Problems fine tuning MK2 kit.

It seems like every time I solve one problem, another appears. I am at a loss on how to proceed. Here is a little back story. Last night, after several days of frustration, I discovered that the print cooling fan plug was reversed. Once corrected, I was hoping the problems would finally go away. Unfortunately, it was not to be. After a couple more failed prints and searching the forums, I cleaned the nozzle and tightened the X-axis belt. Each time I make a correction the problem shifts to a different area of the print. I have rerun all the calibrations and have made numerous tweaks to the Z-access, but cannot figure out what is causing the problem. Currently, Marvin looks like his brains are exposed or has hair instead of a helmet. On the last print everything up to just above his eyes is fine and then the print goes wild. before my last tweak, the scrambled filament was all over his body with a few minor exceptions.

I have also printed the PRUSA sign and whistle, which looks ok except that there are random small holes in the print near the junction of a wall and fill in the prints.

Any ideas on what might be causing these odd prints and how to solve the problem? I am new to 3D printing and have run out of ideas.

Re: Problems fine tuning MK2 kit.

James

There is obviously an extrusion issue with the print. It could be a slipping filament drive gear, but more likely to be caused by too much retraction and maybe the PTFE tube has moved upwards slightly.

The pre-sliced models have 1.5mm retraction settings and the advice regarding retraction was changed after the models had been sliced. Retraction is now recommended to be a maximum of 0.8mm.

With the larger retraction and where the PTFE tube is not properly seated in the extruder body, jamming can occur. Can I suggest that you get the latest Slic3r settings and try slicing with that.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems fine tuning MK2 kit.

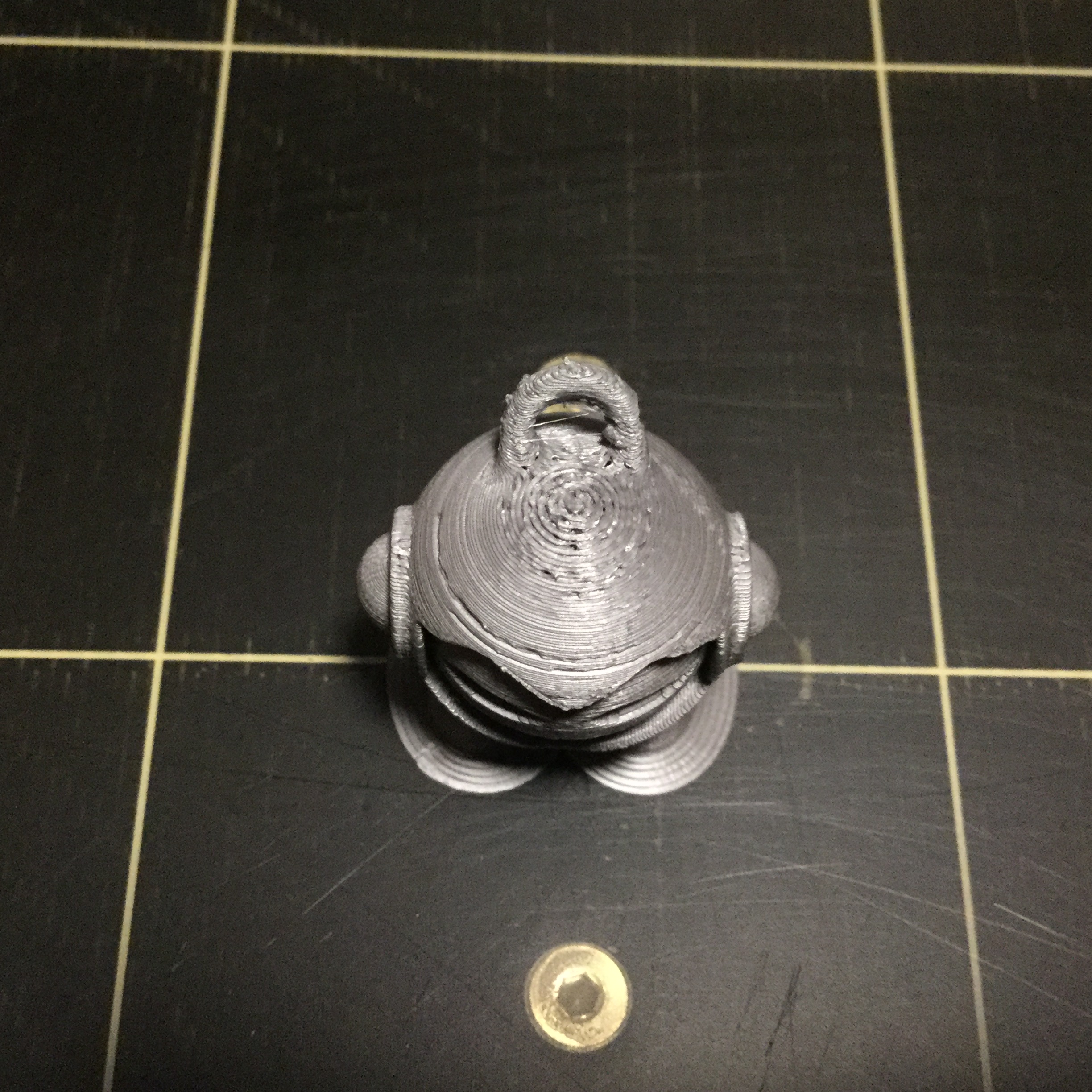

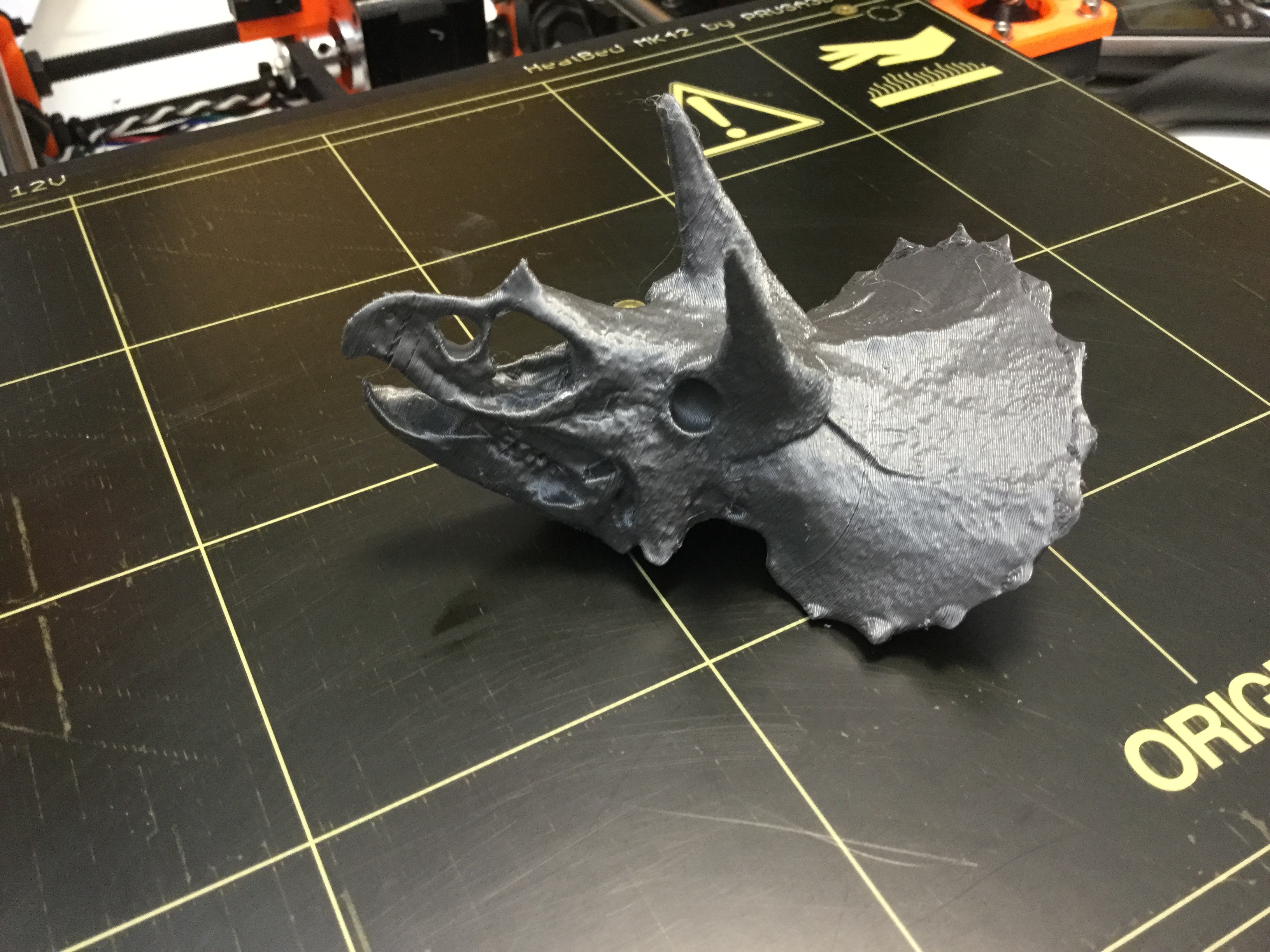

I am making some progress, but there are still problems as seen in the attached picture of Marvin.

Here are the steps I have take today:

- Readjusted and tightend filament drive gear.

- Verified PTFE tube has not moved.

- Updated to 3.07 firmware.

- Re-ran all of the calibration steps.

- Made sure version 1.7.3 of the driver was installed.

- Verified is was set to 0.8 max retraction settings.

- Verified, to the best of my ability, that the pre-compiled gcode reflects the new retraction setting. The only file obviously changed was Marvin.

- Archived and replaced default gcode on SD Card from new driver install.

- Reprinted the updated PLA_3DHubs_Marvin_100um_1H.gcode

The new print looks far better than the print before the re-adjustments, but is still obviously not correct.

I have not had the opportunity to learn how to use slicer program yet and am making big assumptions about the quality the gcode provided, when it comes to specific MK2 slicer configurations.

Any ideas on what to check for next?

Re: Problems fine tuning MK2 kit.

Is the part cooling fan (the radial fan at the front of the extruder) working?

It should start after the first layer or two. If not, then check the connections on the RAMBo; it is a common mistake to get the connector wrong way round.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems fine tuning MK2 kit.

Peter,

I corrected the fan connection problem a couple of days ago. The current issues I am asking about are post fan fix. I have verified several times that the fans are running when they are supposed to, but am still seeing printing problems.

Any other suggestions? It does not hurt to make repeat checks, just to make sure that something has not gone wrong since. 😉

Re: Problems fine tuning MK2 kit.

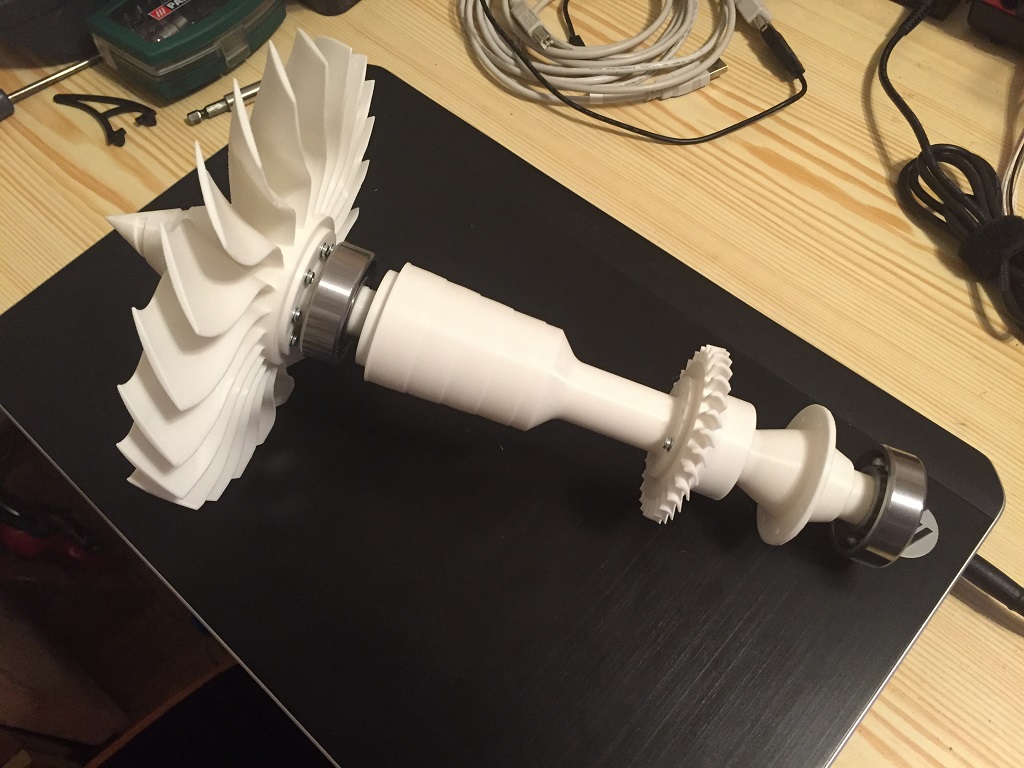

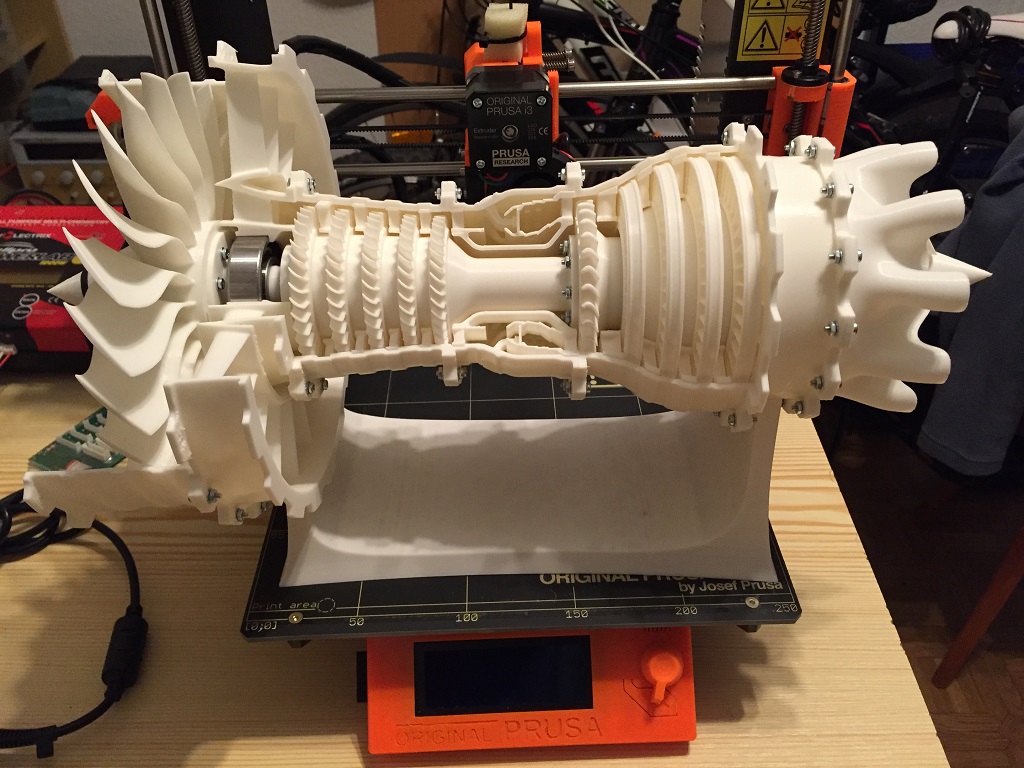

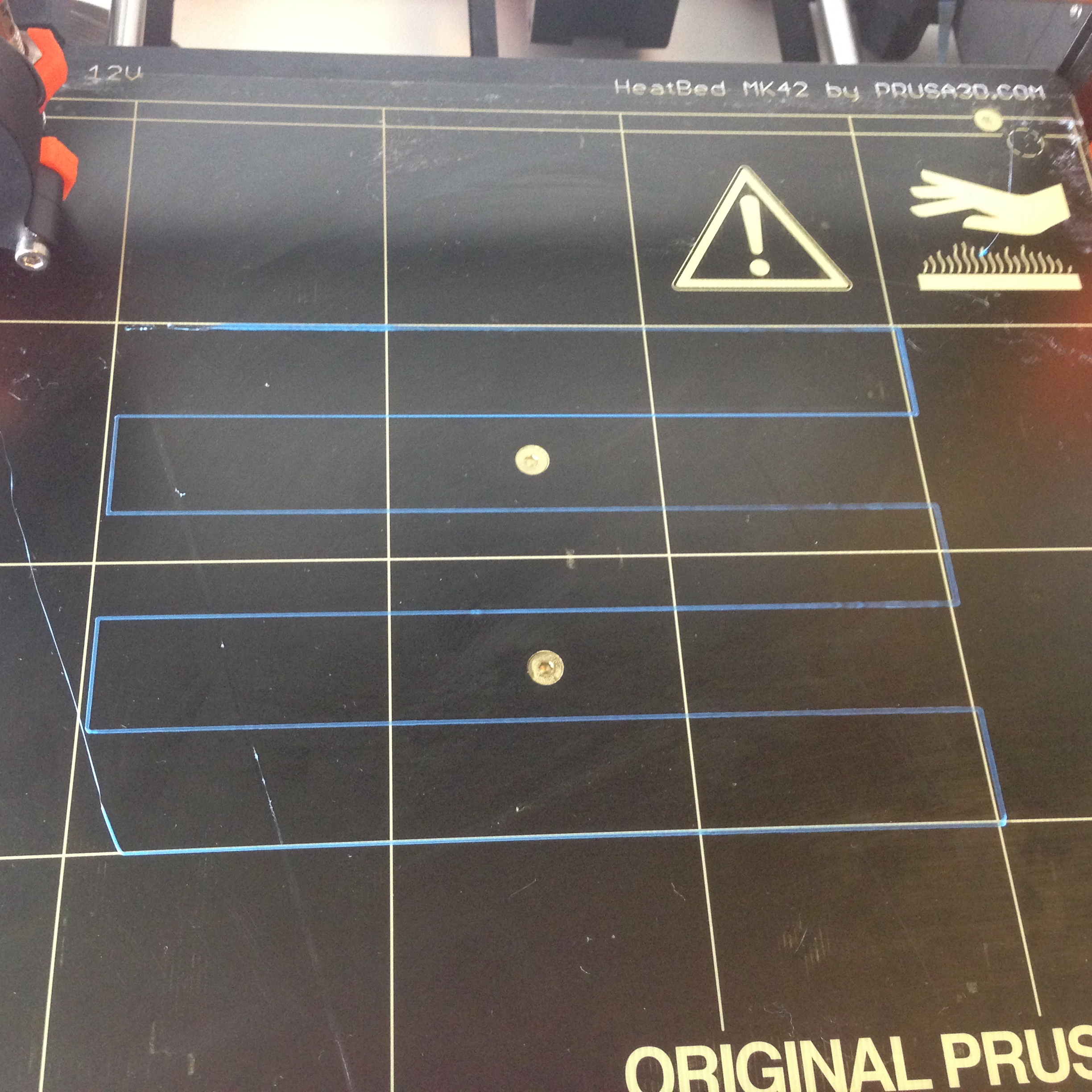

I just finished printing the whistle to see what it would do and you can see the results below.

The top layer does not seem to completed. The sides are perfect and the bottom layer has a few minor flaws between the filler and perimeter.

Re: Problems fine tuning MK2 kit. (Problem may have been found)

I may have just figured out the cause of my recent printing problems. I will hopefully know for sure once the current print is complete.

The filament was binding up on the spool, putting to much tension on the filament drive gear, which caused the random clicking sound that I could not previously identify. Every time this occurred it caused a drop in the amount of filament being extruded during the printing process.

Does anyone have any ideas on how to best minimize or eliminate this problem? I have some ideas, but do not currently have the skills to implement them or even determine if they will really solve the problem.

Re: Problems fine tuning MK2 kit.

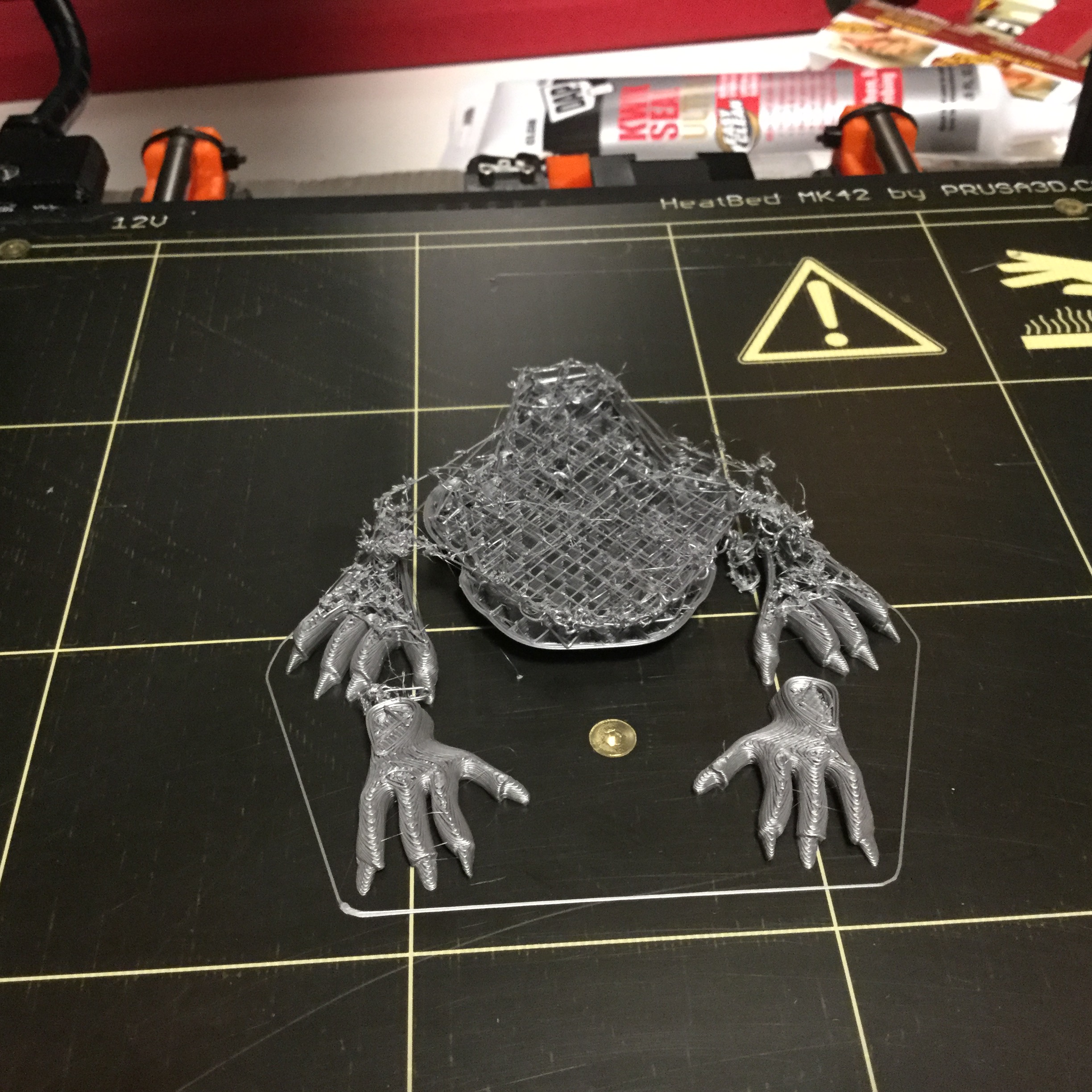

Freeing up the tangled filament on the spool did the trick, but of course there has to be just one more issue. Hopefully this one will be easier to figure out.

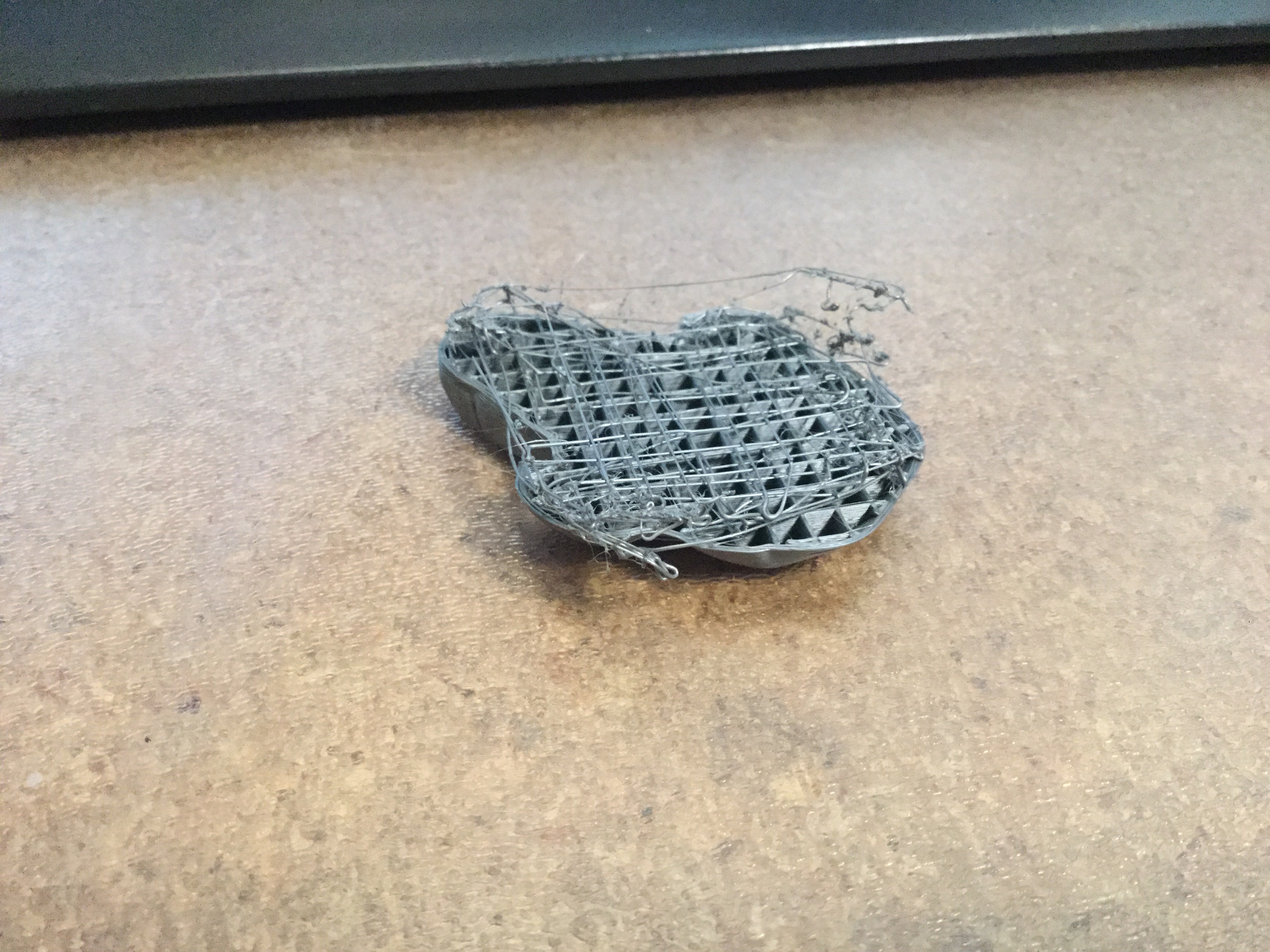

The picture below is turned upside down from its original print position to show the problem. The layers above the first overhanging layers are nearly perfect. It is just that first layer spanning the gap that has issues. I am assuming that this might be fixed by making adjustments to some of the overhang setting in the slicer program? Any hints on specific changes that might be needed or insight to other issues that may cause this problem?

Thank you for your patients and comments that have provided much needed insights into solving these problems.

Re: Problems fine tuning MK2 kit.

Oops, I just noticed that I was posting under my son's account for a while.

I just started another print to run overnight and noticed that the filament drive gear is still slipping (click, click, click...) sometimes even though there is slack in the line. This time it was at the very beginning of the print so very little filament was initially extruded and I was able canceled the print. Now that I think back, this is the third time this has happened at the beginning of a print. This time I decided to use the insert filament option in the menu and push the filament through the extruder until the slipping stopped and now the print is continuing without a hitch for now.

What other types of issues cause filament drive gear slippage?

- I have already re-centered the drive gear and tightened it down.

- I have played with the bolts with the springs on them but I am not sure if that did anything or made it worse.

- I am using the PLA 1.75mm filament that came with the printer and the settings in the slicer all show 1.75mm as the default filament size.

This seems to be an never ending battle to obtain my first print that does not have significant flaws.

Re: Problems fine tuning MK2 kit.

James

There is a sweet spot you will need to find on the tension screws. Too lose and it won't grip good enough and you'll get slipping. Too tight and it will cause the clicking sound and not feed through.

Different brands and kinds of filament may require slight adjustments to the screws.

Re: Problems fine tuning MK2 kit.

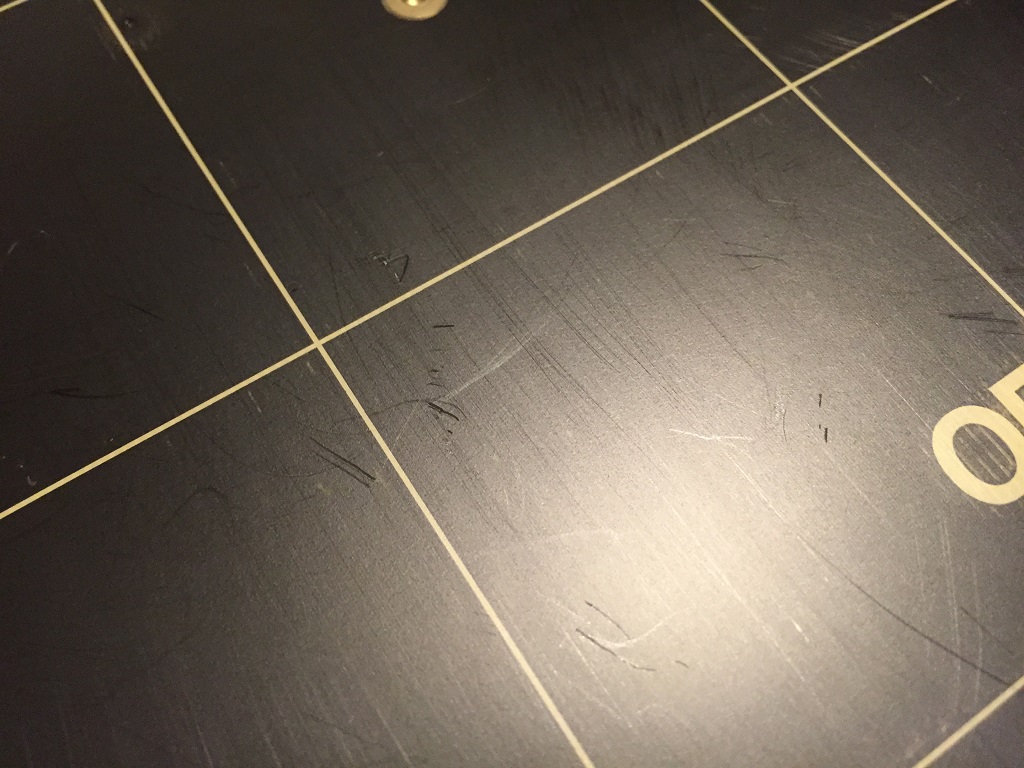

Thank you for that advice. The odd part with the clicking and slipping is that is seems so random. A print will be working perfectly and then out of the blue it starts clicking and the print goes haywire. If I happen to be standing there I have been able to apply some pressure to the filament and eliminate the problem temporarily. I have started playing with the tension to see what happens. Here are some photos to show some of what I am seeing.

Re: Problems fine tuning MK2 kit.

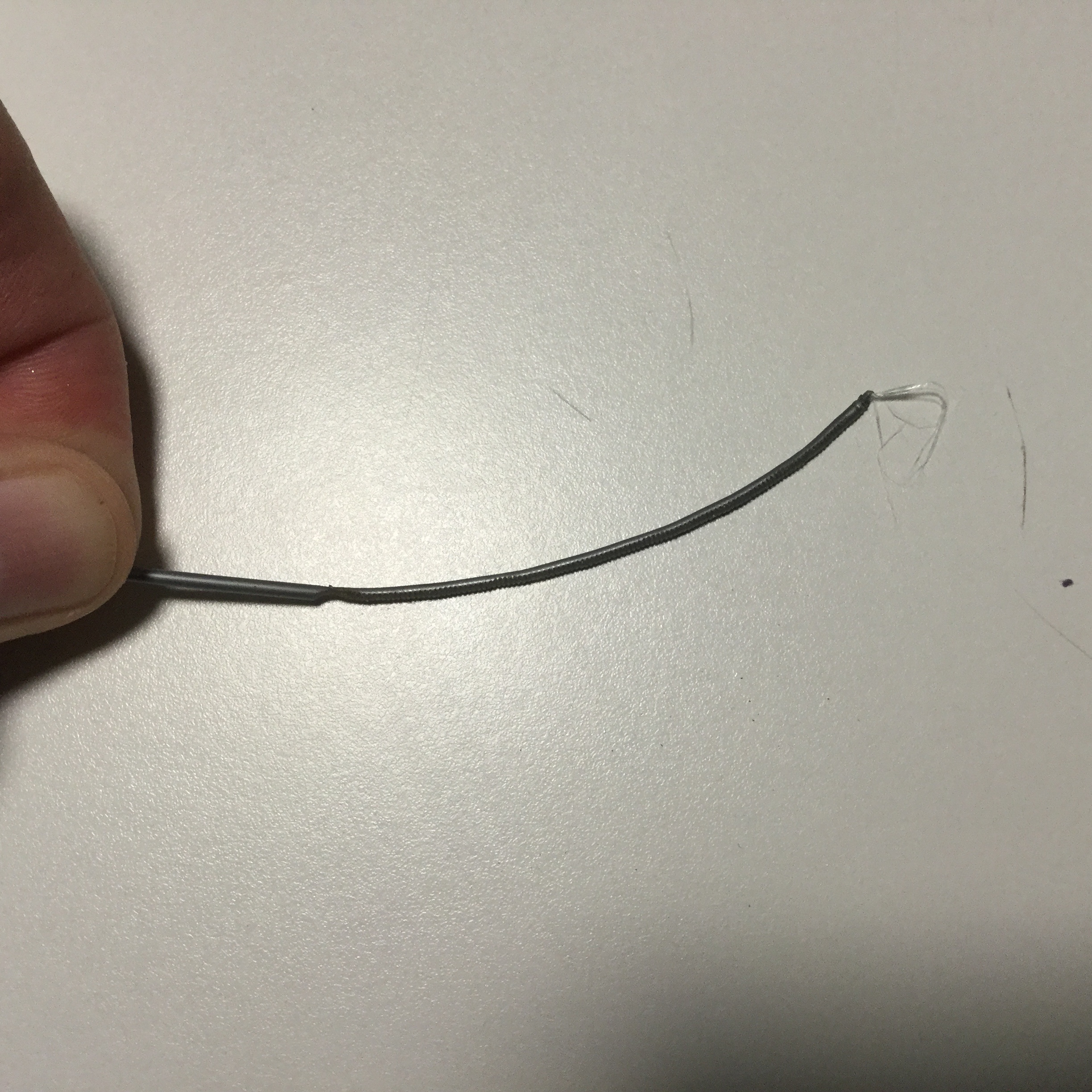

It seems to me that extruder pulley bites to filament more and less, periodically. See the image, I pointed out areas where the pulley cut further. There is very little difference, but I can see it there. Could you check if extruder pulley is centered well? I don't know if it is the root of the problem, but it could cause difficulties setting correct tighteness of extruder idler springs. If it is not centered, it is most likely manufacturing error and you might want to get it replaced.

Re: Problems fine tuning MK2 kit.

Thank you for the suggestion, but before I tear my extruder assembly completely apart to check for a faulty component, I am experimenting with the tension screws. While building one of the Marvin's it started clicking so I paused the print and backed off the screws and the continued the print. I did this until the clicking disappeared. I was amazed how far I needed to back off the screws before it stopped. I started a new Marvin print and it finished without clicking and looks decent. My only concern is that the very top of the dome of his head does not look complete, like a layer is missing just in that area. I am trying to print the whistle again to see if it completes properly. Previous prints of the whistle had a lot of holes in the side making it useless as a whistle.

Re: Problems fine tuning MK2 kit.

James

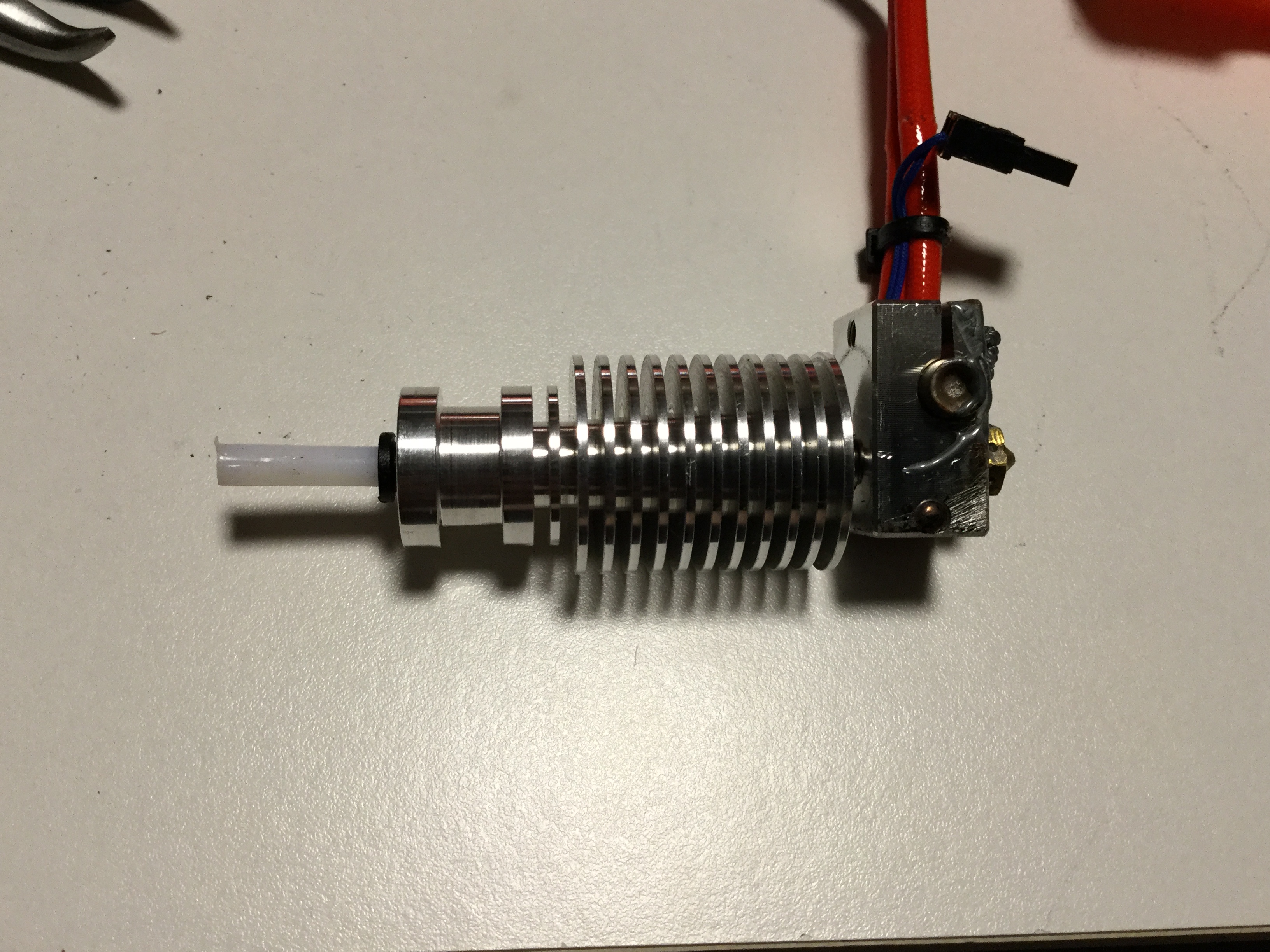

I still have a feeling that you have an issue with the PTFE tube; maybe not straight at the bottom, maybe distorted, maybe some debris inside.

Ot I suppose it could be a nozzle temperature issue, but I don't think so.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Problems fine tuning MK2 kit.

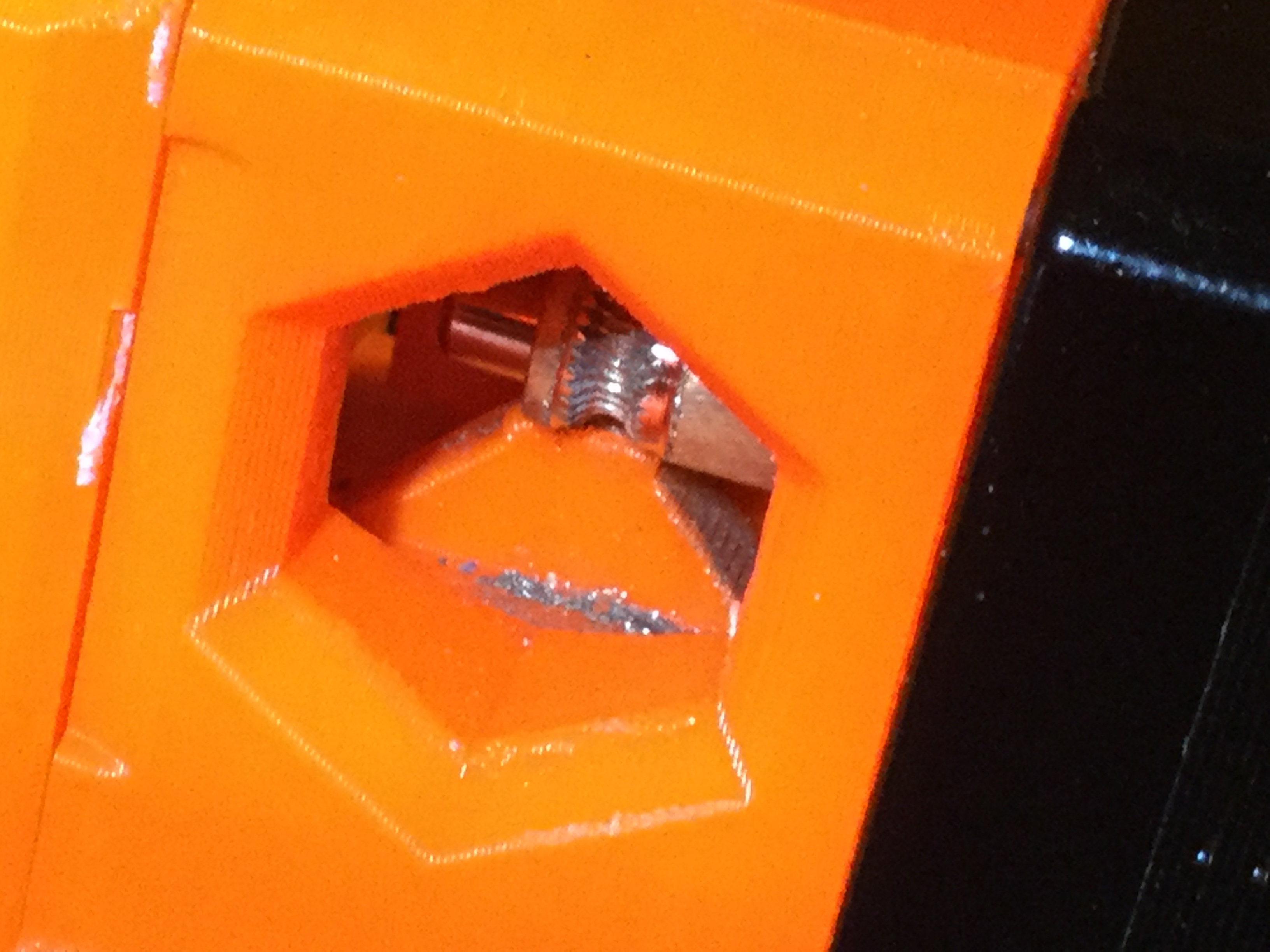

I finally had a little time to tear apart the extruder assembly. Wow, lots of work. The one obvious problem is the missing teeth on the Extruder pulley. There was also a fair amount of metal flakes on the extruder motor from the pulley. I tried to pull the PTFE tube out of the extruder without success so I am not sure how to check the PTFE tube for problems. Can I order replacement 3D printed parts? A small piece of the extruder mount broke off and I am now using hot melt glue to hold one side of the x-access belt in place. Obviously, I will need to replace the Extruder pulley.

Any thoughts?

Re: Problems fine tuning MK2 kit.

I found the article on replacing the PTFE tube and was able to pull it out and check it. Looks fine. I am going to assume my main problem then is the partially stripped extruder pulley. I also found where I can order spare plastic parts so I will put in a request to replace the pulley and buy the replacement plastic.

Hopefully, this will solve most of my current issues.

Re: Problems fine tuning MK2 kit.

So depending on how well your hot glue repair works, you could try printing your broken parts yourself if things are holding together well enough to print in ABS (and if you have the filament)

Prusa is great and made their files available for us. http://www.prusa3d.com/prusa-i3-printable-parts/

I'm still new to 3D printing so I'm not sure how bad the extruder pulley can get before it starts to cause malfunction, so hopefully the replacement gets to you soon.

Re: Problems fine tuning MK2 kit.

The new pulley is on its way. The hot melt glue looks bad, but has been very effective so far. I will have to experiment with printing the part I need replaced. Unfortunately, it will not be orange. I have no desire to purchase an entire spool of ABS in orange just for one part. I am not a fan of the color in general, but it does make the printer stand out in a crowd. 😉

Re: New set of issues after upgrades

I have finally received and installed the replacement filament pully. After upgrading the firmware to 3.08 and the software to v.1.7.4. I am still using the original PLA that came with the printer. The first print or two worked fairly well and then I experienced the first problem. halfway through the print, the filament lost cohesion with the print. I began checking settings and fans and I noticed that the adjust Z-axis setting was missing from the menu. I turned off the printer and turned it back on a few seconds later. The adjust Z-axis setting had returned and was working properly again, but the printer had lost all of its calibration settings. A day later, the problem occurred again while printing Adeline. The first time this happened the printer was sitting out in the open. The second time the printer was positioned in its new enclosure with the door closed.

I also noticed that every time I reconfigured the Live Z Adjust after a failure, the settings changed. The initial setting was -.600. After the first failure I had to adjust it to -.700 to make the filament stick and the second time the failure occurred I had to set it to -.800. I double checked the P.I.N.D.A. sensor and it is secure in its position.

Does anyone have any idea what may be causing this failure?

Secondly, what is the best way to minimize the filament from tangling on the spool? Trying to complete the Adeline print the filament on the spool kept becoming tangled together. I was able to catch and prevent the problem several times during the 6-hour print, but the problem finally ruined the print with only 20 minutes left and I had to cut the filament and carefully untangle the tight knot created while the filament spooled off of the role into the extruder. This problem has happened numerous times since I finished building the printer and it is getting very frustrating.

Re: Problems fine tuning MK2 kit.

I don't have any advice for your printing woes, but I sure would like to know where you got that nice looking enclosure?