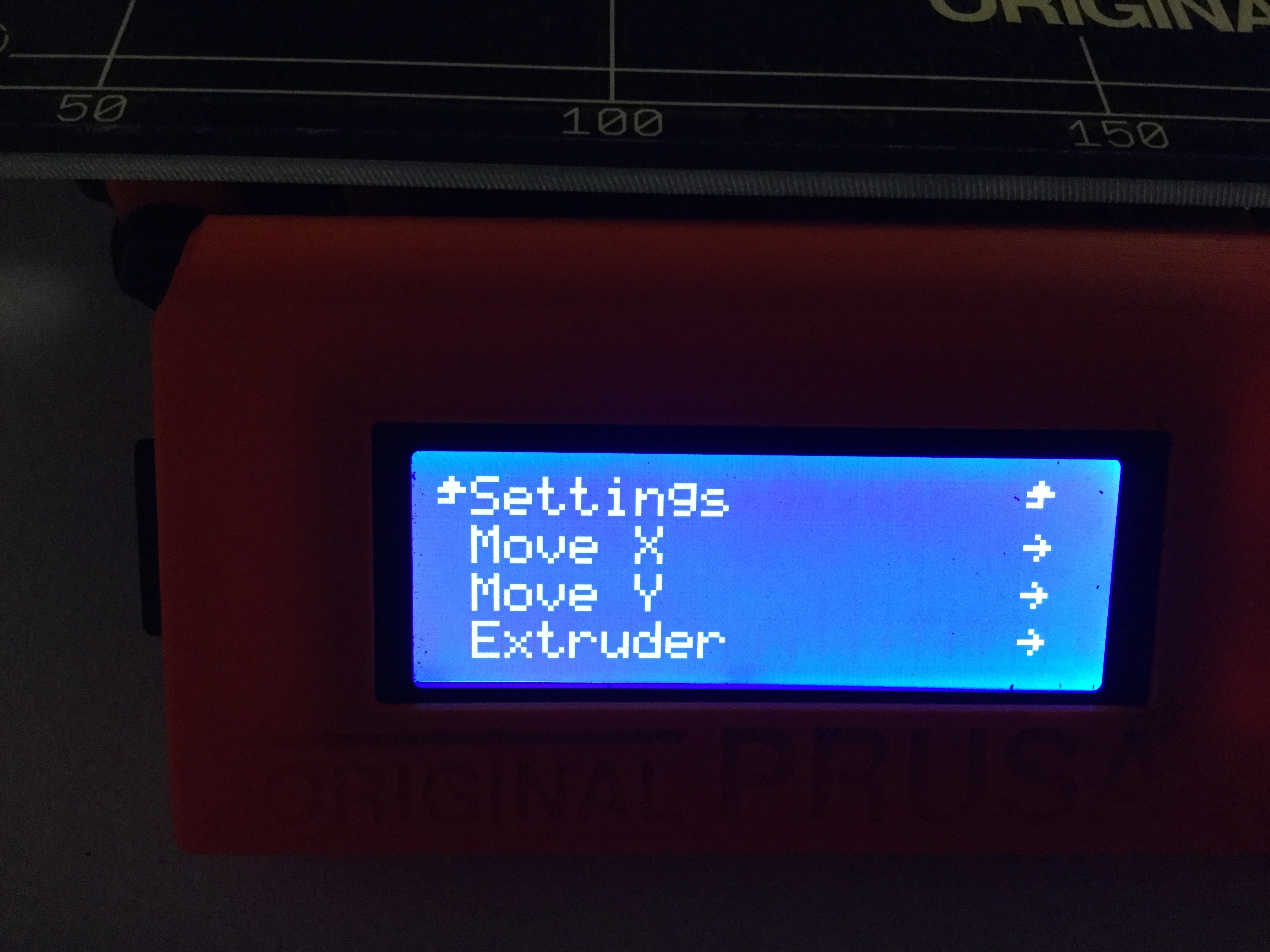

The current set of problems are more difficult to pinpoint, though I am still suspecting the controller board. I have reflashed the firmware to no avail. I have had the calibration settings reset twice in the last 24 hours, making the total 4 times in the last week. I finally remember to take a picture of the Move Axis options on the LCD display after the failure. the Move Z option is not available until the controller is reset. I also noticed that before resetting the system that the X, Y and Z axis' zero out in their new positions. An example would be that if the X-axis is in the center when the failure occurs then when you attempt to use the LCD Display to move the axis it will only move in the positive direct, a.k.a to the right and then back to the center starting point. You can not move it to the left beyond the starting point without resetting the controller.

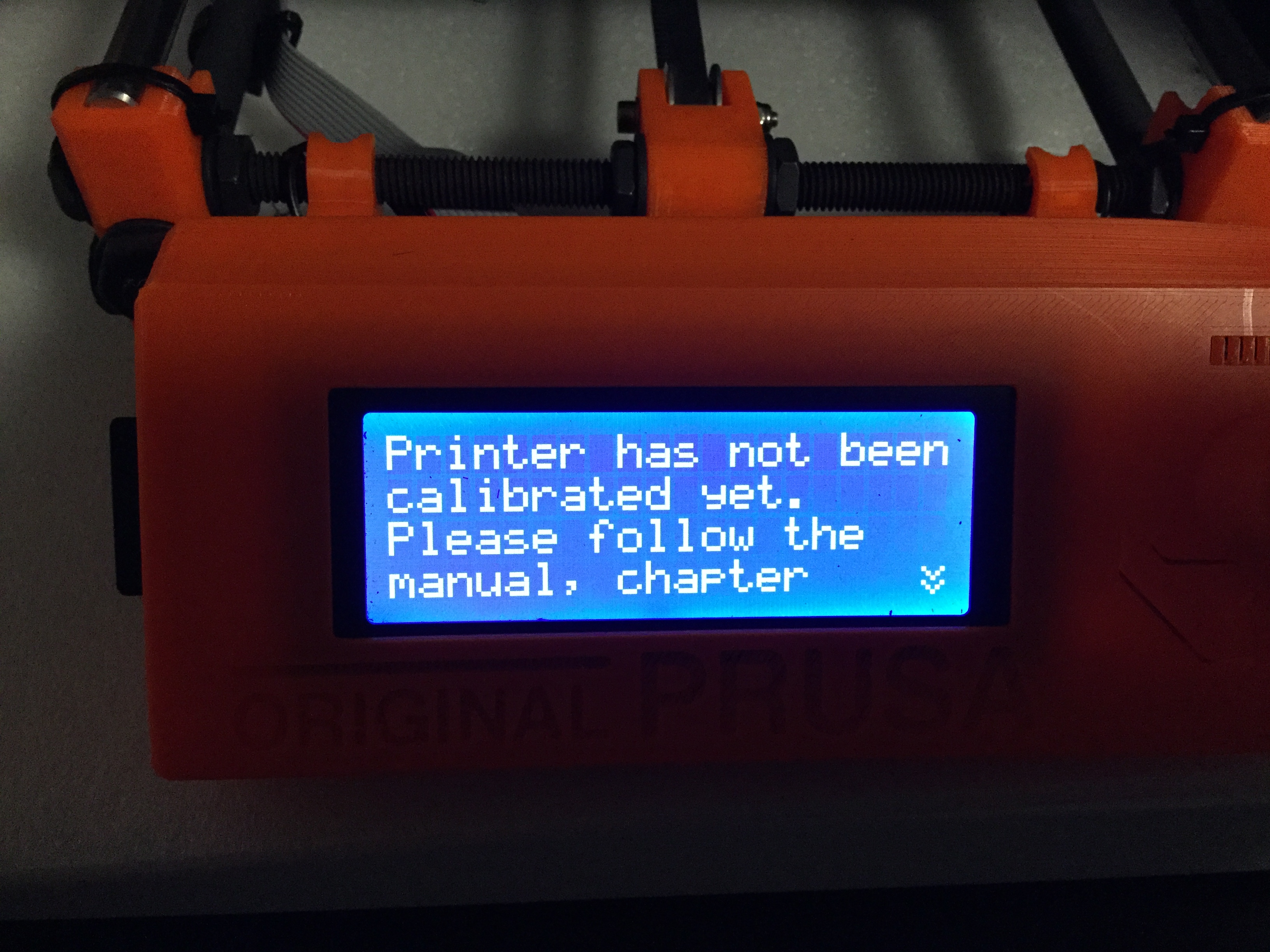

I physically readjusted the PINDA Sensor, decreasing the delta between the PINDA's end and the end of the nozzle. Now I can no longer calibrate the Z-axis so that the filament sticks to the bed. I have gone from 0 to -1.xxx with no visible effect during the V2Calibration process. The last attempt to do the x, y, z calibrate slammed the print nozzle against the, thankfully cool, bed and generate the message that my printer has not been calibrated for the first time.

I am also trying to experiment with ABS for the first time, but cannot seem to get past these problems to make it work. I am really getting tired of continuously recalibrating and losing perfectly good prints in the process.

Re: Problems fine tuning MK2 kit.

There is some variation in the thermistor characteristics. Thermistor is the temperature sensor part inserted into the nozzle heater cartridge. It is possible that your thermistor reports a temperature slightly higher than the true value, then the heater is not heated enough and the PLA has a too high viscosity, so it is difficult to extrude it and the extruder starts to slip. Try to bump up the nozzle temperature by 5 or 10 degrees to see if it helps.

Vojtech

Re: Problems fine tuning MK2 kit.

There is some variation in the thermistor characteristics. Thermistor is the temperature sensor part inserted into the nozzle heater cartridge. It is possible that your thermistor reports a temperature slightly higher than the true value, then the heater is not heated enough and the PLA has a too high viscosity, so it is difficult to extrude it and the extruder starts to slip. Try to bump up the nozzle temperature by 5 or 10 degrees to see if it helps.

Thank you, I will try it, but what does this have to do with calibration issues? I have printed a number of object with minimal problems at the preset temps, why would this be an issue now?

Re: Problems fine tuning MK2 kit.

Re: Problems fine tuning MK2 kit.

Quote

Fri Sep 23, 2016 9:04 pm

There is some variation in the thermistor characteristics. Thermistor is the temperature sensor part inserted into the nozzle heater cartridge. It is possible that your thermistor reports a temperature slightly higher than the true value, then the heater is not heated enough and the PLA has a too high viscosity, so it is difficult to extrude it and the extruder starts to slip. Try to bump up the nozzle temperature by 5 or 10 degrees to see if it helps.

> Thank you, I will try it, but what does this have to do with calibration issues? I have printed a number of object with minimal problems at the preset

> temps, why would this be an issue now?

There are multiple issues mixed in this thread. I was reacting to the filament slippage problem. I should have quoted the question better.

Vojtech

Re: Problems fine tuning MK2 kit.

> Secondly, what is the best way to minimize the filament from tangling on the spool? Trying to complete the Adeline print the filament on the spool kept becoming tangled together. I was able to catch and prevent the problem several times during the 6-hour print, but the problem finally ruined the print with only 20 minutes left and I had to cut the filament and carefully untangle the tight knot created while the filament spooled off of the role into the extruder. This problem has happened numerous times since I finished building the printer and it is getting very frustrating.

When you open the package, the filament is definitely untangled and the end of the filament is plugged into a hole in the spool. Make sure that the end of the filament never gets free. The end is either fixed to the spool or it is loaded into the printer. This way it cannot get tangled.

Vojtech

Re: Problems fine tuning MK2 kit.

Thank you for the tip in maintaining tangle free filament. I wish that had been printed in large font and bold on the side of the filament spindle. I am more careful with the filament spindles I just received.

I finally figured out what was causing my calibration failures. The Y-axis frame was severely out of alignment. I am not exactly sure how that happened since I was printing with minimal problems a few days before. I took me 8 hours to re-align everything so that it would complete the calibration process successfully. I suspect some of the nuts shook loose.

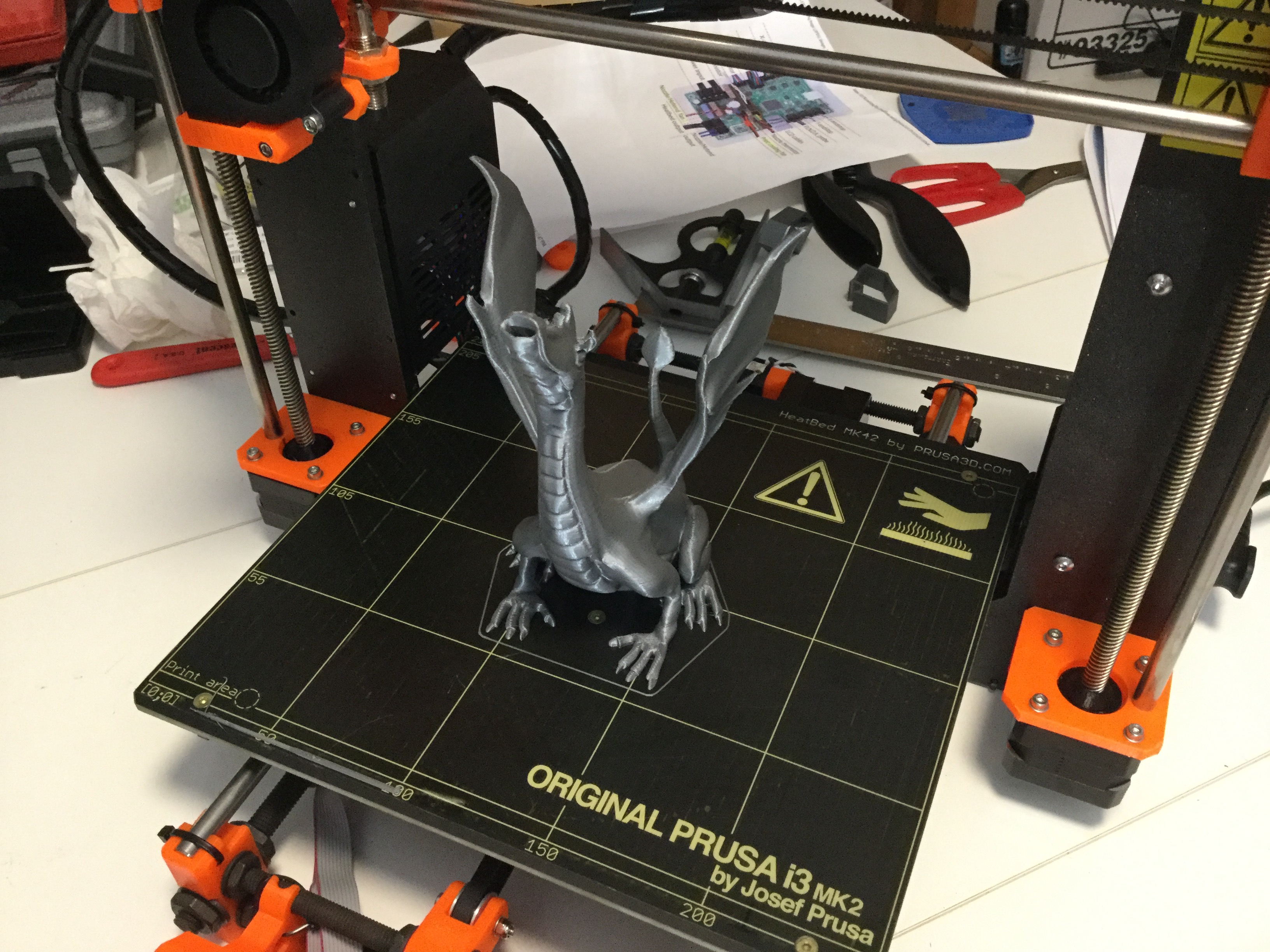

Since fixing the problem I have had only a few problems. The only change I needed to make for ABS Printing was to change the Z Live Adjust by -.15 from the PLA settings.

Re: Problems fine tuning MK2 kit.

Great you figured out the issue. Happy printing!

Re: Problems fine tuning MK2 kit.

Thank you for the tip in maintaining tangle free filament. I wish that had been printed in large font and bold on the side of the filament spindle. I am more careful with the filament spindles I just received.

I finally figured out what was causing my calibration failures. The Y-axis frame was severely out of alignment. I am not exactly sure how that happened since I was printing with minimal problems a few days before. I took me 8 hours to re-align everything so that it would complete the calibration process successfully. I suspect some of the nuts shook loose.

Since fixing the problem I have had only a few problems. The only change I needed to make for ABS Printing was to change the Z Live Adjust by -.15 from the PLA settings.

That's a pretty color, what kind/brand of filament is it?

Re: Problems fine tuning MK2 kit.

It is the PLA Silver filament sold by PRUSA3D.com It is the free spool I received with the printer. It does produce some nice looking prints.